Self-operated discharging valve

An unloading valve, self-operated technology, applied in the field of unloading valves, can solve the problems of complex driving device system, energy consumption, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

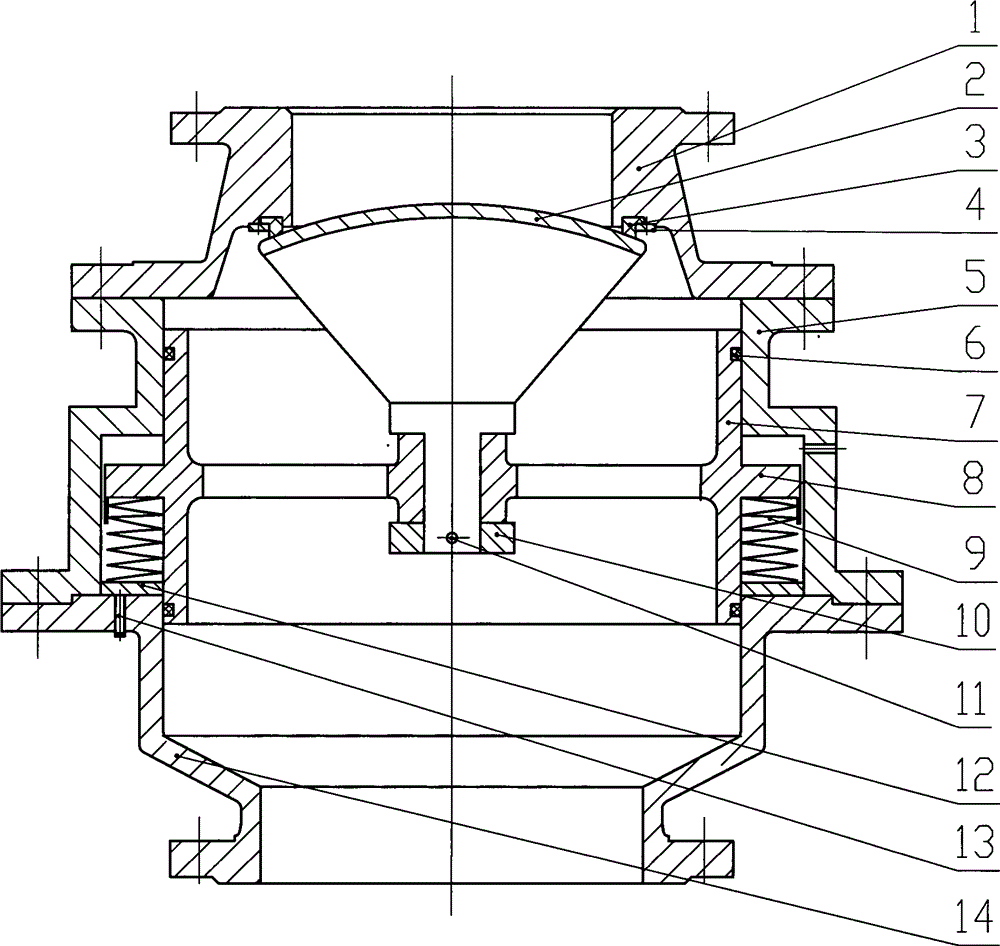

[0010] Such as figure 1 As shown, a self-operated unloading valve includes a valve cover 1, a middle valve body 5, a valve disc 2, a sealing ring 3, a pressure ring 4, and a lower valve body 14, and the sealing ring 3 is fixed on the valve cover 1 through the pressure ring 4. Inside, it forms a sealing pair with the disc 2, the valve cover 1 and the middle valve body 5, the middle valve body 5 and the lower valve body 14 are connected by fasteners, there is a piston 7 in the middle valve body 5, and the valve disc 2 rod The part extends into the piston 7, and is fixed on the piston 7 through the fixed plate 10 and the connecting pin 11. The piston 7, the middle valve body 5 and the lower valve body 14 are sealed by the O-ring 6. There is also a boss 8 on the piston 7, the convex Spring 9 is also housed between platform 8 bottom and lower valve body 14 end faces. An adjusting ring 12 is also housed in the spring 9 bottom, and several threaded holes are arranged on the lower va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com