Driving control system with multiple LED (light emitting diode) loads for automobile

A drive control and automotive technology, applied in lighting devices, light sources, electric light sources, etc., can solve problems such as excessive voltage and reduce the service life of LED lights, and achieve the effects of improving stability, improving work efficiency, and shortening feedback time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

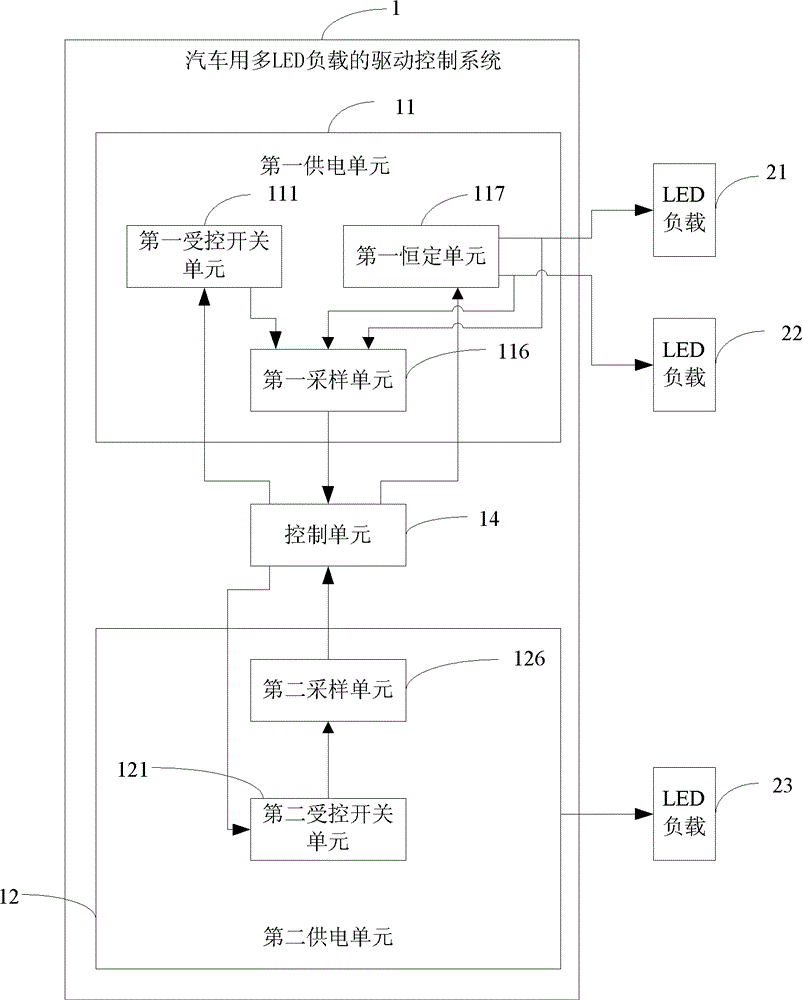

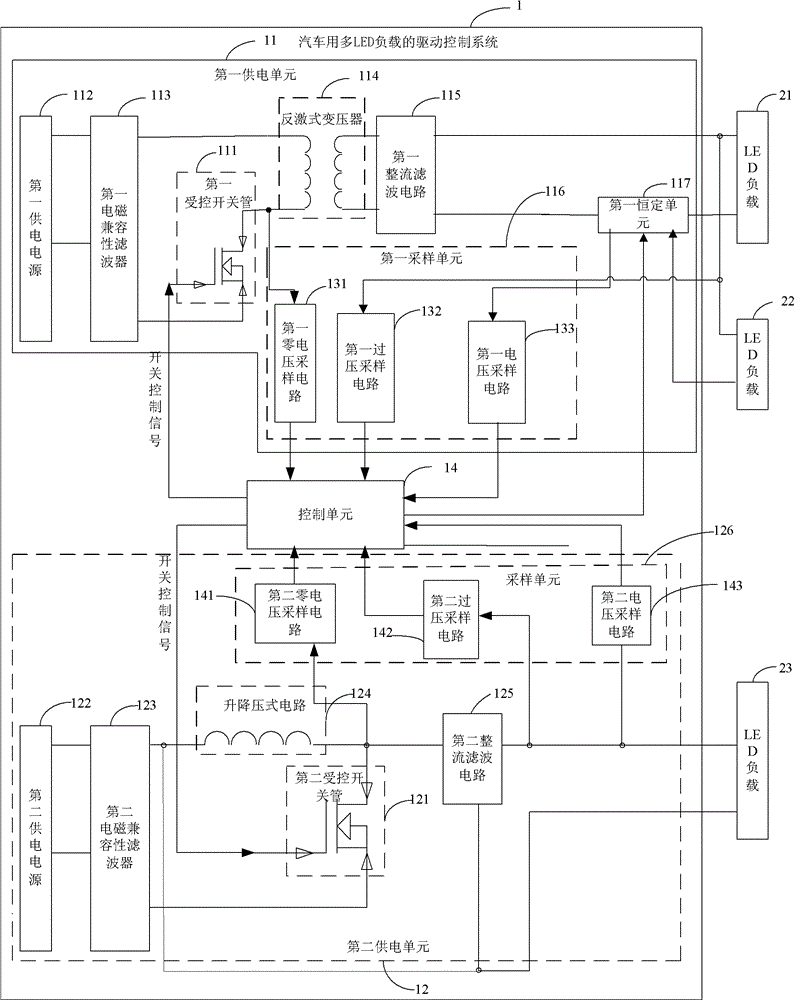

[0037] figure 1 It shows a structural schematic diagram of the drive control system for multiple LED loads used in automobiles of the present invention. The drive control system 1 for multiple LED loads for automobiles includes: a first power supply unit 11 , a second power supply unit 12 and a control unit 14 .

[0038] Wherein, the first power supply unit 11 includes: a first power supply 112 , a first controlled switch unit 111 , a first sampling unit 116 and a first constant unit 117 .

[0039] Preferably, the first controlled switch unit 111 includes a power switch transistor, more preferably, includes but not limited to a controlled switch transistor.

[0040] The first power supply unit 11 is used for provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com