Kilogram group weight automatic calibration device

A verification device and weight technology, applied in the field of weight verification, can solve problems such as error-prone, low efficiency of weight verification, hidden safety hazards of manual handling of weights, etc., to achieve easy coverage, scientific and reasonable physical labor, and elimination of safety hazards Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

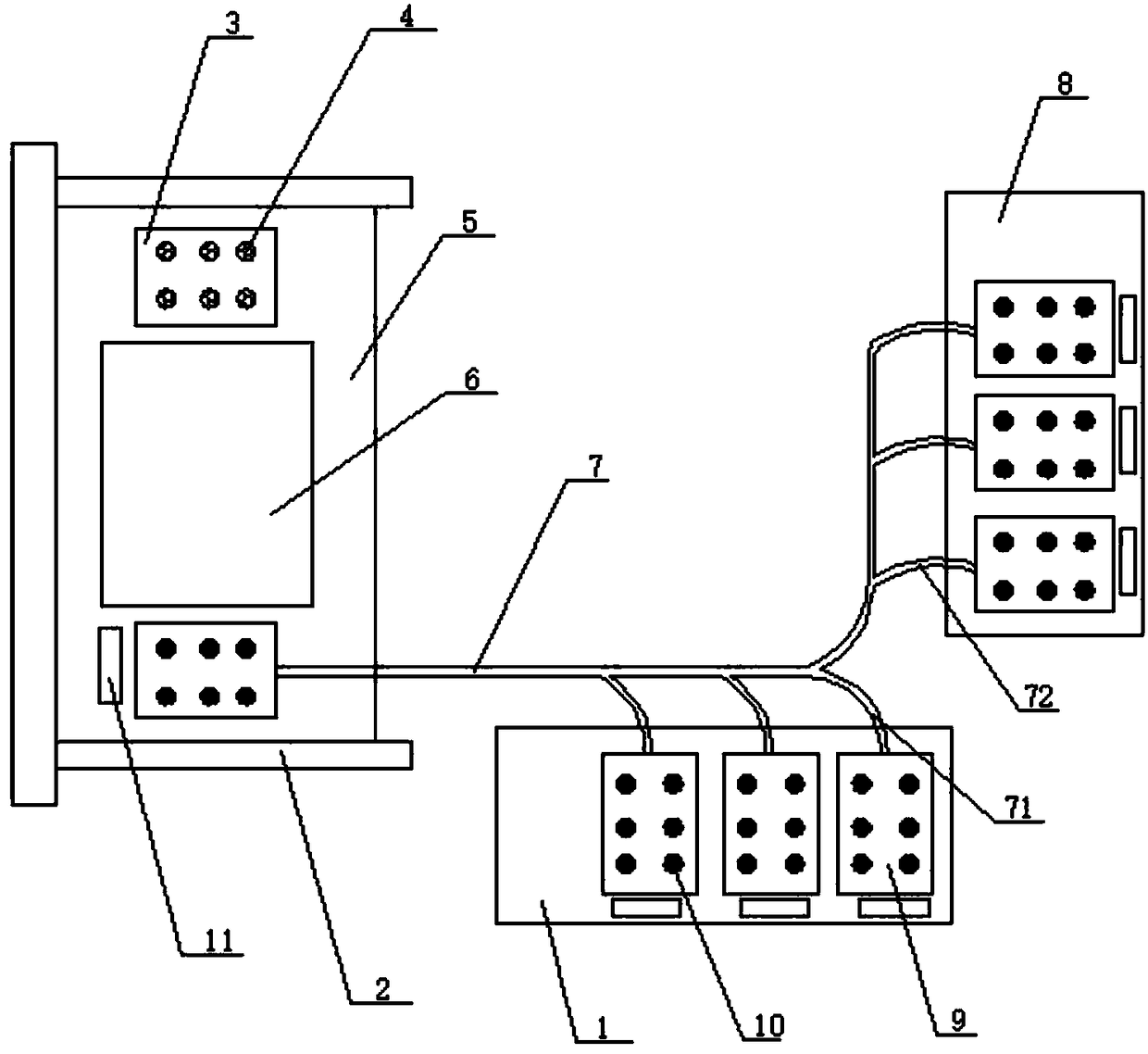

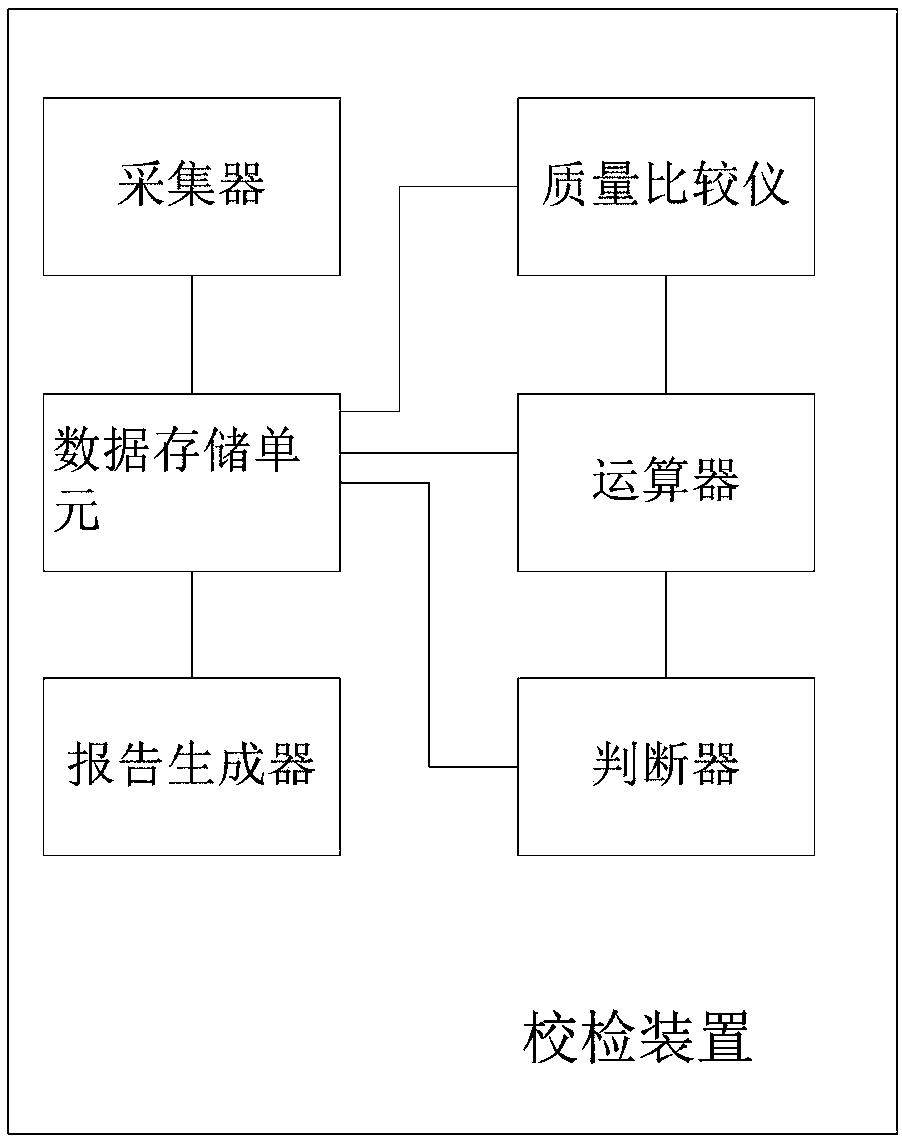

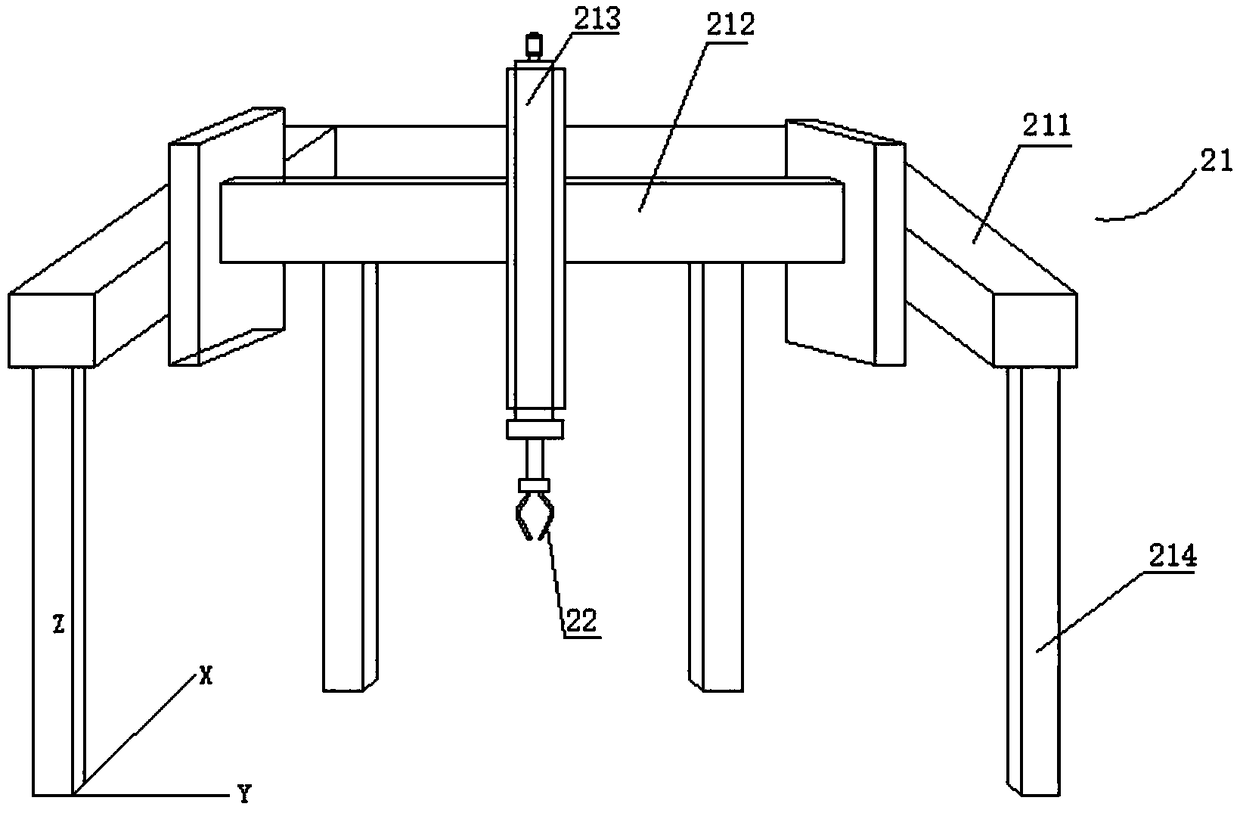

[0028] In order to solve the problems existing in the prior art, the present invention provides an automatic verification device for kilogram group weights, such as figure 1 , figure 2 and image 3 As shown, the device includes an area to be verified 1, an area to be verified 2, an area 8 that has been verified, a weight pick-and-place device 2, an automatic transport vehicle 9 and a transport track 7, and the area to be verified 1 is used to place the area to be verified The test weight 10, the test area 5 is used to test the test weight 10, and the test area 8 is used to place the test weight 10 that has been tested. The weight pick-and-place device 2 is used to realize the loading and unloading of the tested weight 10 and the standard weight 4, and the automatic transport vehicle 9 is used to realize the testing of the tested weight 10 in the area 1 to be verified, the verified area 5 and Transportation between certified areas 8.

[0029] Further, the verification devic...

Embodiment 2

[0053] Different from Embodiment 1, in this embodiment, the transport track 7 is one, and the verified area 8 and the area 1 to be verified are used in combination. When the system starts to work, the automatic transport vehicle 9 will wait for verification. The tested weight 10 in area 1 (verified area 8) is transported to the temporary storage platform, and the verification of the tested weight 10 is completed by the mass comparator on the verification workbench 6. After the verification of the tested weight 10 is completed, The automatic transport vehicle 9 returns the tested weight 10 completed on the transport track 7 to the corresponding position of the verified area 8 (area 1 to be verified) on the transport track 7, and the tested weight completed on the automatic transport vehicle 9 10 After all unloading is performed, the checked weight 10 whose information has been entered is loaded again, and the above verification steps are repeated.

[0054] Further, in this embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com