Retractable shank for machine tools and use of said retractable shank in machine tools

一种伸缩式、柄杆的技术,应用在金属加工机械零件、大型固定成员、夹固等方向,能够解决铣削主轴箱长、失去工作区域等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The object of the invention relates to a telescopic shank for machine tools such as milling and boring machines, in which the unit formed by the rotating bushing and the stationary bushing is divided, there is at least one front unit, which is easily accessible by extracting outwards or towards It is removed by moving inwards, by which it defines a space in the tool box allowing different headstocks to be assembled.

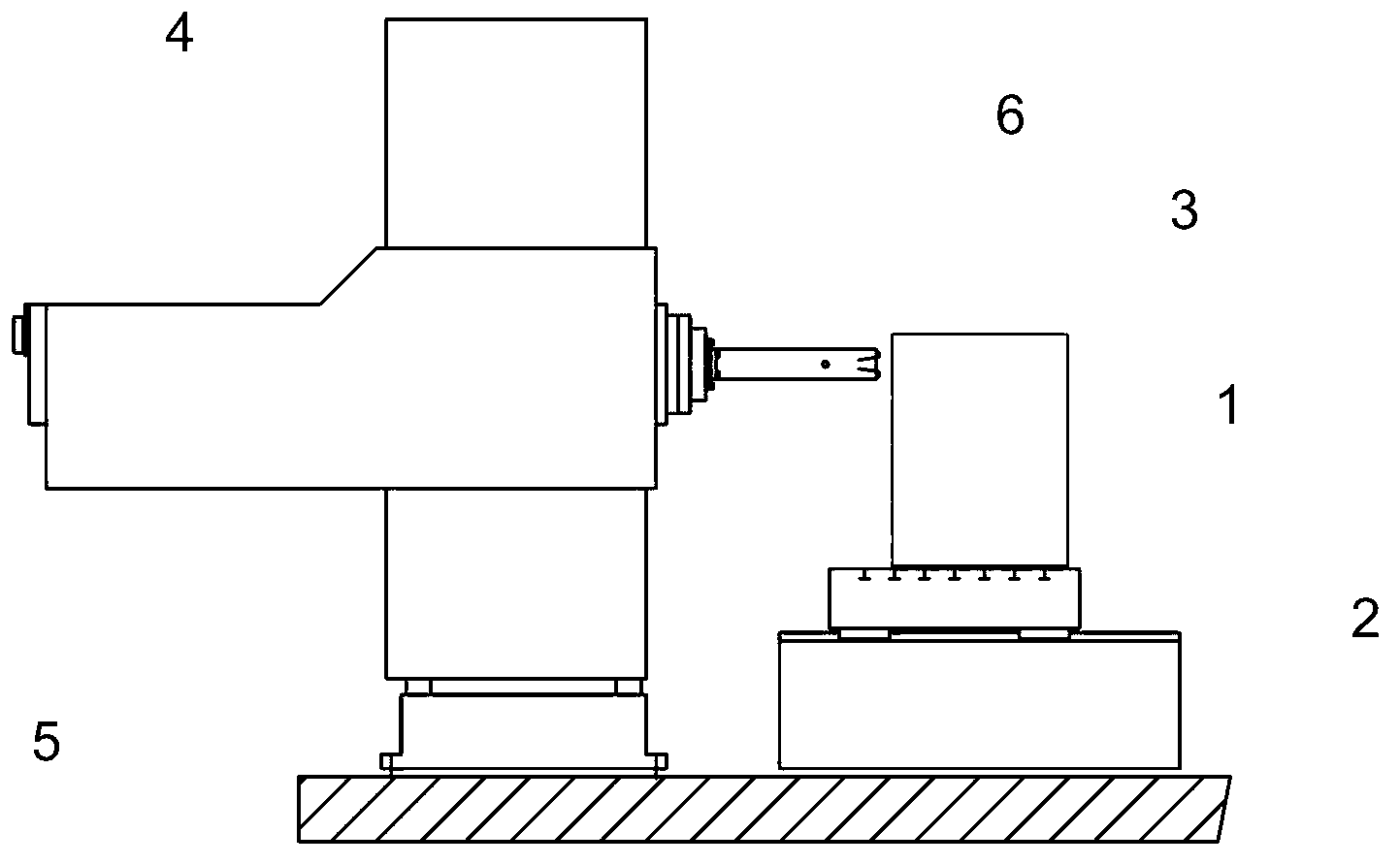

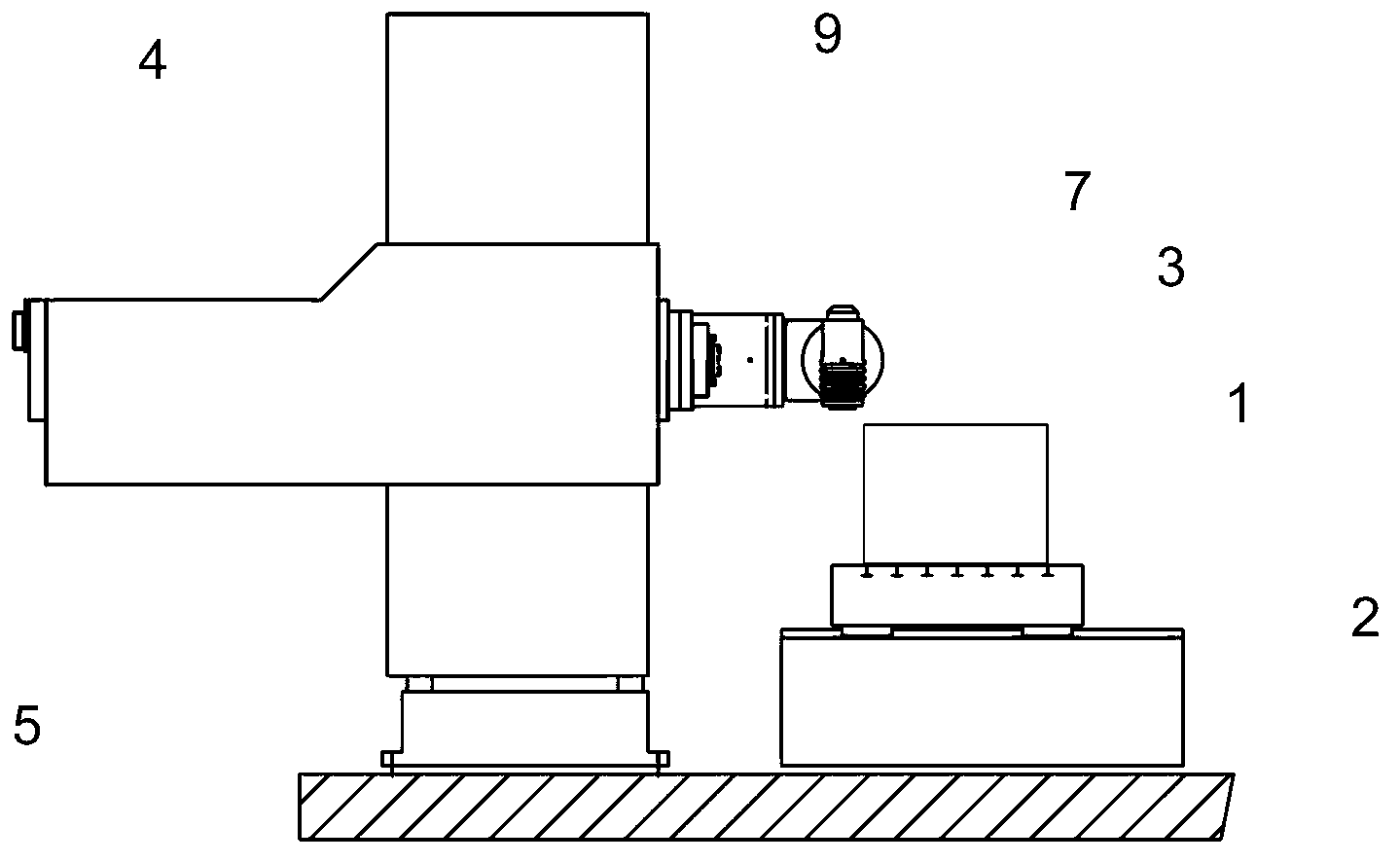

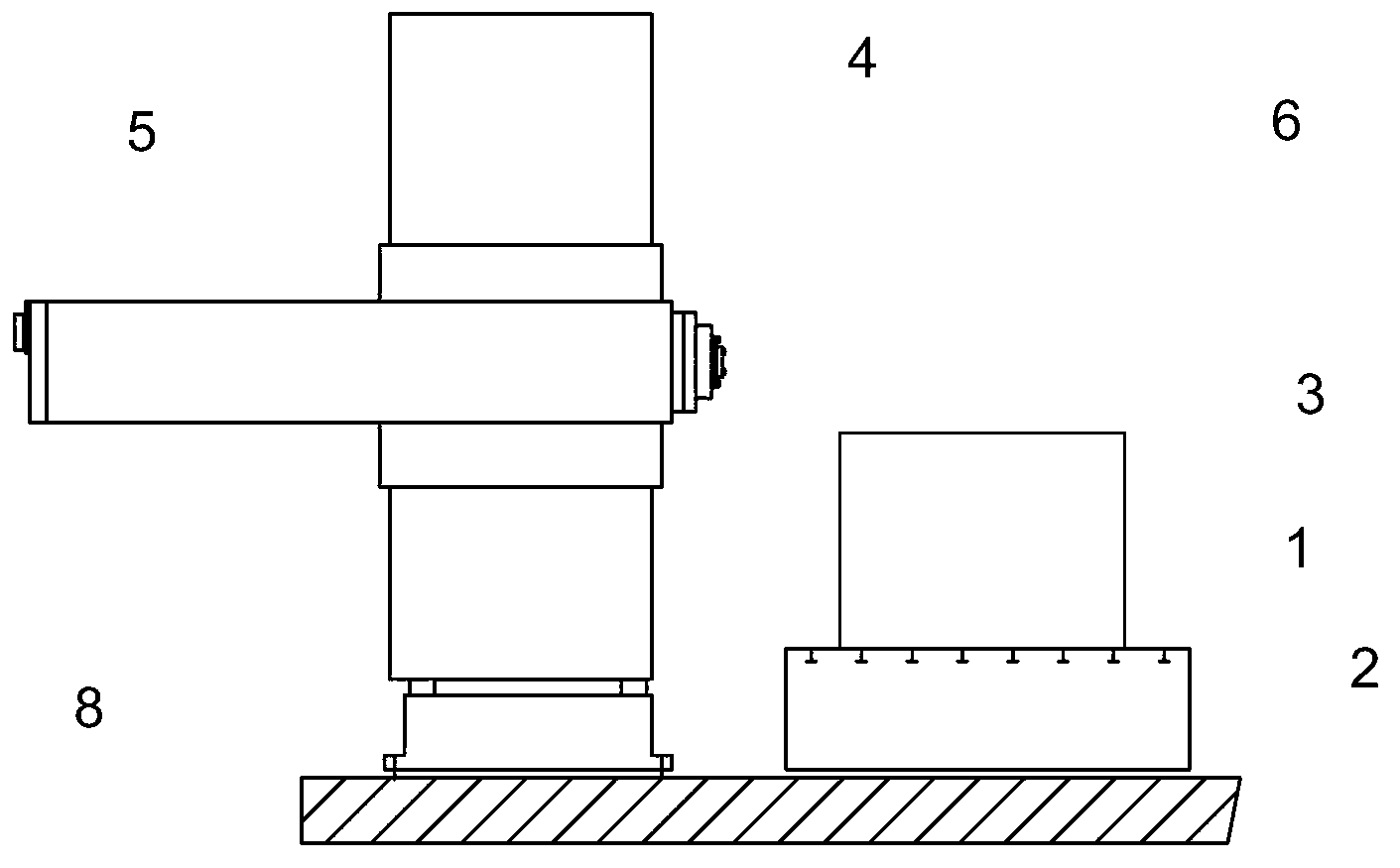

[0025] available at Figure 1A to Figure 1D See the different types of machine tools in, Figure 1A The machine shown has: a horizontal platform (1) fixed to the ground (2) on which the parts to be machined (3) are placed; columns (4), carriages (5) or consoles on which slide vertically , inside the bracket or console there is a handle (6) which slides horizontally in a direction perpendicular to the longitudinal axis of said table (1). Figure 1B show with Figure 1A A similar machine tool where the shank (6) is retracted to facilitate engagement with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com