Automatic transport vehicle system with robotic arm and control method thereof, and robot system

A technology of automatic transport vehicles and robot arms, which is applied in the direction of program control manipulators, manipulators, manufacturing tools, etc., and can solve the problems of restrictions, low degrees of freedom, and low moving accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

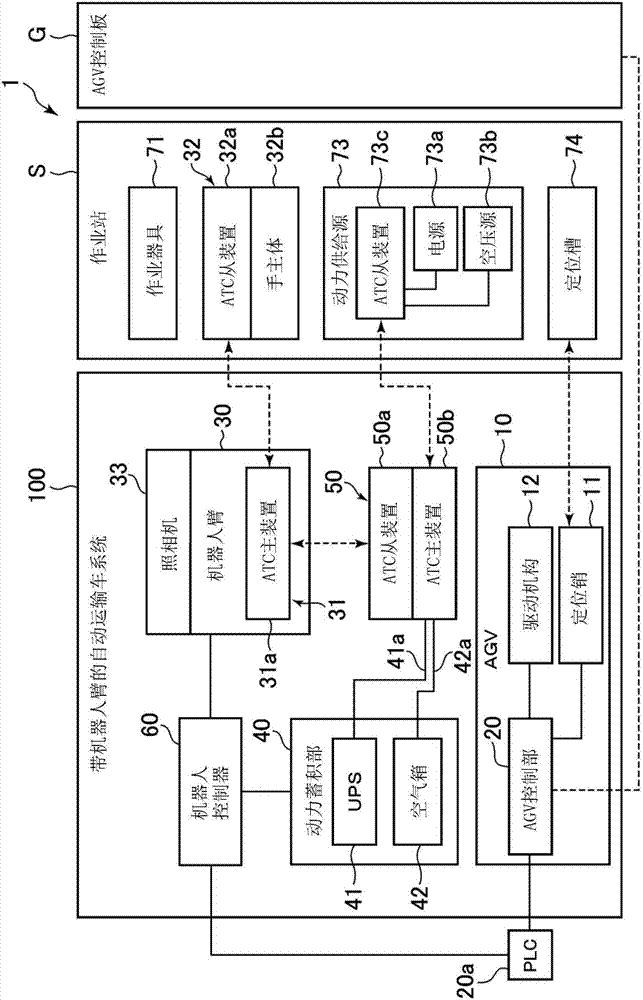

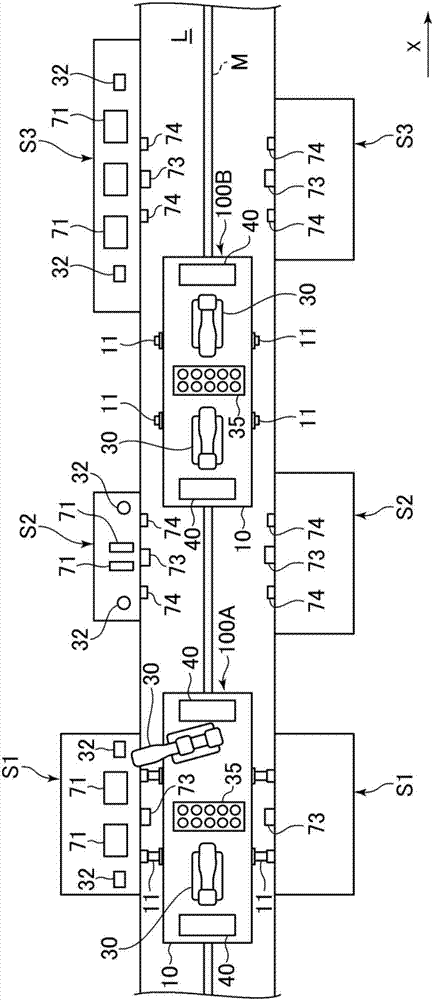

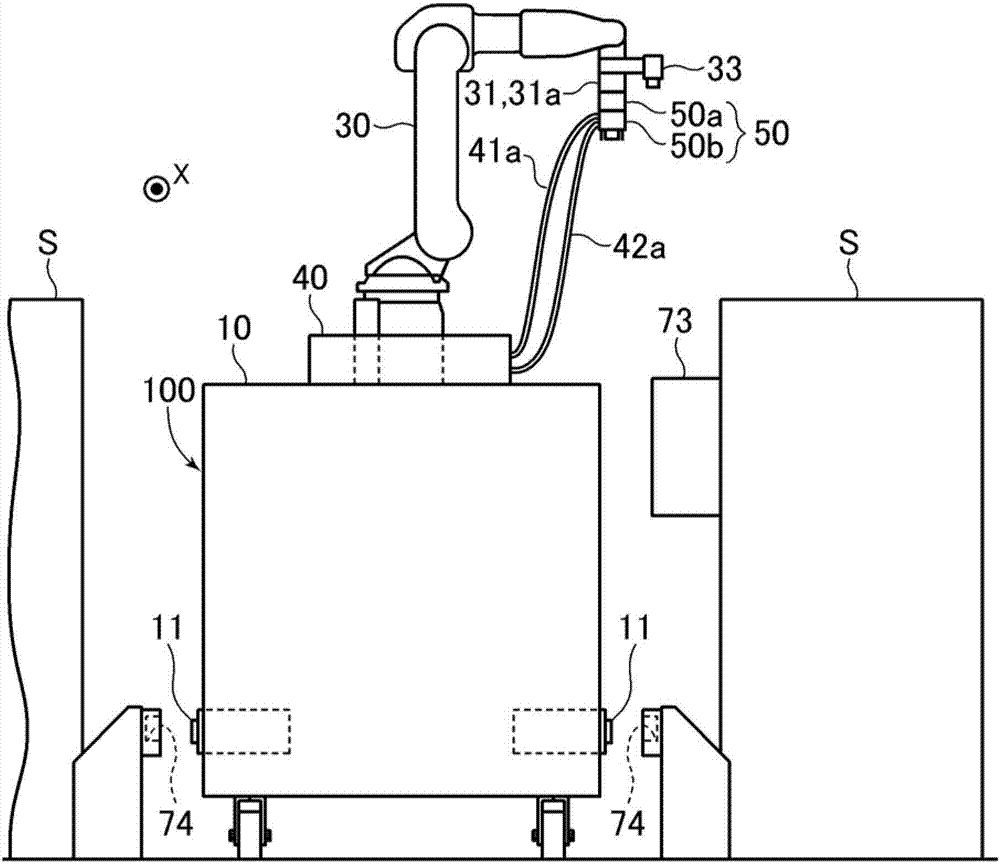

[0033] First, refer to figure 1 , the outline of the overall configuration of the robot system according to the embodiment of the present invention (hereinafter referred to as the present embodiment) will be described. figure 1 It is a block diagram showing the physical system configuration of the robot system of this embodiment. The robot system 1 includes an automatic transport vehicle system 100 with a robot arm, a work station S and an AGV control panel G. In this figure, physical connections such as wired connections and piping are indicated by solid lines, non-contact communications such as wireless connections are indicated by dotted lines, and detachable connection relationships are indicated by dotted double arrows.

[0034] In the automatic transport vehicle system 100 with a robot arm, the robot arm 30 is operably mounted on an AGV (Automatic Guided Vehicle: automatic guided vehicle) 10 . The AGV 10 includes an AGV control unit 20 for controlling the operation of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com