Powder extinguishing device

A dry powder fire extinguishing and powder bottle technology, which is applied in fire rescue and other directions, can solve the problems of time required, wrong release of fire extinguishing gas, and high maintenance cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

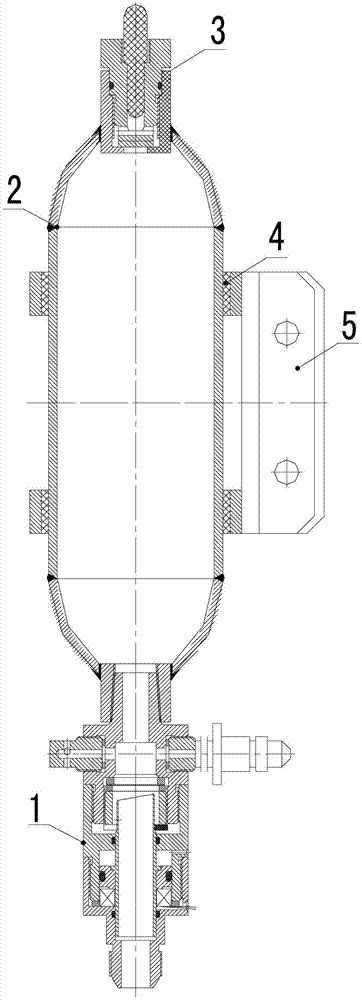

[0020] refer to figure 1 , is a kind of dry powder fire extinguishing device of the present invention. Among them, the fire extinguishing device includes a filling valve 3, the lower part of the filling valve is connected to the powder bottle 2 by welding, and the lower part of the powder bottle is threadedly connected to the bottle head valve 1. When the fire extinguishing device is used, this inverted structure can respond quickly and achieve faster spray effect. Powder bottle 2 side walls are connected with rubber plate 4, and rubber plate outside is connected with support 5, can install fire extinguishing device by support 5, and rubber plate 4 has elasticity, can reduce the relative vibration between powder bottle and support.

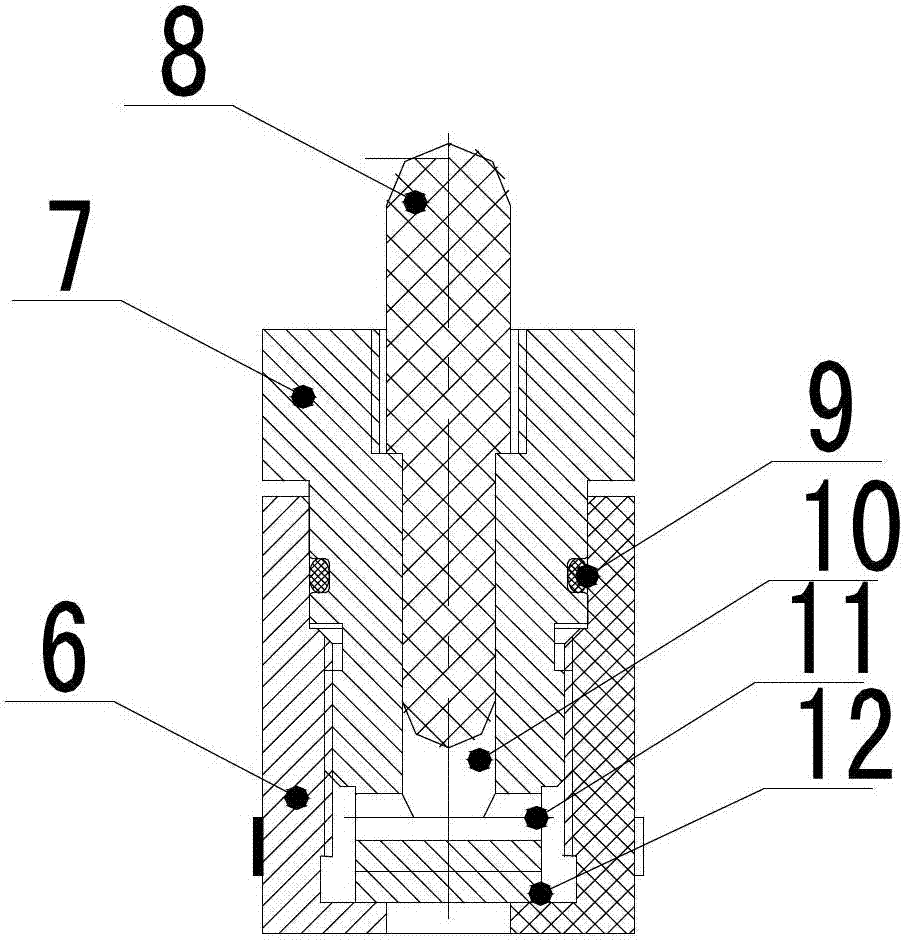

[0021] refer to figure 2 , a filling valve in a dry powder fire extinguishing device of the present invention, the filling valve 3 includes a valve casing 6, the center of the valve casing 6 is provided with a stepped center hole, the entrance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com