Automatic casting blank lifting roller way system and application method thereof

A roller table system and automatic lifting technology, which is applied in the direction of hoisting devices, lifting equipment safety devices, etc., can solve the problems such as the inability to realize the raising and lowering of casting slabs, and achieve the effects of ensuring the level, avoiding unbalanced load, and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

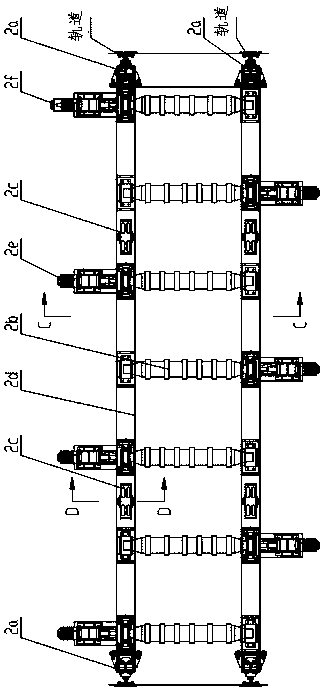

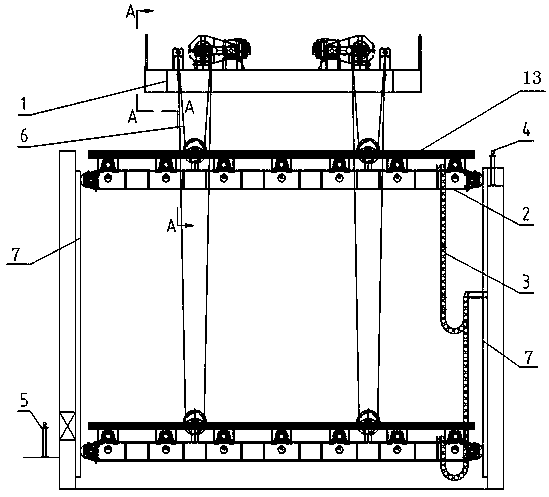

[0044] In order to solve the problem that the existing slab lifting system cannot realize the lifting and lowering of the slab with a super large height difference of more than 2 meters, this embodiment provides a slab automatic lifting roller table system, such as figure 1 and figure 2 , image 3 As shown, it includes the lifting device 1 fixed on the upper foundation 8. The lifting roller table 2 sliding up and down along the track 7 is suspended below the lifting device 1 through the wire rope 6. The lifting roller table 2 is used to carry the billet, receive and transport the casting Blank, the entrance side of the lifting roller table 2 is provided with a photoelectric switch 1 4 installed on the top of the lower foundation 9, and the outlet side is provided with a photoelectric switch 2 5 installed at the bottom of the lower foundation 9; as Figure 7 , Figure 8 and Figure 9As shown, the lifting roller table 2 includes a guide wheel 2a, a roller 2b, a pulley 2c, a ...

Embodiment 2

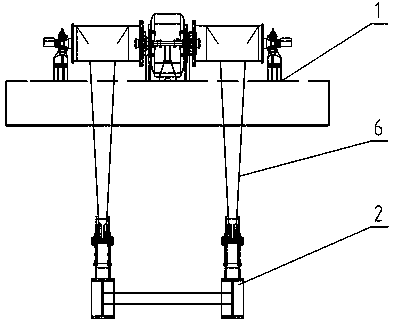

[0049] On the basis of Example 1, such as Figure 4 , Figure 5 and Figure 6 As shown, the lifting device 1 includes a base 1k fixed on the upper foundation 8. Two sets of independent and symmetrical transmission systems are installed on the base 1k. Each transmission system includes a speed reducer 1e installed on the base 1k. The motor 1e is provided with two input shafts and two output shafts, one of which is connected to the motor 1c through a coupling, and the brake 1d is installed on the coupling and the other input shaft, and the two output shafts of the reducer 1e Each reel 1b is equipped with a balance arm 1a installed on the base 1k. One end of the wire rope 6 is connected to the balance arm 1a, and the other end is wound around the pulley 2c on the reel 1b.

[0050] Such as Figure 5 As shown, the motor 1c is connected to the base 1k through bolts, the reducer 1e is connected to the base 1k through bolts, the reducer 1e has two input shafts, both input shafts ar...

Embodiment 3

[0052] On the basis of Example 2, such as Figure 6 As shown, an absolute encoder 1g is installed at the tail of each reel 1b, a weight switch 1f installed on the base 1k is installed under the bearing seat of the reel 1b, and a load cell is also installed on the base 1k 1h. An overspeed protection switch and an incremental encoder are installed at the tail of the motor 1c.

[0053] In the lifting device 1, four absolute value encoders 1g are respectively assembled at the tails of the four sets of reels 1b, and the reading of the absolute value encoders 1g can realize the control of the lifting position and speed of the lifting roller table 1; the weight switch 1f is passed through the bolt It is connected to the base 1k, when the lifting roller table 2 rises to a certain height, the weight switch 1f is triggered, and the lifting device 1 stops; the load cell 1h is respectively installed under the bearing seat, connected to the base 1k by bolts, and passed by the load cell 1h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com