Patents

Literature

31 results about "Autotransporters" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

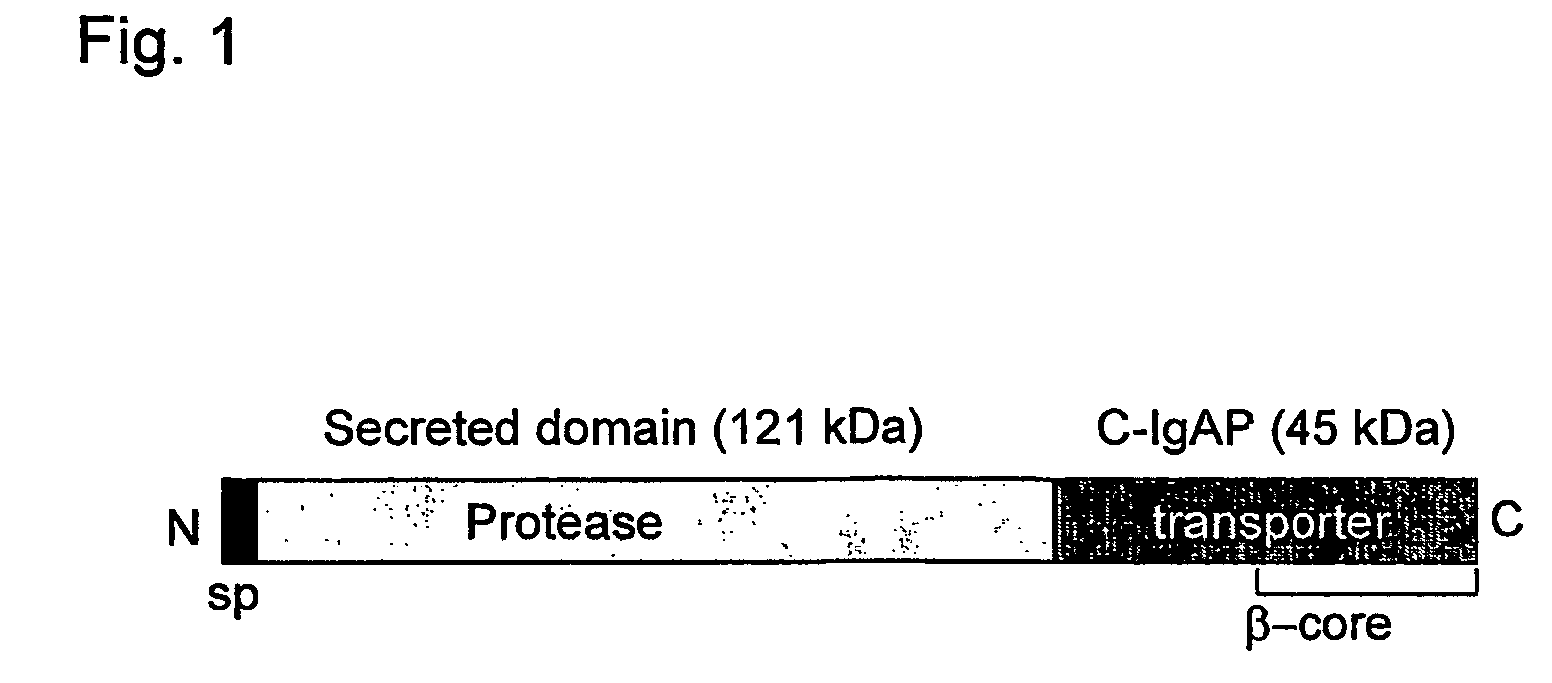

Subtypes of type V secretion systems that contain both a translocator domain and a passenger domain in a single polypeptide. After the passenger domain is transported to the extracellular millieu it is cleaved off as the mature secreted protein.

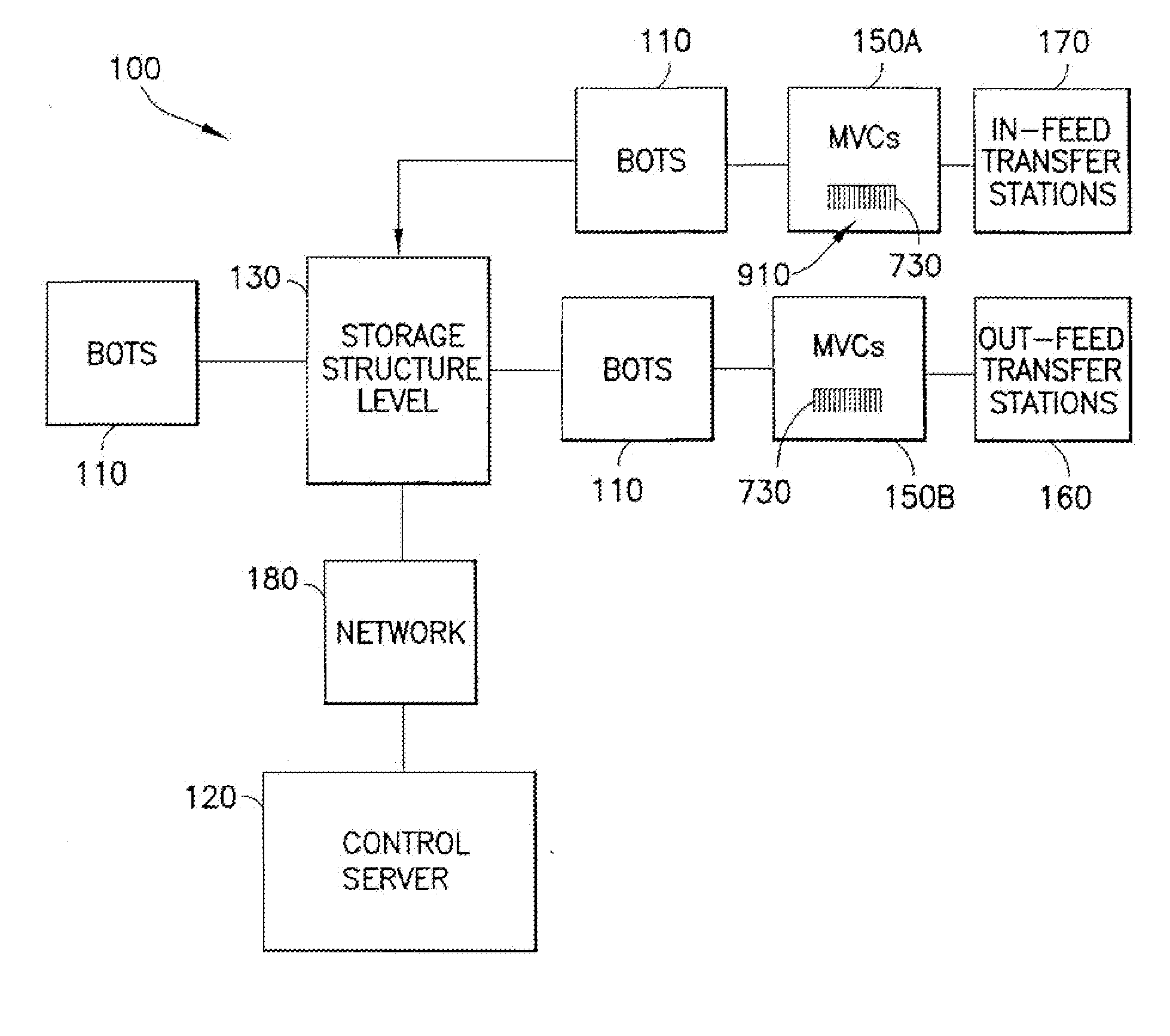

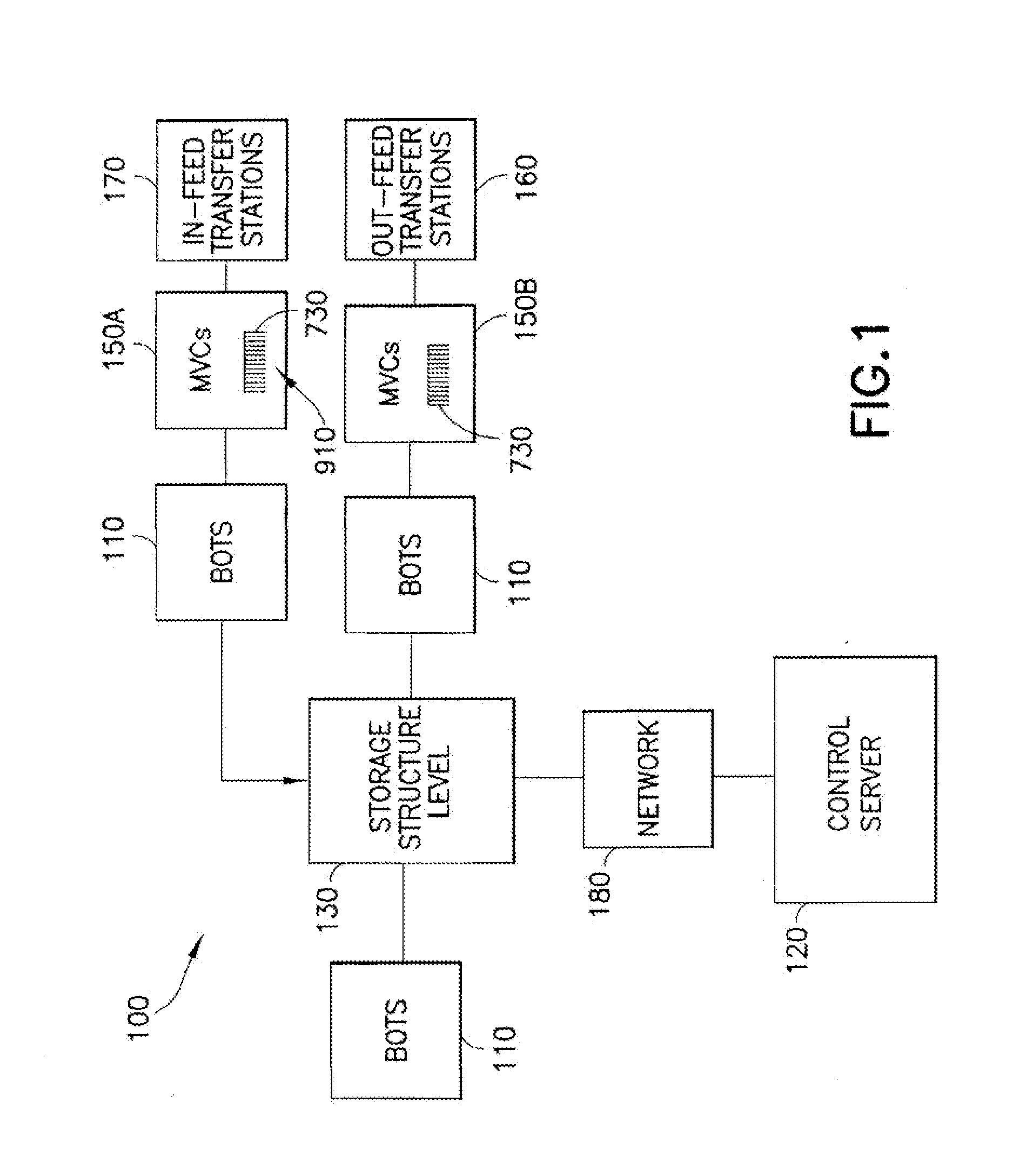

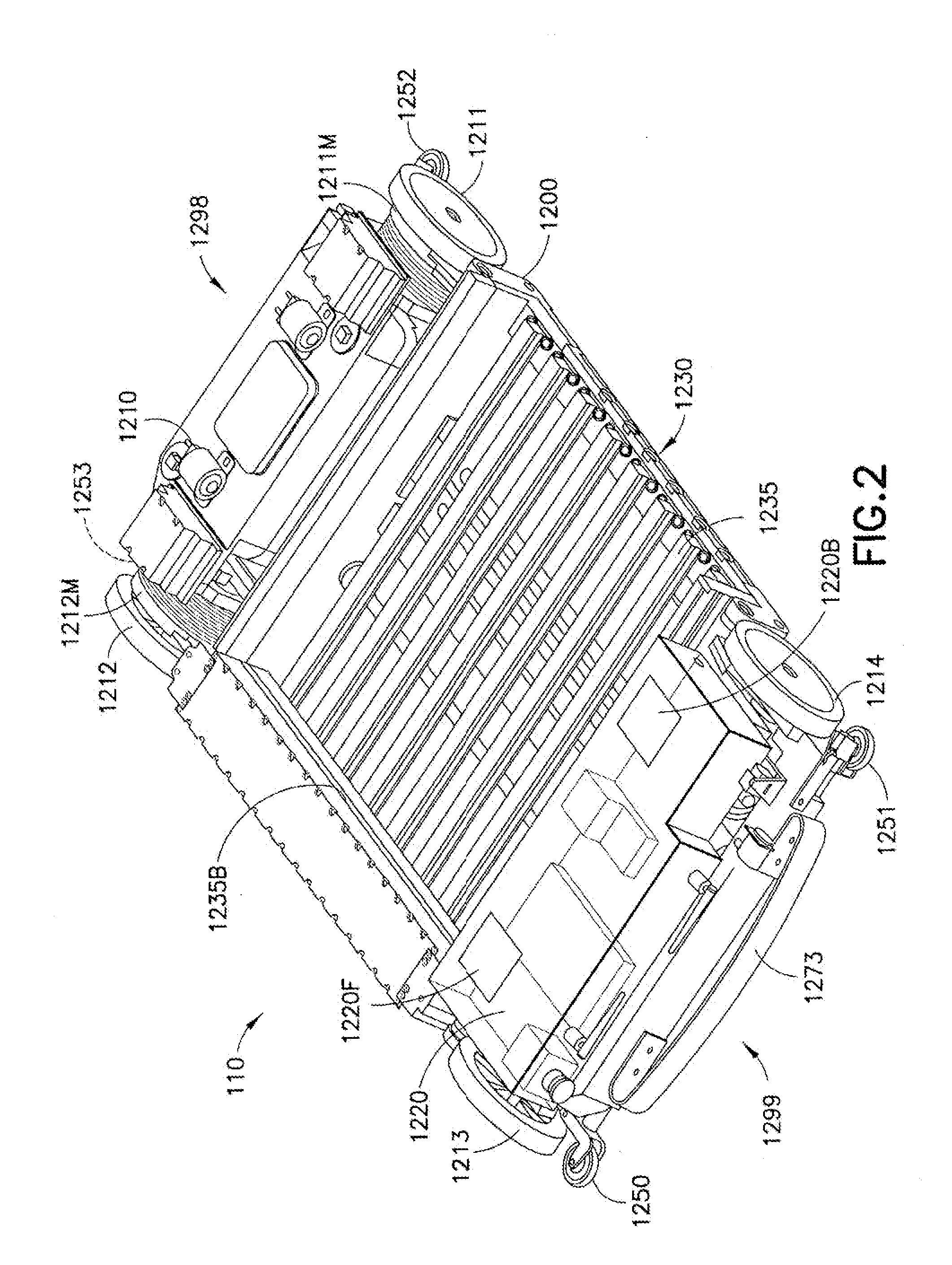

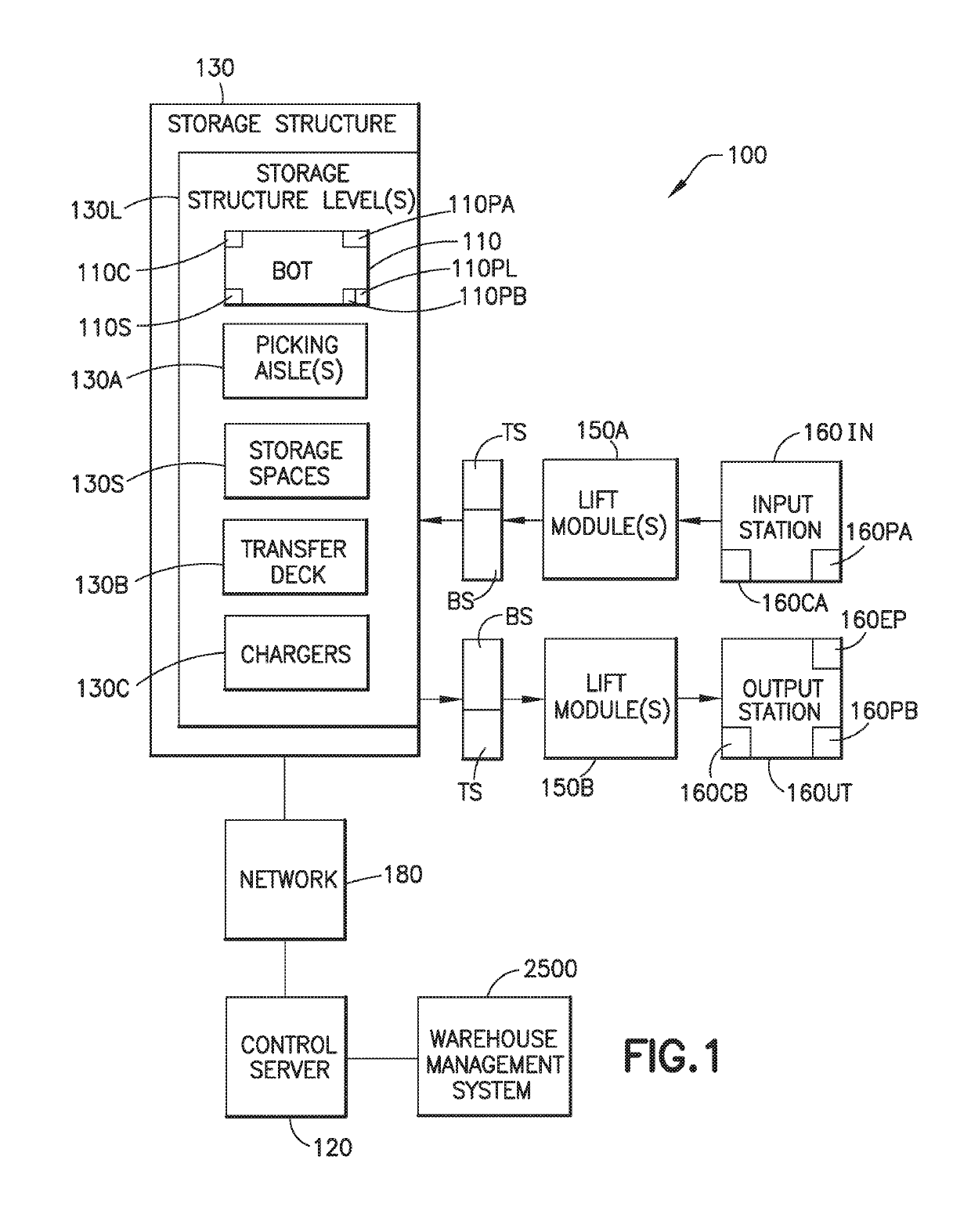

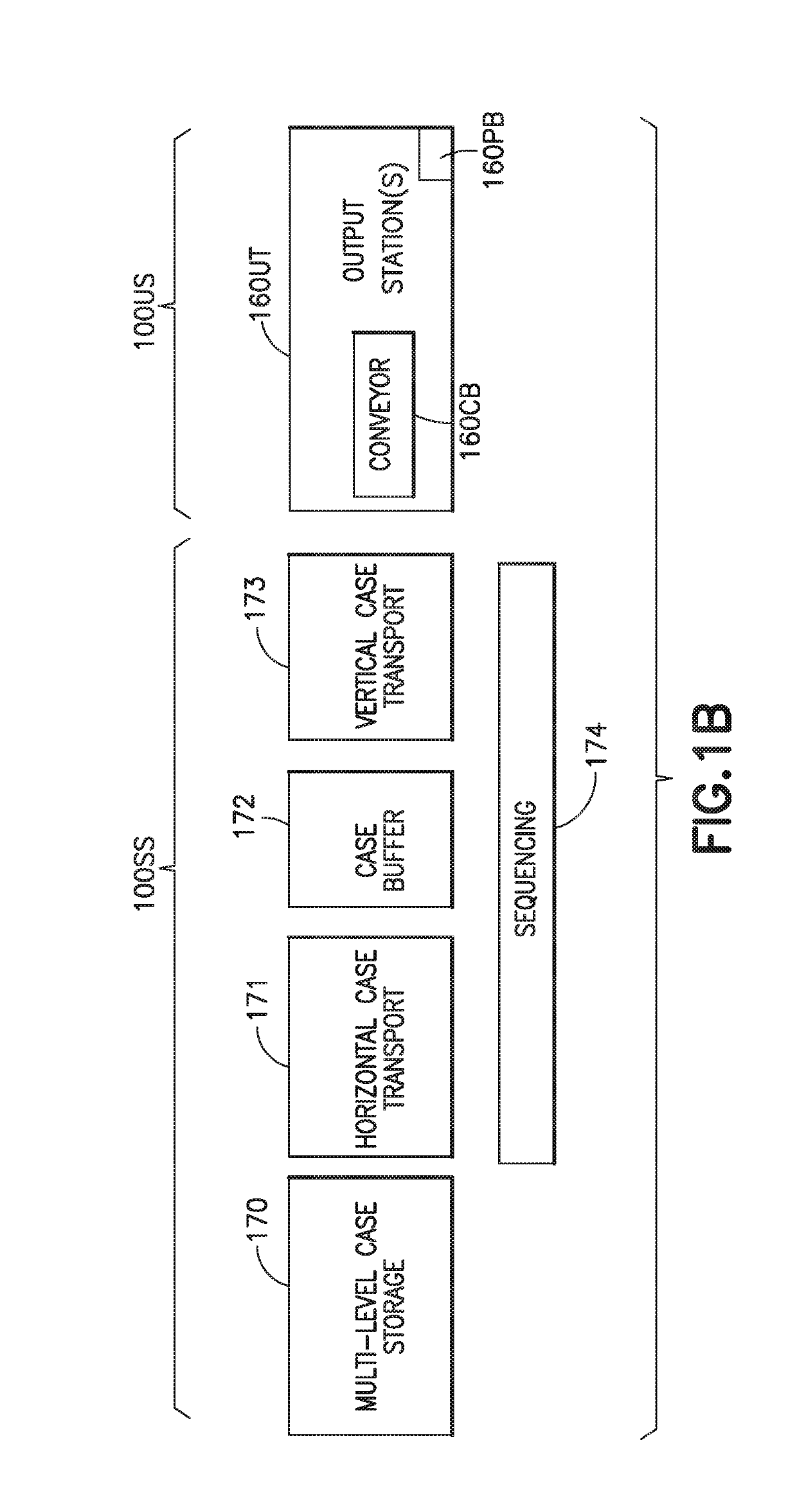

Autonomous transports for storage and retrieval systems

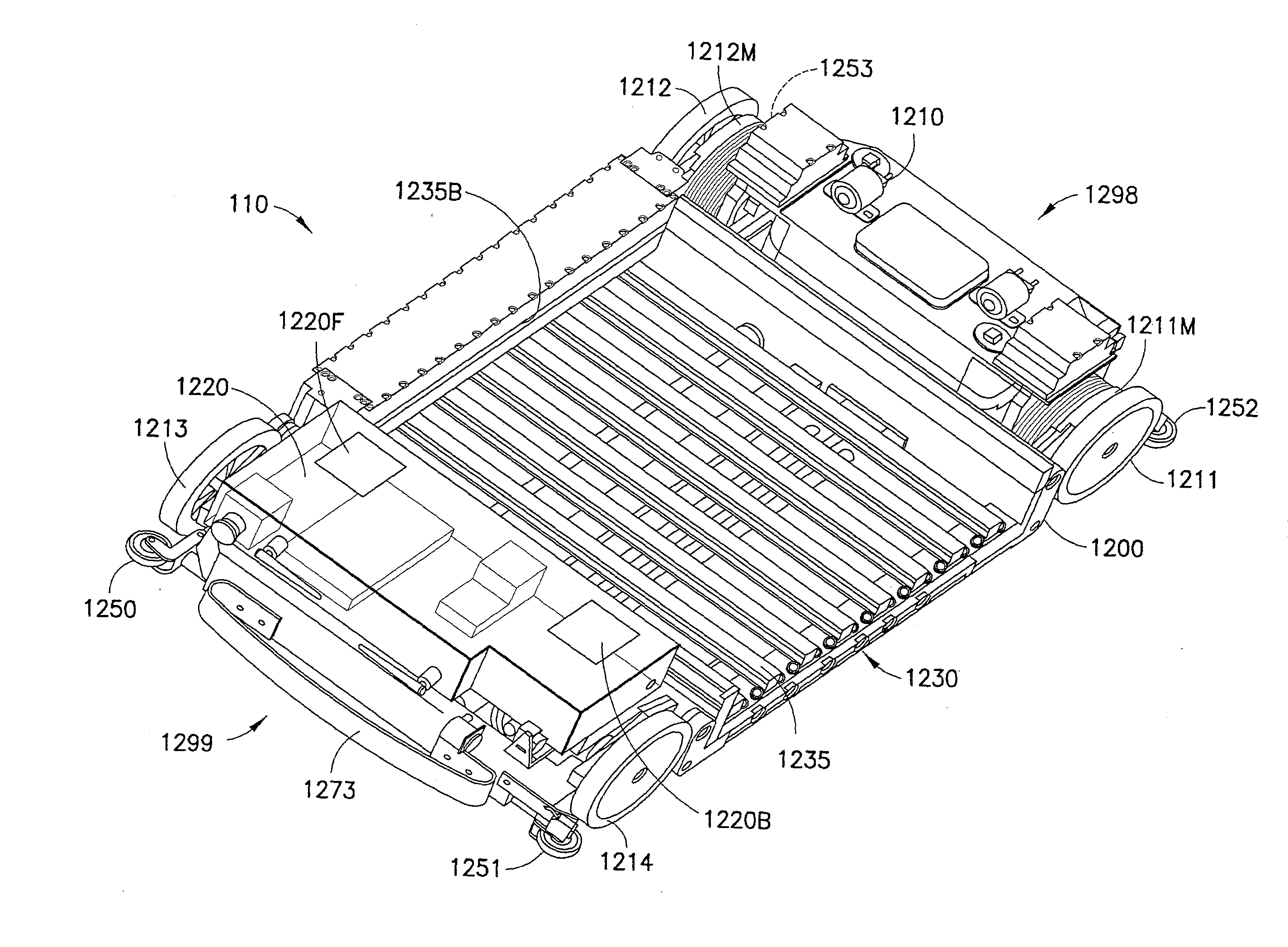

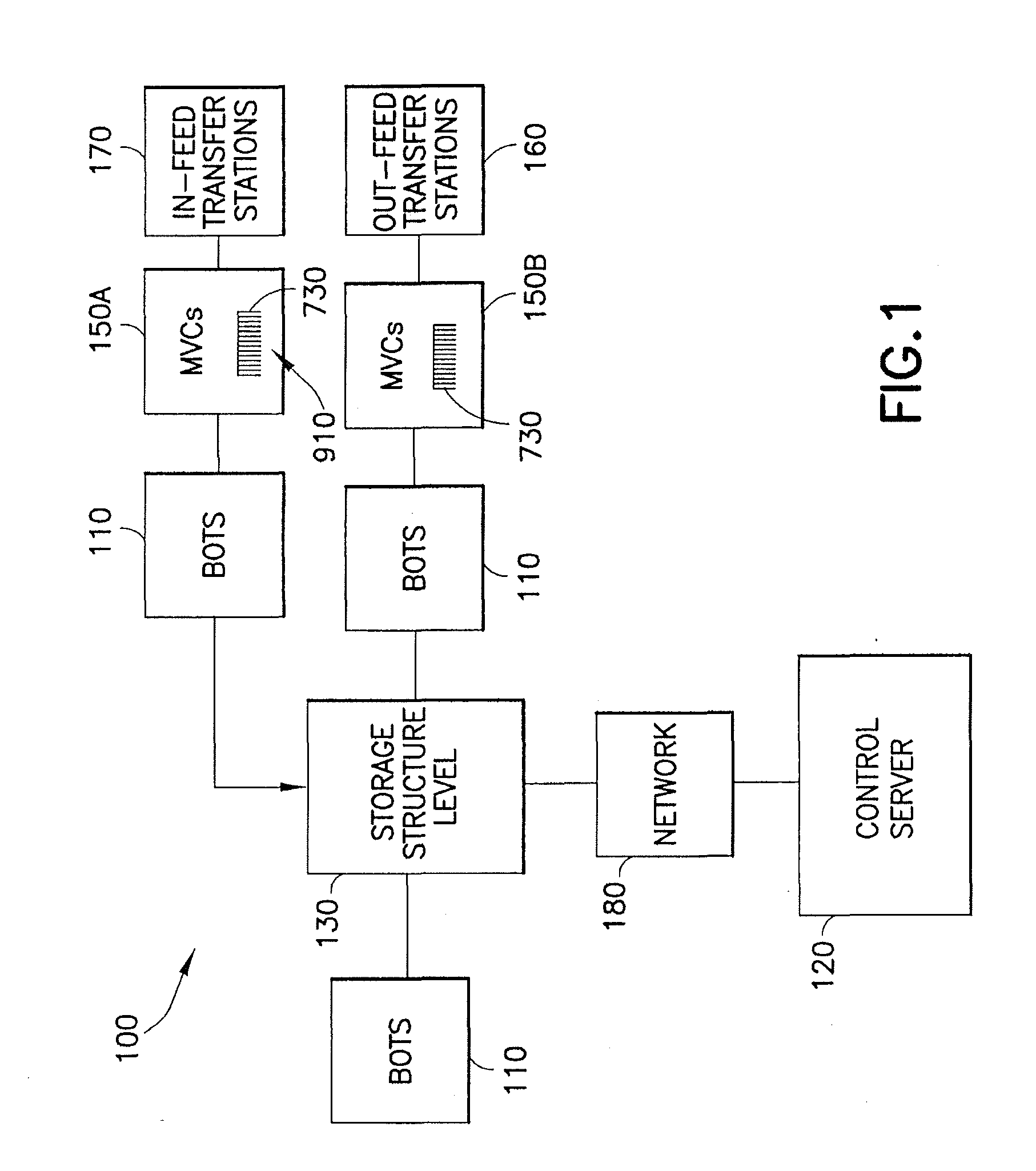

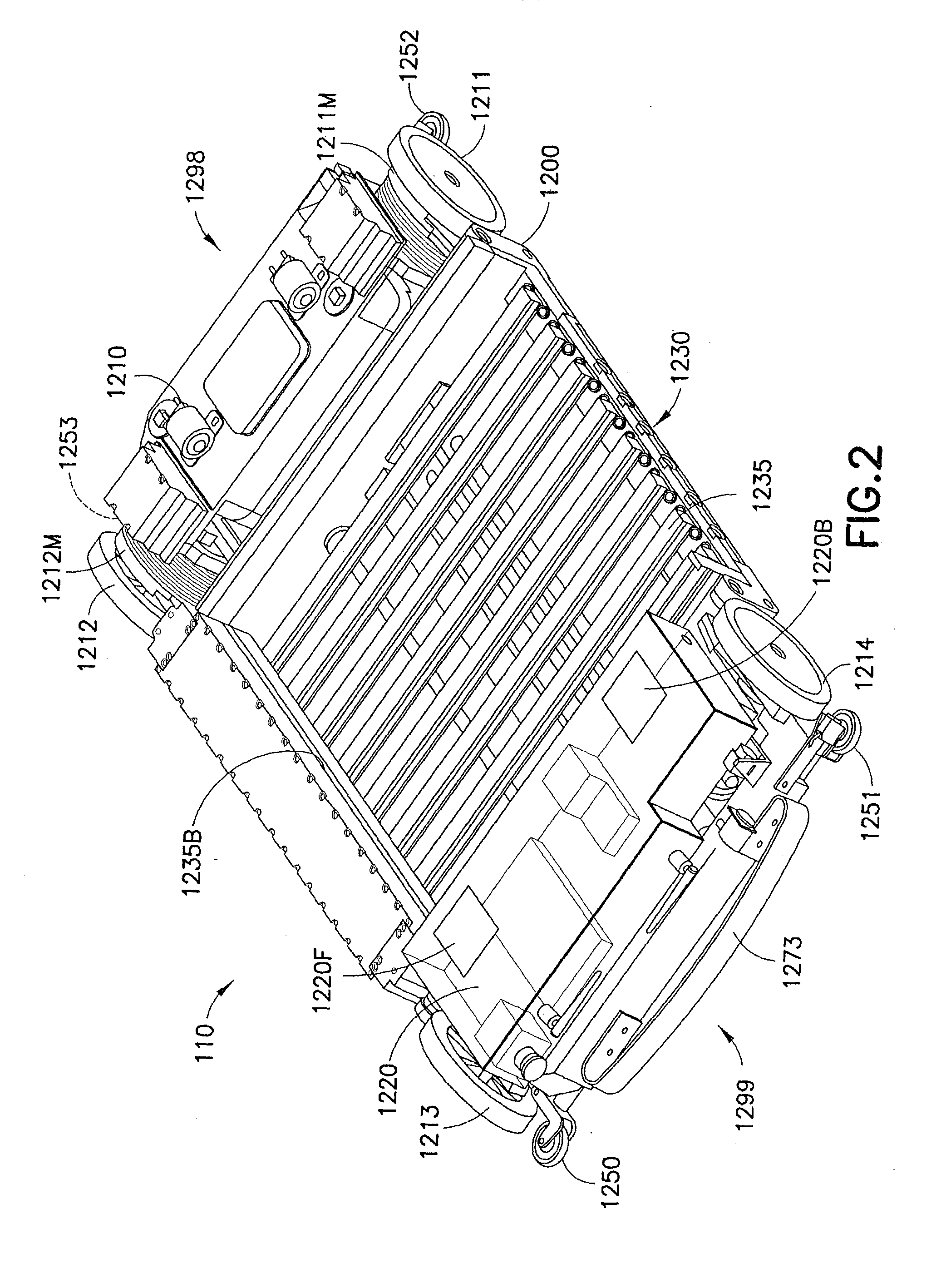

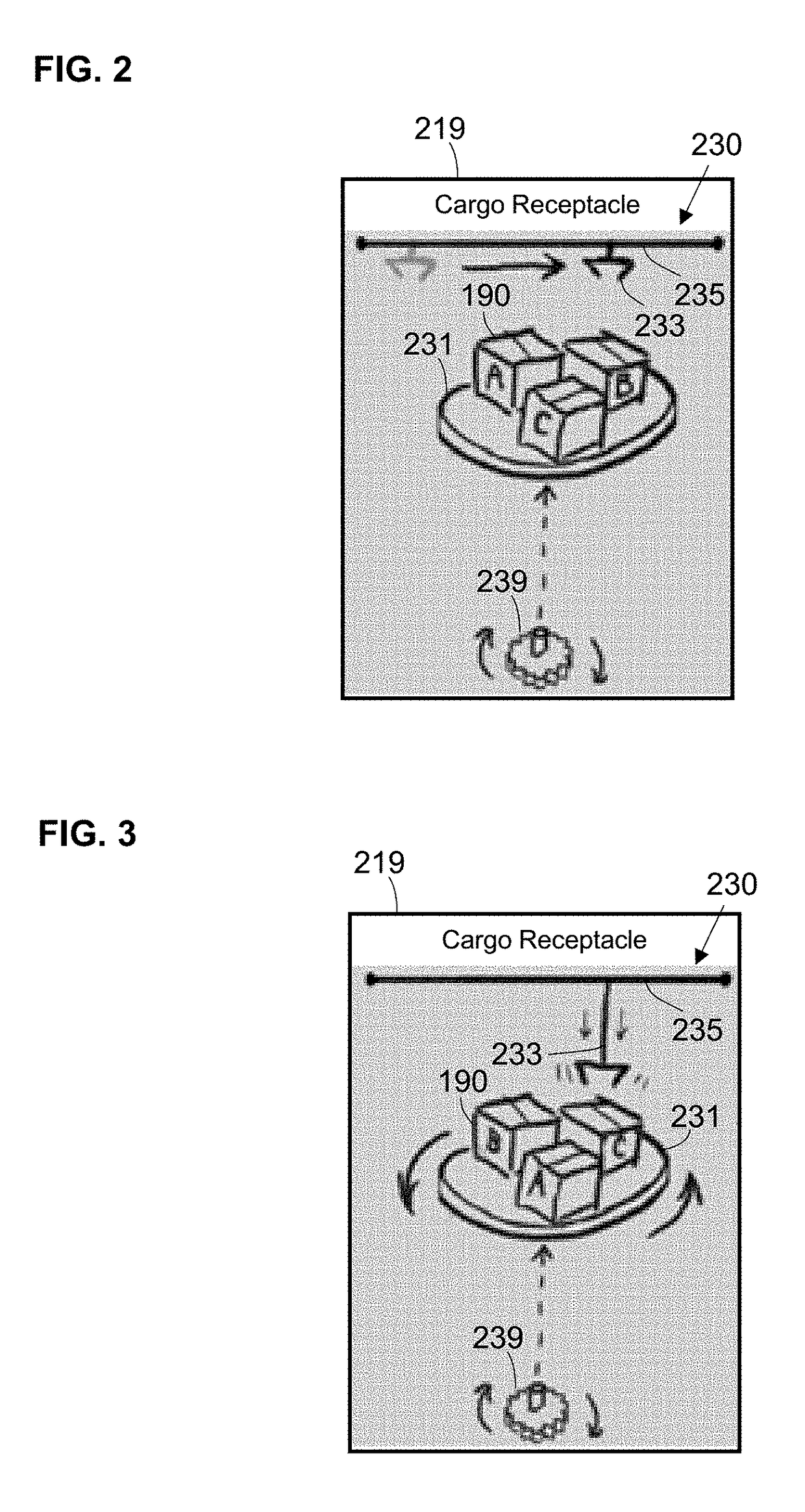

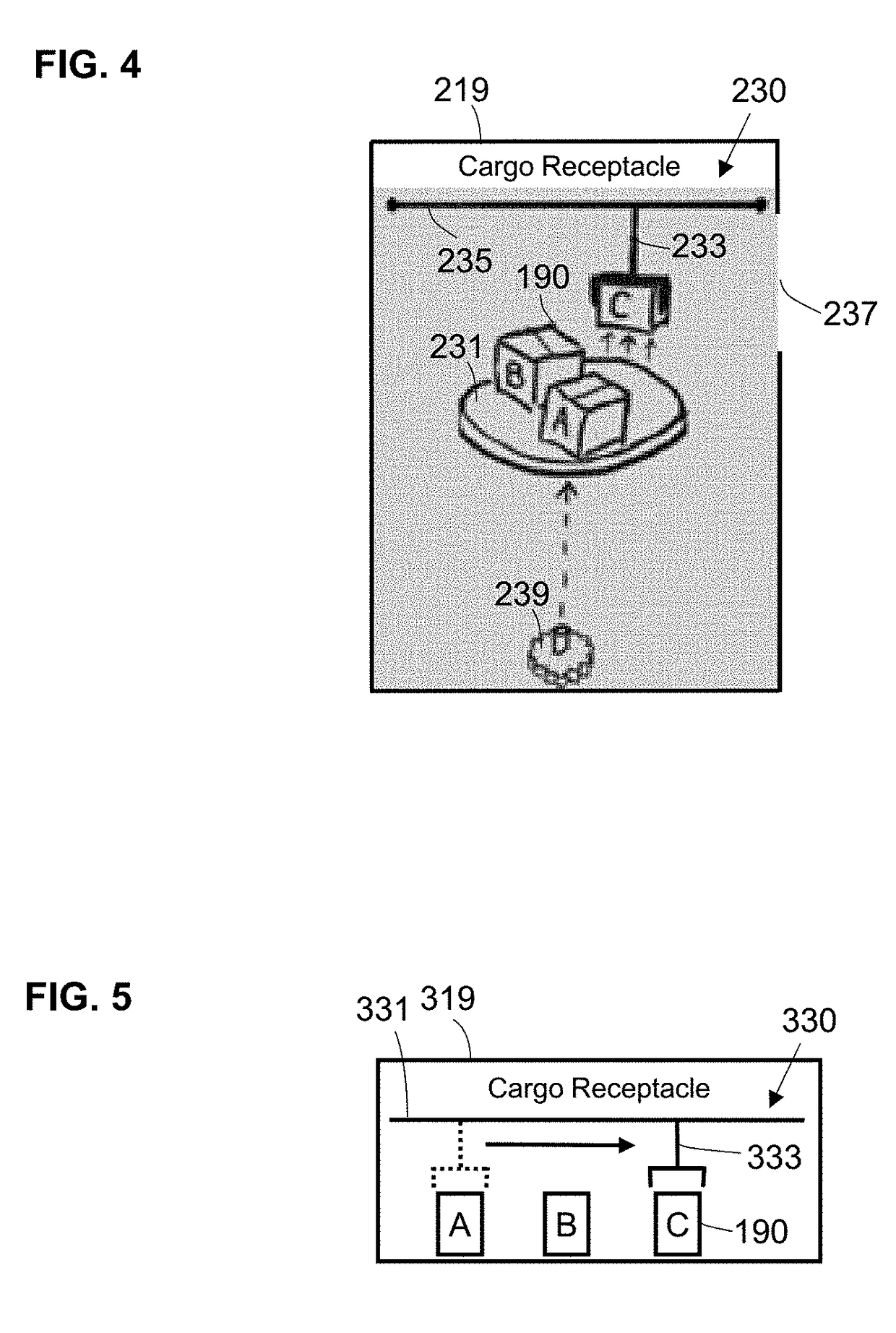

An autonomous transport vehicle for transferring case units to and from predefined storage areas in an automated case unit storage system, the automated case unit storage system including an array of multilevel storage racks with picking aisles passing therebetween and at least one multilevel vertical conveyor having movable shelves, the autonomous transport vehicle including a frame configured to traverse the picking aisles and a transfer deck connecting the picking aisles to the at least one multilevel vertical conveyor for transferring case units between the predefined storage areas and the at least one multilevel vertical conveyor, and a controller connected to the frame, the controller being configured to effect movement of the autonomous transport vehicle through the picking aisles for accessing each storage area within a respective level of the array of multilevel storage racks and each shelf of the at least one multilevel vertical conveyor.

Owner:SYMBOTIC LLC

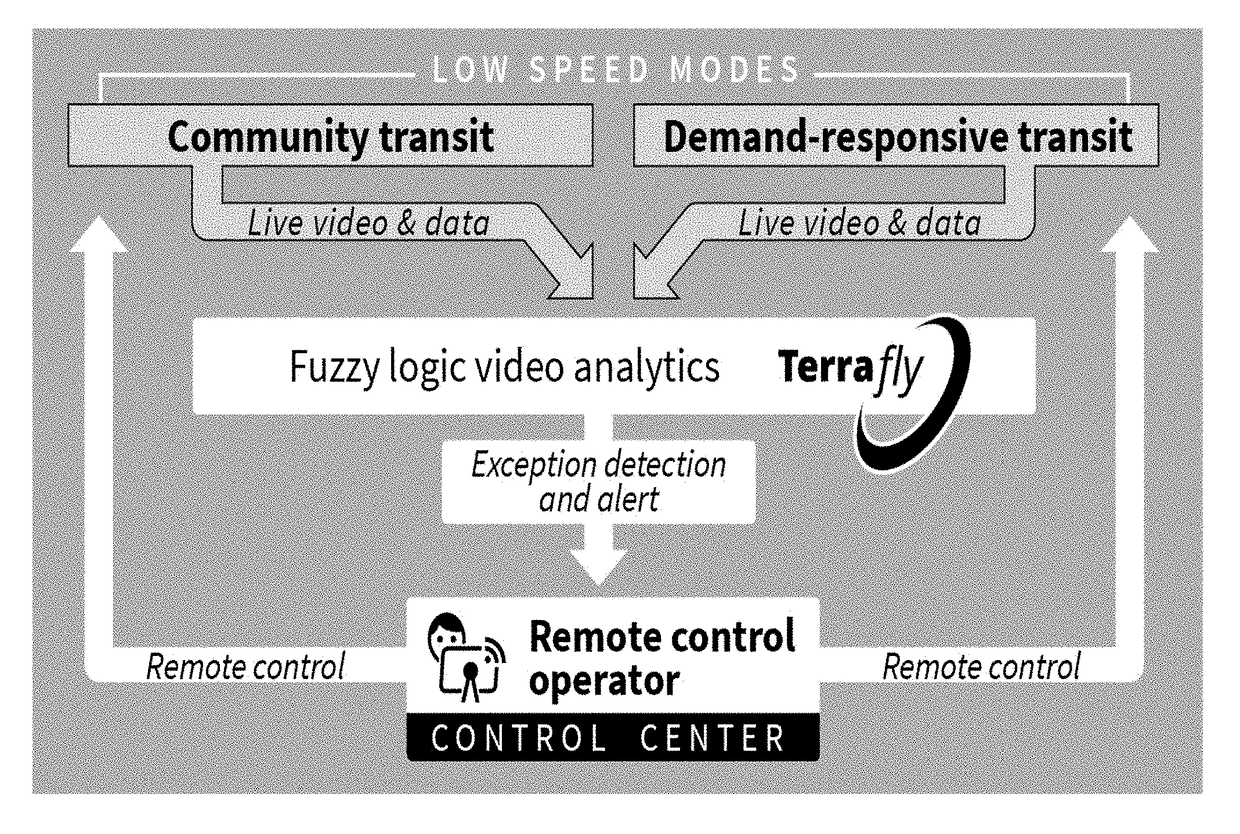

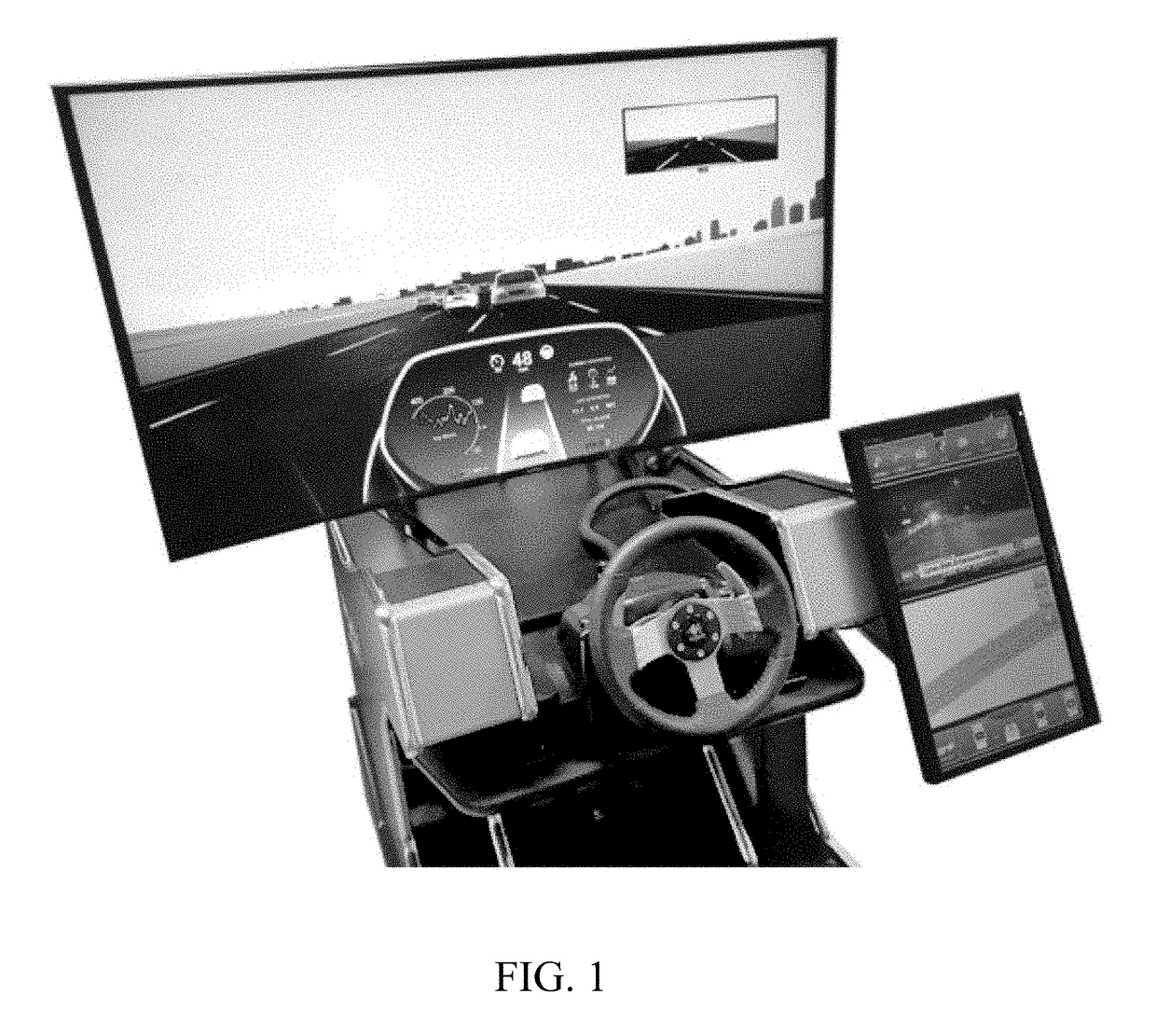

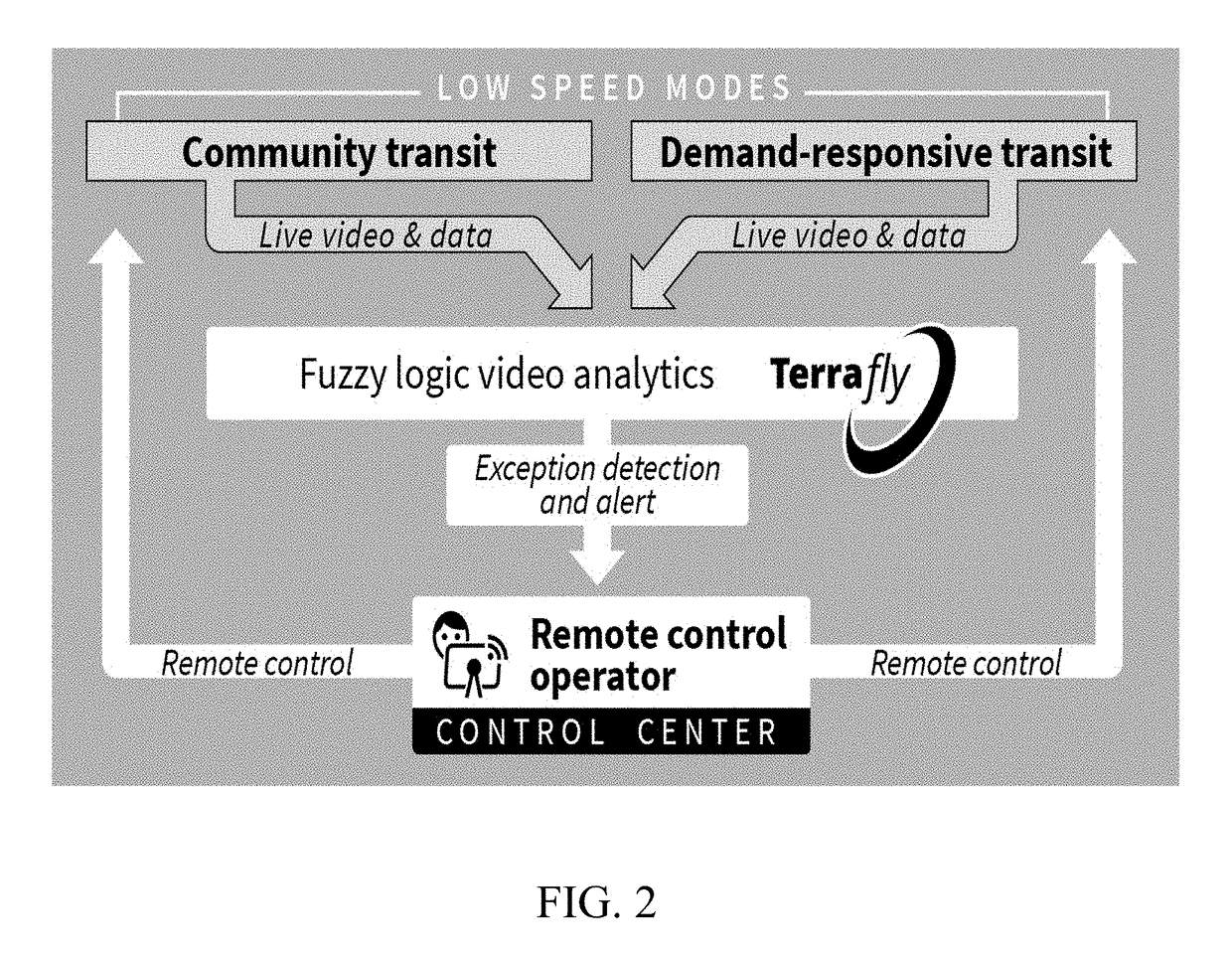

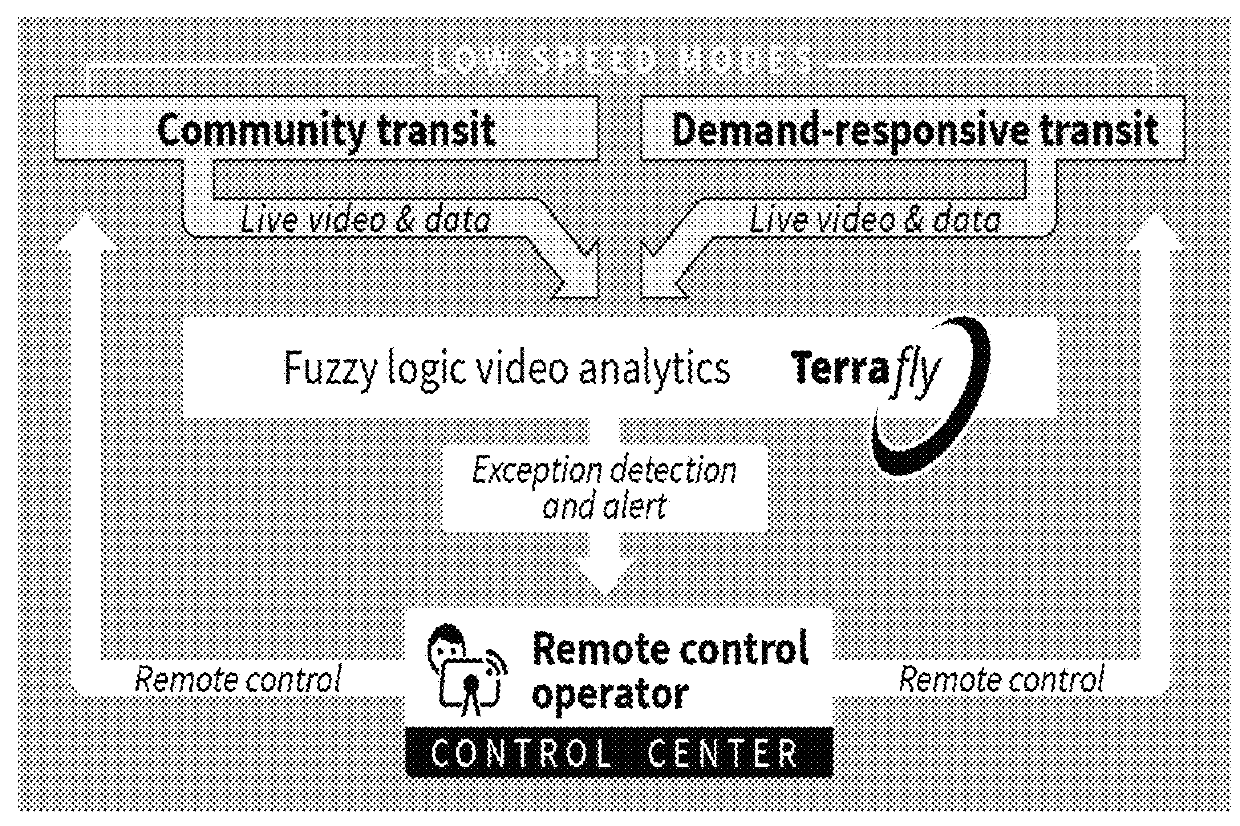

Remote control and concierge service for an autonomous transit vehicle fleet

ActiveUS20170308082A1Autonomous decision making processPosition/course control in two dimensionsRemote controlEngineering

Methods and systems for assisting autonomous vehicles are provided. The methods and systems can help increase safety and consumer satisfaction with autonomous vehicles and help bridge the gap towards completely autonomy. A method for assisting autonomous vehicles can include providing an autonomous vehicle having sensory inputs and providing a remote control center having two-way communication with the autonomous vehicle. The autonomous vehicle can send its sensory input information to the control center and the control center can send control information to the autonomous vehicle.

Owner:FLORIDA INTERNATIONAL UNIVERSITY

Remote control and concierge service for an autonomous transit vehicle fleet

ActiveUS9964948B2Autonomous decision making processPosition/course control in two dimensionsRemote controlEngineering

Methods and systems for assisting autonomous vehicles are provided. The methods and systems can help increase safety and consumer satisfaction with autonomous vehicles and help bridge the gap towards completely autonomy. A method for assisting autonomous vehicles can include providing an autonomous vehicle having sensory inputs and providing a remote control center having two-way communication with the autonomous vehicle. The autonomous vehicle can send its sensory input information to the control center and the control center can send control information to the autonomous vehicle.

Owner:FLORIDA INTERNATIONAL UNIVERSITY

Autonomous transports for storage and retrieval systems

ActiveUS20140308098A1Vehicle position/course/altitude controlStorage devicesTransfer caseTransport engineering

An autonomous transport vehicle for transferring case units to and from predefined storage areas in an automated case unit storage system, the automated case unit storage system including an array of multilevel storage racks with picking aisles passing therebetween and at least one multilevel vertical conveyor having movable shelves, the autonomous transport vehicle including a frame configured to traverse the picking aisles and a transfer deck connecting the picking aisles to the at least one multilevel vertical conveyor for transferring case units between the predefined storage areas and the at least one multilevel vertical conveyor, and a controller connected to the frame, the controller being configured to effect movement of the autonomous transport vehicle through the picking aisles for accessing each storage area within a respective level of the array of multilevel storage racks and each shelf of the at least one multilevel vertical conveyor.

Owner:SYMBOTIC LLC

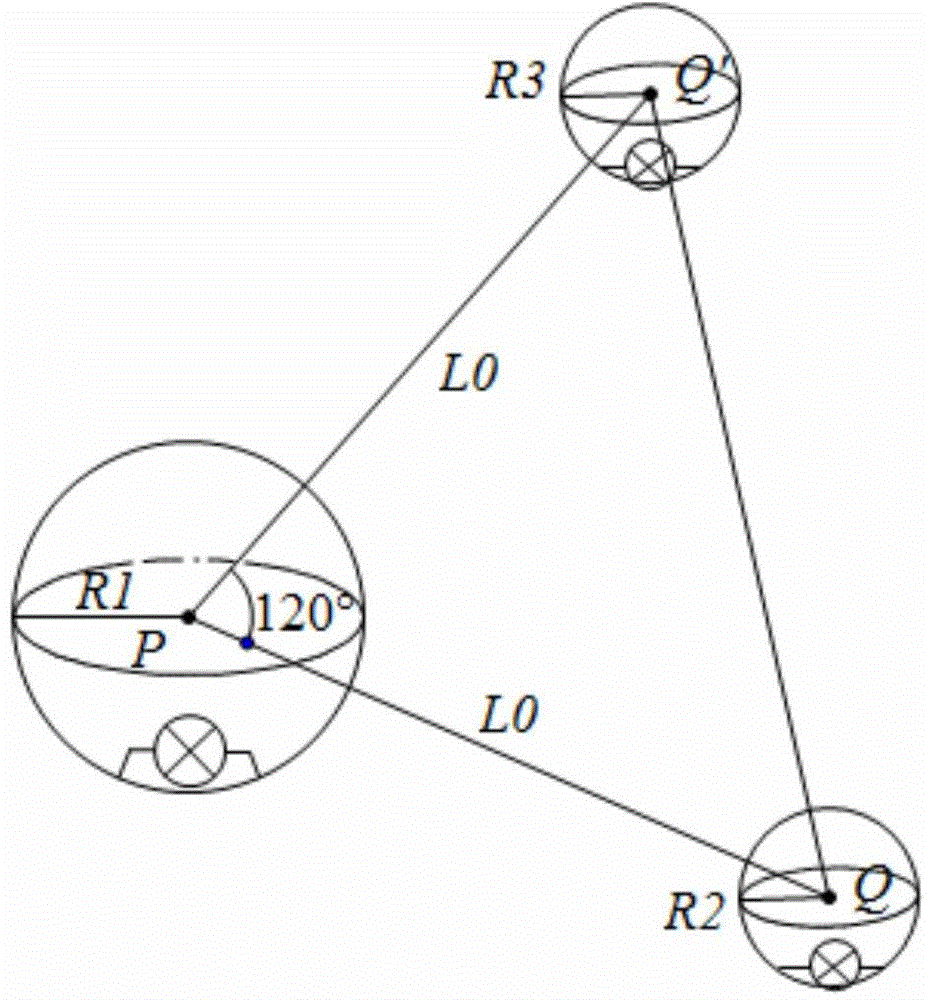

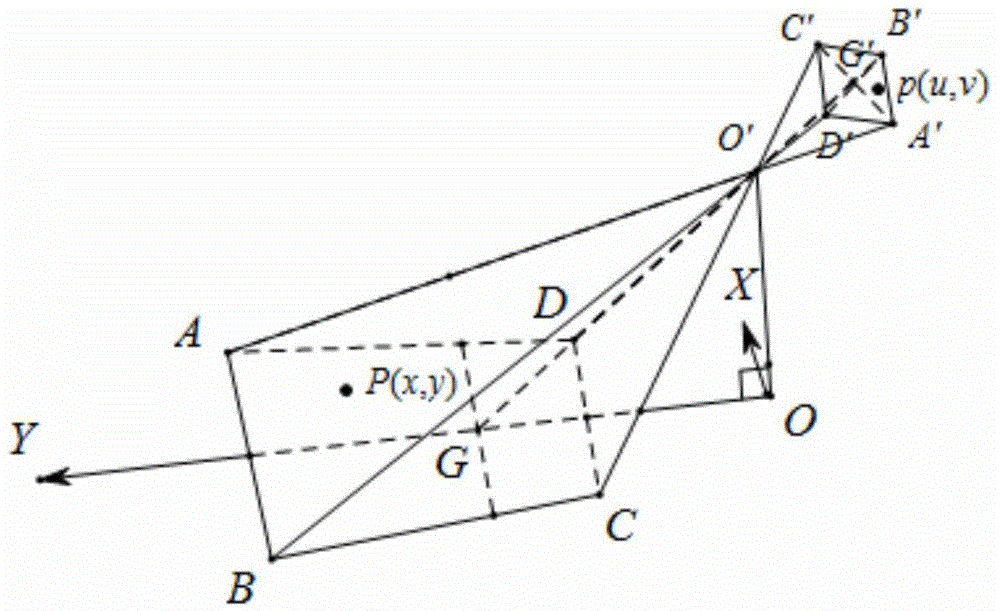

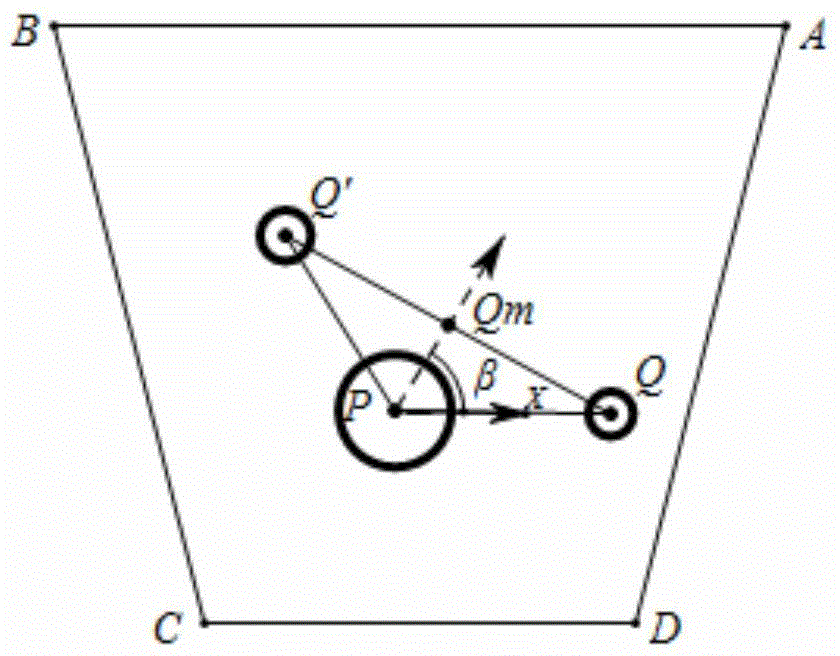

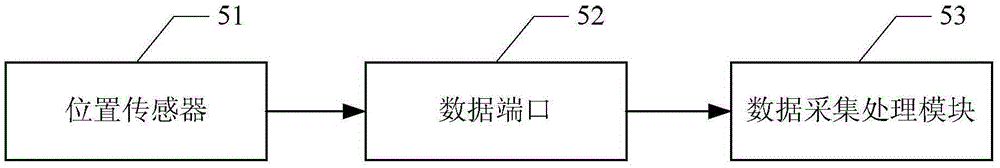

Indoor automatic transport vehicle positioning system with three fixed balls as visual marker

InactiveCN104792312AIncrease overheadStability is not affectedTransmission systemsPhotogrammetry/videogrammetryPinhole cameraLuminescence

The invention discloses an indoor automatic transport vehicle positioning system with three fixed balls as a visual marker. The system is characterized in that three luminescence balls with specific size proportions and specific positions are combined as a marker, and are fixed on an automatic transport vehicle; a pinhole camera is fixed on an indoor ceiling, and downward shoots the marker; and an embedded system connected to the camera is used to carry out marker extraction and analysis of every frame of images in order to complete detection of the pose of the automatic transport vehicle, and communication and control of the automatic transport vehicle are completed through a wireless module according to the above positioning result. The positioning system has the advantages of simple calculation, simultaneous realization of position, direction and inclination angle positioning, good stability, high precision, and completion of positioning in complex environment.

Owner:GUANGDONG UNIV OF TECH +2

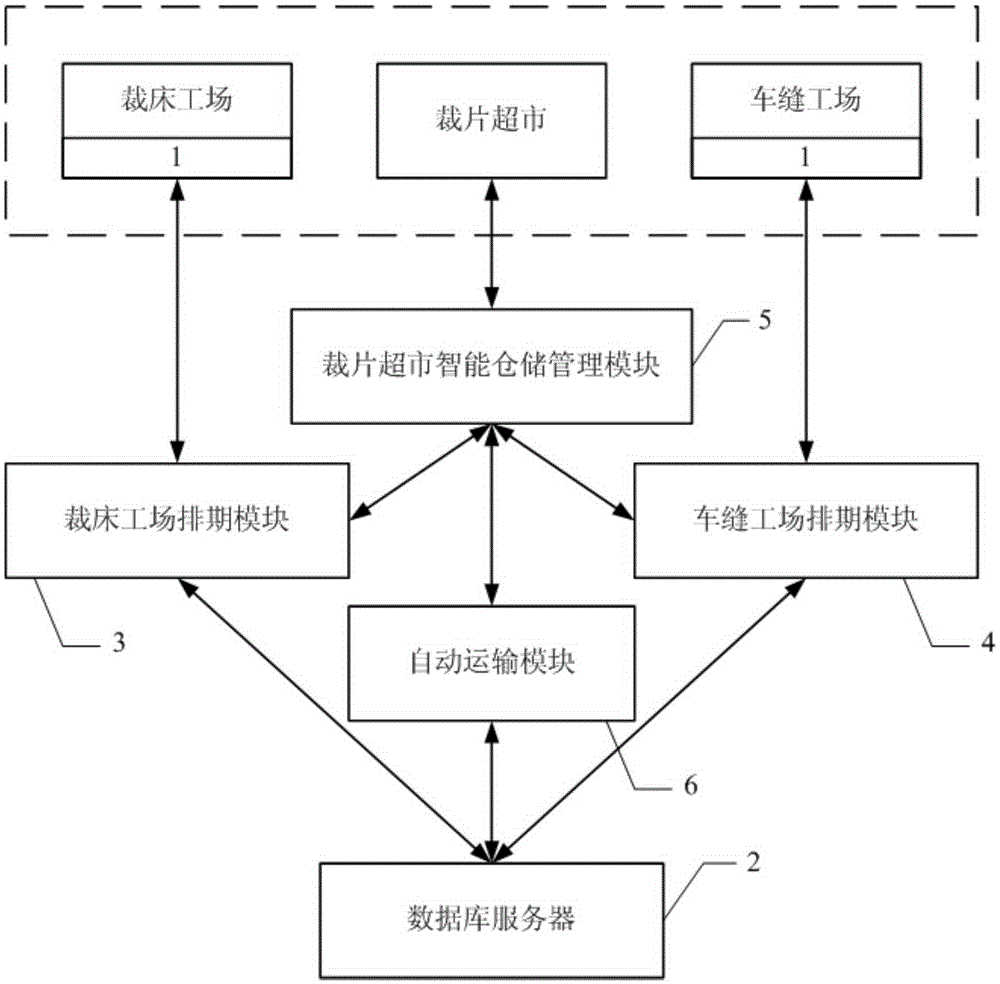

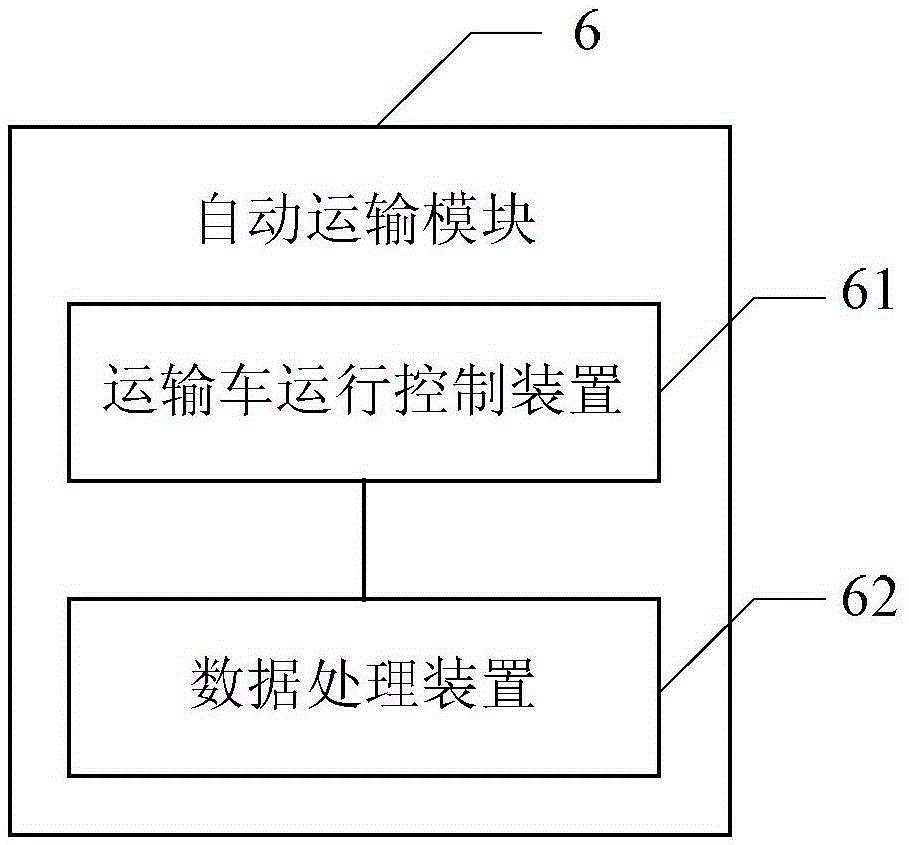

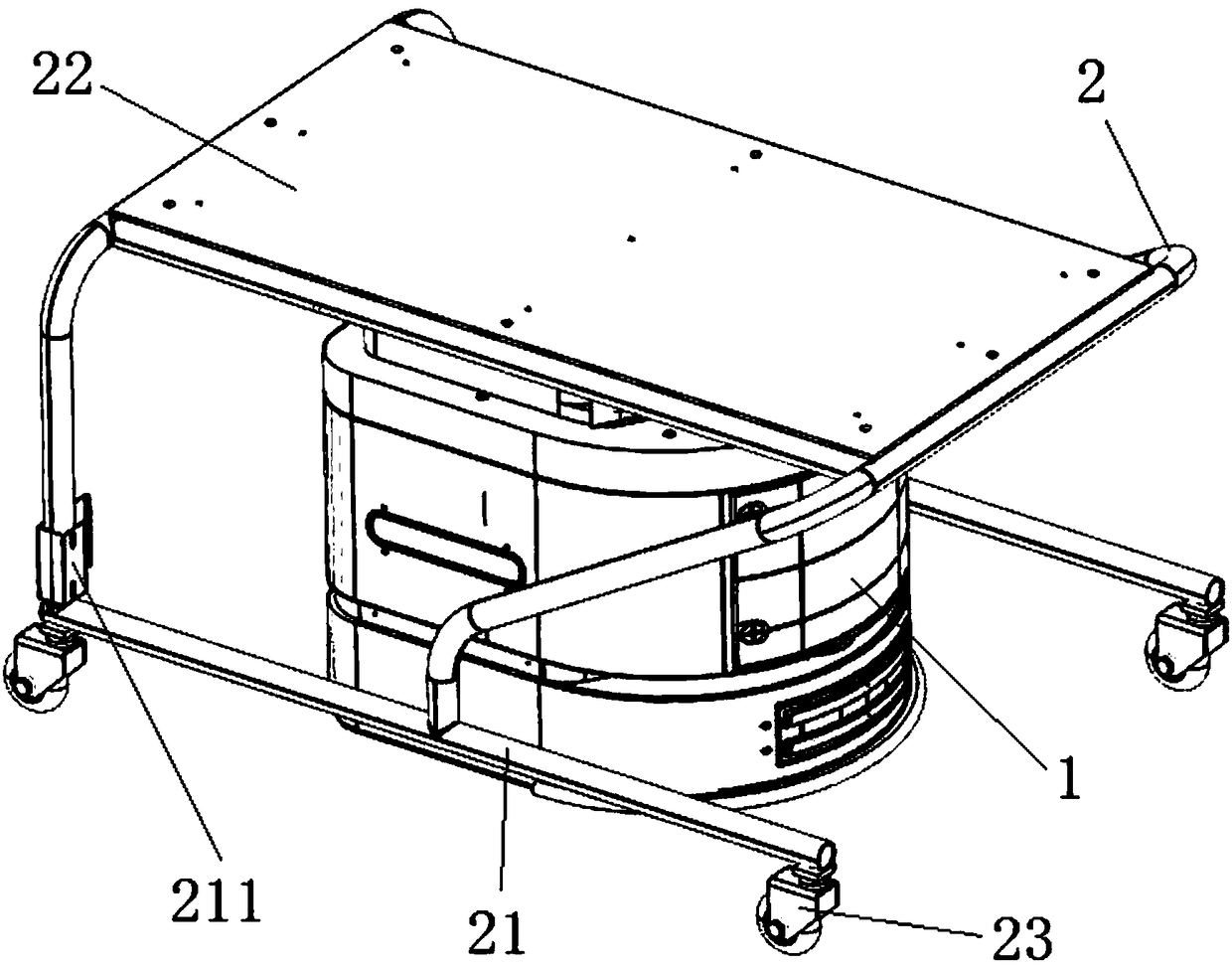

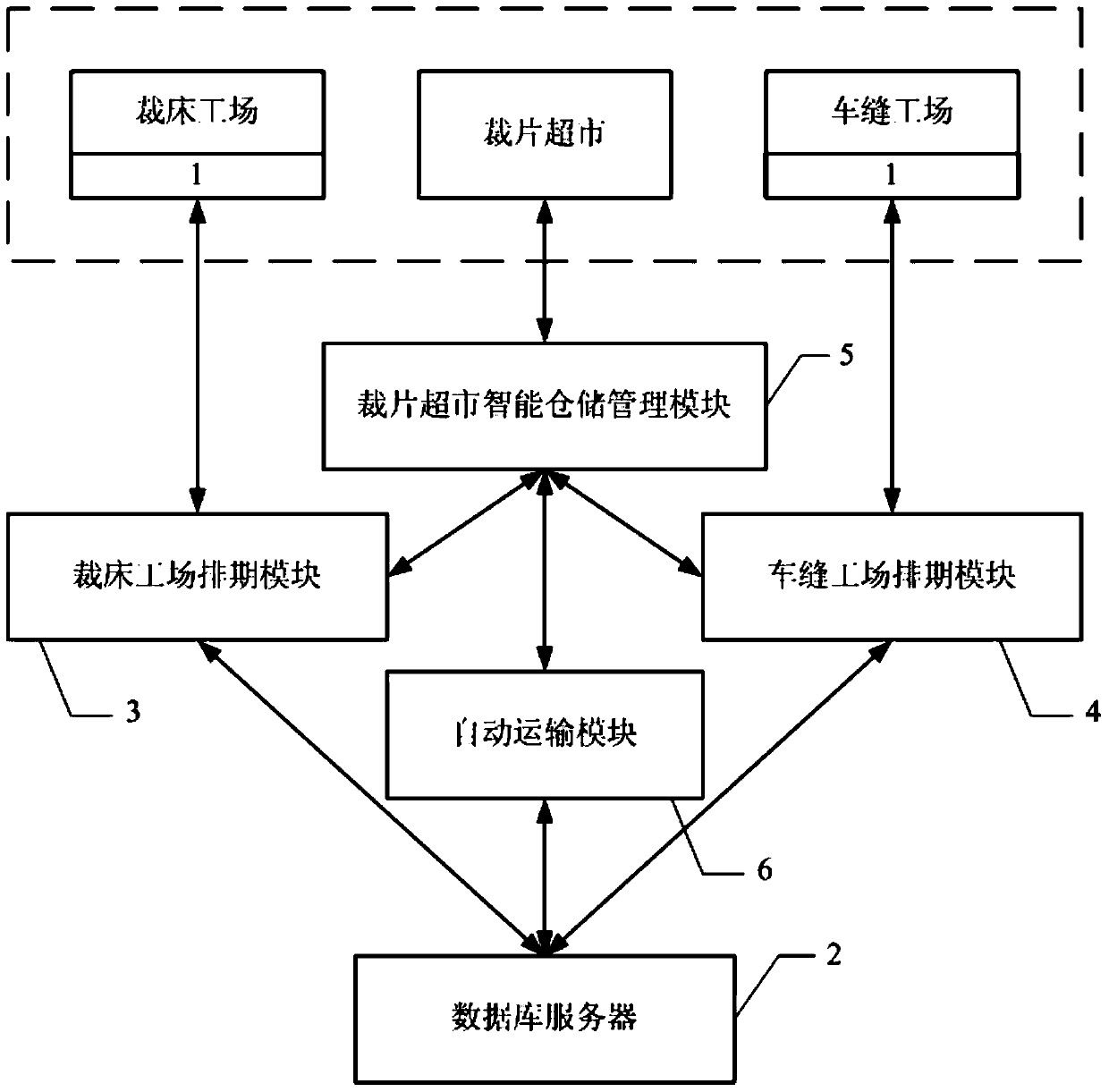

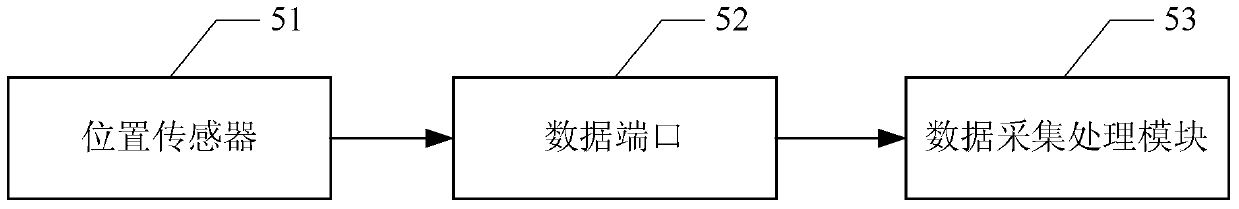

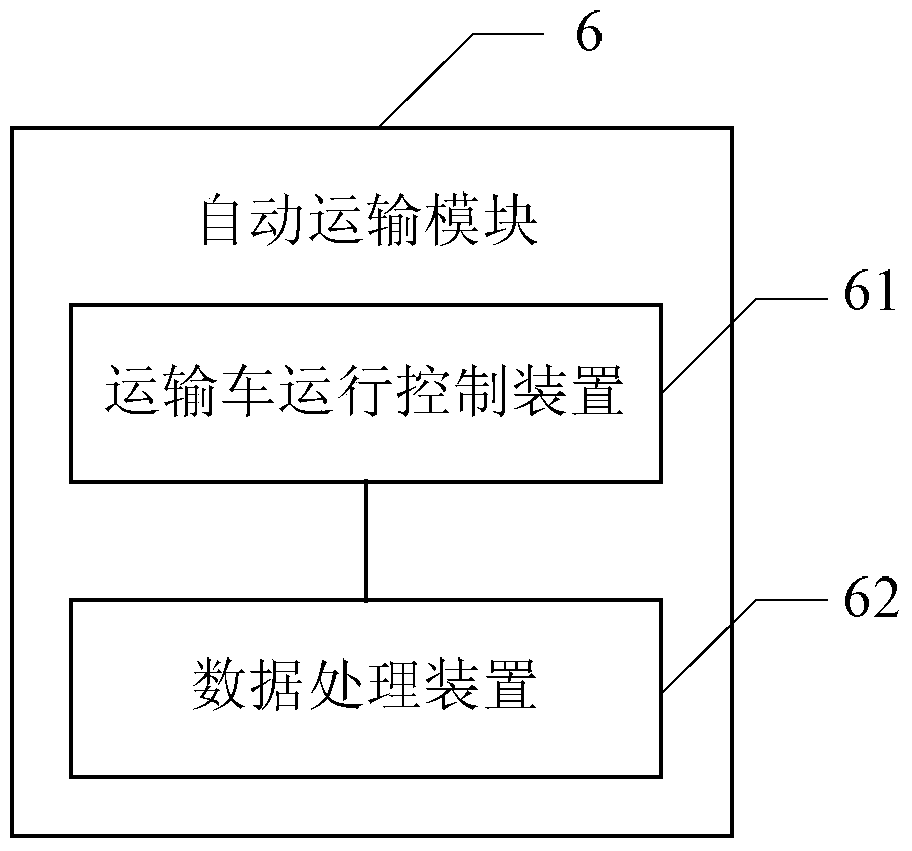

Intelligent and automatic carrying distribution system and method for garment factory lean production

ActiveCN105354667AImprove management levelReduce labor costsResourcesLogisticsDistribution methodDatabase server

The invention provides an intelligent and automatic carrying distribution system and an intelligent and automatic carrying distribution method for garment factory lean production. The system comprises a cutting bed workshop scheduling module which is used for performing production scheduling on the amount of cut pieces in a cutting bed workshop and generating cut piece scheduling information; a stitching workshop scheduling module which is used for generating cut piece demand information according to the cut piece demand situation in a stitching workshop; an RFID wireless data acquisition device which is used for acquiring cutting bed site data of the cutting bed workshop and stitching site data of the stitching workshop in real time; a cut piece supermarket intelligent storage management module which is used for acquiring cut piece site data in a cut piece supermarket, calculating reserved shelf-position information in the cutting bed workshop and calculating the shelf-position location information and shortest path information of the stitching workshop; an automatic conveying module which is used for controlling an automatic conveying vehicle to convey cut pieces in the cut piece supermarket to the stitching workshop and conveying the cut pieces to the cut piece supermarket to the cutting bed workshop; and a database server which is used for receiving and storing the stitching site data, the cutting bed site data and the cut piece site data.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Intelligent tracking conveying management system for warehouses

InactiveCN103760903AEasy to distinguishReduce labor costsPosition/course control in two dimensionsTransportation management systemEngineering

The invention discloses an intelligent tracking conveying management system for warehouses. The intelligent tracking conveying management system for the warehouses comprises the multiple warehouses and a conveying vehicle, wherein the conveying vehicle is an automatic conveying vehicle controlled by a system, black track lines are arranged among the warehouses and are laid according to the route design of the conveying vehicle, a grey level sensor is installed at the bottom of the conveying vehicle, and an automatic collecting and distinguishing system connected with the grey level sensor is installed inside the conveying vehicle. The automatic collecting and distinguishing system automatically adjusts the direction of the conveying vehicle according to color information received by the grey level sensor, enables the conveying vehicle to be always located on the black track lines, and can work continuously without people. Manpower cost is saved, and the problems like fatigue driving are avoided.

Owner:KUNSHAN XIN SHENG UNION TECH

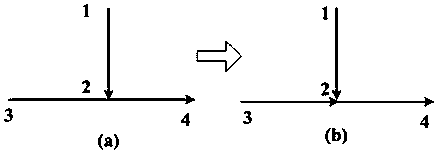

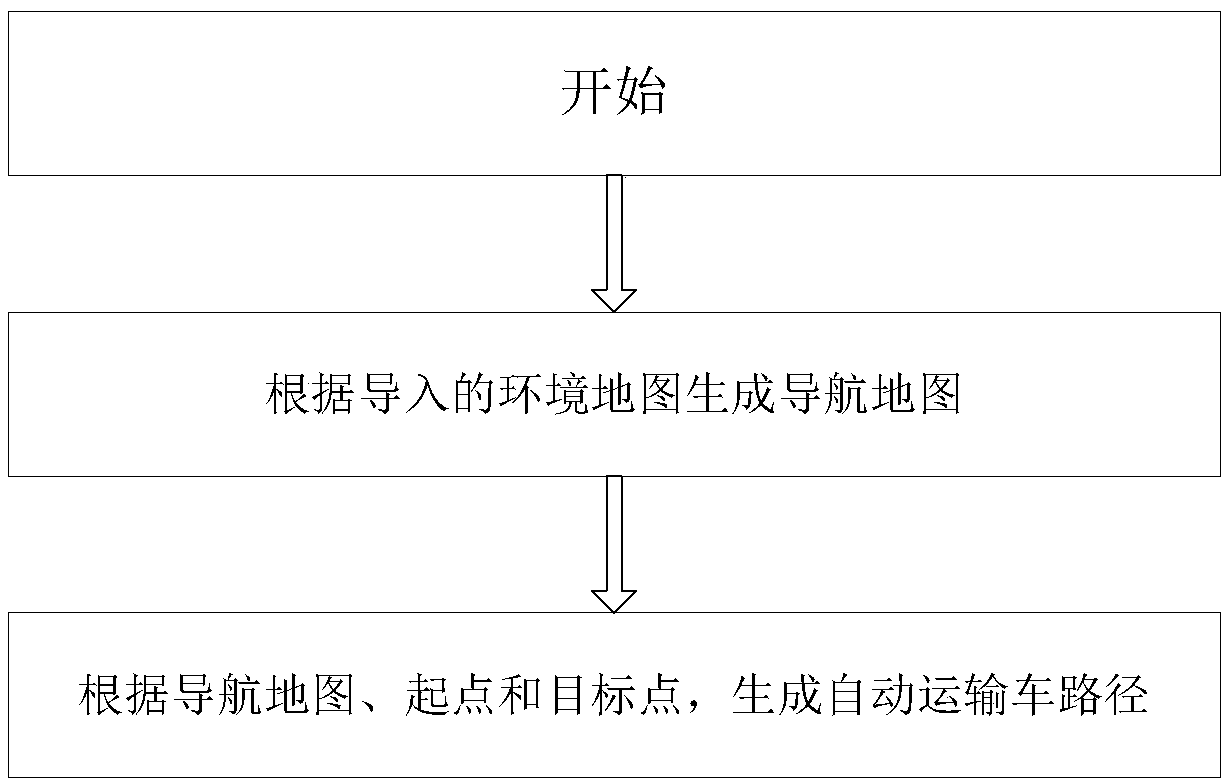

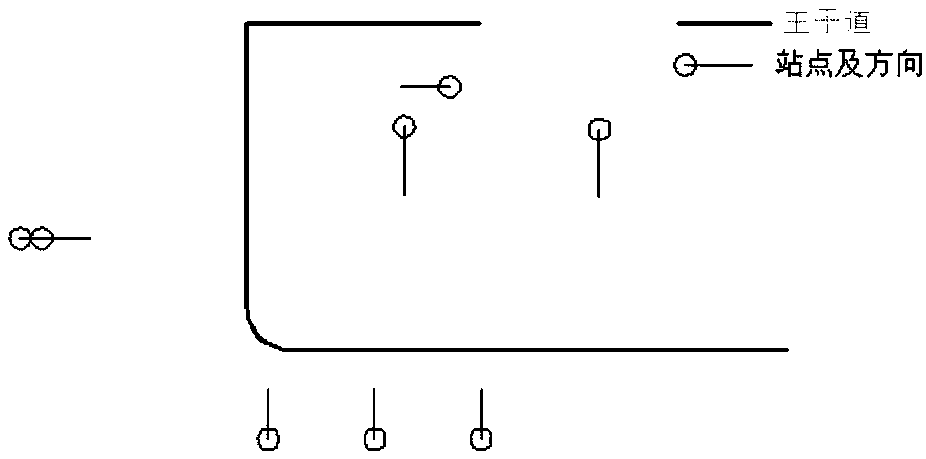

Method for generating path of laser-guided automatic transport vehicle

InactiveCN109612483AFull and comprehensive informationMeet the requirements of real-time position correctionInstruments for road network navigationMarine navigationAutotransporters

The invention discloses a method for generating a path of a laser-guided automatic transport vehicle. The method comprises the following steps: 1) generating a navigation map according to an importedenvironment map; and 2) generating a path of the automatic transport vehicle according to the navigation map, a starting point and a target point. According to the method for generating the path of the laser-guided automatic transport vehicle, sufficient and comprehensive information is provided for the position adjustment of the AGV(Automatic Guided Vehicle), and the requirement of real-time position correction can be met.

Owner:SEIZET TECH SHEN ZHEN CO LTD

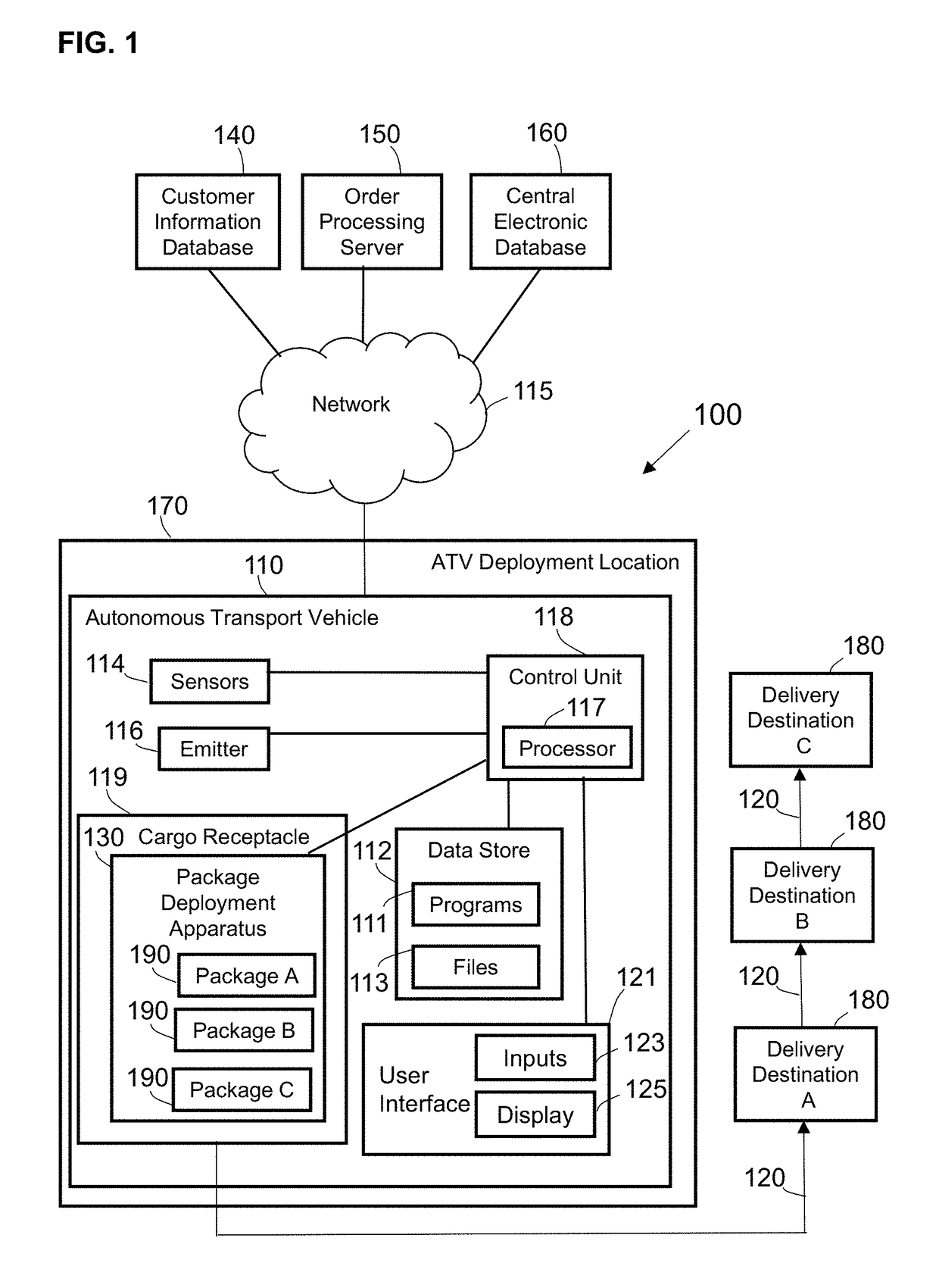

Systems and methods for delivering products to multiple delivery destinations via autonomous transport vehicles

In some embodiments, methods and systems are provided that provided for delivering products ordered by a customer of a retailer to a delivery destination designated by the ordering customer by way of autonomous transport vehicles configured to identify products to be dropped off at their next delivery destinations and to prepare such products for deployment while the ATVs are still en-route to their next delivery destinations, and to automatically deploy such products upon arrival at such delivery destinations.

Owner:WALMART APOLLO LLC

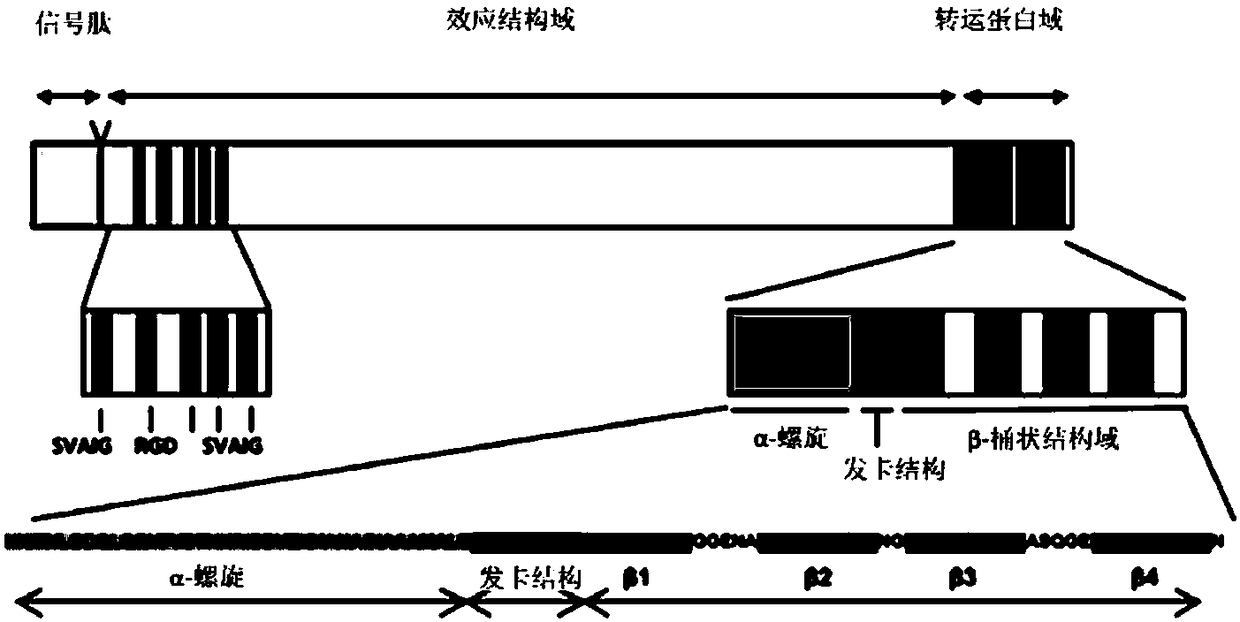

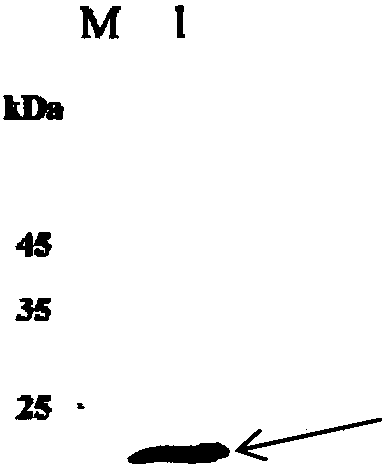

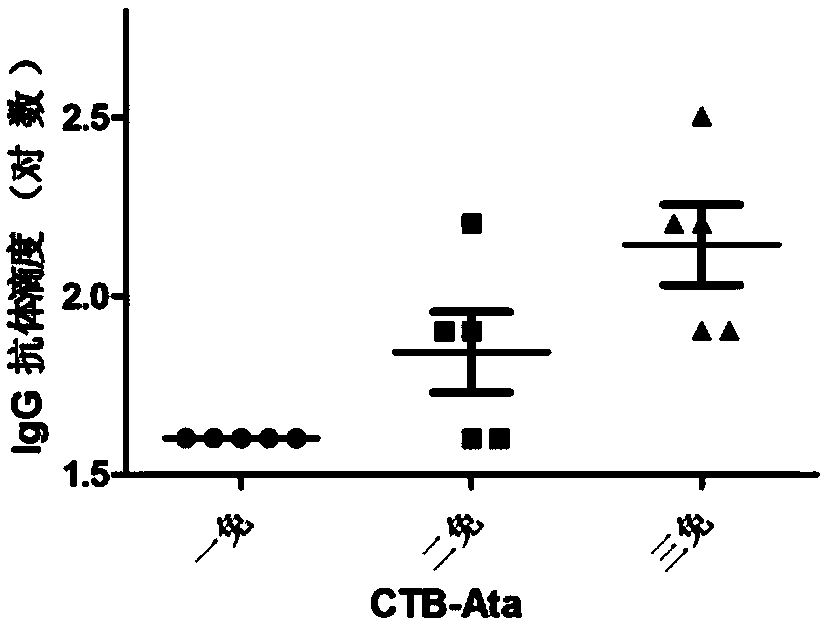

Ab (Acinetobacter baumannii) Ata (acinetobacter trimeric autotransporter) protein immunogenicity

ActiveCN108503698AInfection effect is goodAntibacterial agentsDepsipeptidesSepharoseAcinetobacter baumannii

The invention discloses Ab Ata protein immunogenicity and provides a protein which comprises Ab Ata protein N-terminal alpha-spiral part 39 amino acids and an adjuvant protein; the amino acid sequences of the Ab Ata protein N-terminal alpha-spiral part 39 amino acids are 127th-165th sites of the sequence 2 respectively. According to the Ab Ata, the N-terminal alpha-spiral part 39 amino acids are cut out, fused with CTB and expressed in BL21. Through ni-sepharose purification, peritoneal immunity is performed at 40 mu g / mice, the immunogenicity and the immune protective of the Ab Ata protein are verified through animal experiments, and the Ab Ata protein has excellent Ab infection resistance.

Owner:ACADEMY OF MILITARY MEDICAL SCI

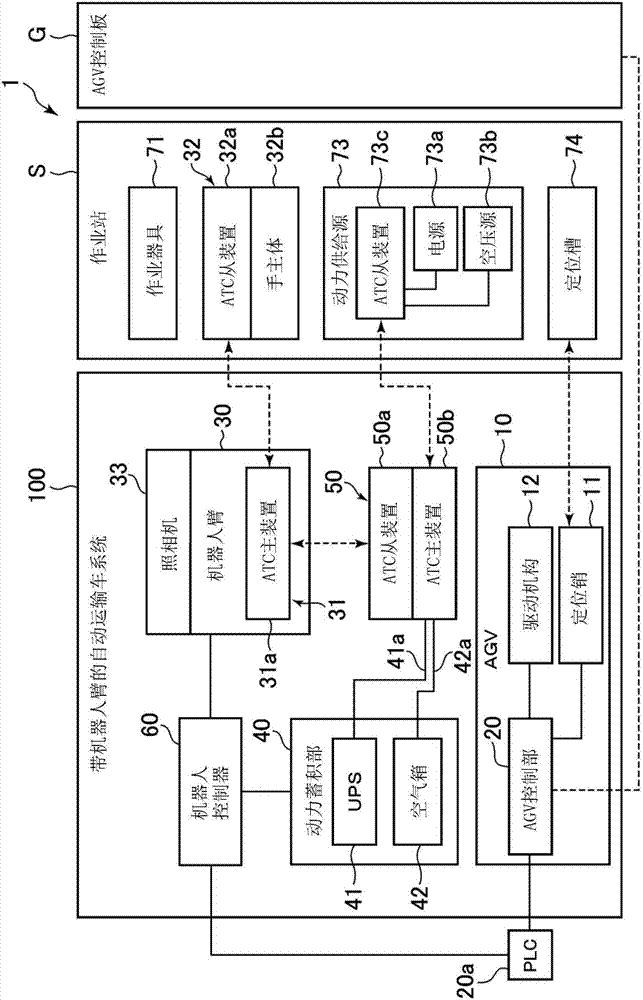

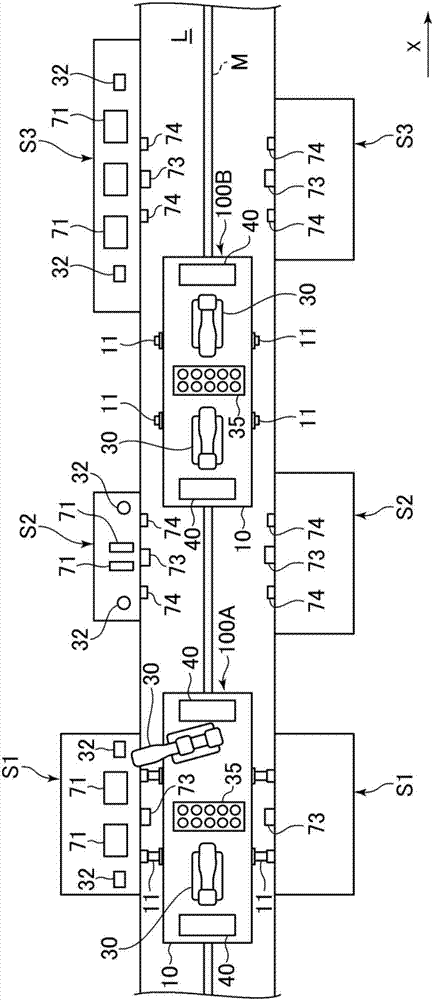

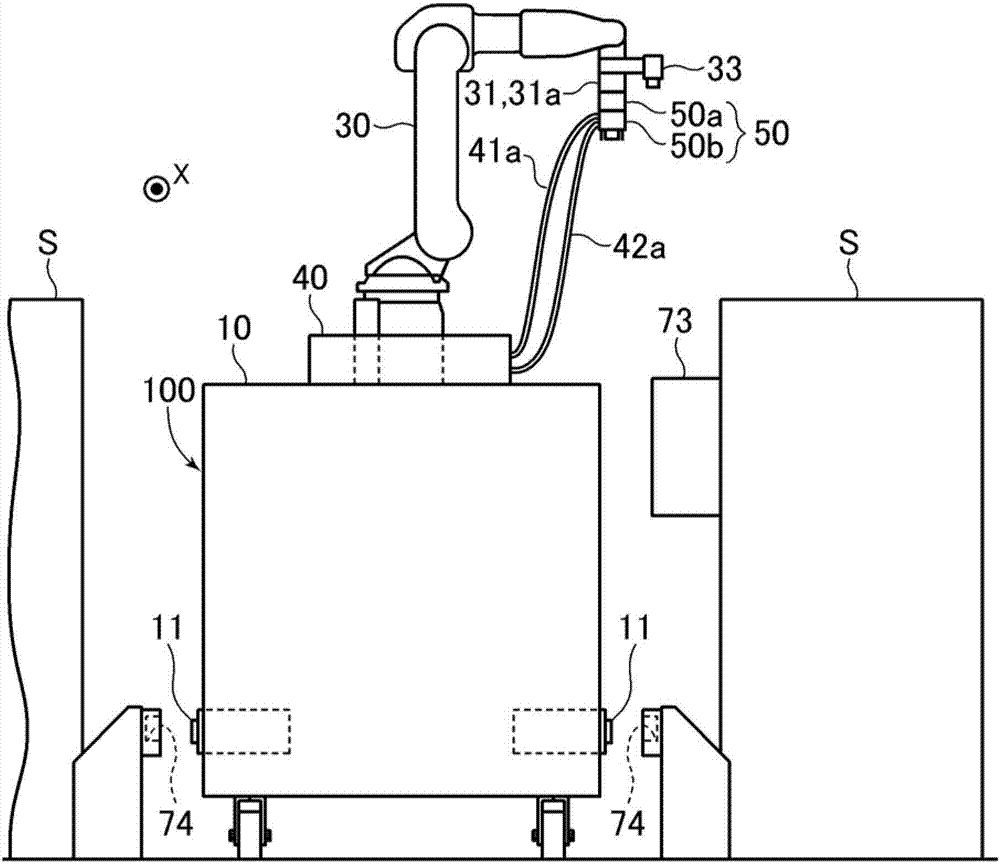

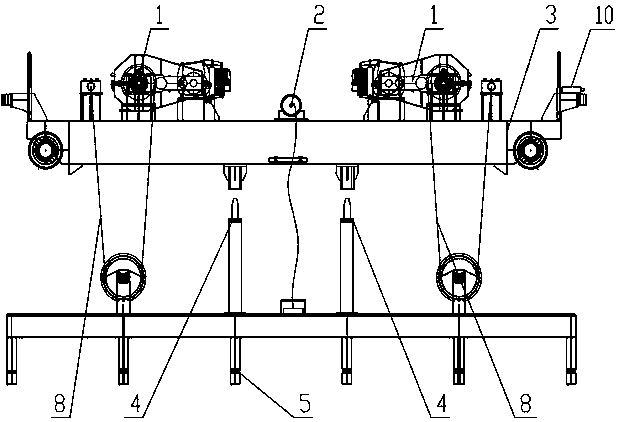

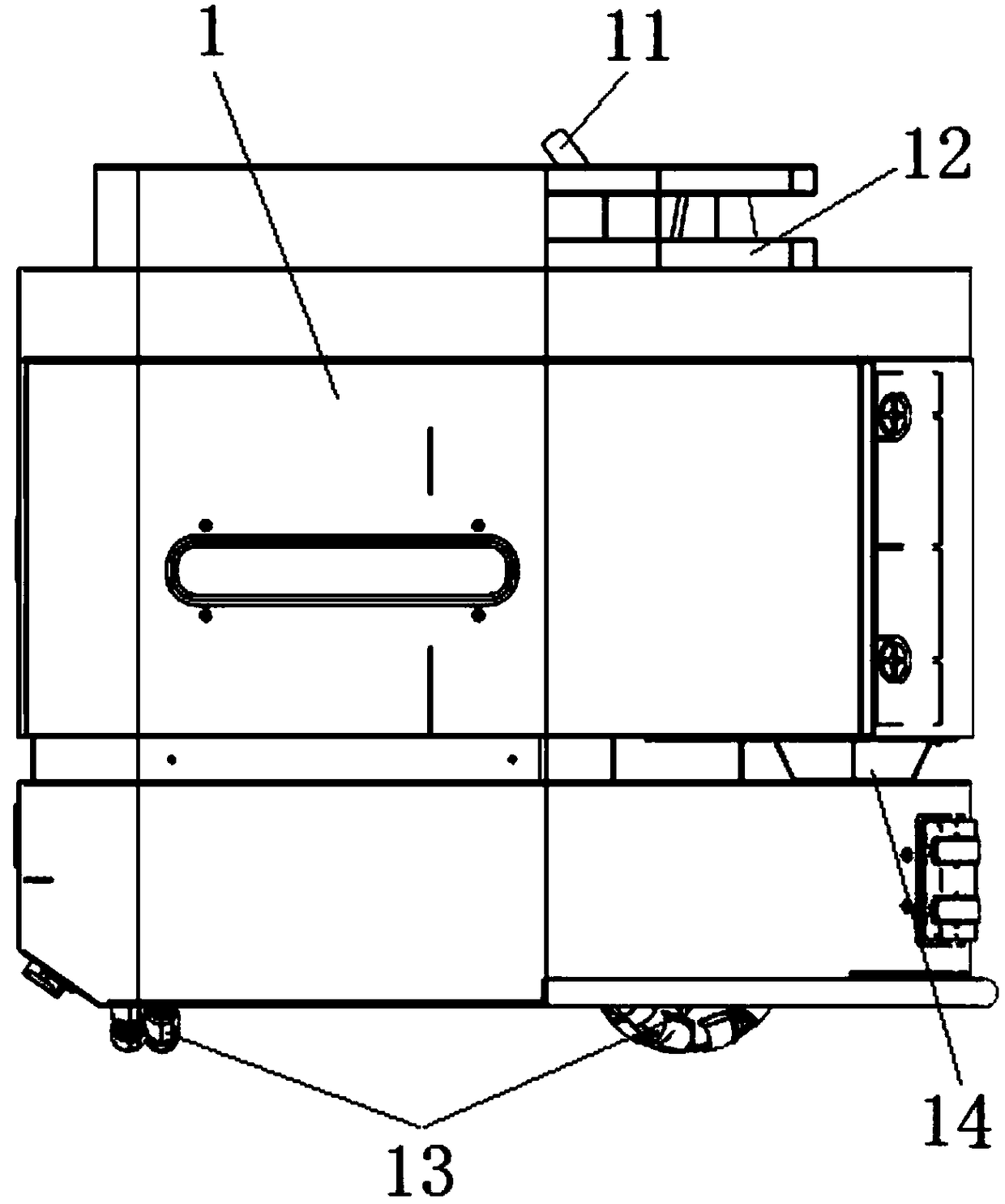

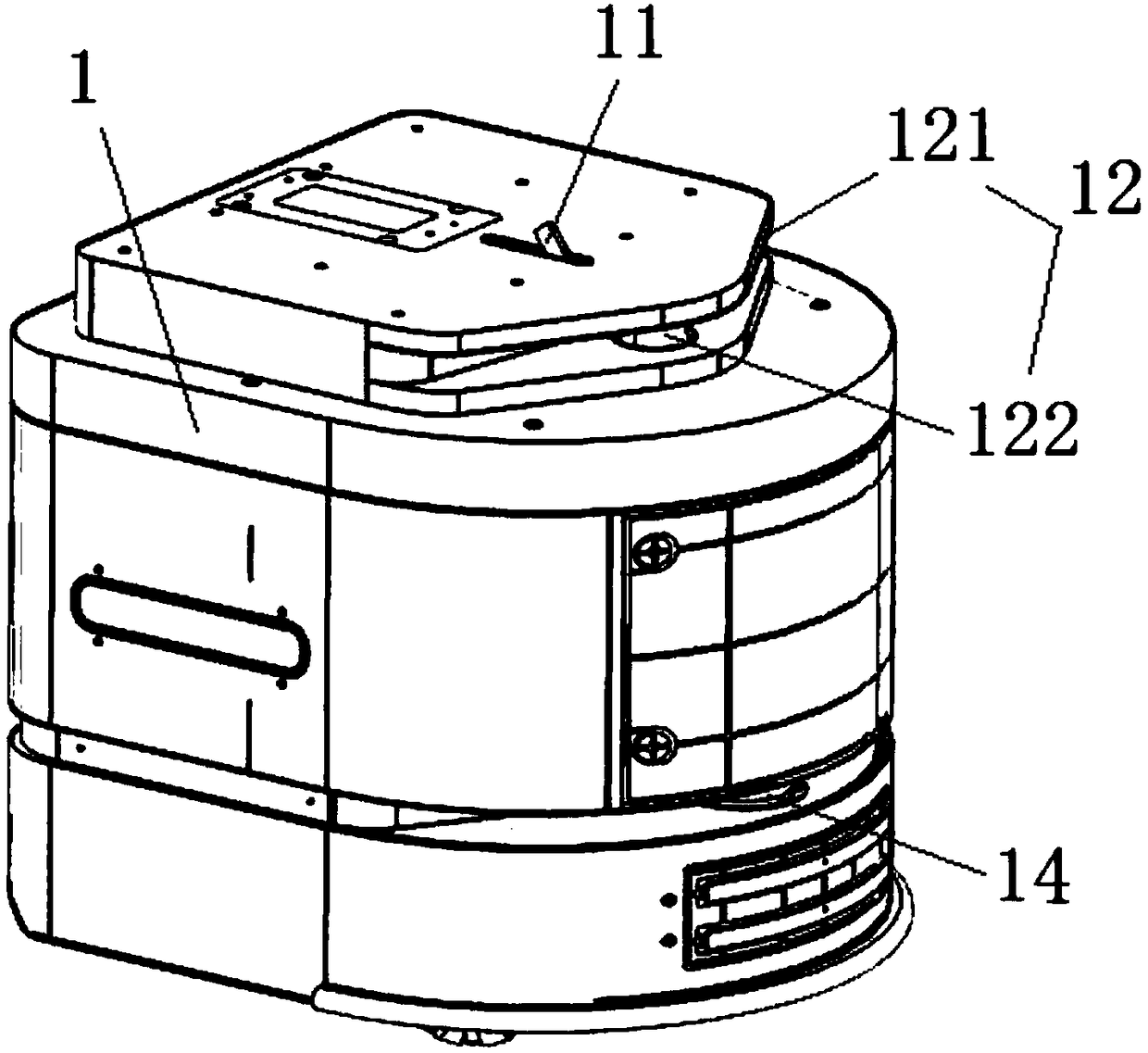

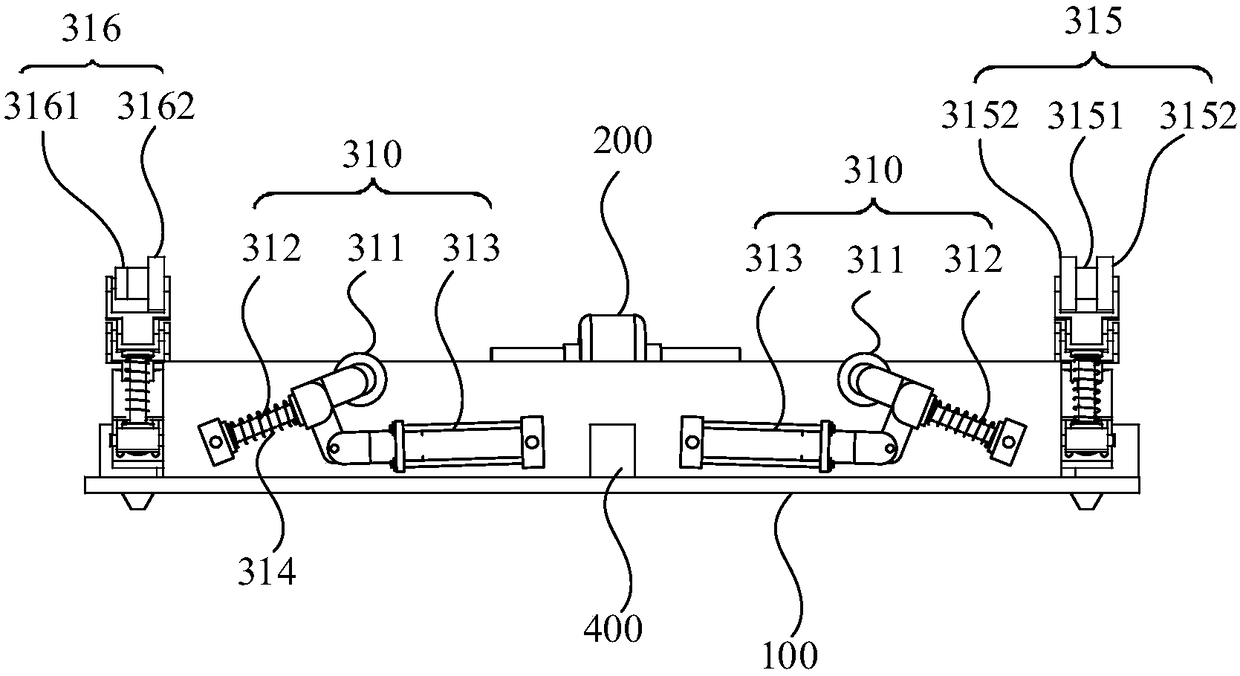

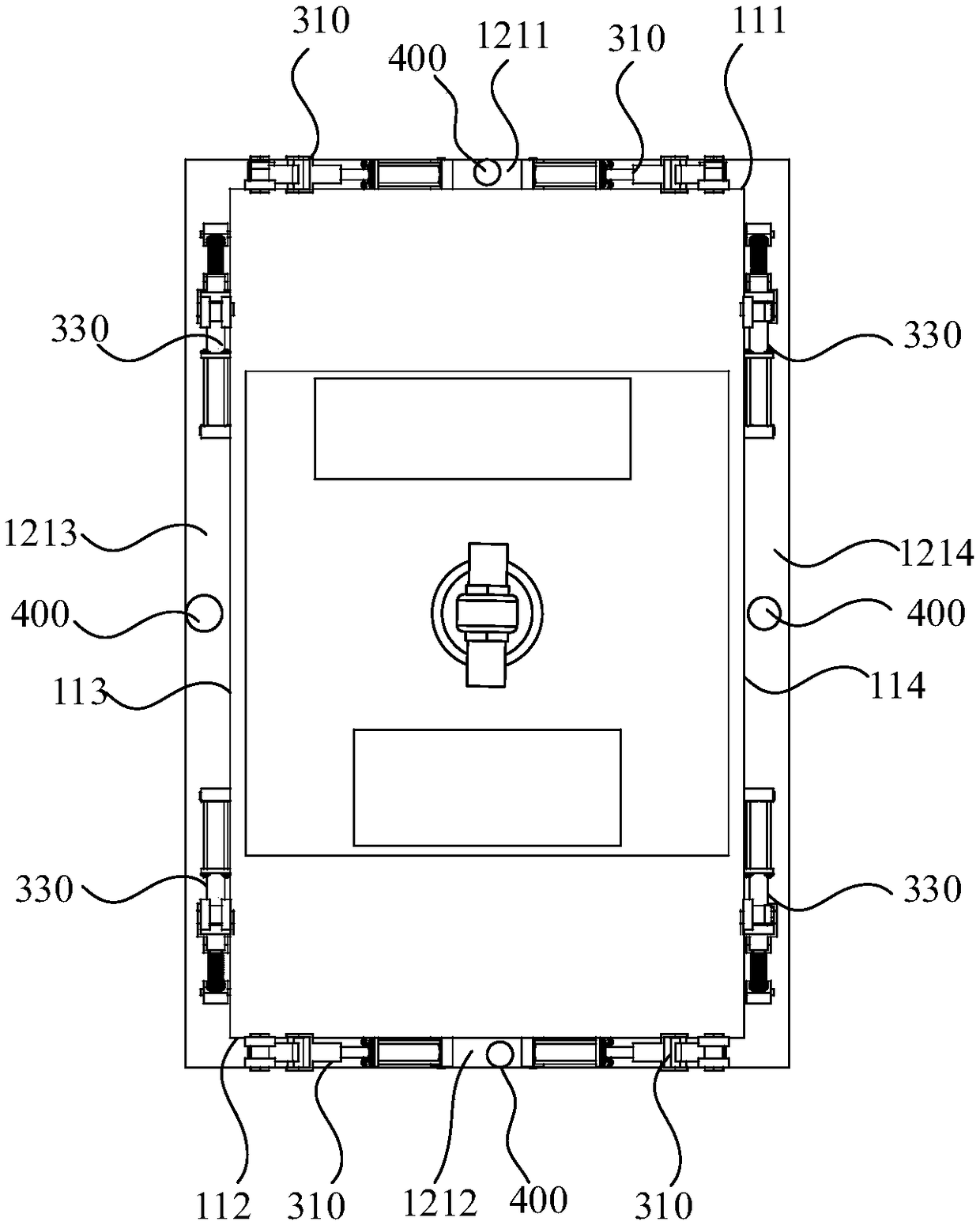

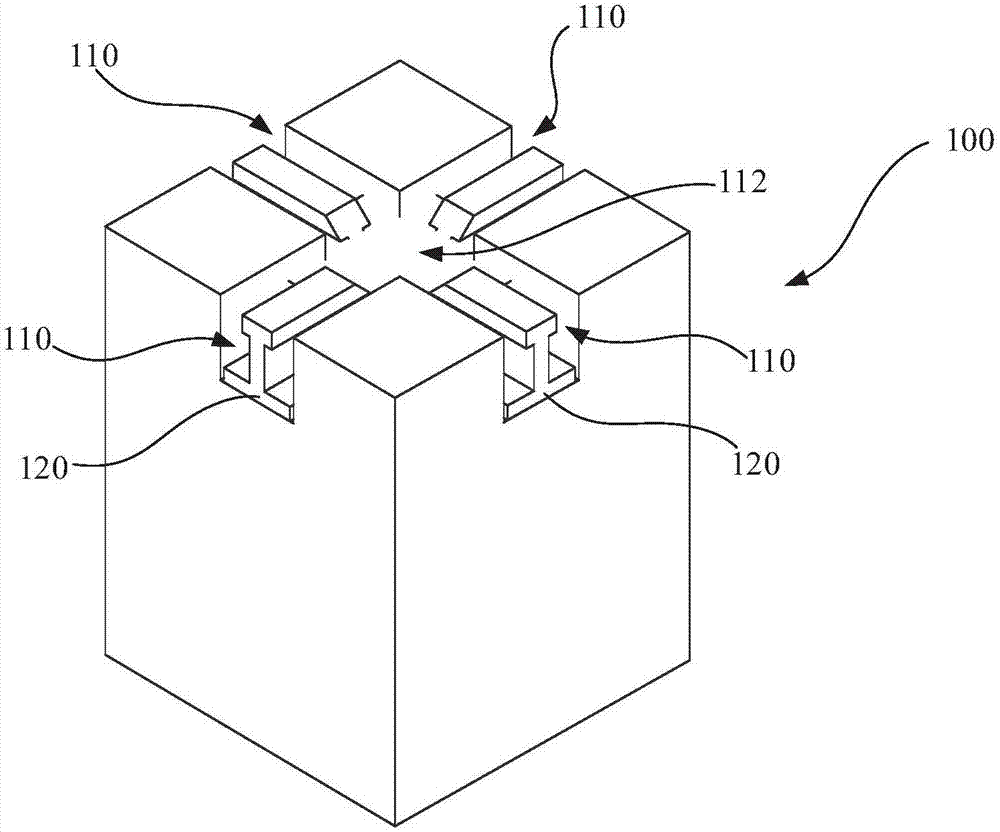

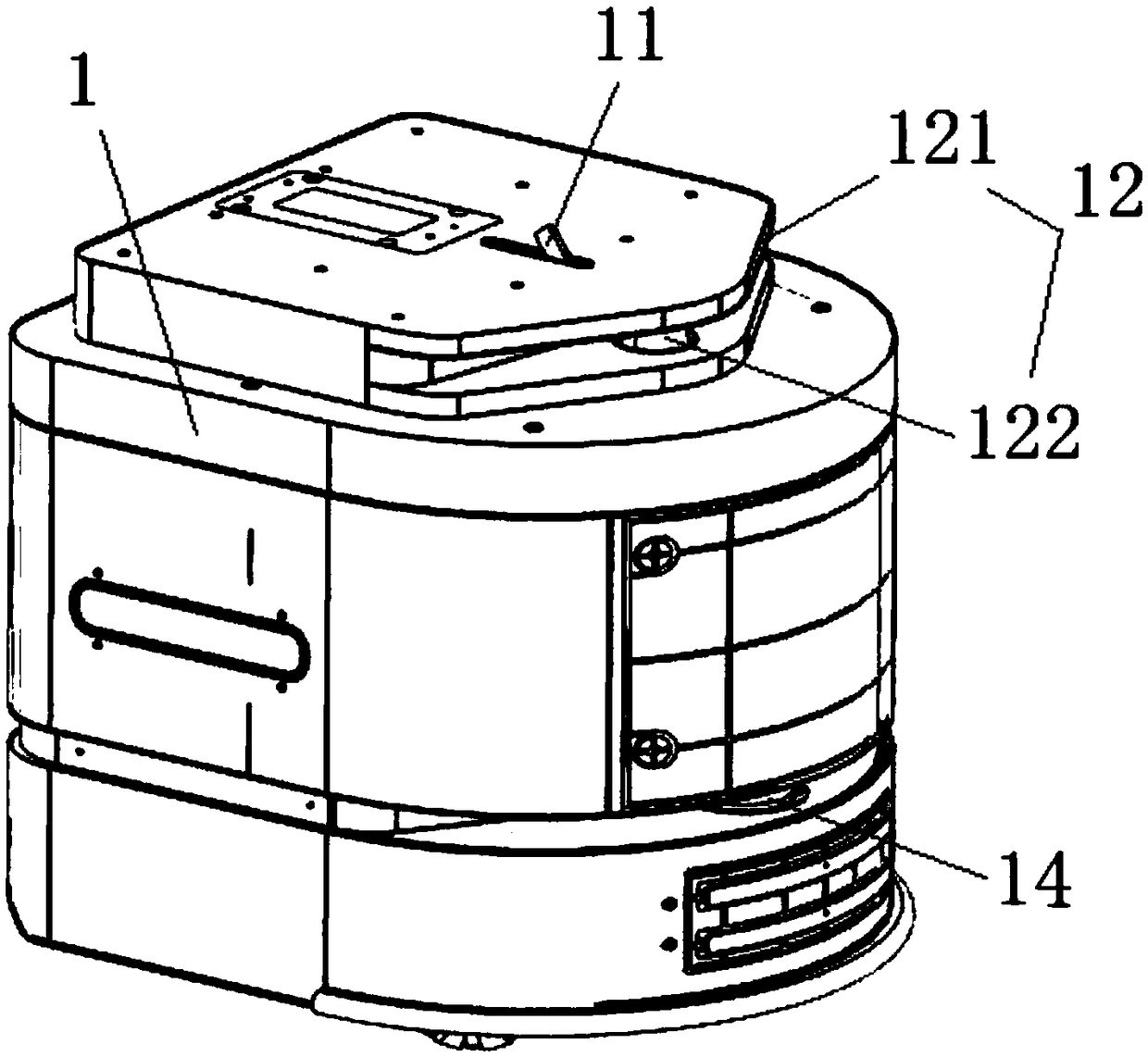

Automatic transport vehicle system with robotic arm and control method thereof, and robot system

The invention provides an automatic transport vehicle system with a robotic arm and a control method thereof, and a robot system. While receiving the power supply in an automatic transport vehicle system (100) with a robotic arm, a general connection mechanism can be used and various power can be used, and the degree of freedom in designing the installation position of the connection mechanism is increased. The automatic transport vehicle system (100) with the robotic arm comprises: an AGV (10); the robotic arm (30) carried on the AGV (10); an ATC connection part (50) held by the robotic arm (30) and moving by means of the robotic arm (30) and connected or disconnected with a power supply source (73); and a power accumulating part (40) which accumulates power supplied by the ATC connection part (50) and at least supplies power to the robotic arm (30).

Owner:YASKAWA DENKI KK

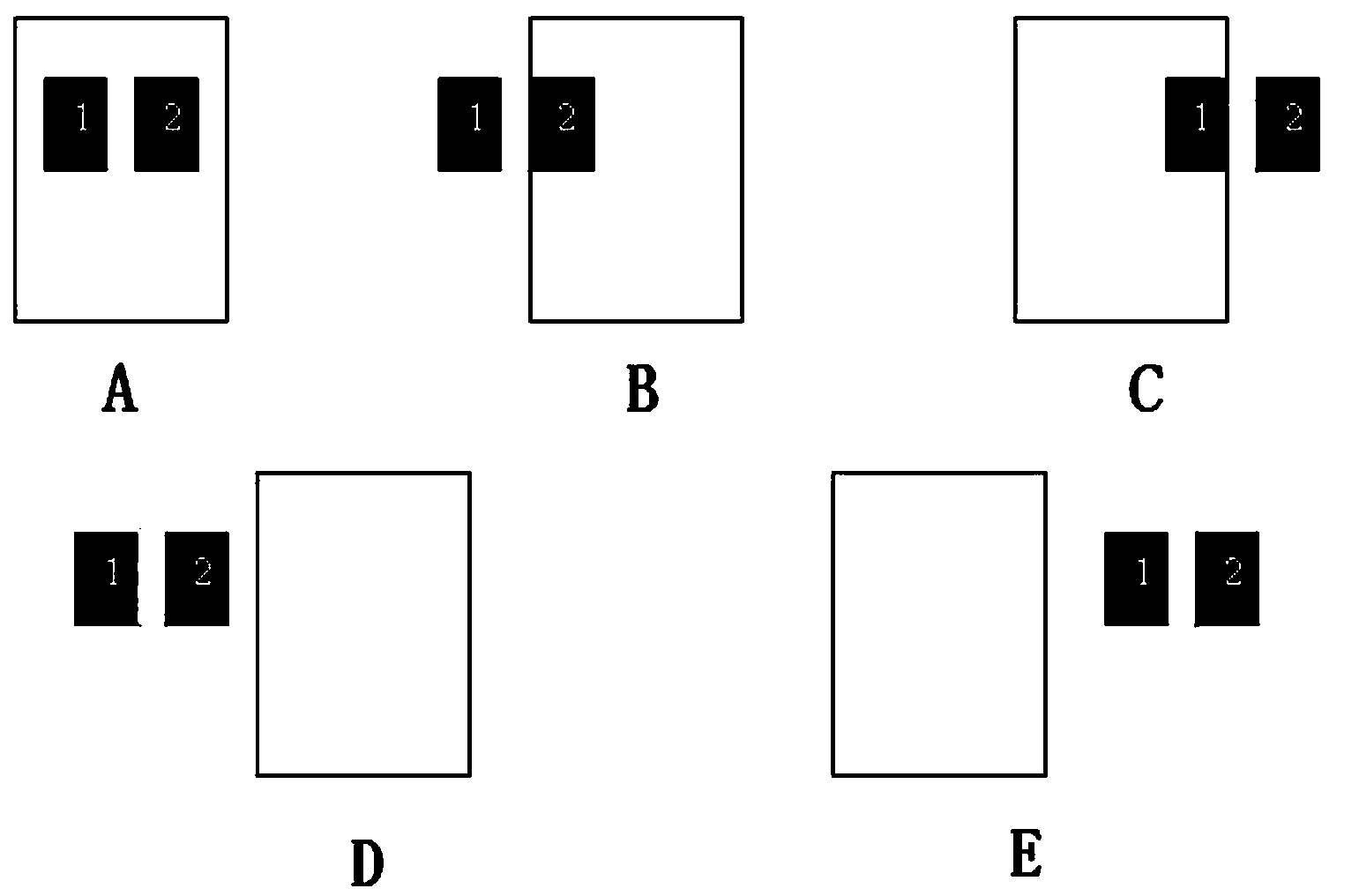

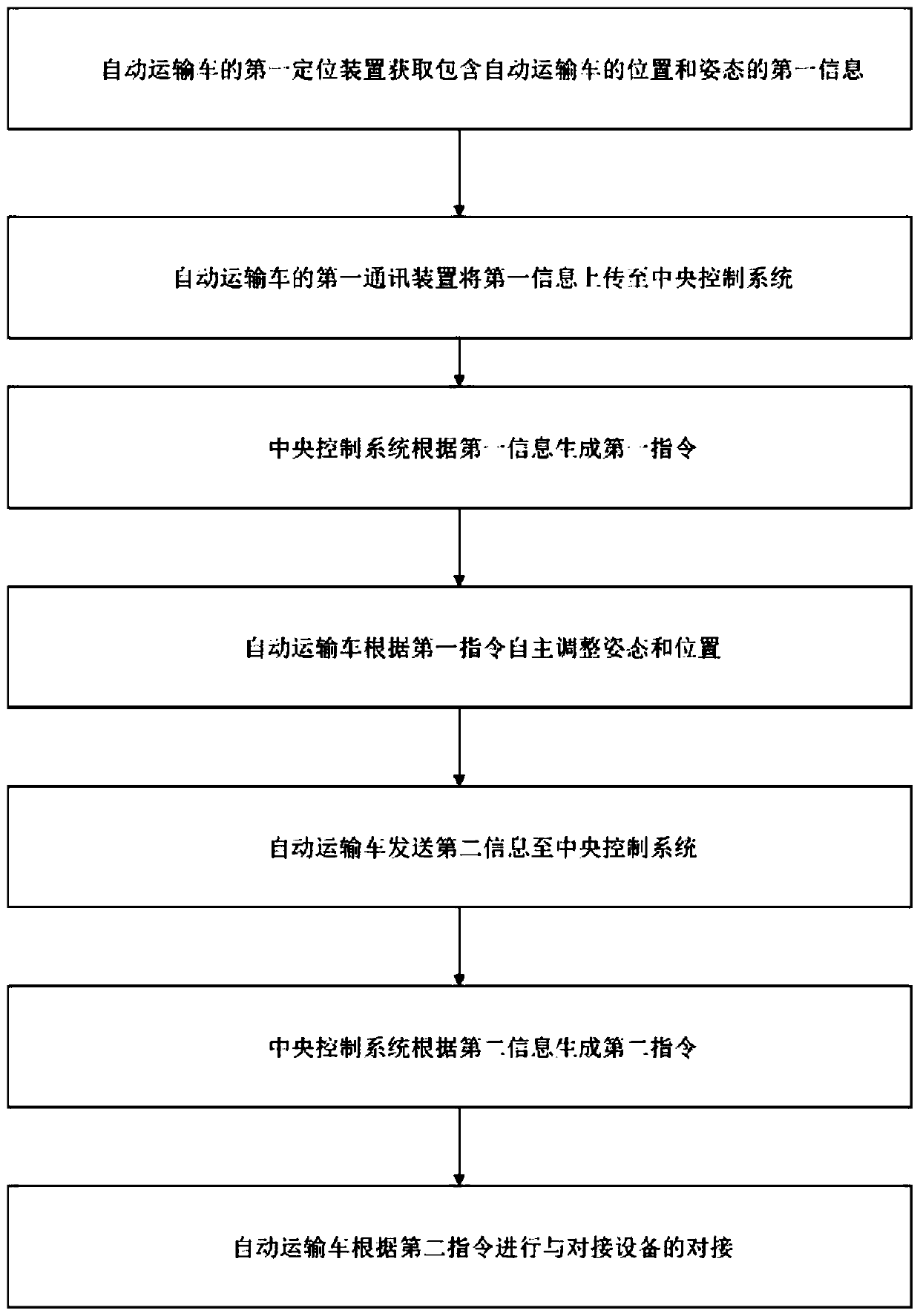

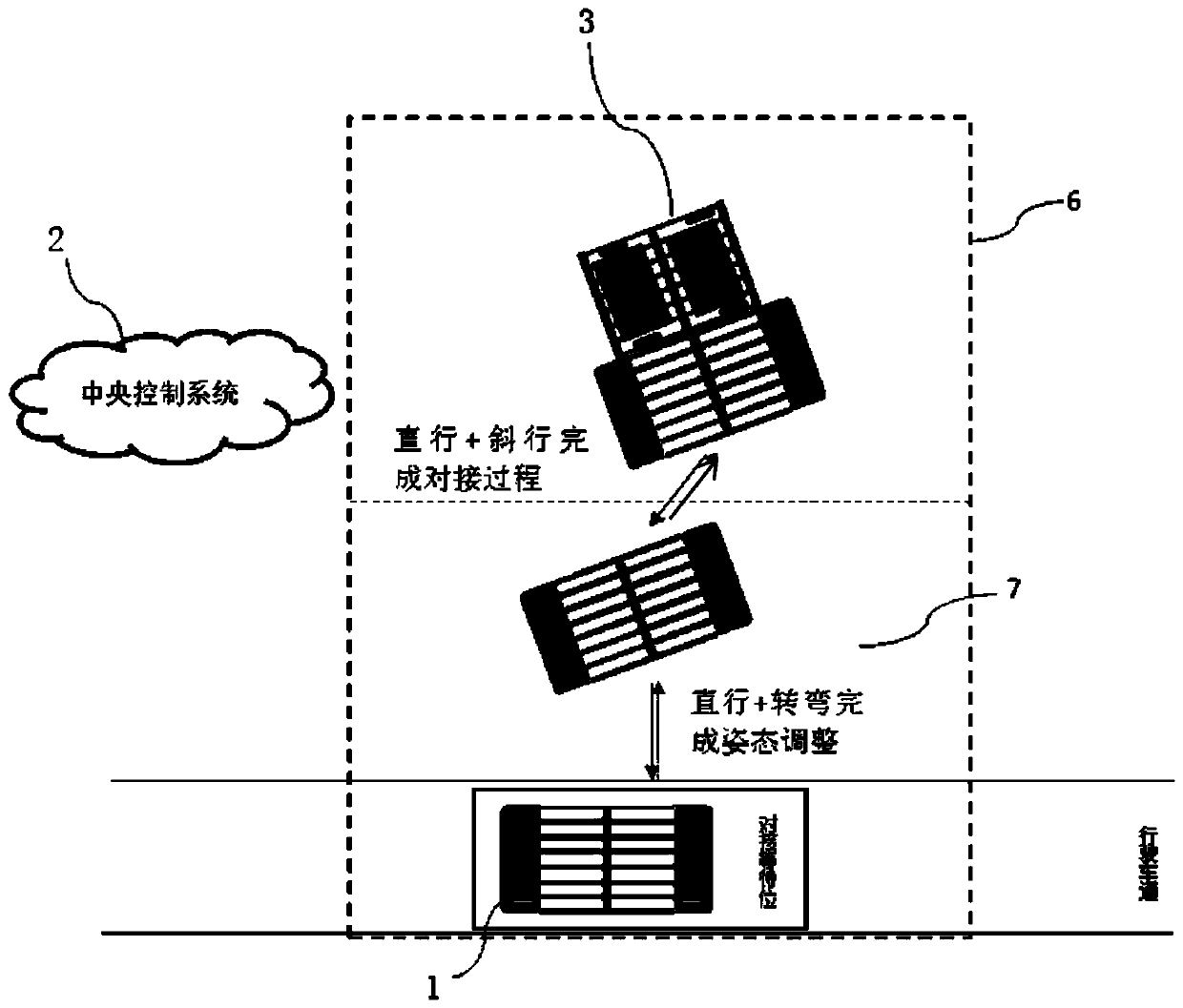

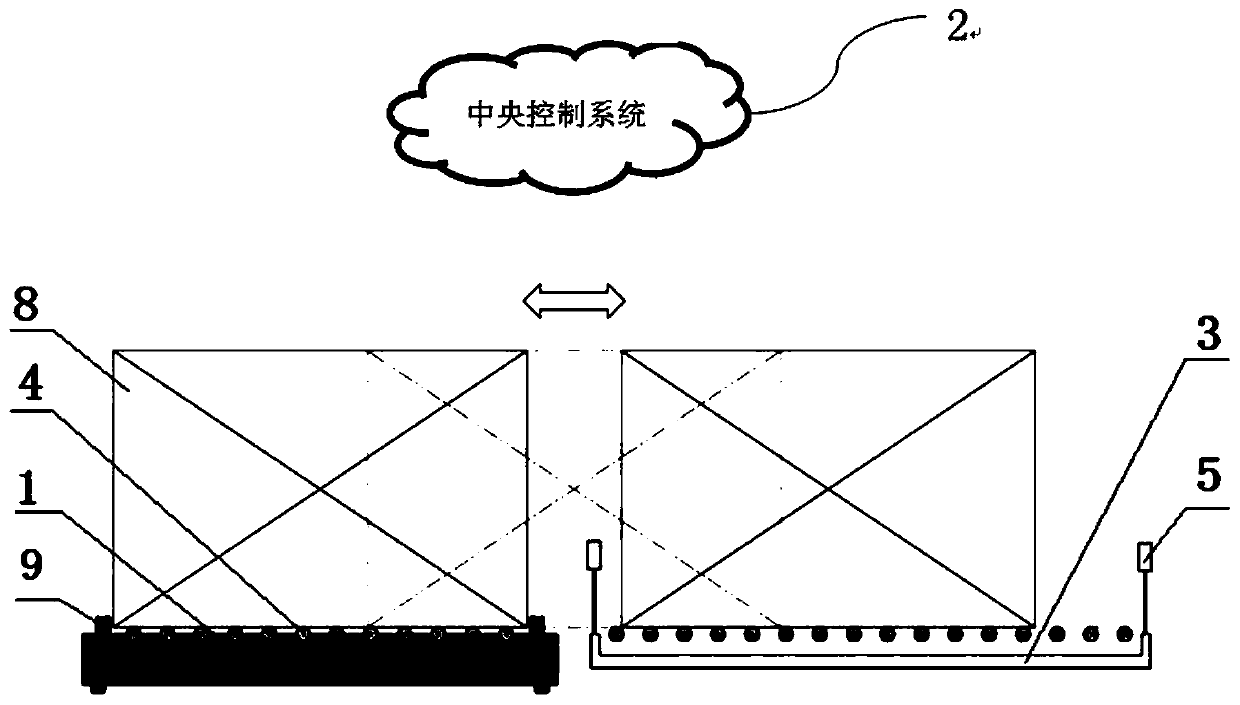

Butt joint method and system for automated guided vehicles

ActiveCN111007856ARealize automatic dockingReduce labor costsPosition/course control in two dimensionsVehiclesAviationControl system

The invention discloses a butt joint method of automated guided vehicles. The butt joint method comprises the steps that: a first positioning device of an automated guided vehicle obtains first information including the position and posture of the automated guided vehicle; a first communication device of the automated guided vehicle uploads the first information to a central control system; the central control system generates a first instruction according to the first information; the automated guided vehicle autonomously adjusts the posture and the position according to the first instruction; the automated guided vehicle sends second information to the central control system; the central control system generates a second instruction according to the second information; and the automatedguided vehicle is in butt joint with butt joint equipment according to the second instruction. According to the invention, manual participation is not needed in operation, safety risks are reduced, automatic butt joint of the automated guided vehicle of the aviation container and butt joint equipment can be achieved, and taking and conveying of the aviation container are completed; the labor costis reduced, the butt joint precision is improved, the butt joint time is shortened, so that the operation efficiency is improved. The invention further discloses a butt joint system of the automated guided vehicle.

Owner:SHANGHAI ZHENHUA HEAVY IND +1

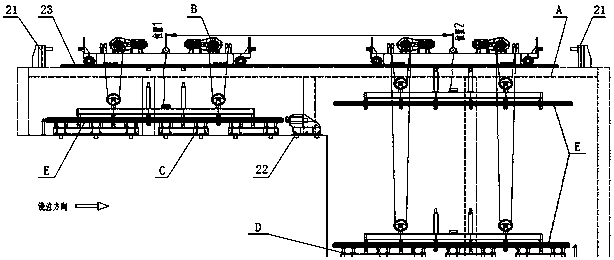

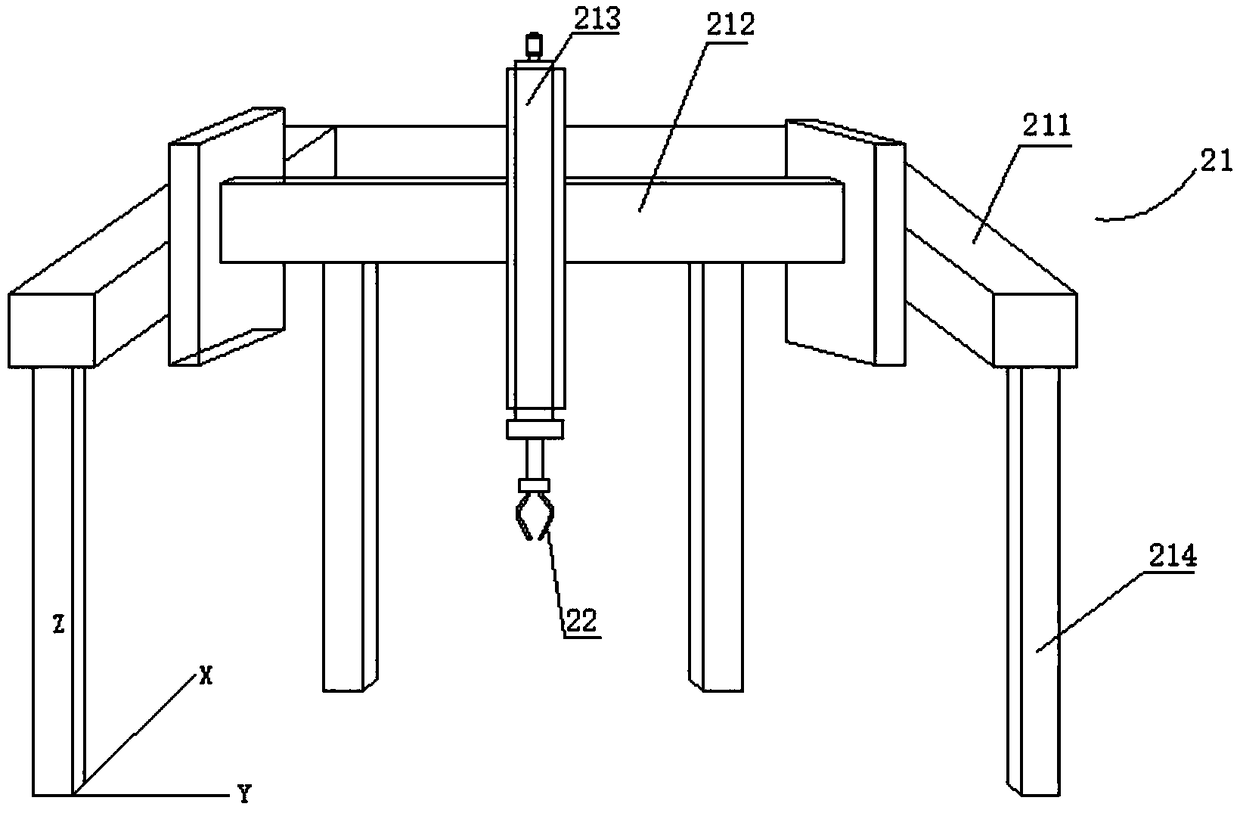

Automatic casting blank transport system and method thereof

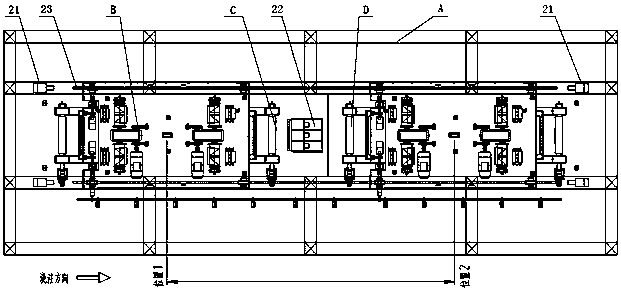

PendingCN108163706ASolve automatic transportPrecise positioningWinding mechanismsTravelling gearTransport systemVehicle frame

The invention relates to an automatic casting blank transport system and a method thereof. The transport system comprises a transport vehicle supporting frame, a casting blank automatic transport vehicle is arranged on the transport vehicle supporting frame, the side face of the casting blank automatic transport vehicle is connected with a towing device, a vehicle body walking device is arranged at the bottom, a casting blank receiving roller way and a casting blank conveying roller way which are arranged in parallel are arranged below the transport vehicle supporting frame, the height difference between the casting blank receiving roller way and the casting blank conveying roller way is larger than 2 m; the casting blank automatic transport vehicle is composed of a frame walking along a rail and a hanging beam used for conveying the casting blank, a lifting device is fixed to the frame, the hanging beam is located under the frame and is suspended, a movable pulley is fixedly mounted on the hanging beam, the movable pulley and the lifting device are connected through a steel wire rope, and the lifting device controls the casting blank on the hanging beam to be horizontally transported and vertically lifted and transported through the movable pulley. According to the automatic casting blank transport system and the method thereof, lifting of the casting blank with the superlargeheight difference being two meters or above can be finished, and horizontal transport of the casting blank can be achieved.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

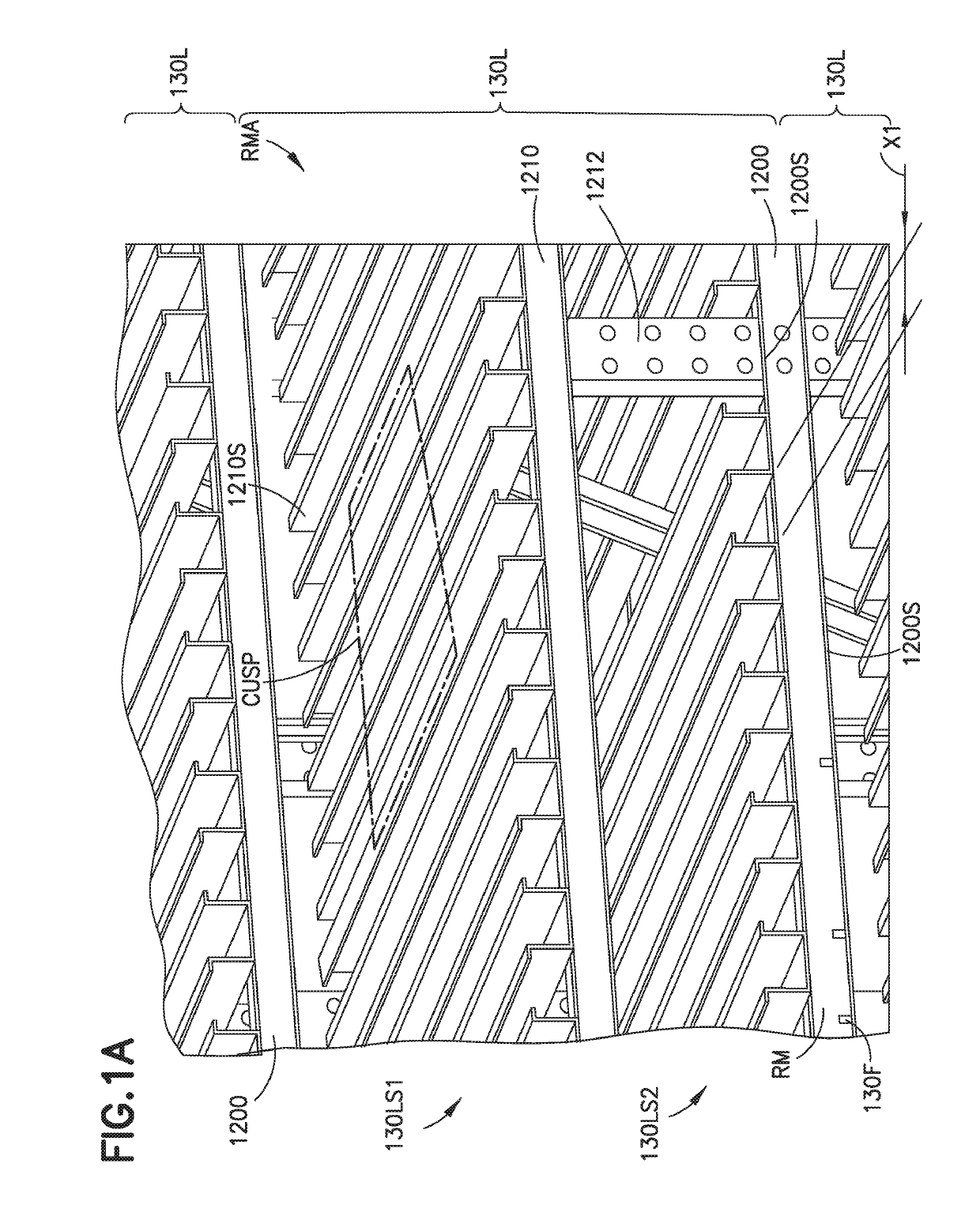

Storage and retrieval system

A product order fulfillment system includes multiple decks arrayed at different levels and defining multilevel decks, at least one autonomous transport vehicle on each of the decks, and configured for holding and transporting a pickface on each deck, at least one lift, traversing and connecting more than one level of the decks, and arranged for lifting and lowering the pickface from the decks, and at least one pickface transfer station on each deck interfacing between the transport vehicle and the at least one lift to effect transfer of the pickface between the transport vehicle and the at least one lift, the at least one lift defines a fulfillment stream of mixed case pickfaces outbound from the multilevel decks to a load fill, at least one stream of the fulfillment stream has an ordered sequence of streaming pickfaces wherein the ordered sequence of streaming pickfaces is based on another fulfillment stream.

Owner:SYMBOTIC LLC

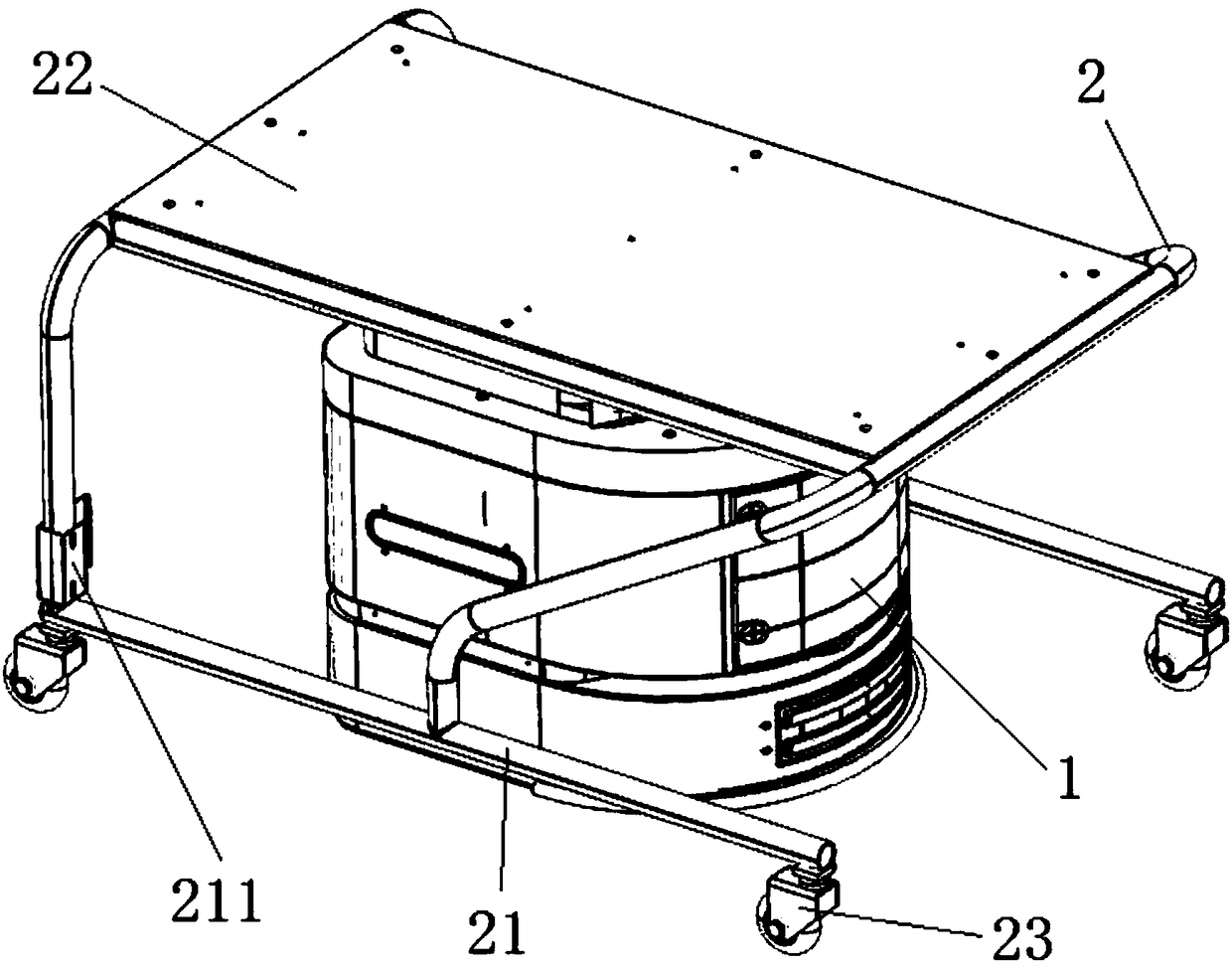

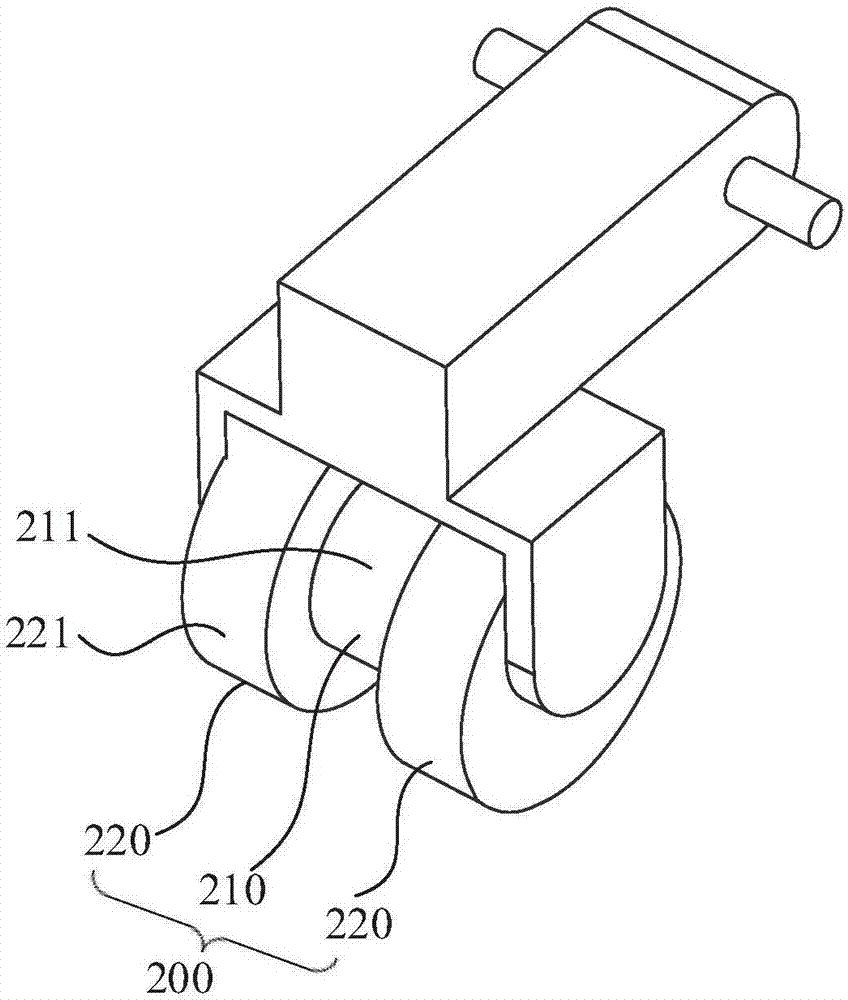

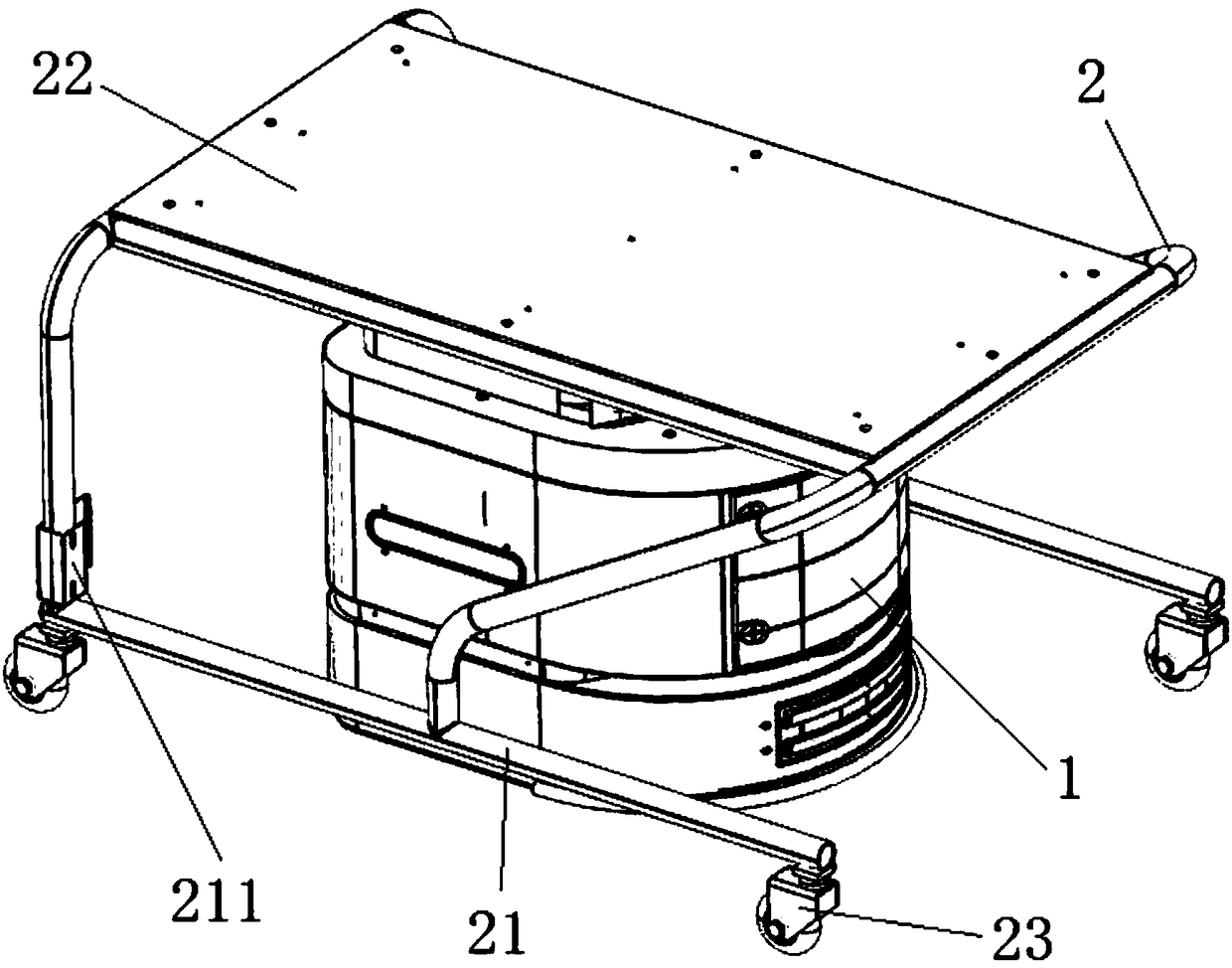

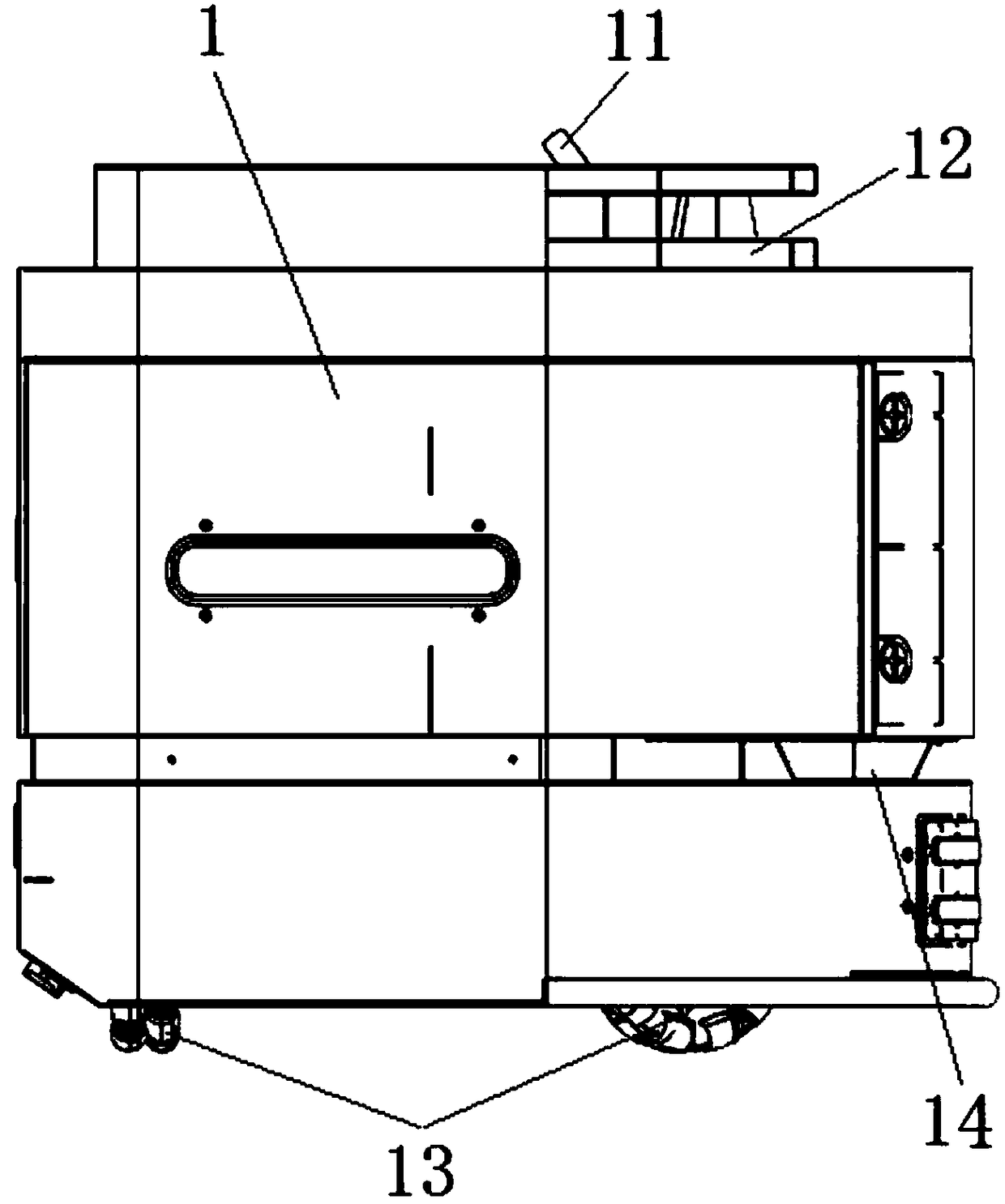

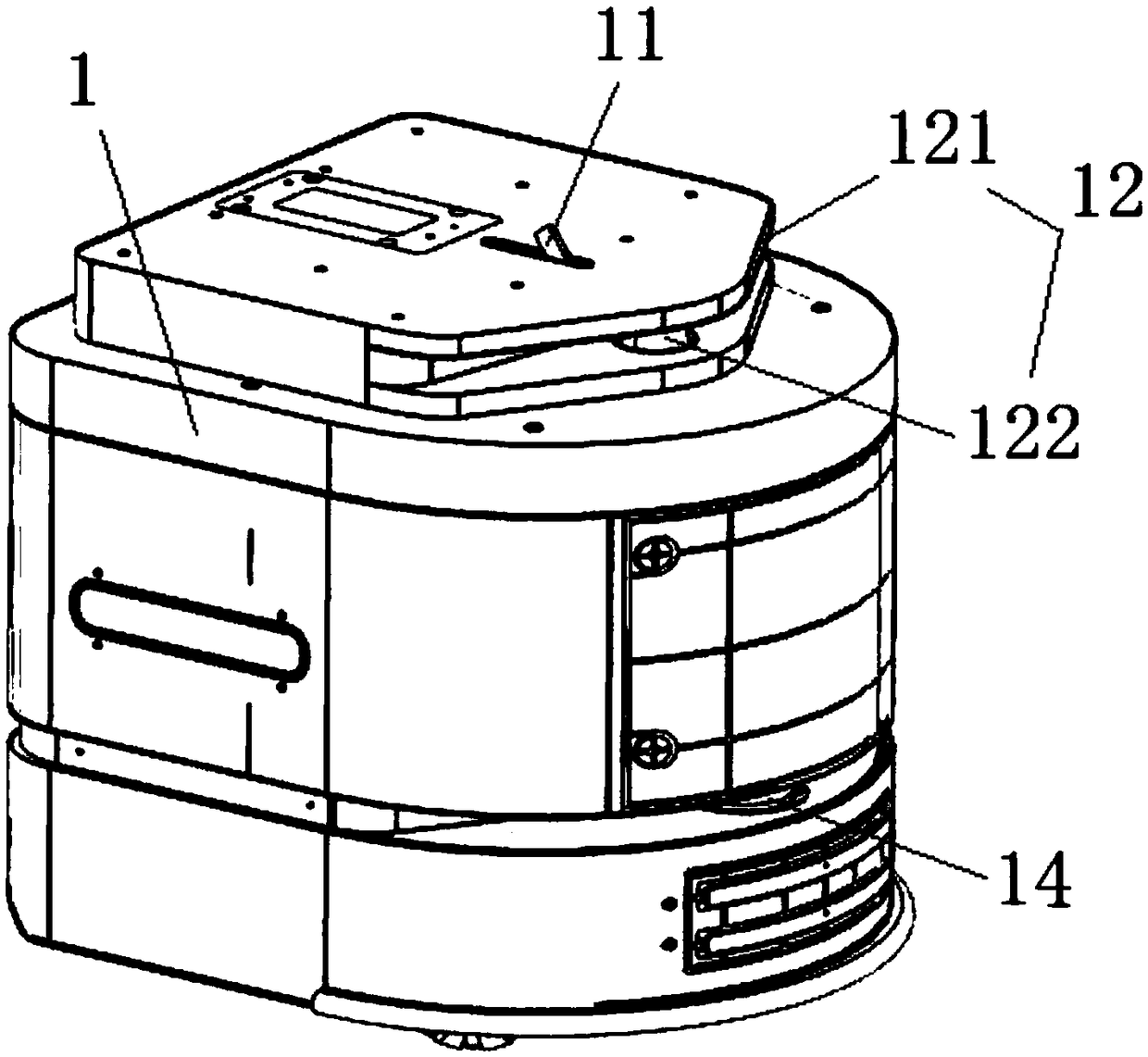

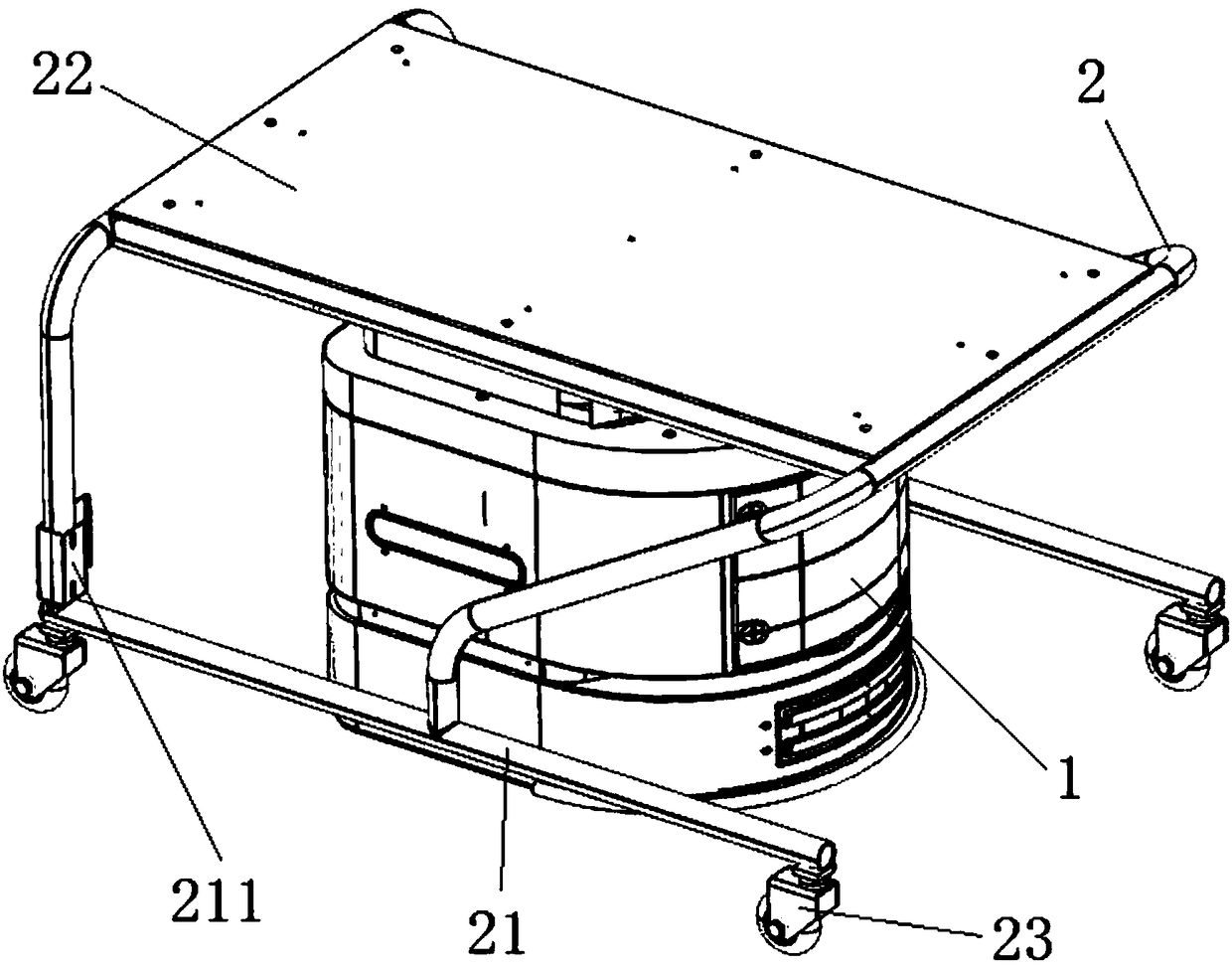

Skip transportation robot

The invention belongs to the technical field of robots and relates to a skip transportation robot. The skip transportation robot comprises an automatic transportation vehicle and multiple skips, all of which are matched. The automatic transportation vehicle comprises a locking hook device located on the middle portion of the top face, a lower stopping part located on the front portion of the top face, all-directional wheel devices located on the bottom face and a lower laser radar inductor located on the front portion. Each skip comprises a hollow frame, a table top located above the frame, multiple movable wheels located below the frame and an upper stopping part fixed to the bottom of the table top and matched with the lower stopping part, a locking groove for fixing the locking hook device is formed in the bottom of each table top, the automatic transportation vehicle is contained in the hollow portion of one corresponding frame, and the corresponding frame avoids the position of adetection region of the lower laser radar inductor. By the adoption of the robot, the multiple skips can be carried by the automatic transportation vehicle, each skip and the automatic transportationvehicle are fixed into a whole through the locking hook device, and the robot is high in use freedom degree and suitable for various occasions such as a factory, a hospital and a service area.

Owner:SUZHOU BOZHON ROBOT CO LTD

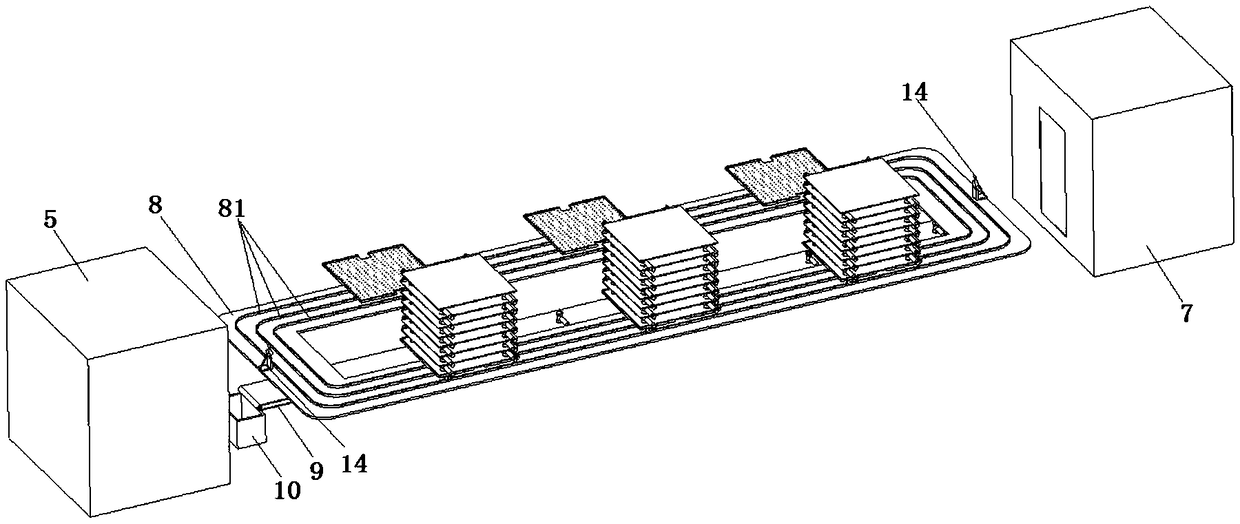

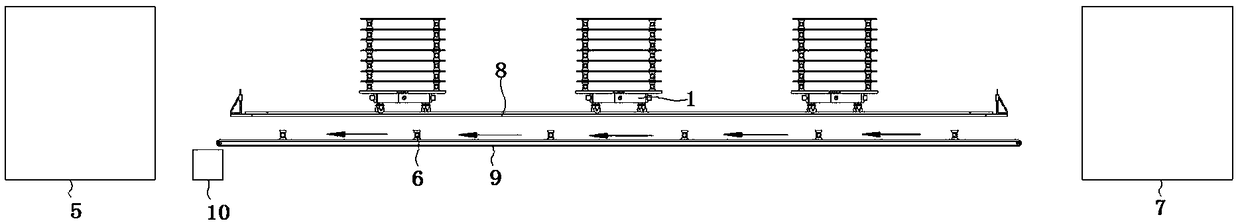

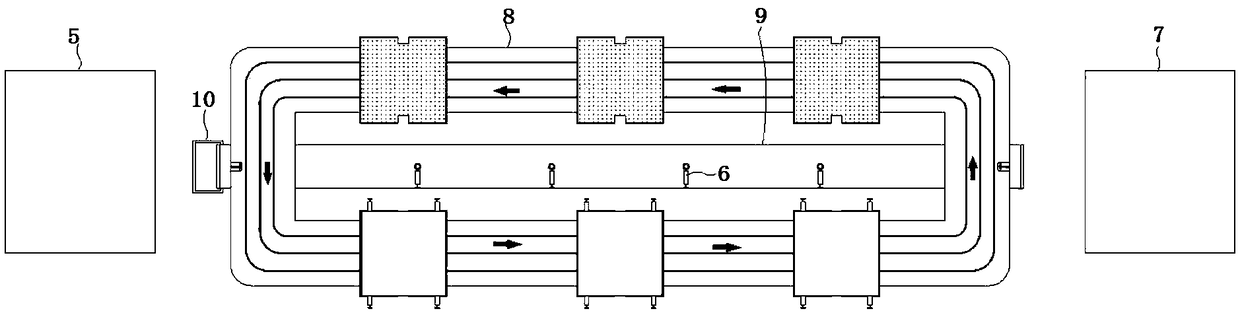

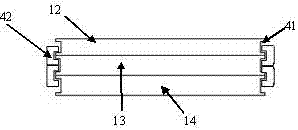

Rotary transport line for PCB production and processing plant and working method thereof

ActiveCN108820734AAchieve fixationEasy to fixControl devices for conveyorsMechanical conveyorsEngineeringProcessing plants

The invention discloses a rotary transport line for a PCB production and processing plant and a working method thereof. The rotary transport line comprises a PCB production area, a PCB storage area and a PCB rotary conveying line, and the PCB rotation conveying line is arranged between the PCB production area and the PCB storage area; the PCB rotary conveying line comprises a closed supporting plate and a plurality of conveying devices capable of being overlaid with and fixing a plurality of PCBs, a plurality of tracks are arranged on the PCB rotary conveying line along the outline, and the conveying devices are arranged on the tracks in a movable mode at a safety interval; and each conveying device comprises automatic transport carts and a plurality of sets of negative pressure type fixing pieces. According to the rotary transport line for the PCB production and processing plant and the working method thereof, PCBs produced in the PCB production area can be transported to the PCB storage area, the transportation efficiency is high, and safety and reliability are realized.

Owner:嘉兴考普诺机械科技有限公司

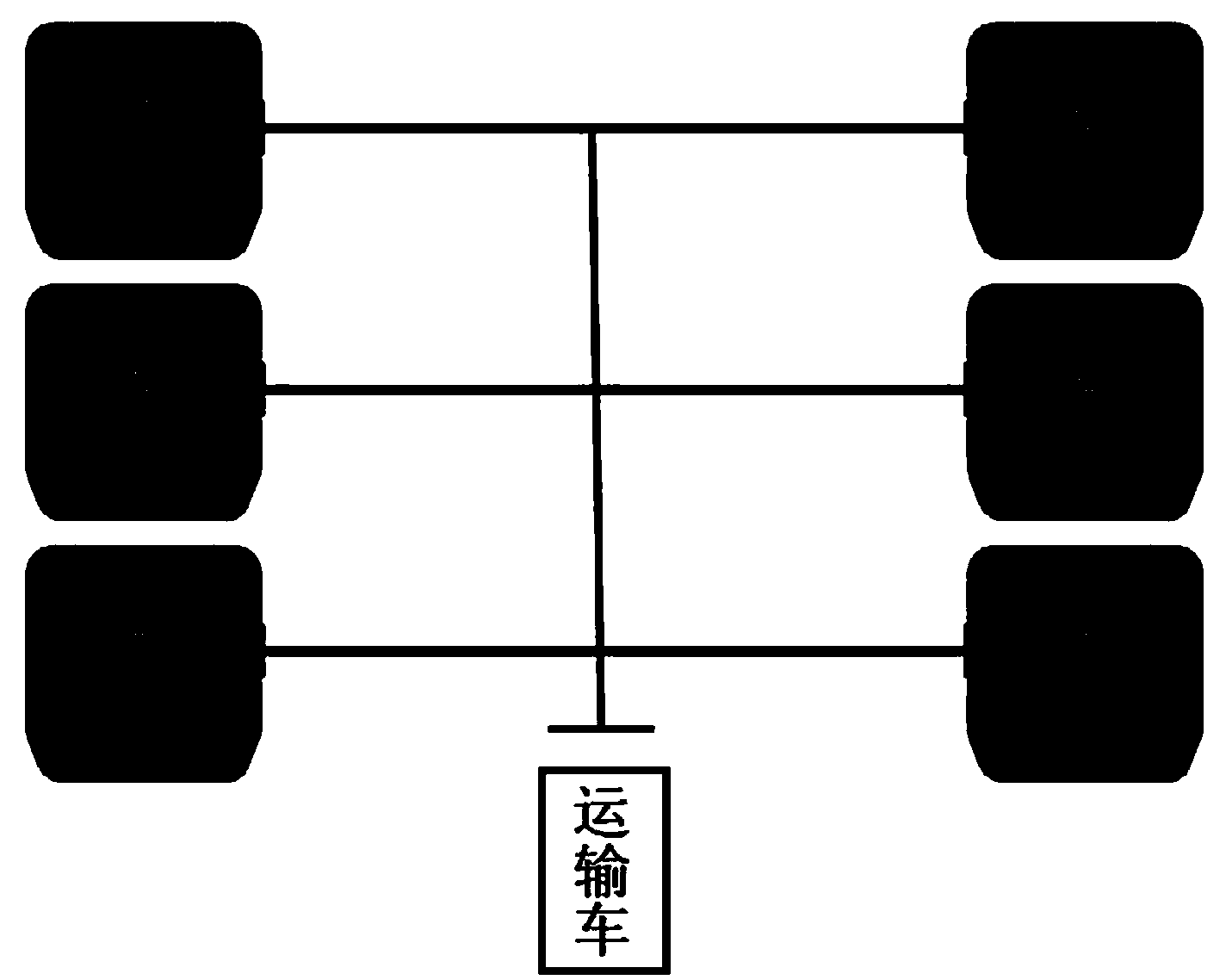

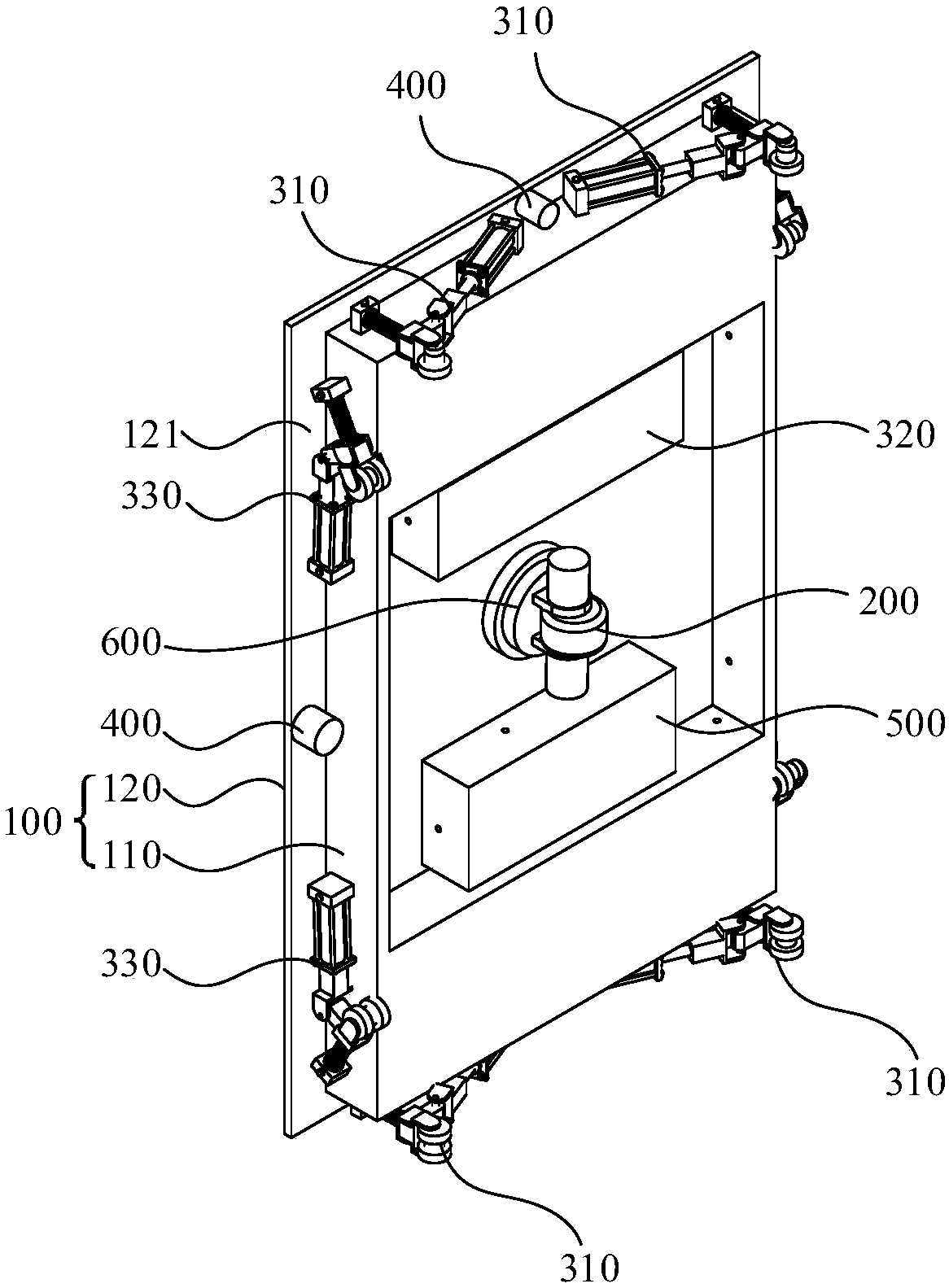

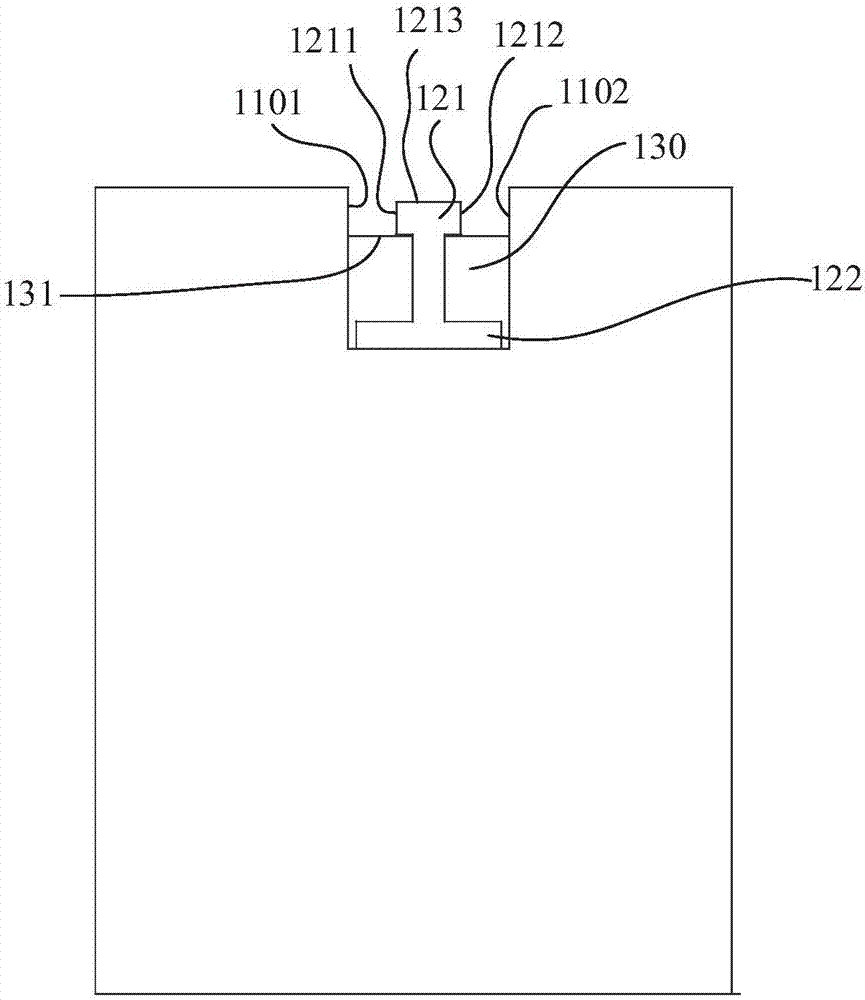

Guide-rail type automatic carrier vehicle and automatic parking lot

The invention relates to a guide-rail type automatic carrier vehicle and an automatic parking lot. The guide-rail type automatic carrier vehicle includes a carrier vehicle body, a steering wheel mechanism, a support mechanism, a distance sensor module and an energy supply element; the steering wheel mechanism is arranged on the carrier vehicle body; the support mechanism includes a first support assembly, a second support assembly and a control module which are all arranged on the carrier vehicle body, the first support assembly is movably matched with a guide rail in the X-axis direction, andthe second support assembly can be movably matched with a guide rail in the Y-axis direction; the distance sensor module is arranged on the carrier vehicle body; and the energy supply element is arranged at the carrier vehicle body to supply energy for other electric assemblies in a carrier vehicle. The automatic parking lot includes the guide-rail type carrier vehicle, an orthogonal type guide rail and parking lots; the guide-rail type automatic carrier vehicle can be driven on the orthogonal type guide rail; and the parking lots communicate with the orthogonal type guide rail.

Owner:GUANGDONG INST OF INTELLIGENT MFG

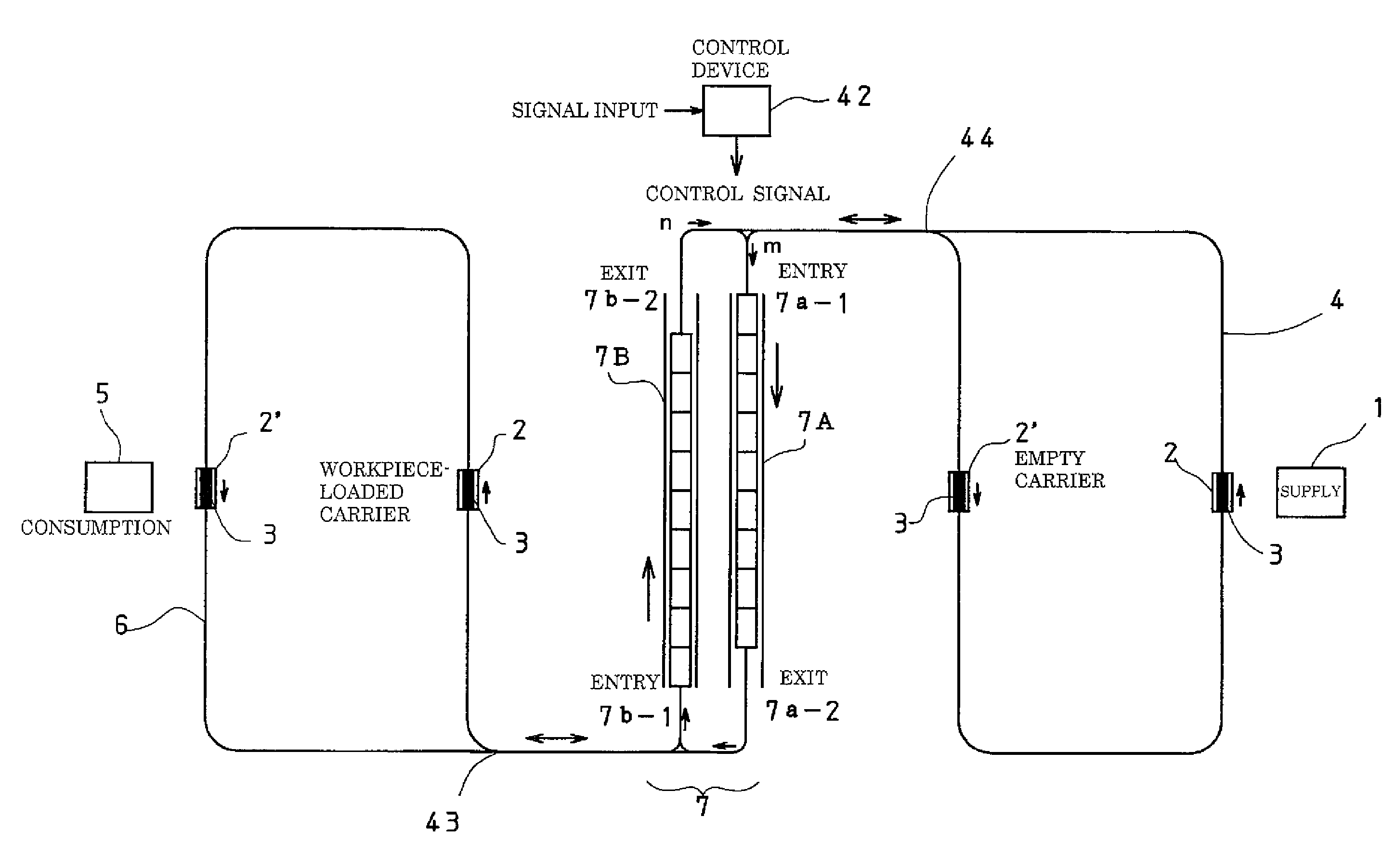

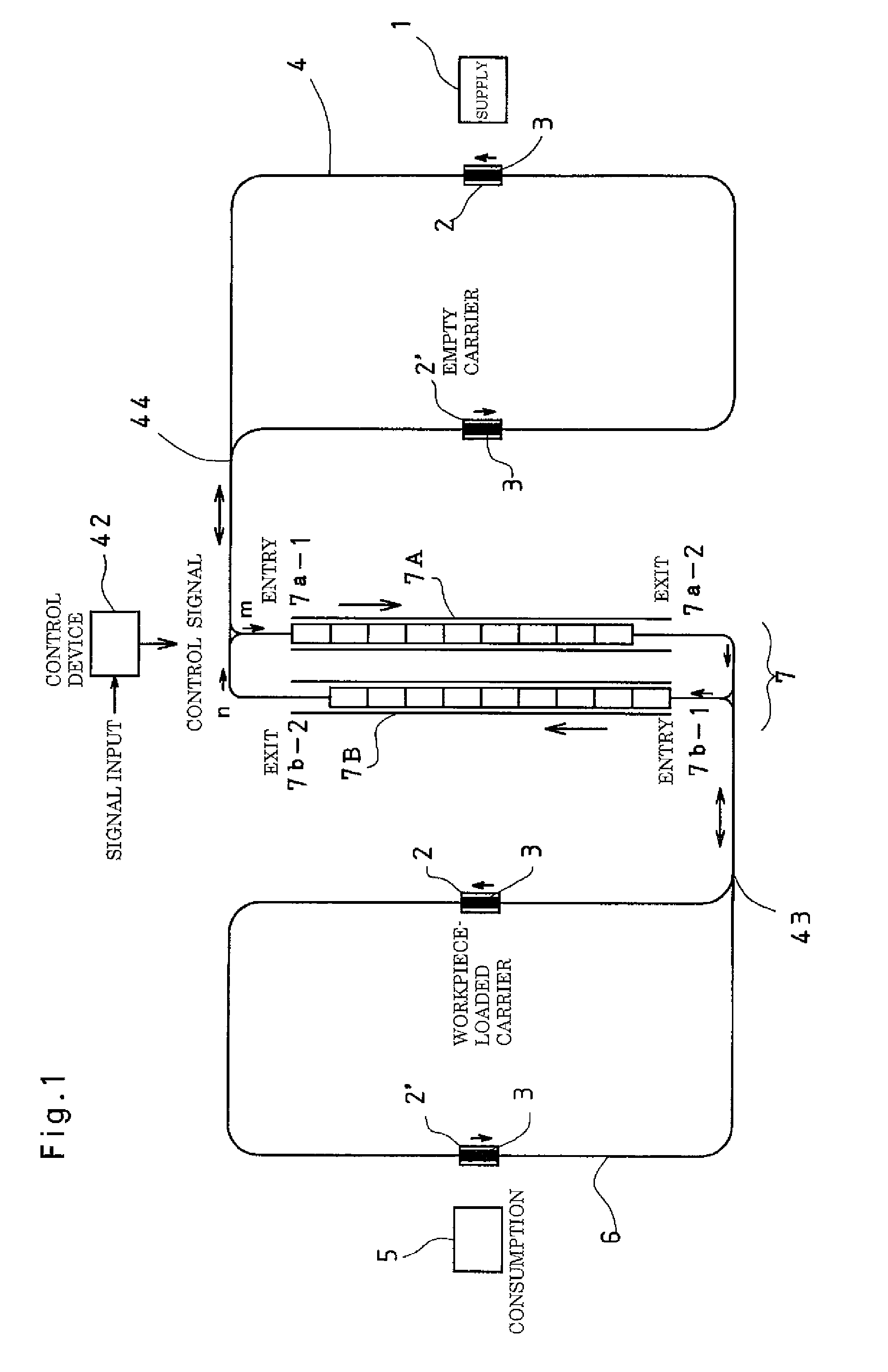

Workpiece transportation system comprising automated transport vehicles and workpiece carriers

InactiveUS20090317217A1Easy to createEasy to changeProgramme controlLifting devicesComputer control systemAutomated guided vehicle

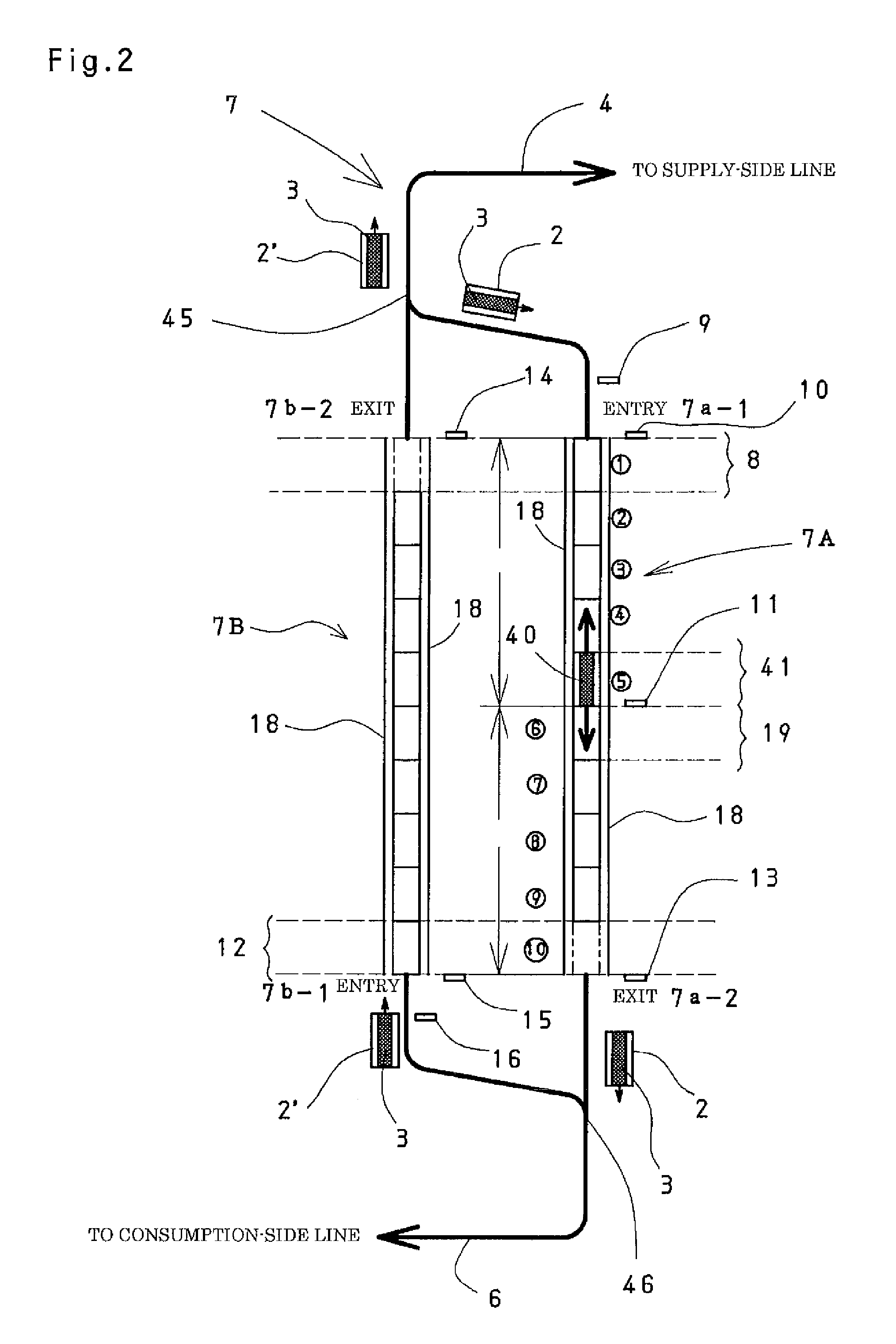

A conveyance facility system for transporting an appropriate amount of work at a time at an appropriate time to the consumption side area by automatically controlling through a computer control system an automated guided vehicle for allowing a truck that has mounted the work in the supply side area to travel accompanying the vehicle from the supply side area to the consumption side area along the guidance course of the automated guided vehicle, and allowing the empty truck that has unloaded the work in the consumption side area to return to the supply side area. The work conveyance facility system comprises a plurality of work mounting trucks (2) for loading and conveying work, an automated guided vehicle (3) for allowing the work mounting truck (2) to travel accompanying the vehicle to a set position and releasing the truck thereat, and a guidance course of the automated guided vehicle (3). The guidance course is constituted of a supply side line (4) for loading the work onto the work mounting truck (2) in the supply area (1) and driving the truck, a consumption side line (6) for leading in the work mounting truck (2) and driving the empty work mounting truck (2′) that has unloaded the work in the consumption area (5), and a buffer line (7) for coupling the supply side line (4) with the consumption side line (6).

Owner:YAZAKI IND CHEM CO LTD

Wheel-rail structure, intelligent parking lot and intelligent logistics warehouse

PendingCN107882397ASimple structureLow costStorage devicesMechanical conveyorsLogistics managementEngineering

Owner:GUANGDONG INST OF INTELLIGENT MFG

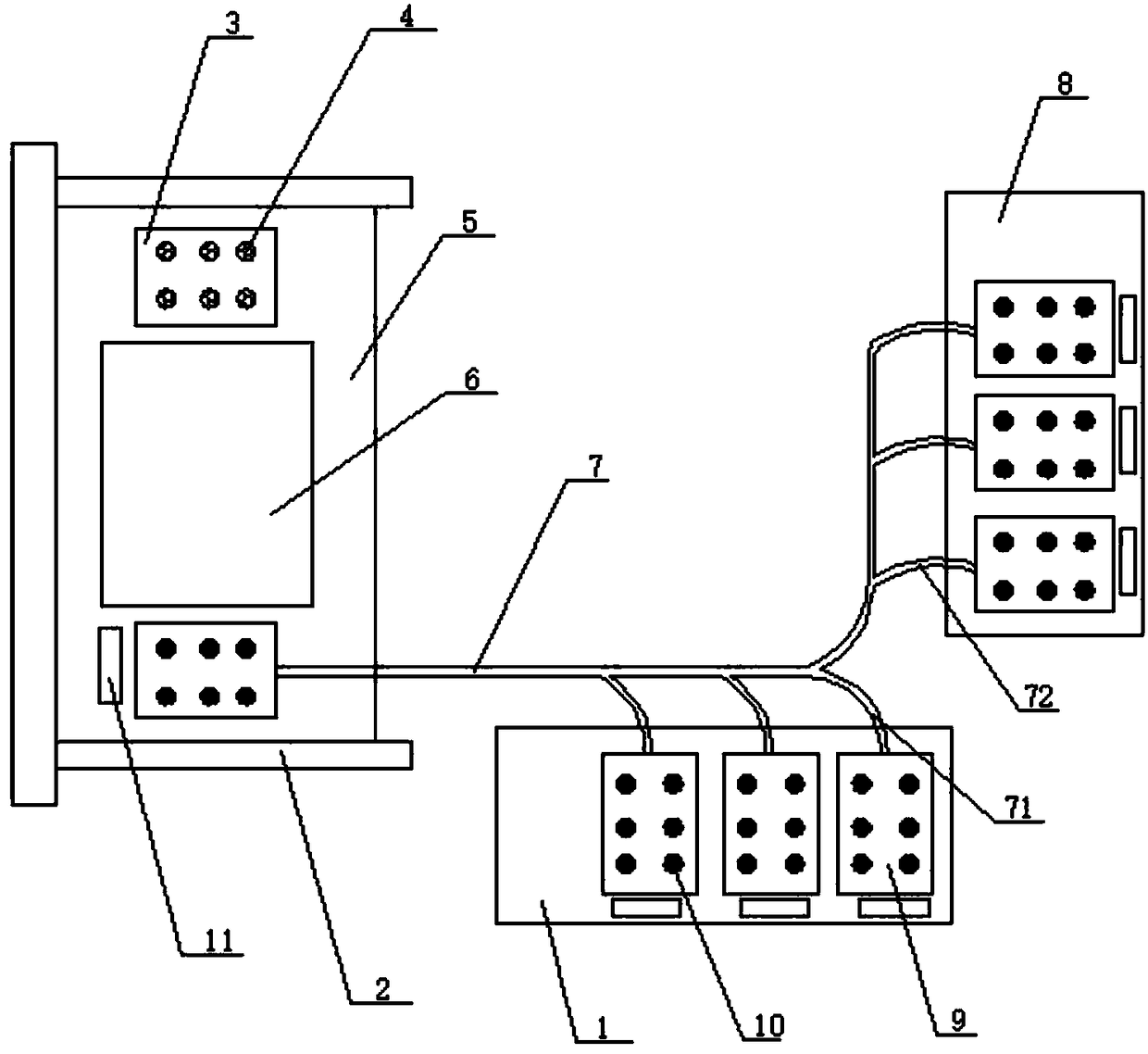

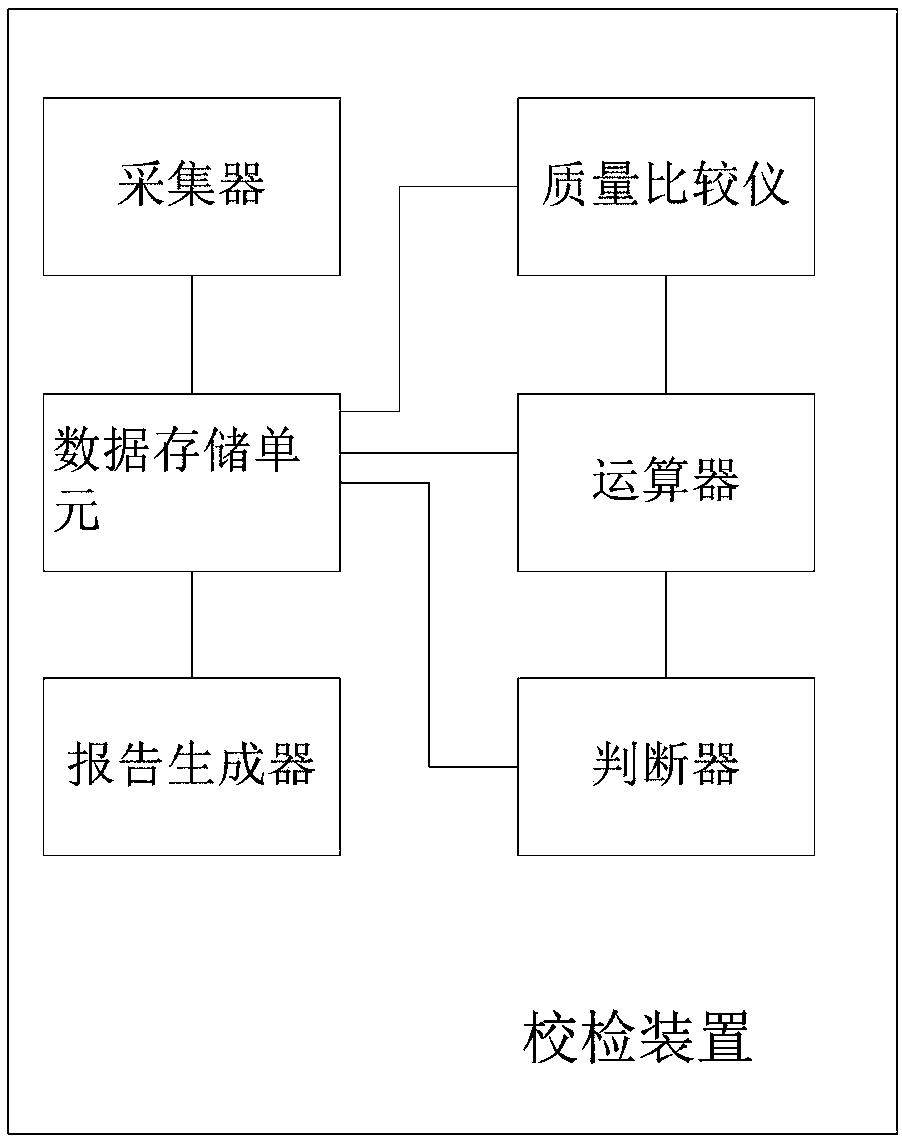

Kilogram group weight automatic calibration device

InactiveCN109141612ASolve efficiency problemsSolve processingWeighing apparatus testing/calibrationProximity sensorPhysical hard work

The invention relates to the technical field of weight calibration, and discloses a kilogram group weight automatic calibration device comprising an area to be calibration, a calibration area, a calibrated area, an automatic transport vehicle, a transport track and a weight taking and placing device. The automatic transport vehicle operates on the preset track to realize automatic transportation of the calibrated weight among all the areas. A proximity sensor and a calibration workbench are arranged in the calibration area. The proximity sensor is arranged to be near the end of the transport track. The proximity sensor is used for limiting the position of the automatic transport vehicle in the calibration area. A mass comparator is arranged on the calibration workbench. The weight taking and placing device is used for realizing loading or unloading of the calibrated weight and the standard weight. Automatic transportation of the weight, automatic loading and unloading and automatic calibration of the weight can be realized, and the problems of low calibration efficiency, low automation degree, error-prone result and heavy and repeated physical labor in the calibration process and hidden safety hazards in manual weight transporting in the weight calibration process in the prior art can be solved.

Owner:苏州市计量测试研究所

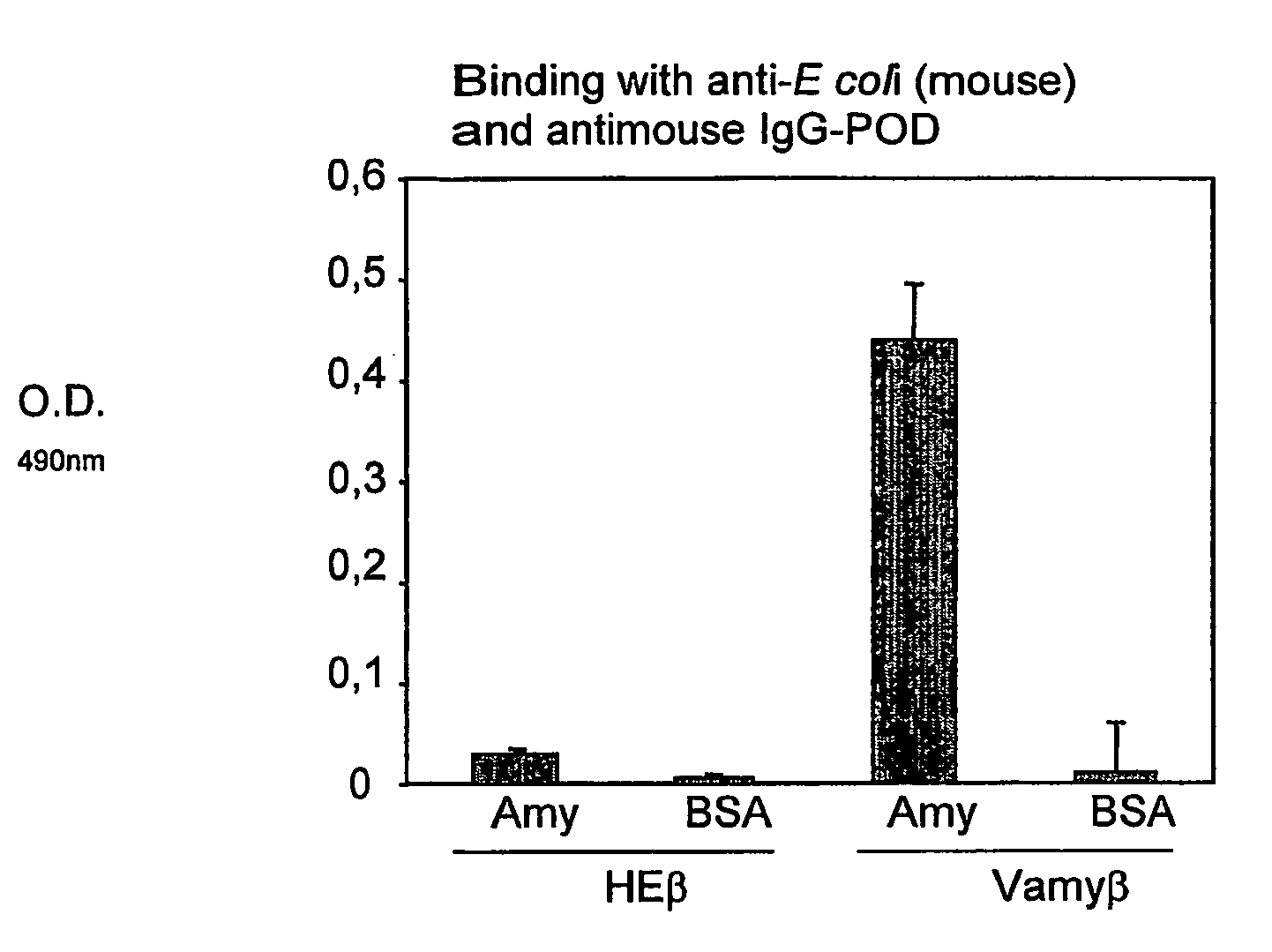

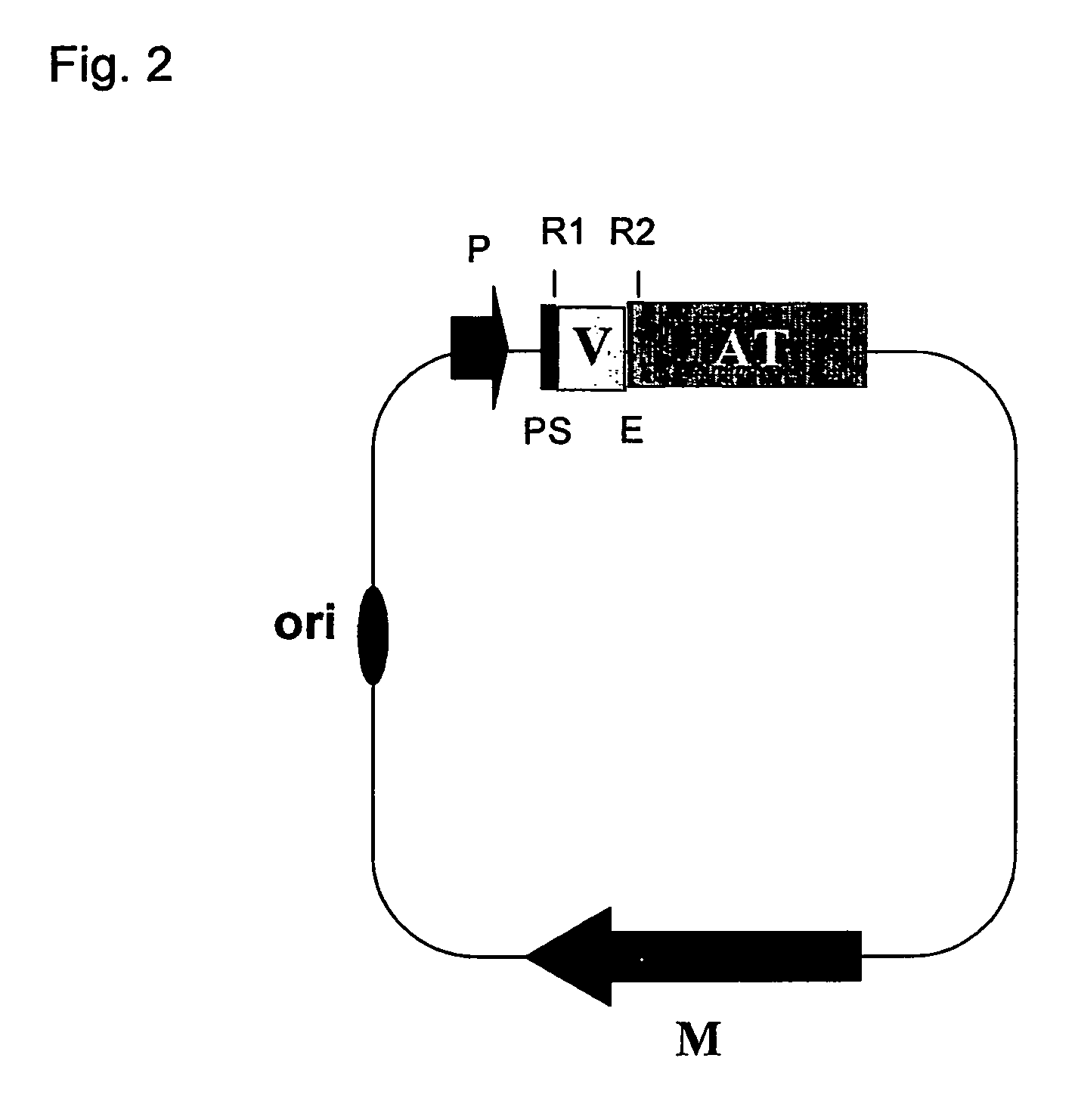

Generation of specific adhesion in gram-negative bacteria by means of anchoring immunoglobulin single domains on their surface with autotransporters

InactiveUS20090155849A1Reduce decreaseImprove efficiencyBacteriaHydrolasesAntigenBacterial Adhesions

The present invention refers to an expression vector for gram-negative bacteria allowing for the production of hybrid proteins between single domain recombinant antibodies and a transporter domain of an autotransporter, as well as to its anchoring and expression on the external surface of a bacterial membrane, and to a method of specific bacterial adhesion to a surface containing a specific antigen.

Owner:CONSEJO SUPERIOR DE INVESTIGACIONES CIENTIFICAS (CSIC)

High strength automatic transfer bed

InactiveCN106618884BReduce secondary damageCooperate wellStretcherNursing bedsSupporting systemEngineering

The invention relates to a high-strength automatic transfer bed which comprises a transfer plate system, a chain wheel system, a power system and a supporting system. The transfer plate system is improved, so that the transfer bed thoroughly replaces manpower carrying, secondary harm caused by manpower carrying to a patient is avoided, and the medical environment of the critical patient is improved accordingly. The structure and material of an upper-layer transfer plate in the transfer plate system are specifically improved, so that the transfer bed can bear high pressure, and the durability of the transfer bed is guaranteed.

Owner:THE THIRD PEOPLES HOSPITAL OF QINGDAO

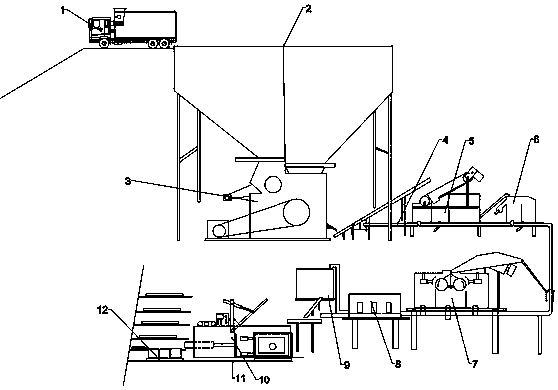

Garbage recovering-sorting-packaging system with automatic finished-product transportation function and working process thereof

InactiveCN109226192AImprove sorting process efficiencyIncrease loading capacitySolid waste disposalRefuse cleaningAir separationSteel belt

The invention provides a garbage recovering-sorting-packaging system with an automatic finished-product transportation function and a working process thereof. The garbage recovering-sorting-packagingsystem comprises a garbage transportation cart, a garbage temporary-storage bin, a crushing device, a conveying device, a belt type inclined-net transporting and sorting device, a secondary air-separation device, an electric sorting device, a secondary magnetic-separation device, a non-ferrous metal color temporary storage bin, a compressing and packaging device, an automatic transportation vehicle and a disinfection device, wherein a pre-magnetic-separation device is arranged on the garbage transportation cart; an electromagnetic suctioning disc of the pre-magnetic-separation device is fixedat the bottom part of a conveying steel belt and can rotate along with the steel belt; a pushing plate and a cleaning and disinfecting device are arranged on the garbage transportation cart; the conveying device is connected with the sorting device and the compressing and packaging device in series; the automatic transportation cart is used for transporting the compressed-packaged-formed metal blocks to a loading area. According to the garbage recovering-sorting-packaging system and the working process provided by the invention, the design is ingenious, the sorting function is complete, metalblocks after compressing and packaging treatment can be automatically transported to a loading area for loading, so that the garbage recovering-sorting-packaging system is very suitable for being promoted and used.

Owner:冯门娟

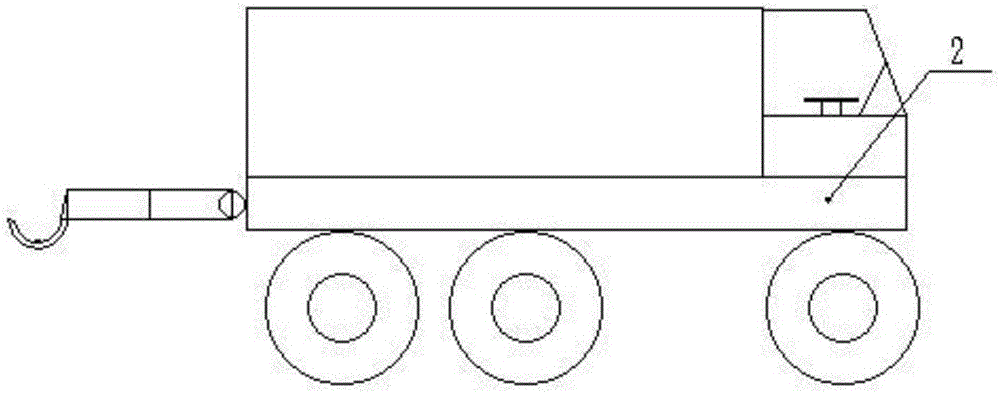

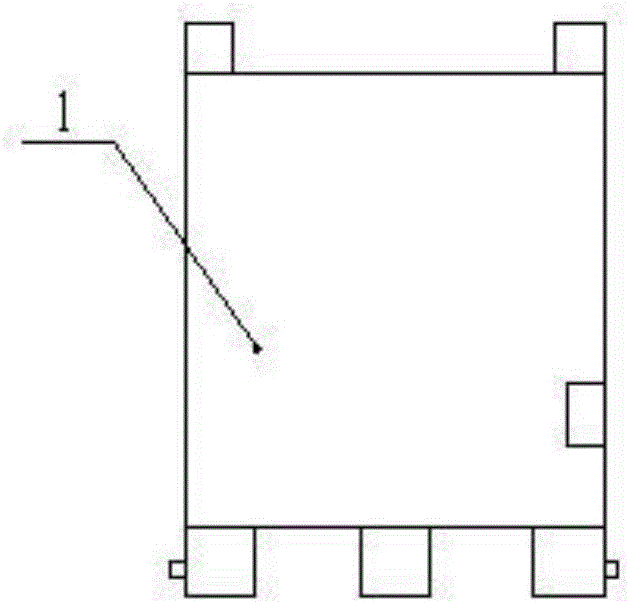

Intelligent waste collection and transportation system

InactiveCN106144336AReduce labor costsImprove working environmentRefuse receptaclesRefuse vehiclesDriver/operatorDrive wheel

The invention discloses an intelligent waste collection and transportation system and belongs to the technical field of environmental sanitation. In order to solve the problem that more staff is needed in a process of transporting garbage, the system comprises an intelligent garbage box and an automatic transport car. The intelligent garbage box is of a cuboid structure, wherein three wheels are arranged in the bottom of the intelligent garbage box; two of the three wheels are driving wheels and the other one is a universal wheel; the three wheels are arranged in a triangular shape; the axes of the two driving wheels are overlapped with each other; and each driving wheel is provided with a driving motor; and therefore, the human cost is effectively reduced. The driver needs not to get off the car but only needs to control the car in the cab, so that the driver works in the cab all the time, and the work environment is extremely improved.

Owner:ANHI SHENGYUN HEAVY MACHINERY CO LTD

Looseness-proof skip transport robot

PendingCN108328234AAvoid affecting docking accuracyClosely positionedMechanical conveyorsEngineeringFuture of robotics

Owner:SUZHOU BOZHON ROBOT CO LTD

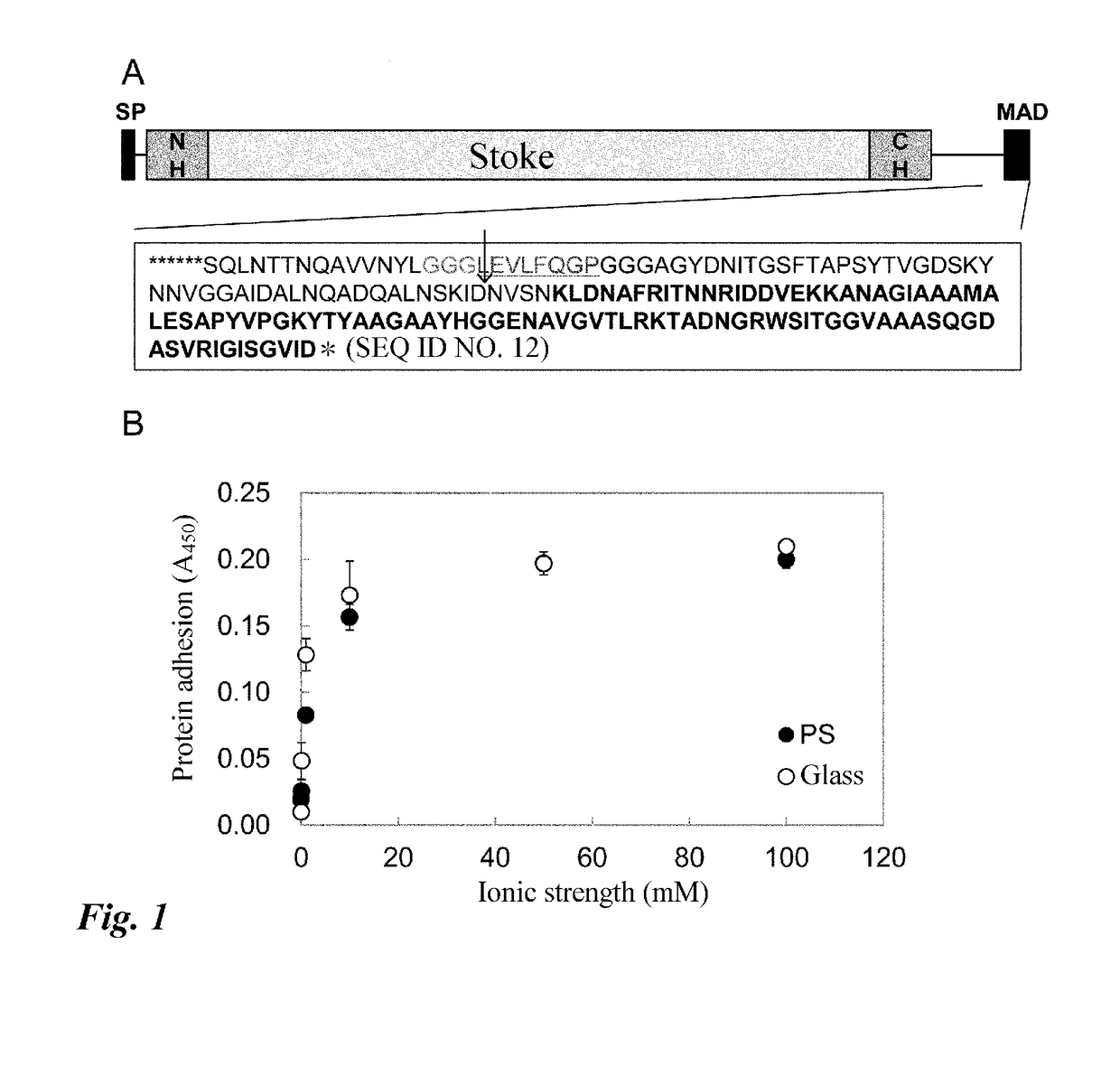

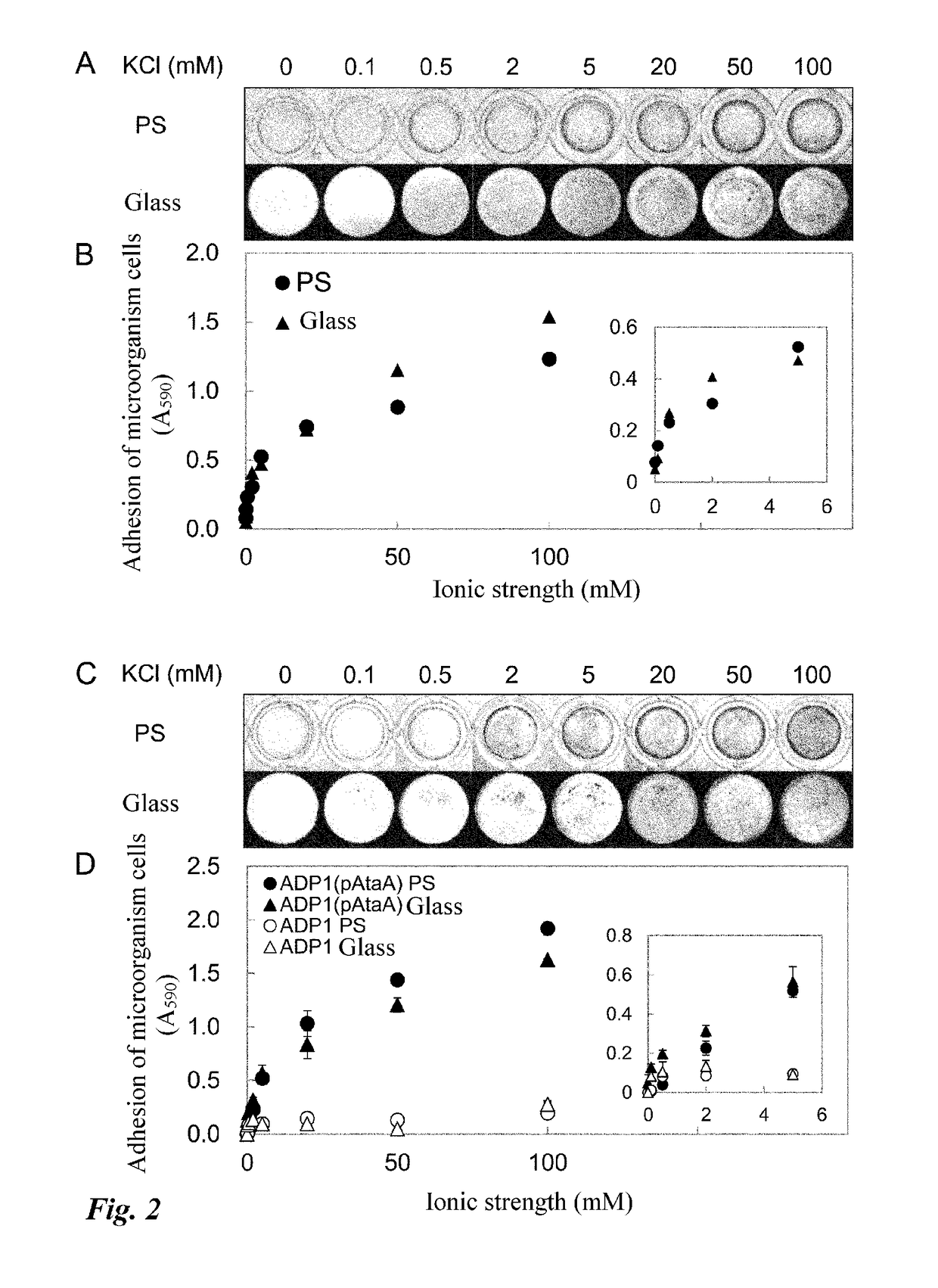

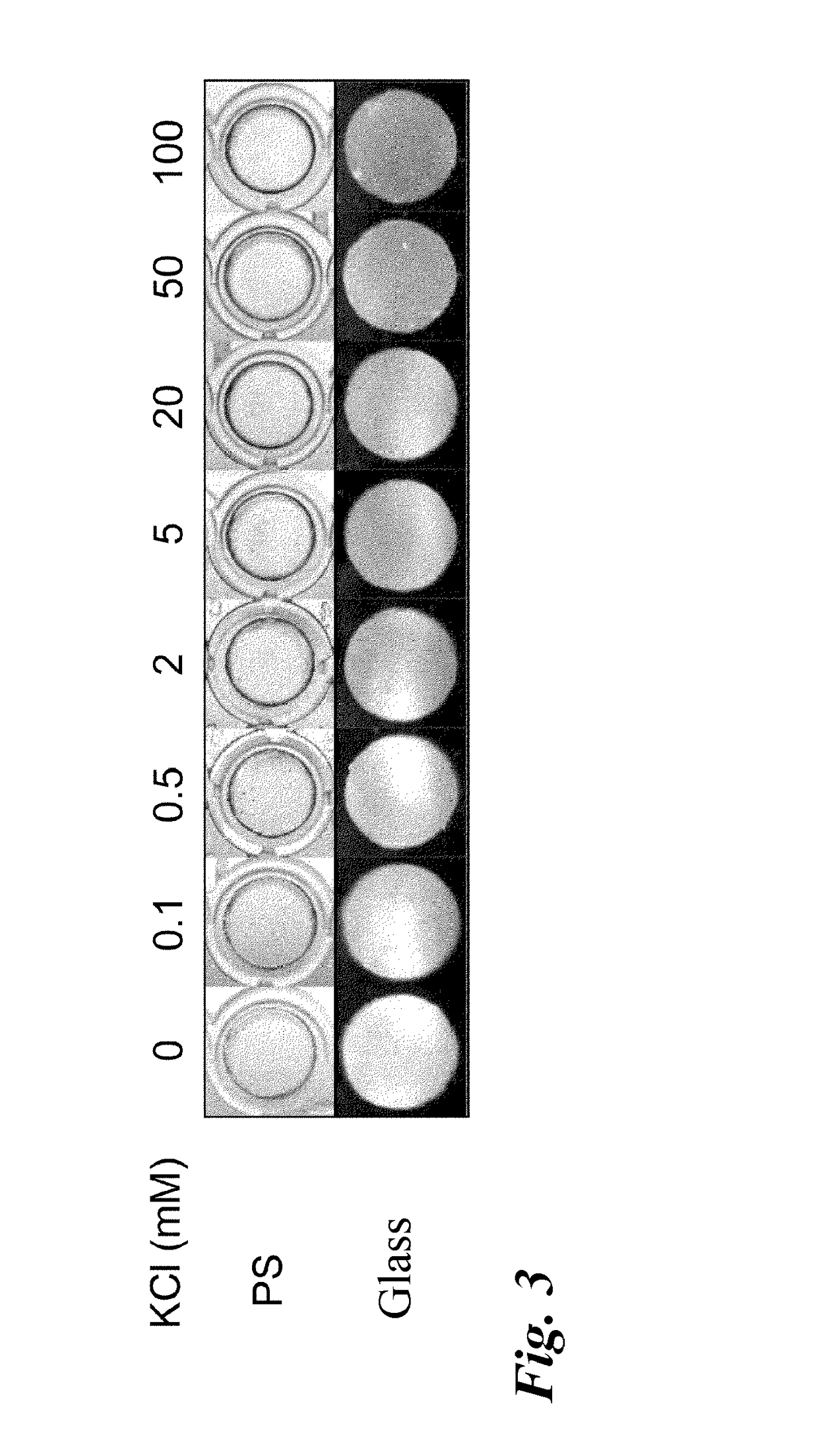

Method for immobilizing and releasing microorganism

ActiveUS9631189B2Unique adhesive propertySimple structureBacteriaDepsipeptidesMicroorganismBacterial Adhesins

Intended is to provide a more practical technique for immobilizing a microorganism using an adhesive protein AtaA derived from Acinetobacter sp. Tol 5. Provided is a method for attaching and releasing a microorganism, including (1) a step of contacting a microorganism, into which DNA encoding autotransporter adhesin derived from a microorganism belonging to the genus Acinetobacter has been introduced to impart or enhance non-specific adhesiveness, with a carrier under a high ionic strength and thus attaching the microorganism to the carrier; and (2) a step of releasing the microorganism from the carrier by washing under a low ionic strength.

Owner:NAGOYA UNIVERSITY

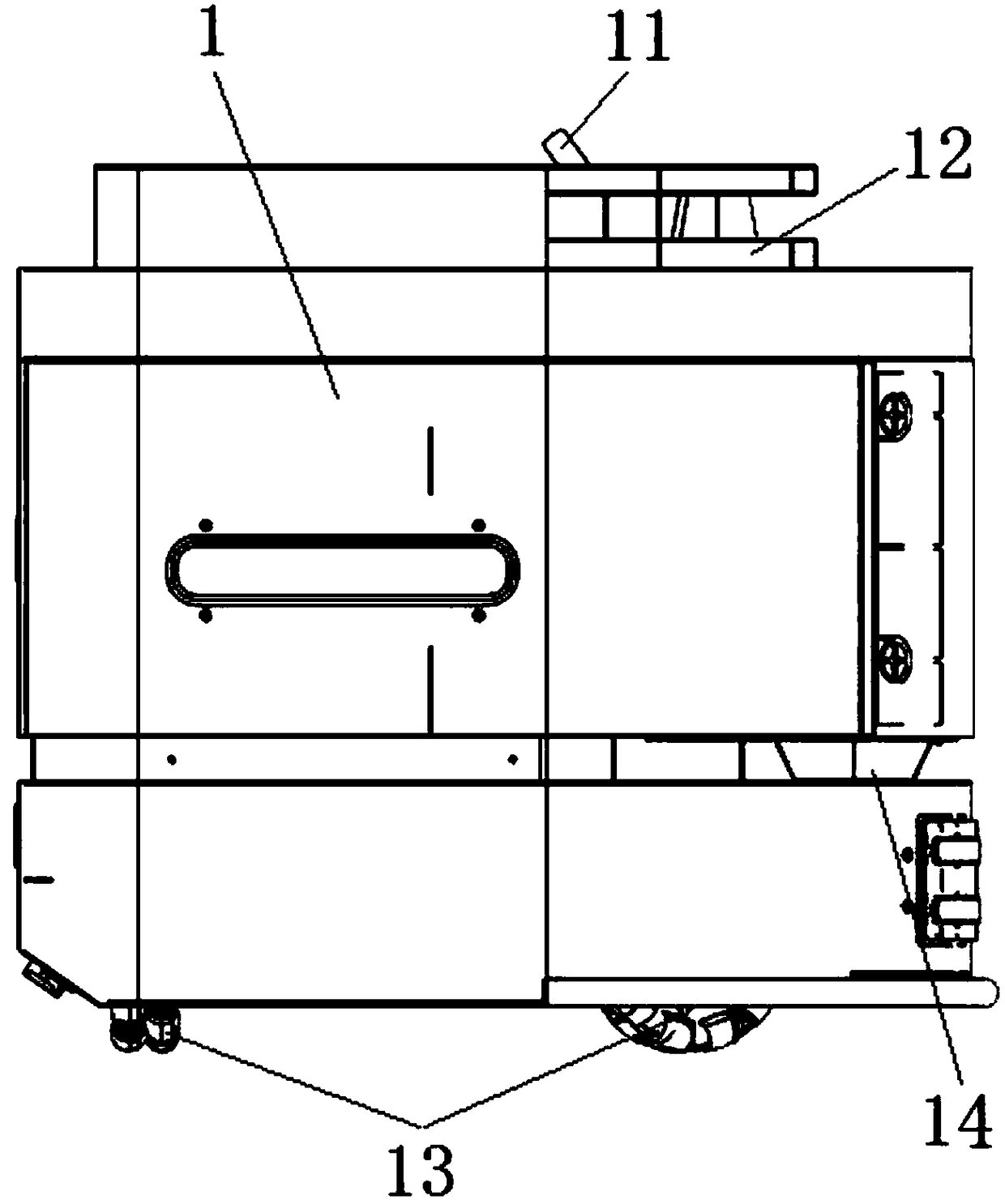

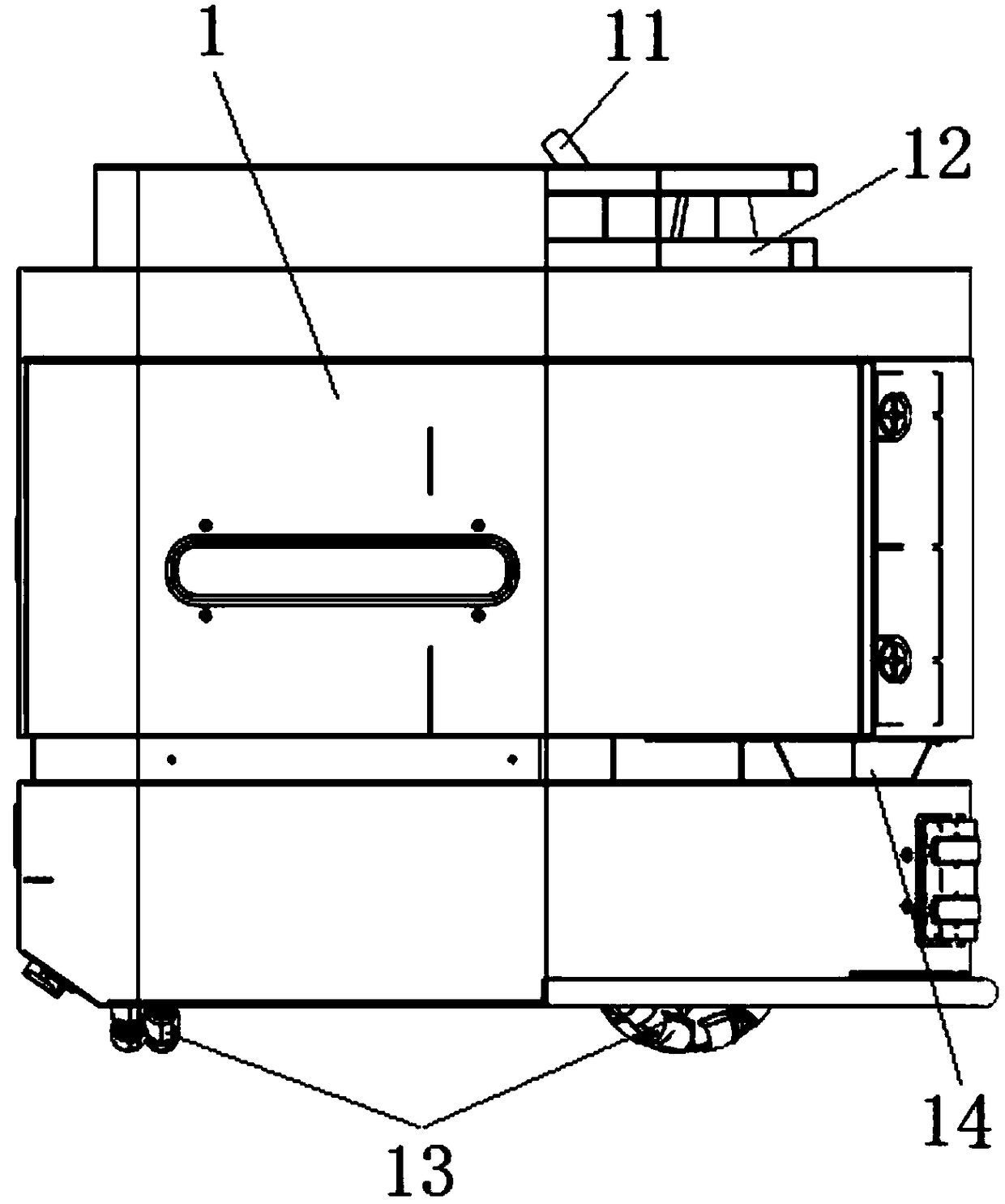

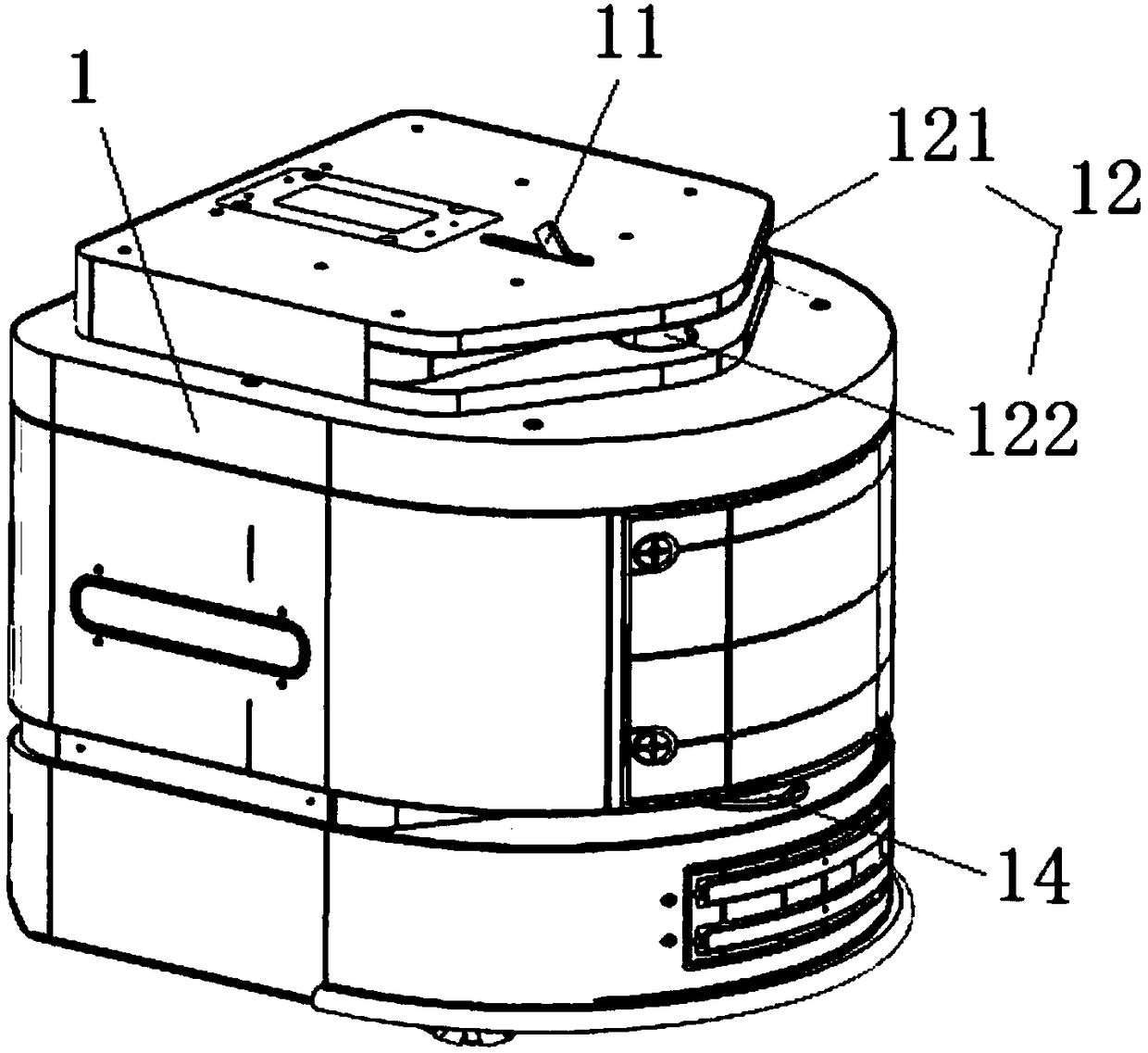

Automatic induction positioning charging skip transportation robot

The invention belongs to the technical field of robots, and relates to an automatic induction positioning charging skip transportation robot. The automatic induction positioning charging skip transportation robot comprises an automatic transport vehicle and a plurality of charging skips which are matched. The automatic transport vehicle comprises a lock hook device and a lower blocking portion. Each of the charging skips comprises a table top and an upper blocking portion fixed to the bottom of the table top and matched with the lower blocking portion, and locking grooves for fixing the lock hook devices are formed in the bottoms of the table tops. The lower blocking portion includes a convex V-shaped blocking body and an upper laser radar sensor located inside the convex V-shaped blockingbody, the upper blocking portions include concave V-shaped blocking bodies matched with the convex V-shaped blocking body, and the upper laser radar sensor is used for sensing the concave V-shaped blocking bodies. According to the automatic induction positioning charging skip transportation robot, the automatic transport vehicle can directly sense the presence of the concave V-shaped blocking bodies by means of the upper laser radar sensor close to the convex V-shaped blocking body, so that the automatic transport vehicle and the charging skips can be better matched to avoid unnecessary collision and damage to the appearance surface.

Owner:SUZHOU BOZHON ROBOT CO LTD

Lean intelligent automatic handling and distribution system and method for garment factory

ActiveCN105354667BImprove management levelReduce labor costsResourcesLogisticsDistribution methodDatabase server

The invention provides an intelligent and automatic carrying distribution system and an intelligent and automatic carrying distribution method for garment factory lean production. The system comprises a cutting bed workshop scheduling module which is used for performing production scheduling on the amount of cut pieces in a cutting bed workshop and generating cut piece scheduling information; a stitching workshop scheduling module which is used for generating cut piece demand information according to the cut piece demand situation in a stitching workshop; an RFID wireless data acquisition device which is used for acquiring cutting bed site data of the cutting bed workshop and stitching site data of the stitching workshop in real time; a cut piece supermarket intelligent storage management module which is used for acquiring cut piece site data in a cut piece supermarket, calculating reserved shelf-position information in the cutting bed workshop and calculating the shelf-position location information and shortest path information of the stitching workshop; an automatic conveying module which is used for controlling an automatic conveying vehicle to convey cut pieces in the cut piece supermarket to the stitching workshop and conveying the cut pieces to the cut piece supermarket to the cutting bed workshop; and a database server which is used for receiving and storing the stitching site data, the cutting bed site data and the cut piece site data.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

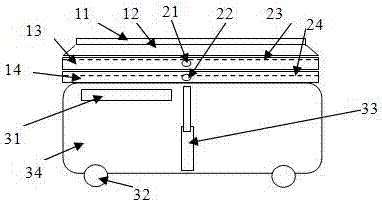

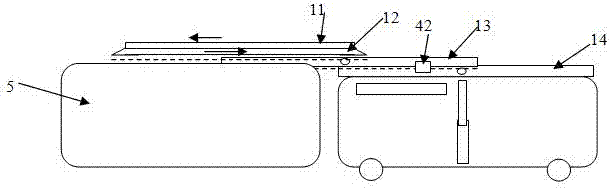

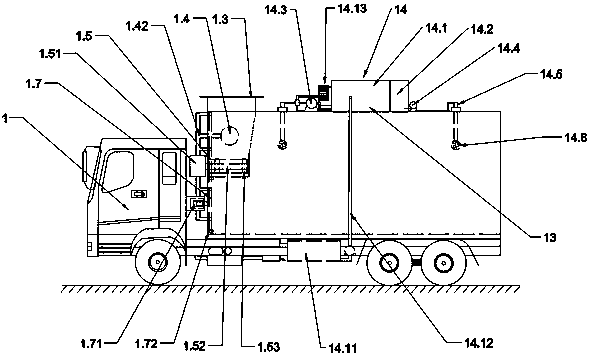

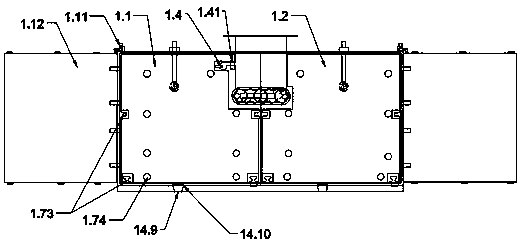

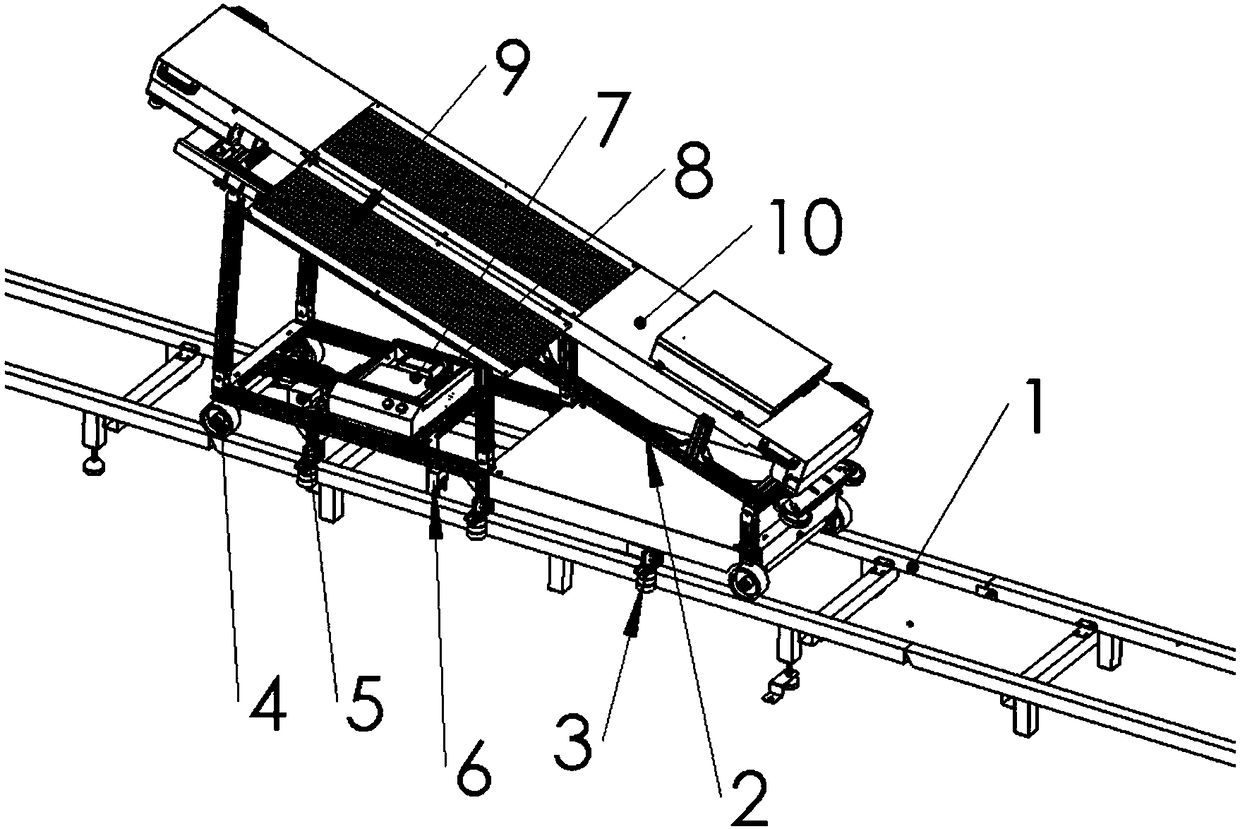

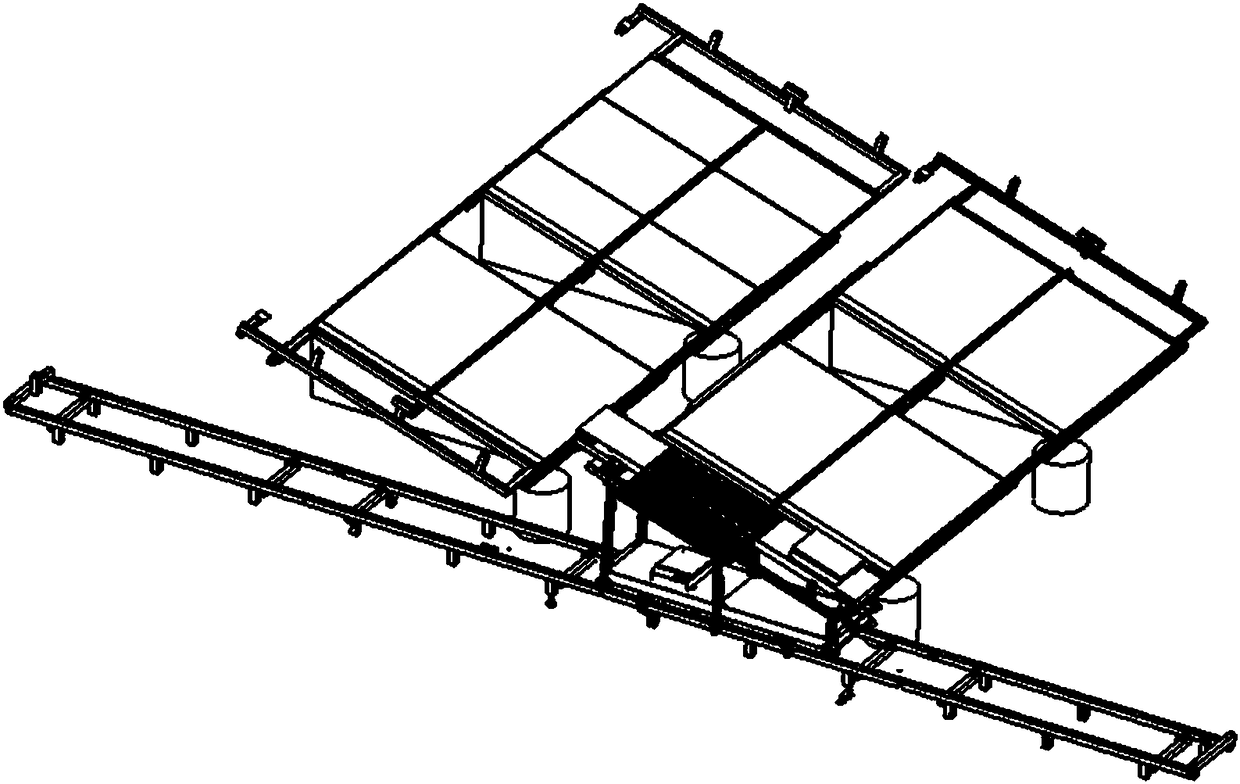

Photovoltaic array operation cleaning robot automatic transport vehicle

InactiveCN108471290AIncrease profitHigh return on investmentPhotovoltaicsRailway transportGear driveControl system

The invention provides a photovoltaic array operation cleaning robot automatic transport vehicle comprising an operation cleaning robot, a transport track, a transport framework, a running gear, a driving device and a control system; the running gear drives the transport framework to move on the transport track; the operation cleaning robot and the driving device are arranged on the transport framework; the driving device drives the running gear; the control system controls the driving device and exchanges information with the operation cleaning robot. The design is excellent, only one photovoltaic array operation cleaning robot automatic transport vehicle can clean a plurality of photovoltaic arrays, thus reducing equipment investment, and greatly improving the operation robot utilizationrate and investment rate of return; the photovoltaic array operation cleaning robot automatic transport vehicle is high in automation level, far higher in the cleaning efficiency when compared with the manual works, thus reducing the operation personnel risks.

Owner:SHANGHAI ANXUAN AUTOMATION TECH CO LTD

Automatic brake truck transport robot

The invention belongs to the technical field of robots, and relates to an automatic brake truck transport robot, comprising an automatic transport vehicle and a plurality of trucks which are matched.The automatic transport vehicle comprises a lower blocking portion, each truck comprises an upper blocking portion, the lower blocking portion comprises a convex V-shaped blocking body, the upper blocking portion comprises a concave V-shaped blocking body matched with the convex V-shaped blocking body, two linear guide devices used for making the concave V-shaped blocking body to telescope front and back, and springs sleeved on the linear guide devices and used for making the concave V-shaped blocking body to return; and the bottom of a frame is provided with a brake device, and the brake device comprises a brake line of which the upper end is connected to the concave V-shaped blocking body and a brake pad hanging at the bottom of the brake line. According to the robot, when the automatictransport vehicle and the trucks are locked, the concave V-shaped blocking bodies retreat to make the brake line naturally sag, so that the brake pad makes contact with the ground, in this way, the trucks can be stopped on the flat road without easily moving.

Owner:SUZHOU BOZHON ROBOT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com