A dimensional arc chopper control circuit and cutting machine

A control circuit and arc cutting technology, applied in manufacturing tools, arc welding equipment, welding equipment, etc., can solve the problem that the chopping power switch tube IGBT has no fixed frequency, the loss of gun electrodes and nozzles, and the arc arc is easy to break. and other problems, to achieve the effect of solving the problem of arc starting and arc breaking, fast cutting transfer, and stable arc current.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

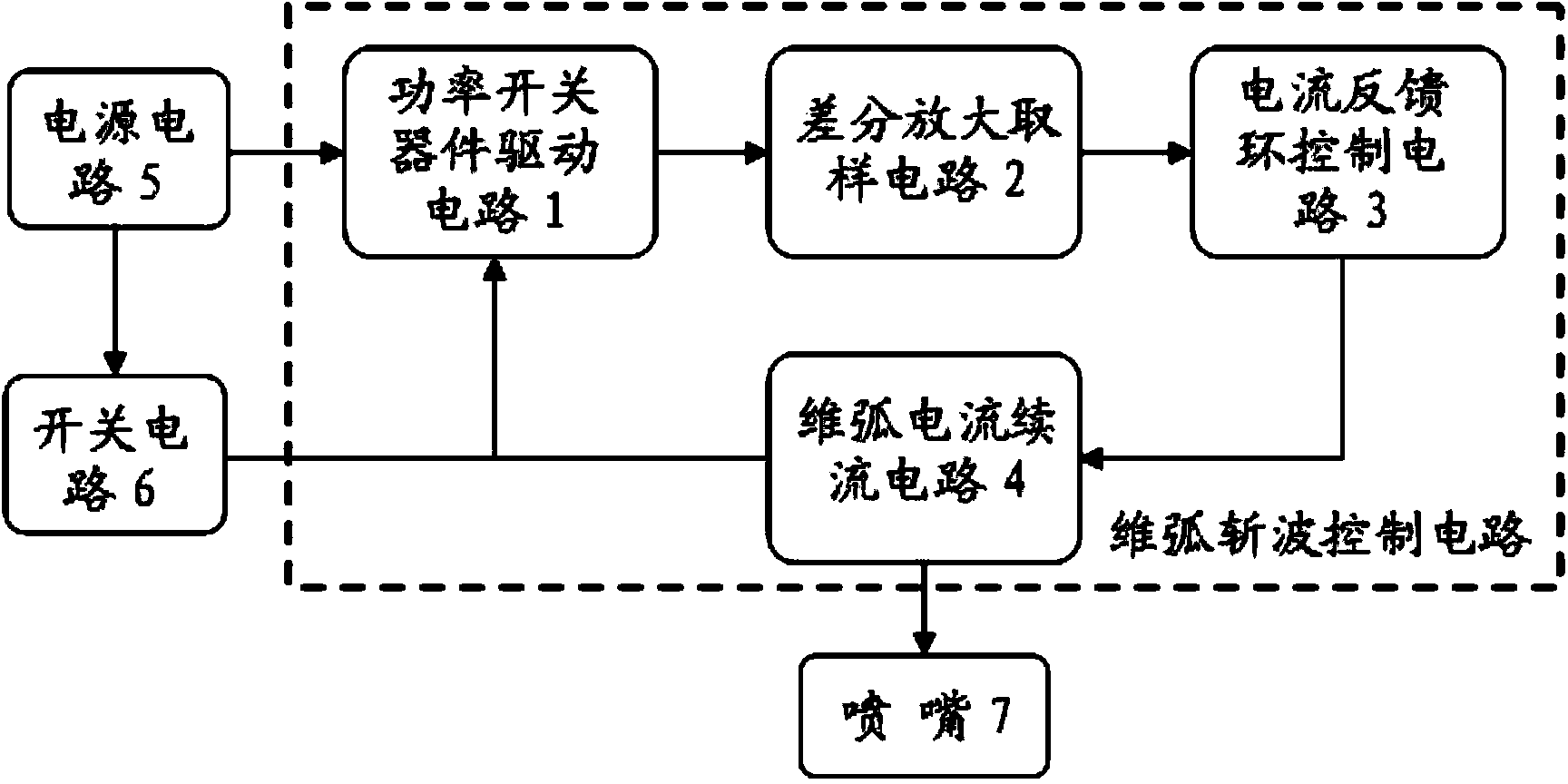

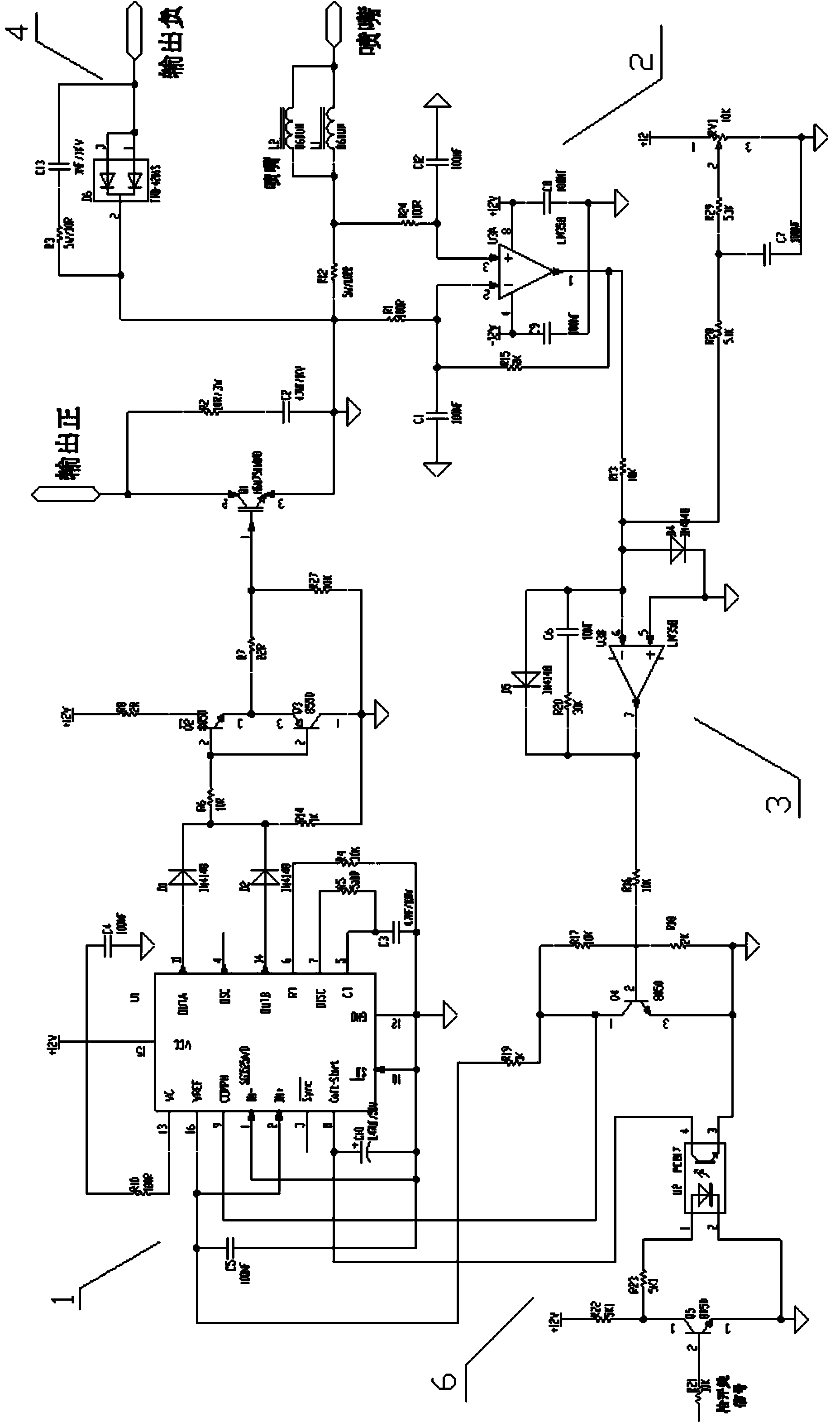

[0023] Such as figure 1 and to figure 2 as shown in:

[0024] An arc-dimensioning chopper control circuit described in an embodiment of the present invention includes a power switch device drive circuit 1 for generating a pulse width regulation drive signal and limiting the current of the power switch tube under low power grid input conditions, and a drive circuit for controlling the current of the power switch tube. A differential amplification sampling circuit 2 for sampling and amplifying the current input by the low power grid, a current feedback loop control circuit 3 for adjusting the pulse width and adjusting the pulse width of the driving signal according to the amplified current signal, and a current feedback loop control circuit 3 for when the power switch is turned off When it is off and the output negative terminal is positive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com