A hydrogenation catalyst with non-uniform distribution of active metal components and its preparation

A non-uniform distribution, hydrogenation catalyst technology, applied in the direction of metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of catalyst deactivation and achieve the preparation method Simple, good metal performance, low production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Take a portion of the pseudo-boehmite wet strip and dry it at 200° C. for 5 hours. Measure its water absorption rate to be 0.76.

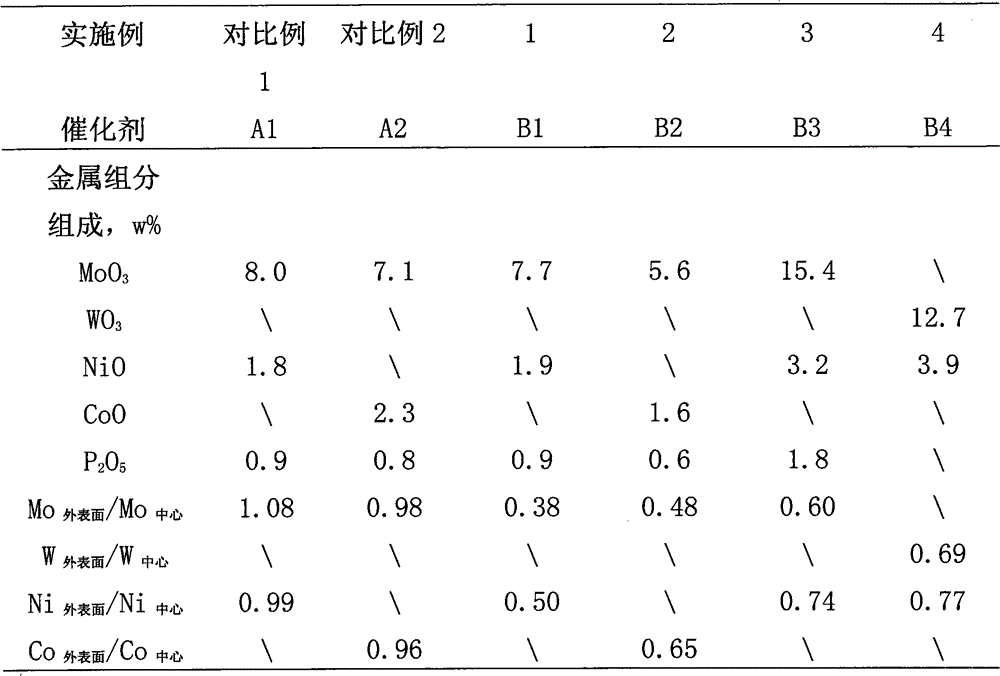

[0050] Weigh 4.0g basic nickel carbonate, 9.0g molybdenum oxide, and 1.7g phosphoric acid, add water and heat to dissolve to form 109ml nickel-molybdenum-phosphorus solution, and impregnate 143g of the aforementioned carrier with the solution for 1 hour. Thereafter, it was dried at 120° C. for 4 hours to obtain catalyst B1. Catalyst B1 metal content and distribution are listed in Table 1.

Embodiment 2

[0052] A portion of the wet pseudo-boehmite strip was taken and dried at 240° C. for 5 hours. Measure its water absorption rate to be 0.76.

[0053] Weigh 2.5g basic cobalt carbonate, 6.0g molybdenum oxide, and 1.2g phosphoric acid, add water and heat to dissolve to form 109ml cobalt molybdenum phosphorus solution, and impregnate 143g of the aforementioned carrier with the solution for 1 hour. Thereafter, it was dried at 120° C. for 4 hours to obtain catalyst B2. Catalyst B2 metal content and distribution are listed in Table 1.

Embodiment 3

[0055] A portion of the wet pseudo-boehmite strip was taken and dried at 240° C. for 5 hours. Measure its water absorption rate to be 0.76.

[0056] Weigh 25.2g basic nickel carbonate, 64.4g molybdenum oxide, 12.0g phosphoric acid, add water and heat to dissolve into 429ml nickel-molybdenum-phosphorus solution, and impregnate 143g of the aforementioned carrier with the solution for 5 hours. After filtration, it was dried at 120° C. for 4 hours to obtain catalyst B3. Catalyst B3 metal content and distribution are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com