Detection method of automobile glass louver

A technology of automobile glass and detection method, which is applied in the direction of measuring device, mechanical measuring device, mechanical counter/curvature measurement, etc., can solve the problems of complex detection process, large error, low efficiency, etc., and achieve high accuracy, short cycle, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

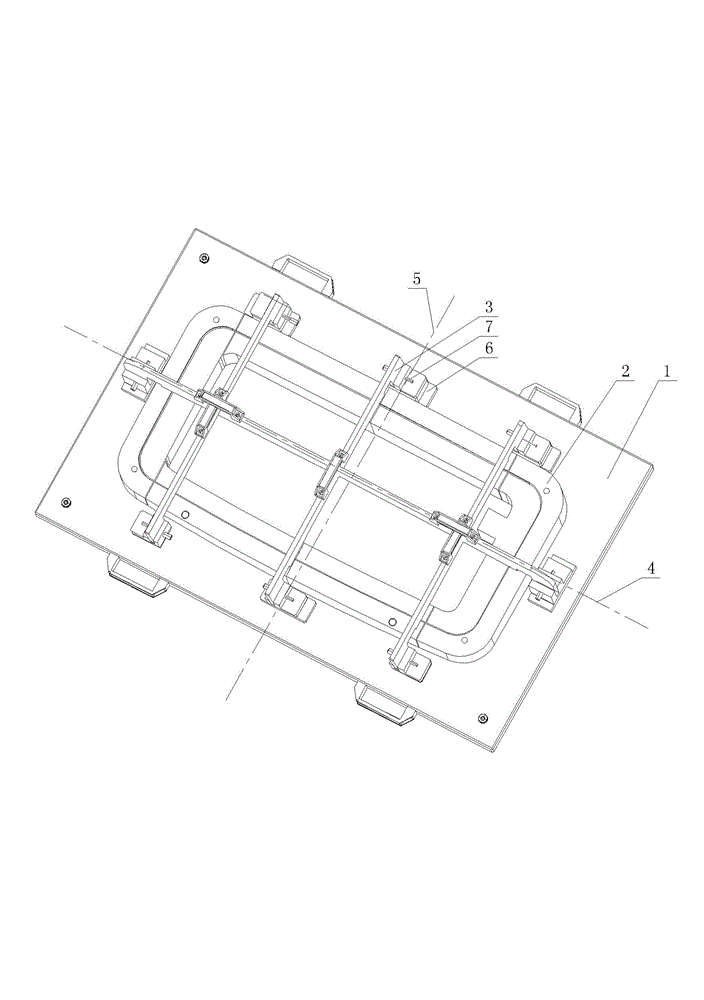

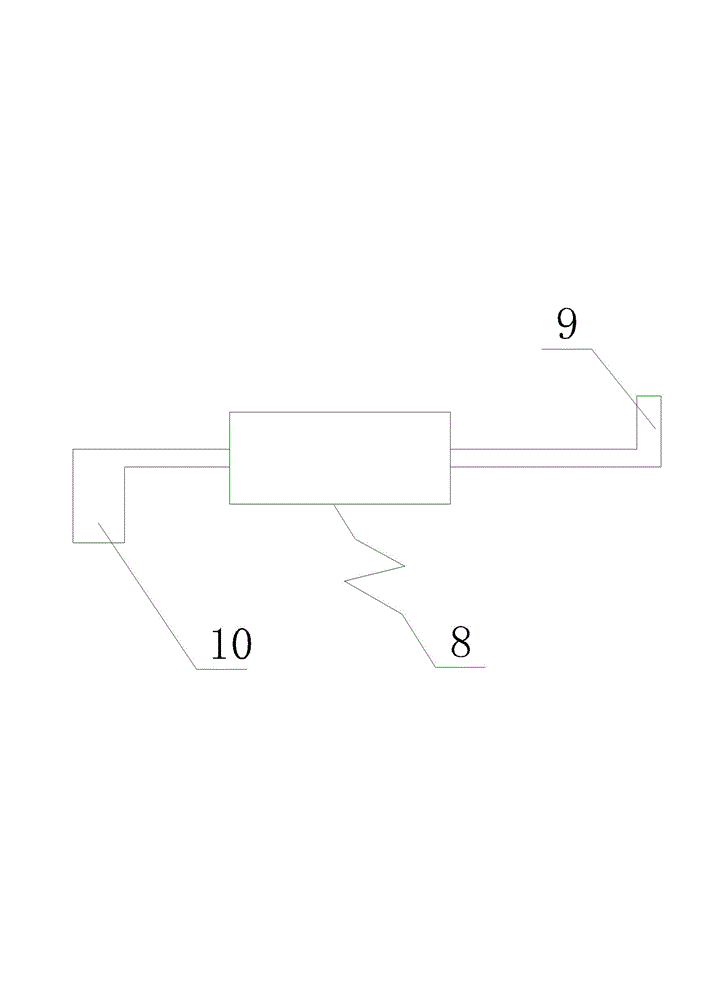

[0009] A kind of automobile glass sunroof inspection fixture structure, see figure 1 , figure 2 : It comprises base plate 1, and base plate 1 is provided with simulation block 2, and simulation block 2 encloses the outer contour structure of automobile glass sunroof, and the upper surface of simulation block 2 fits the inner surface of automobile glass sunroof, and the outer contour of simulation block 2 is based on The outer contour of the automobile glass sunroof shrinks inwardly by 3mm, the bottom plate 1 is provided with an end gauge 3, and the cross-section gauge 3 is symmetrically arranged on both sides of the X-axis centerline 4 and Y-axis centerline 5 of the outer contour of the simulation block, and the cross-section gauge 3 is supported On the corresponding section gauge support 6, the section gauge 3 is mounted on the corresponding section gauge support 6 through the pin shaft 7, and is symmetrically arranged on the sections on both sides of the X-axis centerline 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com