Piston type hidden hinge capable of being adjusted in six directions

A hidden hinge technology, applied in the field of hidden hinges, can solve problems such as time-consuming, insufficient hinge bearing capacity, and easy sagging affecting opening, etc., to achieve the effects of increasing installation difficulties, prolonging service life, and strengthening bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

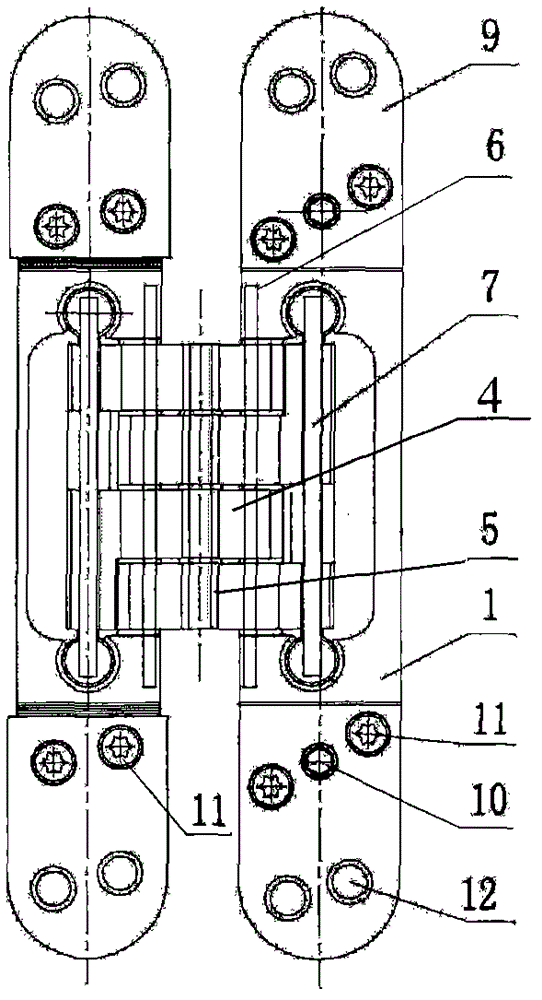

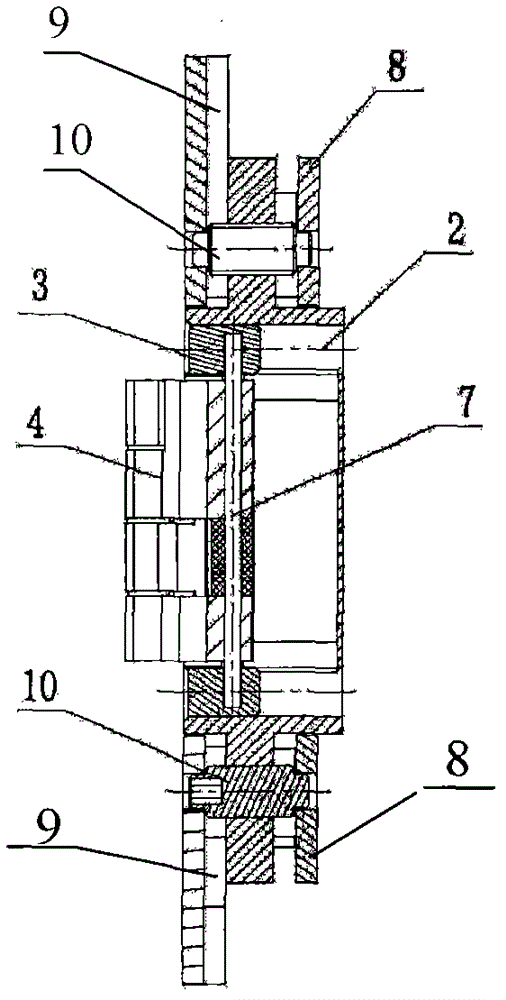

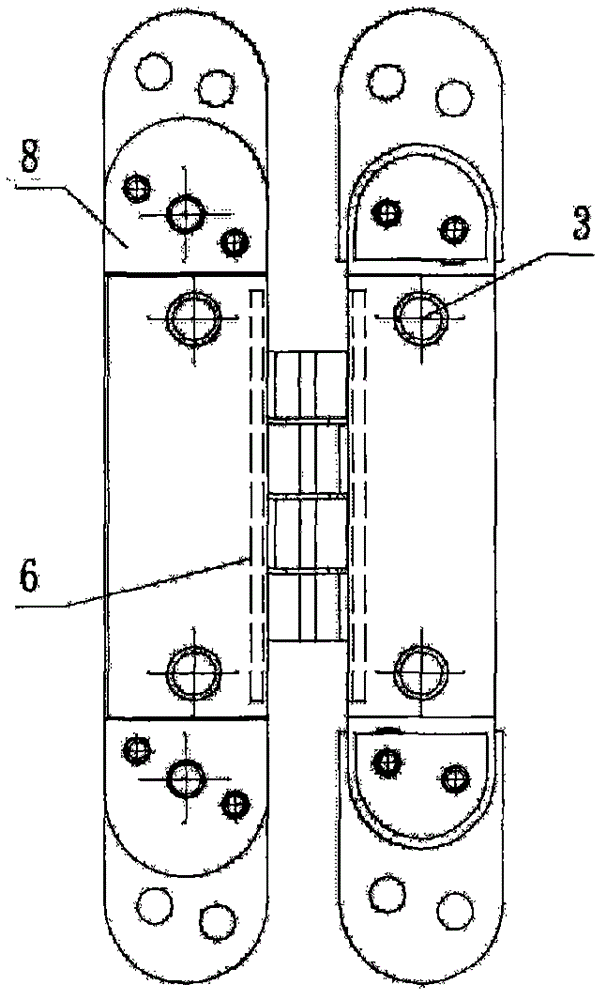

[0014] Such as figure 1 figure 2 image 3 As shown, the piston-type hidden hinge that can be adjusted in six directions includes two bases 1 on the left and right. The base 1 is provided with two column-shaped rail-fixing grooves 2 up and down, and the column-shaped rail-fixing groove 2 is provided with Cylindrical movable plug 3; there are four connecting pieces 4, two connecting pieces 4 are respectively arranged on the left and right bases 1 through two attached shafts 6, and the other two connecting pieces 4 are set on the left and right bases 1 through two moving shafts 7 Installed on the left and right column-type movable plugs 3; the connecting piece 4 on the left base 1 and the connecting piece 4 on the right base 1 are hinged together through the main shaft 5; the surfaces at both ends of the base 1 are respectively provided with adjustment plates 8 and movable plate 9, front and rear adjustment screws 10 are provided between the adjustment plate 8 and the movable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com