Detachable novel truss node testing device

A test device and detachable technology, applied in the field of detachable new type truss node test device, can solve the problems of insufficient accuracy and reliability, poor economy, complex structure, etc., and achieve improved accuracy and reliability and easy operation. , the clear effect of transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

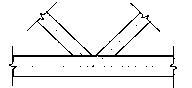

[0034] figure 1 It is a schematic diagram of a test device for testing a K-shaped truss node according to an embodiment of the present invention.

[0035] The structure of the main body 1 of the test device is made according to the Warren truss applied to K-shaped joints, and space for K-shaped joints is reserved in typical positions. At the same time, the strength and stiffness of the bar section of the main body 1 of the test device should be more than 1.5 times that of the truss node 2 to be tested (the truss node 2 to be tested includes the node chord 3 and the node web 5), so as to ensure that the test Finally, the effect of the failure of the truss node 2 to be tested is obtained. The K-shaped truss node 2 to be tested is composed of a node chord 3 and two node webs 5. In order to ensure that the node area of the K-shaped truss node 2 to be tested is not affected by the rod end load, the length of the node chord 3 is taken as 7 to 8 times the outer diameter of the no...

Embodiment 2

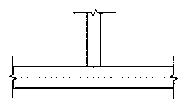

[0039] figure 2 It is a schematic diagram of a test device for testing T-shaped truss nodes according to an embodiment of the present invention.

[0040] The structure of the test device main body 1 is made according to the truss applied to the T-shaped node, and the bar section strength and stiffness of the test device main body 1 are the truss node 2 to be tested (the truss node 2 to be tested includes the node chord 3 and the node 1.5 times of the web member 5) to ensure that the test finally obtains the effect of the failure of the truss node 2 to be tested. The T-shaped truss node 2 to be tested is composed of a node chord 3 and a node web 5, which are perpendicular to each other. The length of the node chord is 7~8 times of the outer diameter of the node chord 3; the length of the node web 5 is 5~6 times of the outer diameter of the node web 5.

[0041]The main body 1 of the test device and the truss node 2 to be tested are connected by three flanges 4 and two flanges...

Embodiment 3

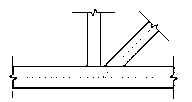

[0044] image 3 It is a schematic diagram of a test device for testing N-shaped truss nodes according to an embodiment of the present invention.

[0045] The structure of the main body 1 of the test device is made according to the truss applied to the N-shaped node, and the cross-sectional strength and stiffness of the bar of the device 1 are the truss node 2 to be tested (the truss node 2 to be tested includes the node chord 3 and the node web 5) more than 1.5 times to ensure that the test finally obtains the effect of the failure of the truss node 2 to be tested. The N-shaped truss node 2 to be tested is composed of a node chord 3 and two node webs 5. In order to ensure that the node area of the N-shaped truss node 2 to be tested is not affected by the rod end load, the length of the node chord 3 is taken as 7 to 8 times the outer diameter; the length of the node web 5 is 5 to 6 times the outer diameter.

[0046] The main body 1 of the test device and the truss node 2 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com