Permanent-magnet rotor and rotating machine comprising such a rotor

A permanent magnet, rotating technology, used in synchronous motors with static armatures and rotating magnets, magnetic circuit rotating parts, manufacturing stator/rotor bodies, etc., can solve problems such as reducing rotor performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

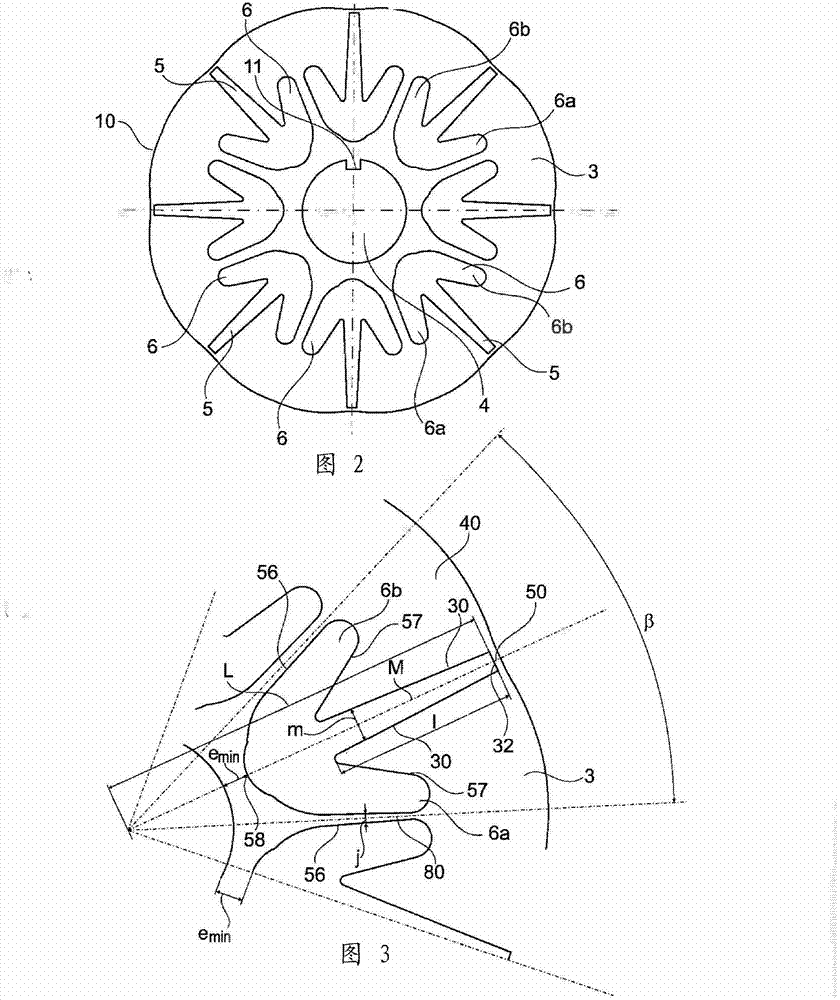

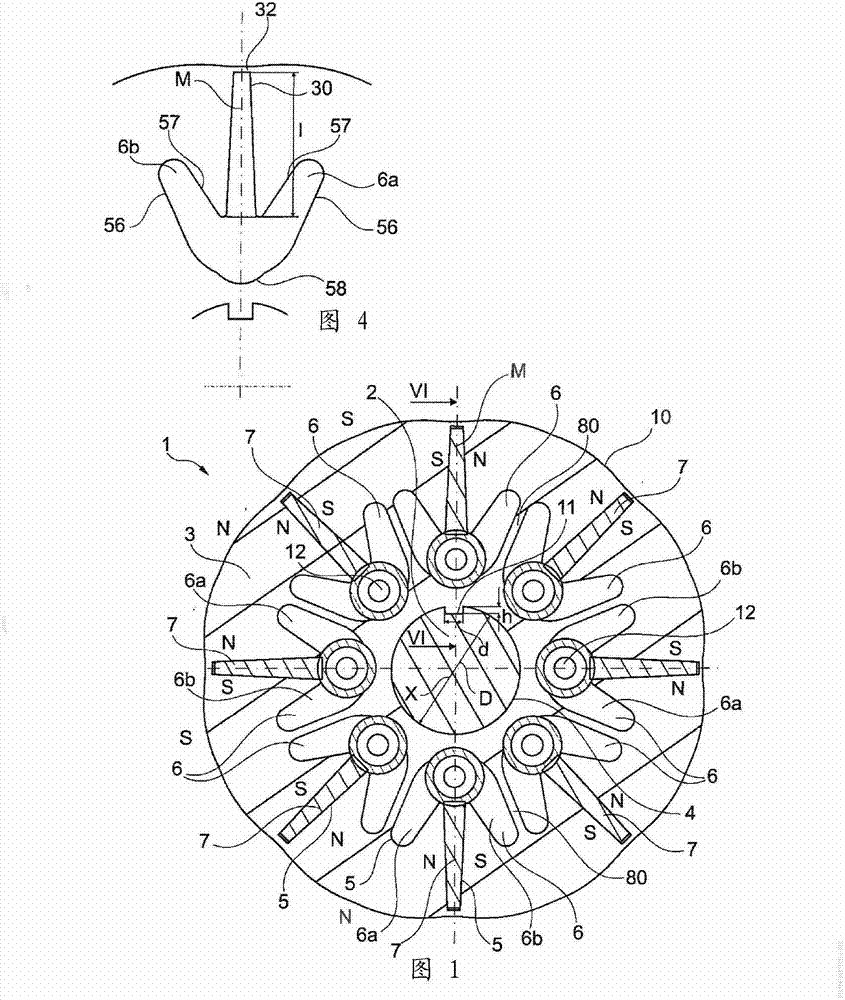

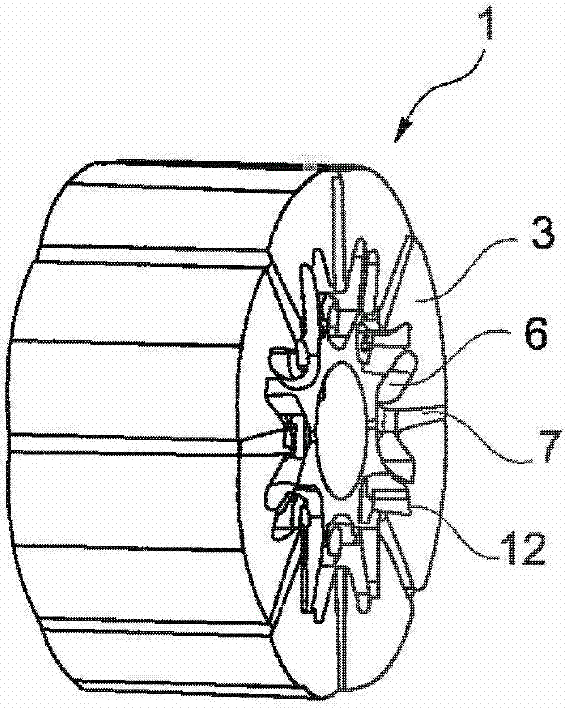

[0116] figure 1 The device 1 depicted in includes a magnet frame 3 extending radially along the axis of rotation X of the rotor, which frame is preferably formed of stacks of laminations stacked along the axis X, the laminations being considered in this example as complete identical and exactly overlapping.

[0117] The rotor 1 comprises a plurality of permanent magnets 7 placed in respective accommodation areas 5 of the magnetic rotor frame 3 so that two consecutive magnets 7 have the same polarity on faces facing each other.

[0118] The rotor frame 3 is mounted on a support body 2 , which is, in the example considered, a shaft made of a magnetic material such as steel.

[0119] The rotor frame 3 has a central opening 4 for mounting it on the shaft 2 . D The central opening 4 has a diameter D of, for example, between 40 mm and 50 mm.

[0120] Furthermore, the central opening 4 has an anti-rotation projection 11 which engages in a corresponding slot in the shaft.

[0121]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com