Paper defect detection system based on image pattern recognition

A pattern recognition and paper defect detection technology, applied in the field of pattern recognition, can solve the problems that cannot meet the requirements of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

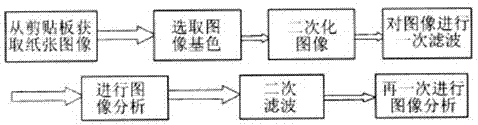

[0037] figure 1 It is a system schematic diagram of an embodiment provided by the present invention. This system is mainly composed of image acquisition from CCD, primary color selection, binarization, primary filtering, image analysis, and secondary filtering.

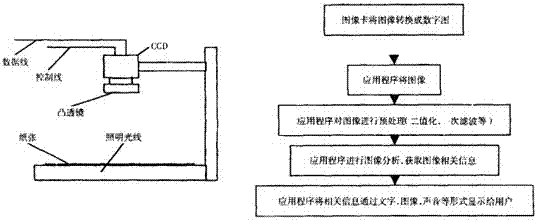

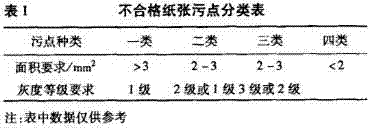

[0038] figure 2 Flow chart for CCD paper detection. The CCD static paper detection system uses CCD to take the paper image into the computer and converts the image into a digital signal, that is, the computer image is composed of many pixels, and then these pixels are analyzed through computer software to detect the black spots on the paper And transparent dots, etc., count the number and area of black dots and transparent dots on the paper, compare the paper standards stored in the computer in advance, automatically classify the paper quality, and automatically alarm for unqualified paper, and automatically calculate it The failure rate of paper and the proportion of paper at all levels, the working principle and fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com