Automatic induction positioning charging skip transportation robot

A technology of automatic sensing and automatic transport vehicles, applied in the field of robots, can solve problems such as damage to the appearance surface and collisions, and achieve the effect of avoiding collisions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

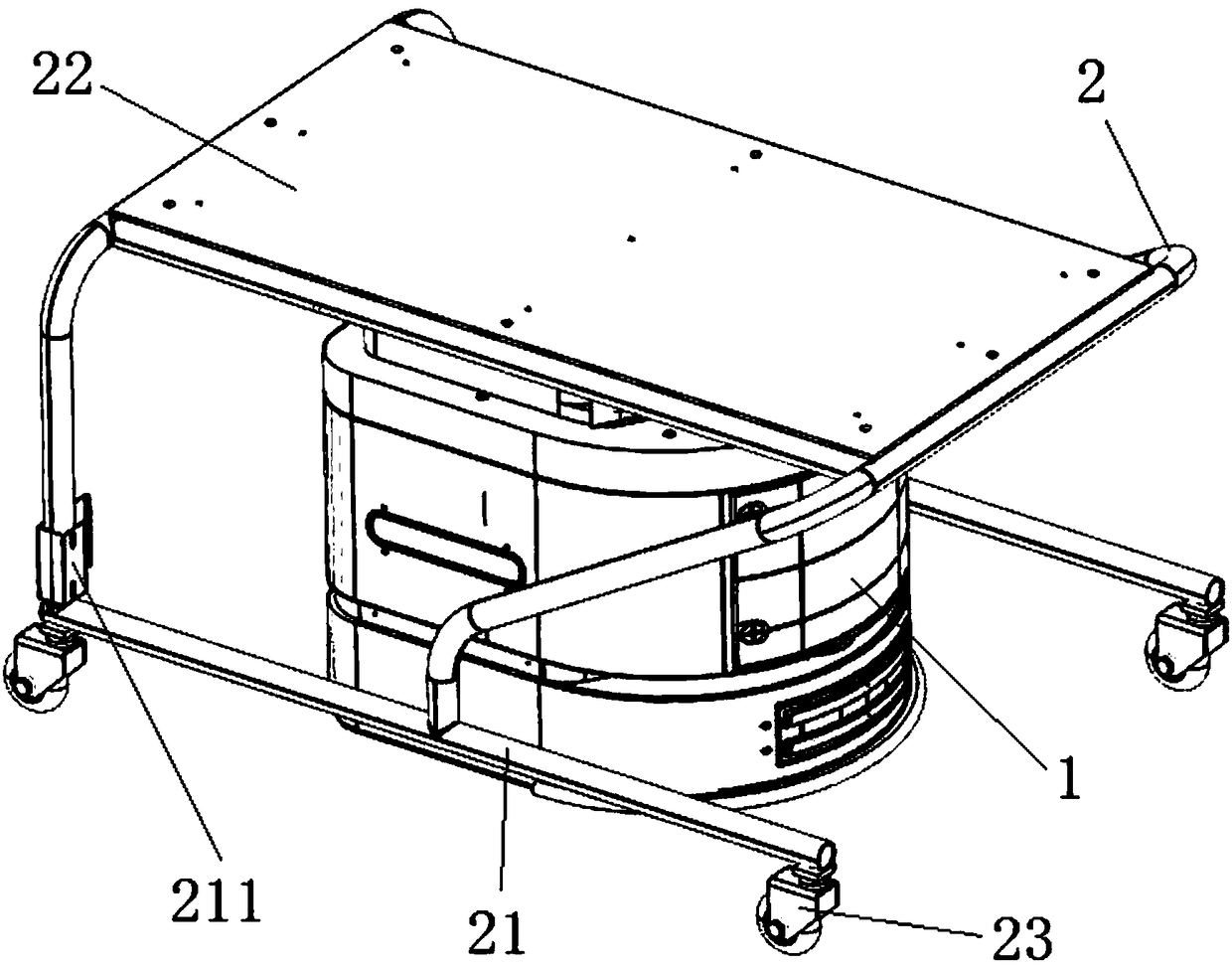

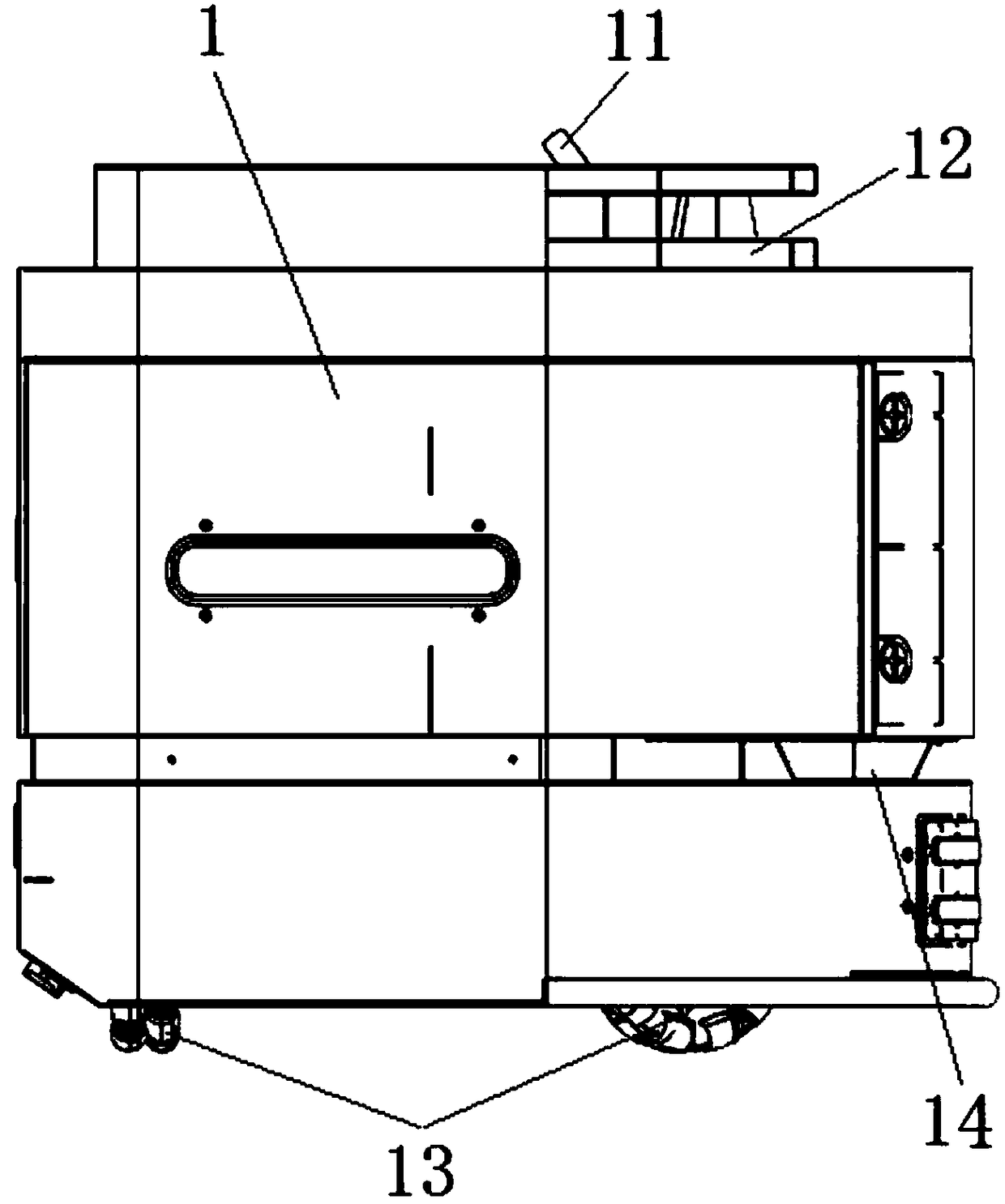

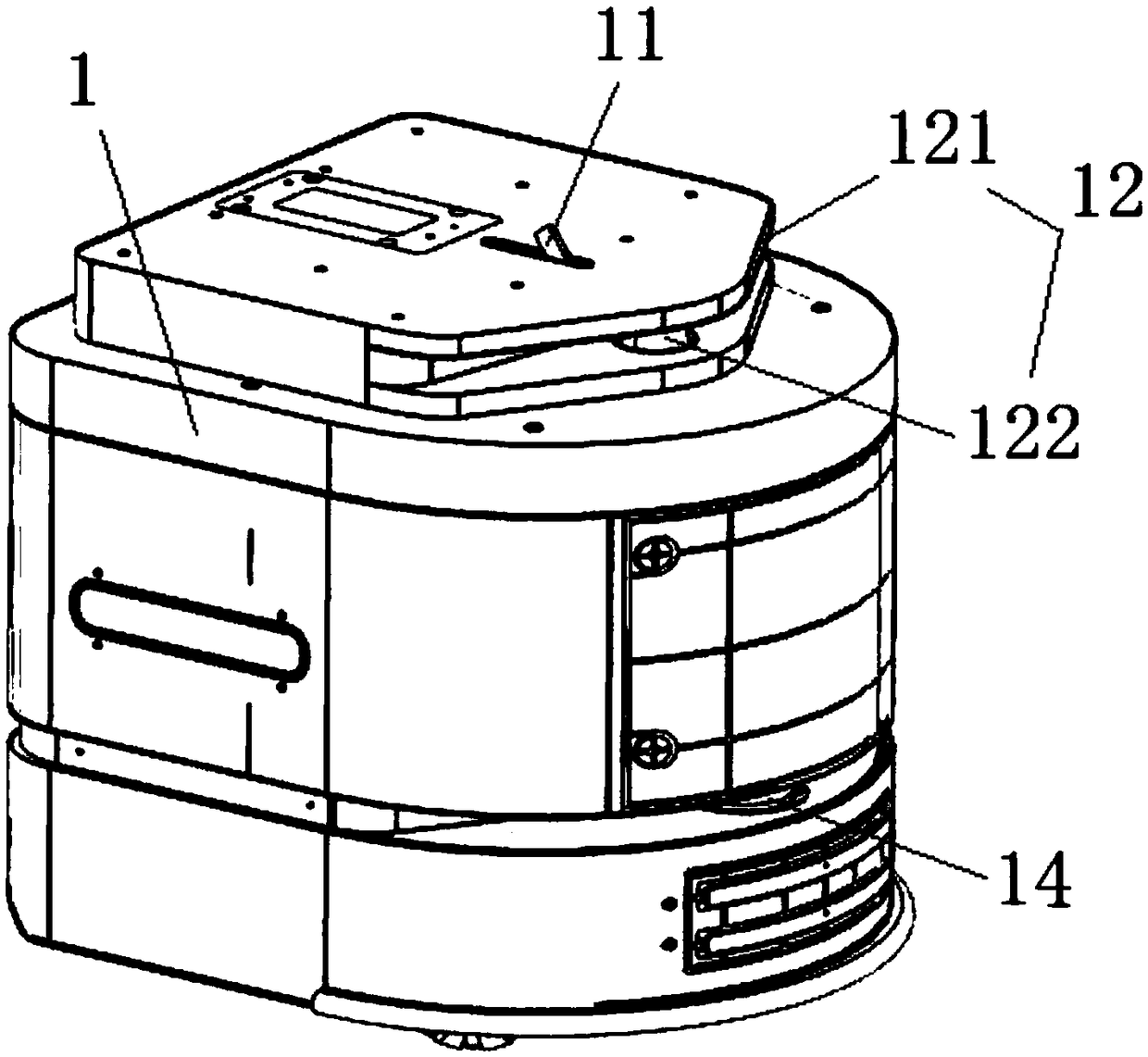

[0048] like Figure 1 to Figure 7 As shown, the present invention is an automatic induction positioning material truck transport robot, including a supporting automatic transport vehicle 1 and a plurality of material vehicles 2, the automatic transport vehicle 1 includes a hook device 11 located in the middle of the top surface, and is located in the front of the top surface. The lower blocking part 12 of the upper part, the omnidirectional wheel device 13 located on the bottom surface and the lower laser radar sensor 14 located at the front; A number of moving wheels 23 below and an upper stopper 24 fixed on the bottom of the desktop 22 and matched with the lower stopper 12, the bottom of the desktop 22 is provided with a locking groove 221 for fixing the hook device 11, and the automatic transport vehicle 1 is accommodated in the frame 21, the frame body 21 avoids the detection area of the lower laser radar sensor 14; the lower blocking part 12 includes a convex V-shaped b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com