Mold locking structure for injection mold

A technology of clamping and clamping, which is applied in the field of mold manufacturing, can solve the problems of inability to seal glue, front mold slider rubbing, product burrs, etc., and achieves the effect of simple structure and avoiding rubbing damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

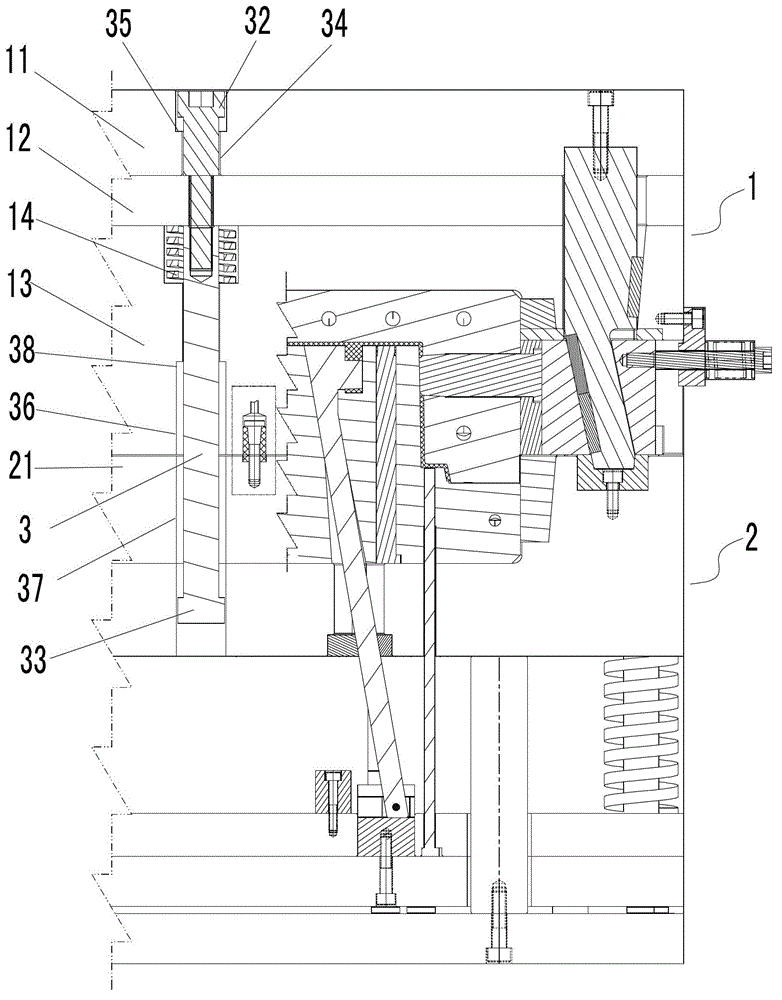

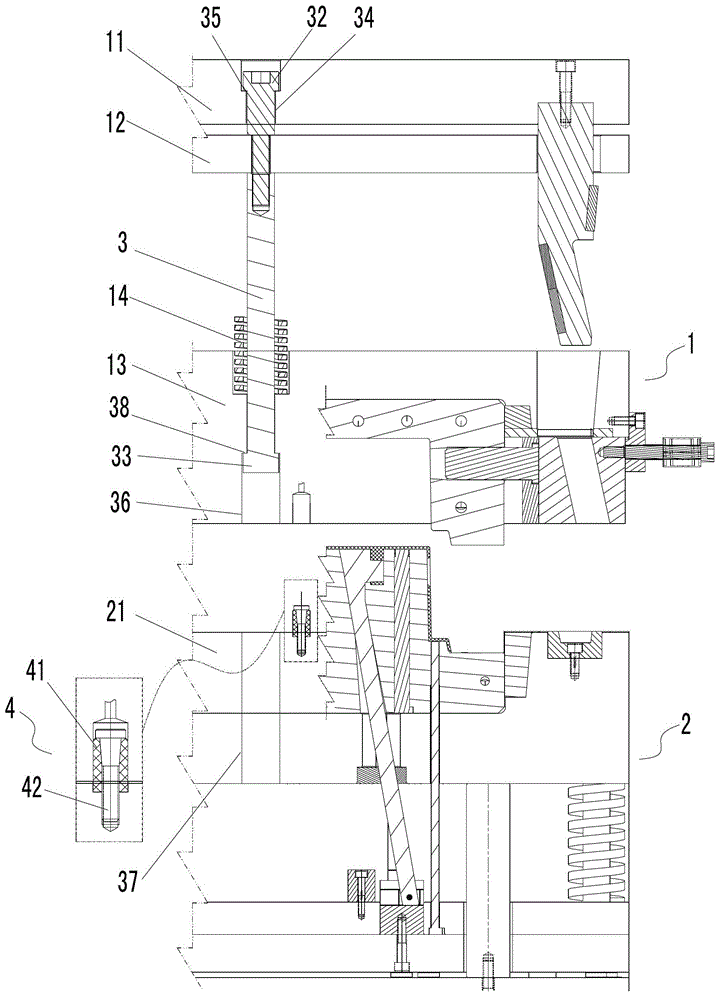

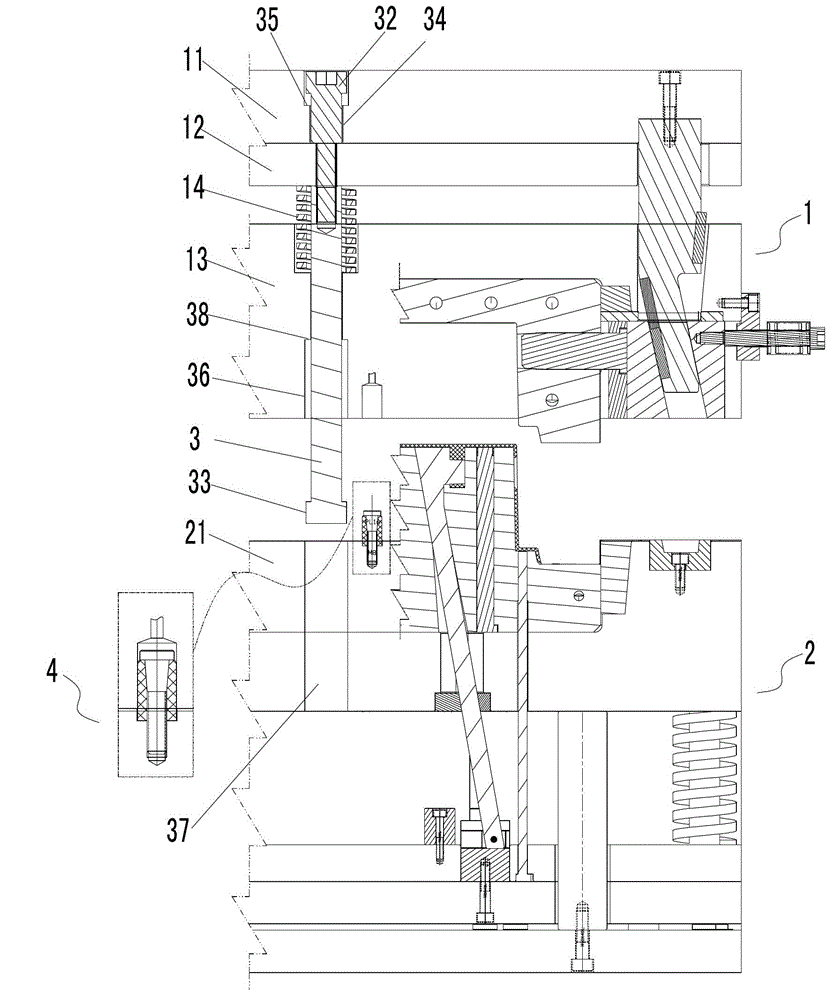

[0026] like Figure 4 to Figure 9 As shown, an injection mold clamping structure includes a static mold part 100, a movable mold part 200 and a mold clamping assembly 400. The static mold part 100 includes a panel 101, a nozzle plate 102, a static template 103, and a nozzle plate from front to back. A compression spring 104 is arranged between 102 and the static template 103, and the movable mold part 200 includes a movable template 201 and its driving device (not shown in the figure); wherein, a pull rod penetrating through the nozzle plate is fixed on the nozzle plate 102 300, the upper end of the pull rod is provided with a first limit end 301, and the lower end of the pull rod is provided with a second limit end 302; the panel 101, the static template 103 and the movable template 201 are provided with guides corresponding to the pull rod Channels ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com