VB group metal-containing heavy oil hydrodemetallization catalyst, preparation method thereof and heavy oil hydrotreating method

A heavy oil hydrogenation and catalyst technology, which is applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem that the performance of heavy oil hydrotreating needs to be further improved, and achieve excellent heavy oil hydrodehydration. The effect of metal properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

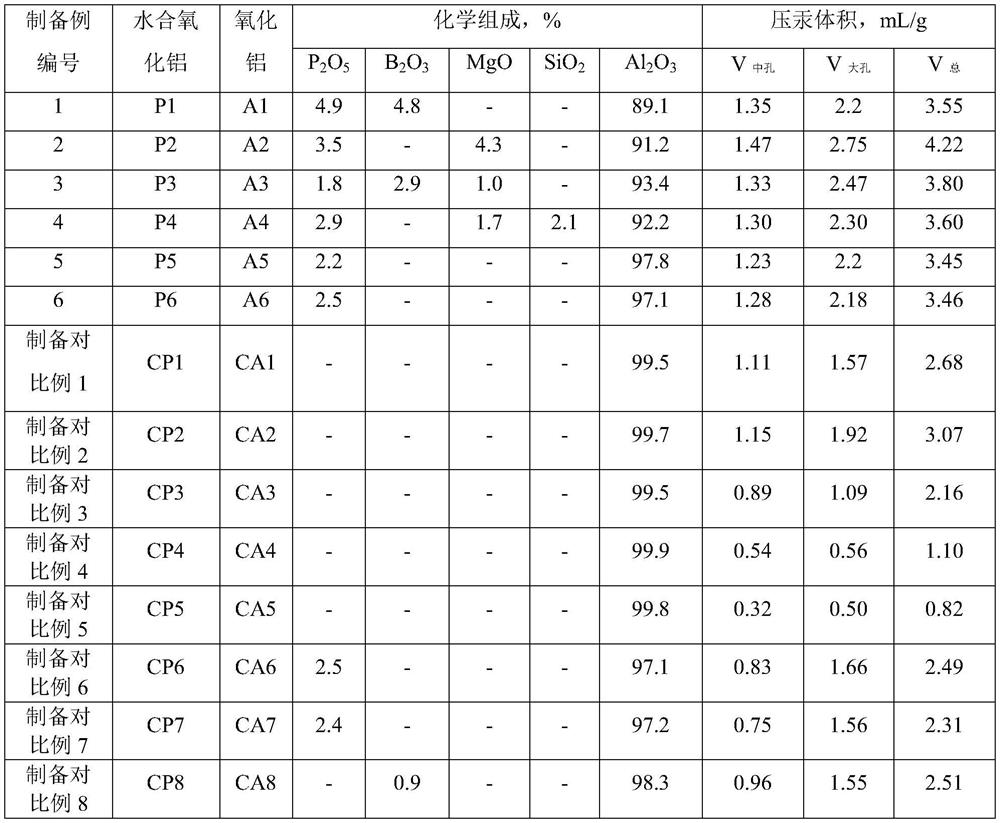

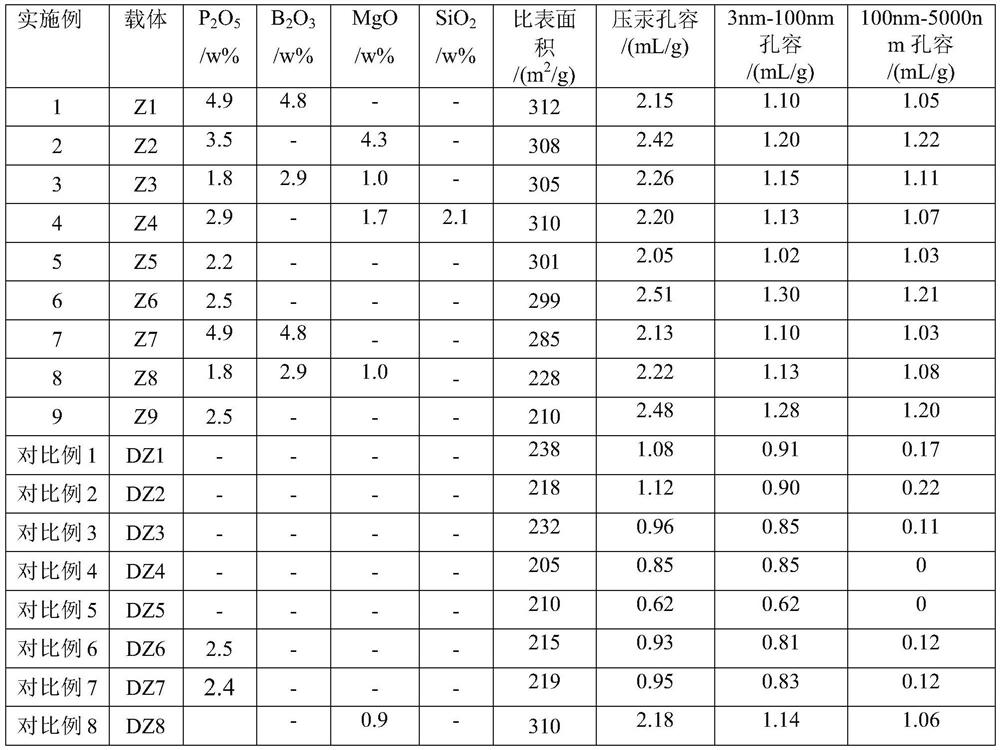

preparation example Construction

[0027] The present invention also provides a method for preparing a heavy oil hydrodemetallization catalyst, comprising the steps of preparing a phosphorous-containing alumina carrier and introducing a Group VB metal and a Group VIB metal into the carrier, wherein the Group VB metal and the Group VIB metal The amount used is such that in the finally obtained catalyst, the metal content of Group VB in terms of oxides is not higher than 12% by weight, and the content of Group VIB metals is 0.2-12% by weight; wherein, the preparation of the phosphorus-containing alumina carrier Proceed as follows:

[0028] (1) Carry out a gelation reaction under the conditions of the simultaneous presence of an aluminum-containing compound and a phosphorus-containing compound to obtain a slurry containing phosphorus-containing alumina hydrate, and the phosphorus-containing compound makes the final carrier, with P 2 o 5 The calculated phosphorus content is 0.1-8.0% by weight;

[0029] (2) adjust...

Embodiment approach

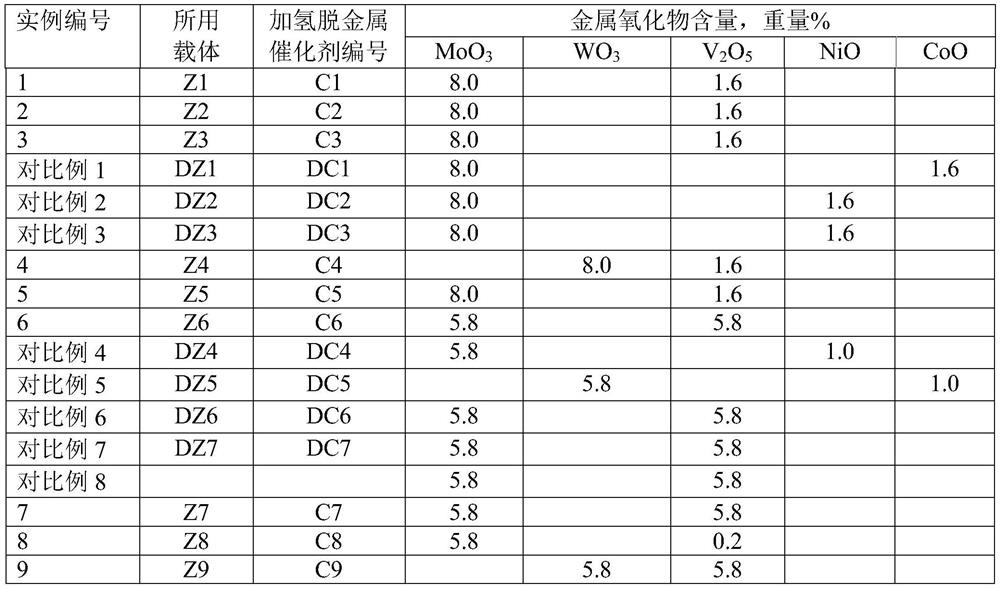

[0033] According to a preferred embodiment of the present invention, the amount of the Group VB metal and the Group VIB metal is such that in the finally obtained catalyst, the content of the Group VB metal in terms of oxide is 0.2-8% by weight, and the Group VIB metal is The metal content is 2-10% by weight.

[0034]The present invention has no particular limitation on the specific implementation and method of the step of introducing the VB group metal and the VIB group metal into the carrier, preferably, the method of introducing the VB group metal and the VIB group metal into the carrier For impregnation. Specifically, it includes preparing a solution containing a hydrogenation active metal (group VB metal and / or group VIB metal) compound and impregnating the support with the solution, followed by drying and optional calcination. The Group VB metal and the Group VIB metal may be introduced into the support sequentially (step-by-step impregnation), or jointly introduced int...

preparation example 1

[0085] (1) Preparation of Al 2 o 3 Concentration is 2L of aluminum sulfate solution of 50g / L, add 5mL concentrated phosphoric acid (concentration 85% by weight, the same below), 9.5g boric acid, obtain the aluminum sulfate solution containing phosphorus, boron element. In a 5-liter reaction tank, the above-mentioned aluminum sulfate solution and an 8% ammonia solution were added in parallel for reaction and precipitation, and then filtered (using XRD to characterize the hydrated aluminum oxide precipitation as an amorphous structure), the reaction temperature was 40 ° C, Control the flow rate of the ammonia solution to make the pH of the reaction system 5.5. In a 5-liter reaction tank, filter cake, deionized water and ammonia water are mixed and beaten. The amount of ammonia water is used to make the pH value of the slurry 8.0. The slurry is aged at 65°C for 60 minutes and filtered, and the filter cake is beaten with deionized water. After washing twice, the filter cake was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com