Automatic casting blank transport system and method thereof

A technology of automatic transportation and automatic transportation vehicles, which is applied in the field of metallurgy, can solve the problems such as the inability to realize the automatic transportation of billets, and achieve the effect of guaranteeing the level, avoiding partial load and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

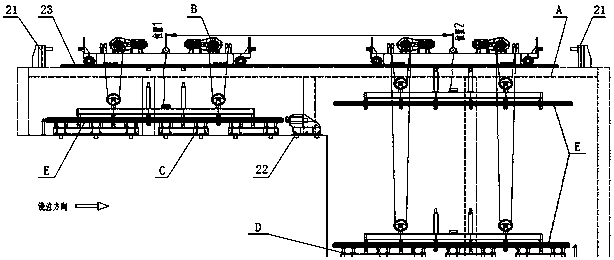

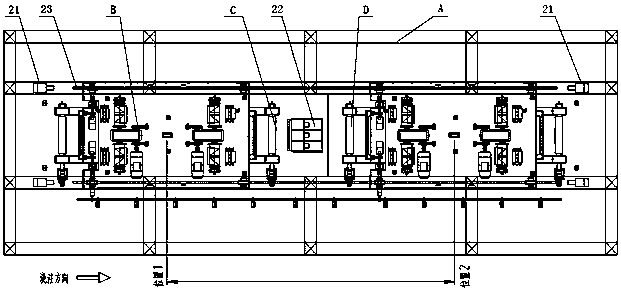

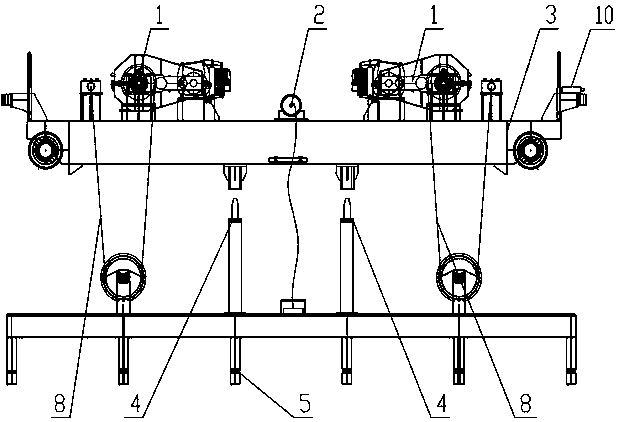

[0068] In order to solve the problem that the existing slab lifting system cannot realize the automatic transportation of slabs with a super large height difference of more than 2 meters, this embodiment provides an automatic slab transportation system, such as figure 1 and figure 2 As shown, it includes a transport vehicle support frame A, and the transport vehicle support frame A is provided with an automatic slab transport vehicle B (referring to the attached image 3 , attached Figure 4 , attached Figure 5 And attached Figure 6 ), the side of the billet automatic transport vehicle B is connected to the tow cable device 7, and the bottom is installed with the car body walking device 6, and the casting billet receiving roller table C and the casting billet conveying roller table are arranged in parallel under the support frame A of the transporter D, along the pouring direction of the slab E, the slab receiving roller table C is laid on the basis directly under the fi...

Embodiment 2

[0074] On the basis of Example 1, such as Figure 11 and 12 As shown, the billet automatic transport system also includes a mechanical anti-sway device 4, which consists of a positioning sleeve 4a, a positioning pin 4b, and a column 4c from top to bottom. The positioning sleeve 4a is fixed on the lower surface of the vehicle frame 3, and the positioning The pin 4b is fixed on the top of the column 4c, and the bottom of the column 4c is fixed on the upper surface of the hanging beam 5. When the hanging beam 5 rises, the positioning pin 4b is inserted into the positioning sleeve 4a.

[0075] The mechanical anti-sway device 4 is mainly composed of a positioning sleeve 4a, a positioning pin 4b, and a column 4c. The positioning sleeve 4a is connected to the vehicle frame 3 through bolts, the positioning pin 4b is connected to the column 4c through bolts, and the column 4c is connected to the hanging beam 5 through bolts. Before the automatic transport vehicle moves horizontally, t...

Embodiment 3

[0077] On the basis of Example 1, such as Figure 13 , 14 As shown in and 15, the hanging beam 5 is composed of a support frame 5a, a movable pulley 5b, a support plate 5c and a heat-insulating steel plate 5d. There are 4 groups of movable pulleys 5b, and the 4 groups of movable pulleys 5b are surrounded by a rectangle parallel to the ground and installed on the support frame 5a On the top, the support plate 5c is used to carry the slab E and is fixedly laid on the bottom surface of the support frame 5a, and the heat-insulating steel plate 5d is installed on the support frame 5a around the slab E to provide heat insulation protection for the support frame 5a and the movable pulley 5b. The function of the hanging beam 5 is to carry the cast slab. The four sets of movable pulleys 5b are assembled with the supporting frame 5a through bolts, the supporting plate 5c is connected with the supporting frame 5a through bolts, and the heat shield 5d is connected with the supporting fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com