Automatic receiving and discharging conveyer

An automatic material receiving and conveyor technology, applied in the fields of unloading equipment, material receiving, and transportation, can solve the problems of equipment differences and the lack of a national standard for equipment, and achieve good economy and efficiency, simple structure, and low failure rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

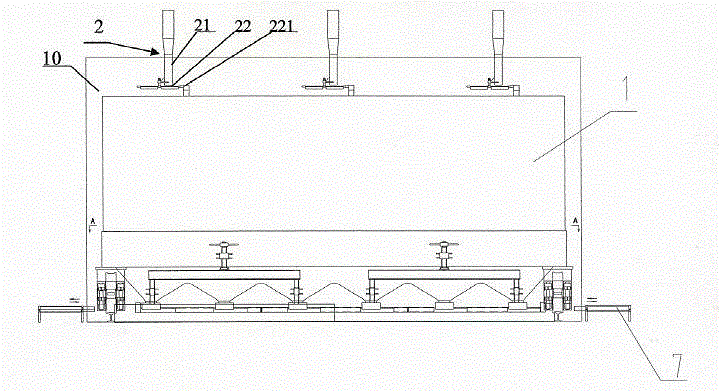

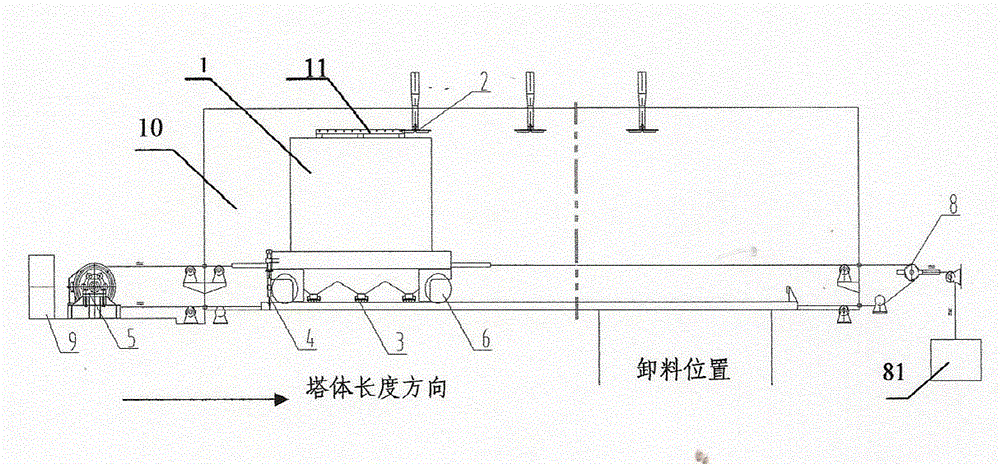

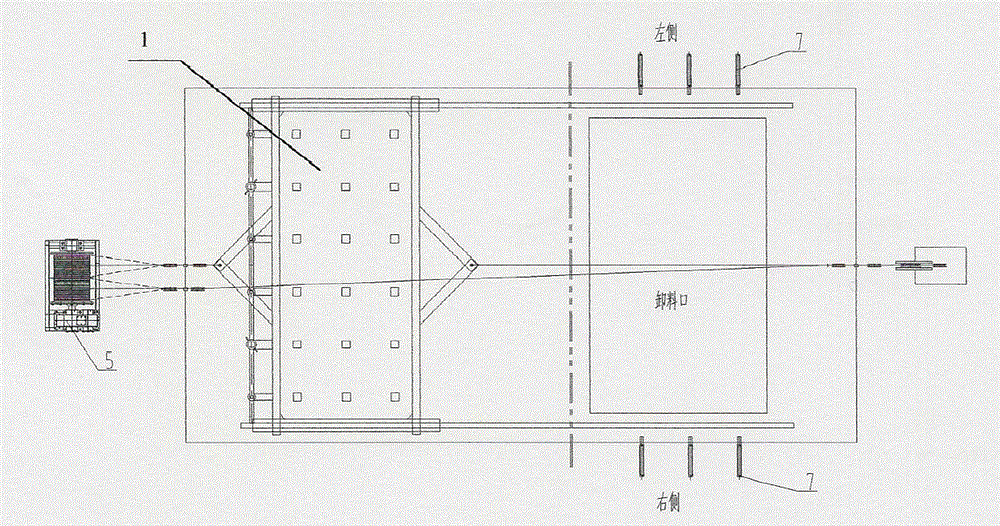

[0024] Such as figure 1 , 2 , 3, the automatic feeding and unloading conveyor includes a steel container (1), a receiving assembly (2), a discharging push-pull rod (3), a regular cleaning assembly (4), a driving assembly (5), Traveling component (6), unloading executive power component (7), tensioning component (8) and electrical component (9). The steel container can be of any shape ( figure 1 Cuboid shape shown), only needs to meet the strength and volume of the medium contained.

[0025] The receiving assembly includes a drop tube (21) and a tray (22). The tray is arranged at the lower opening of the drop tube, and a gear (221) is provided on the edge of the tray. There are two positions of the tray sealing opening and the discharge opening.

[0026] The discharge push-pull rod (3) is located at the lower part of the discharge port, and is a frame structure composed of section steel, which relies on the two positions of the push-pull rod to discharge and close the discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com