Heat supply regulating and controlling method based on water mixing device

A control method and water mixing technology, applied in space heating and ventilation, space heating and ventilation details, heating methods, etc., can solve problems such as non-compliance with heating characteristics, large electrical energy consumption, and energy waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

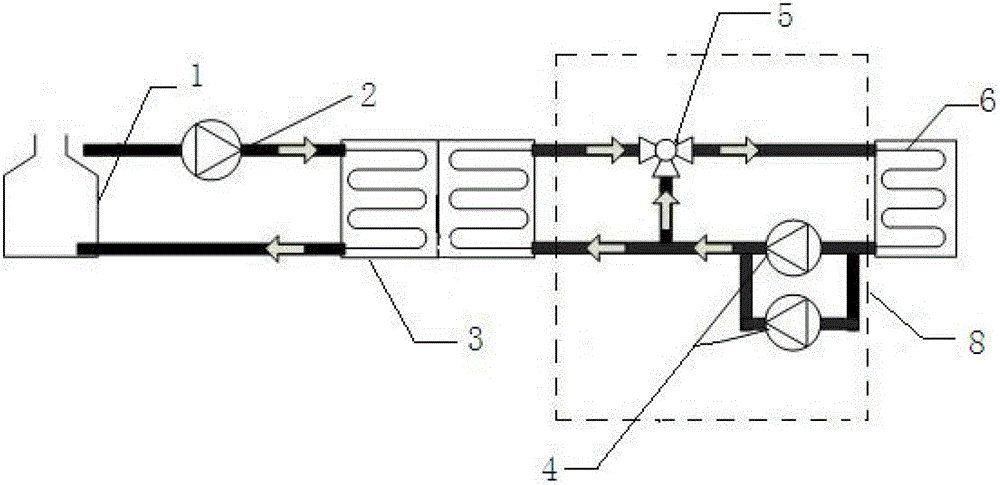

[0085] (1) Adjustment and control of water mixing mode of single heat exchanger

[0086] The overall regulation and control strategy during the heating period is: according to figure 1 Schematic diagram of the water mixing mode of a single heat exchanger. By adjusting the opening of the three-way valve, the ratio of the flow through the heat exchanger to the flow of the bypass pipe is controlled to control the temperature of the water supply flowing through the heat exchanger in the building. , and the temperature of the temperature sensor installed in the end room is used as the feedback signal, and the temperature of the end room is controlled to the set heating temperature through the frequency conversion adjustment of the secondary side circulation pump located on the return flow of the main pipe. The control method is room constant temperature adjustment. The automatic loading control strategy of the circulating pump is: when the heat supply load is small, only one circul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com