Glass bulb cutting fixture

A technology of glass bubbles and fixtures, applied in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve problems such as difficult connection of machines, low efficiency, and low quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

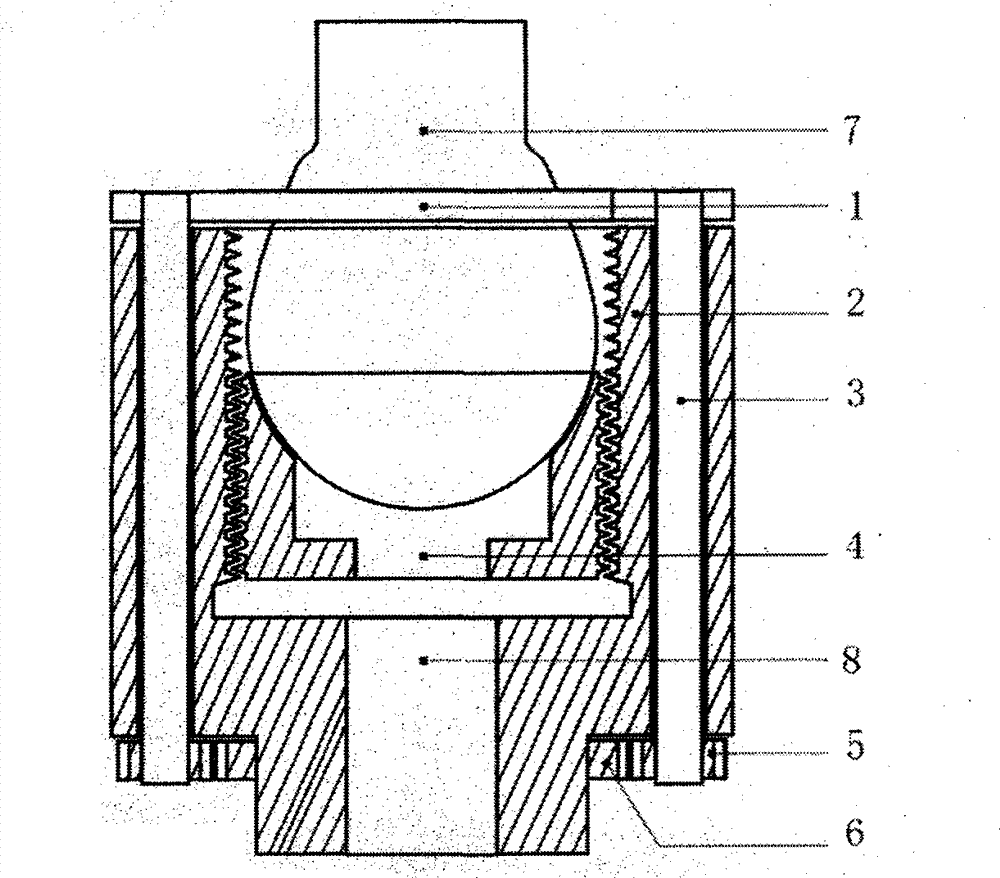

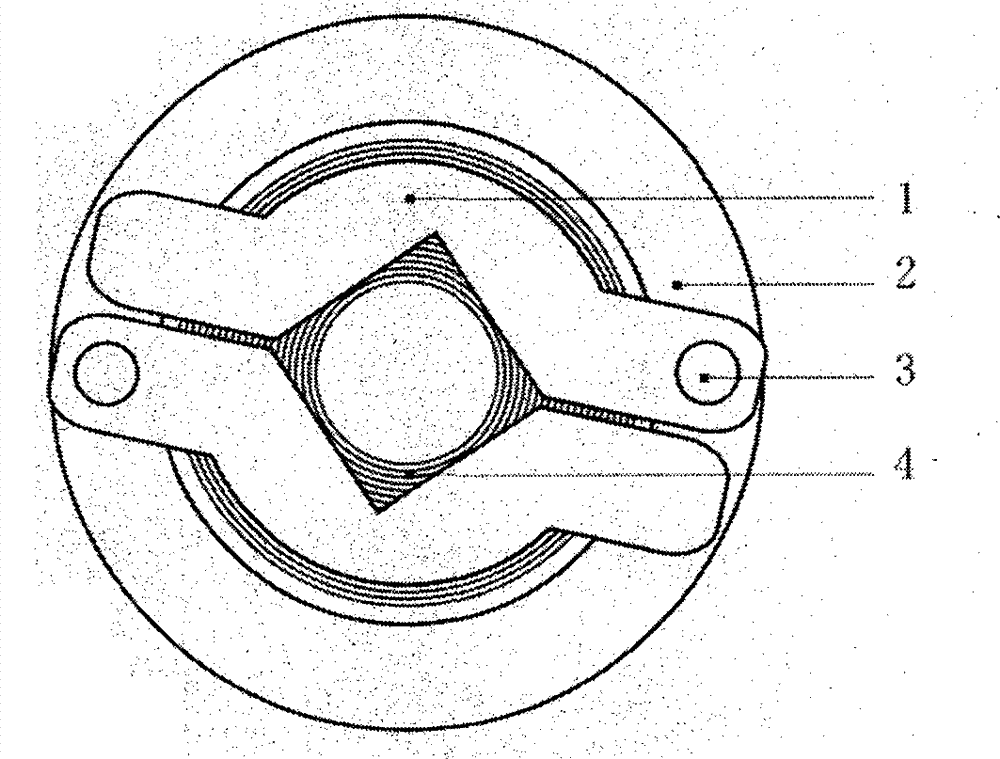

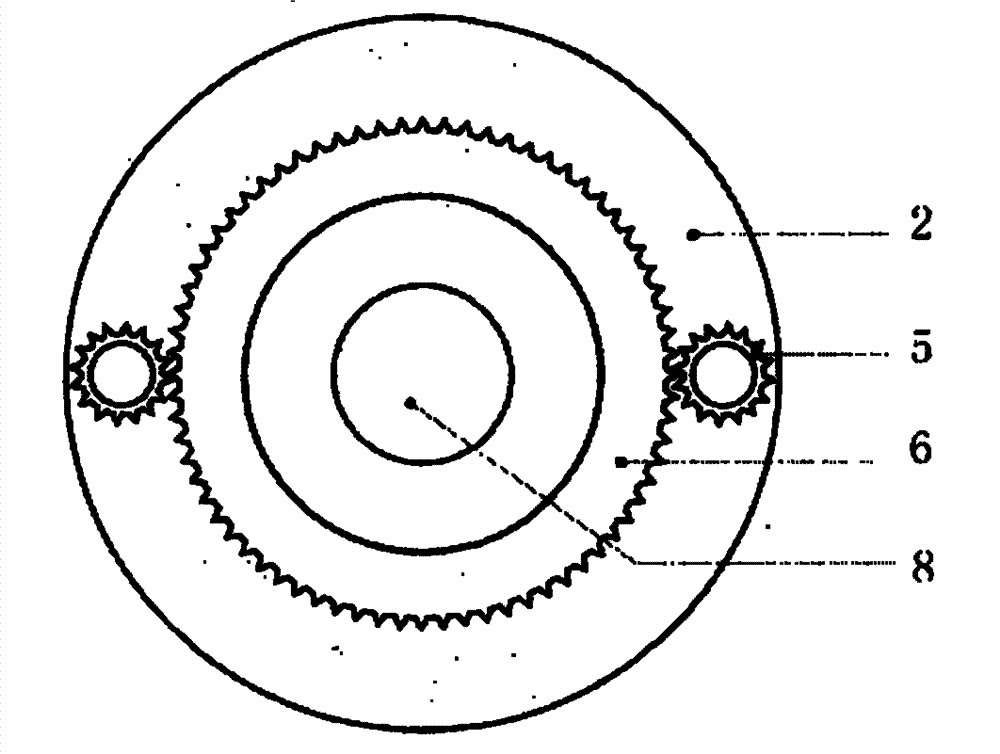

[0007] Connect the metal seat 2 of the glass bulb cutting fixture to the machine through the metal seat hole 8 connecting the machine, the machine will drive the glass bulb cutting fixture to rotate as a whole, and the manipulator on the machine can control the large gear 6 on the metal seat, and the metal When the big gear 6 on the seat rotates, it will drive the pinion gear 5 on the gripper shaft. Since the pinion gear 5 on the gripper shaft is connected to the gripper 1 through the gripper shaft 3, the gripper 1 will follow the glass bulb cutting jig at the specified time. The working station is automatically opened or closed under the control of the machine. When it is opened, the universal base 4 of the bulb is exposed. At this time, put the glass bulb 7 to be cut on the universal base 4 of the bulb, and enter the next station. , at the same time, the fixture 1 will be closed with the change of the station. The fixture 1 will firmly clamp the glass bulb 7 and enter the fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com