Loaded slope-expansion-type cap plug fastening mechanism

A technology of fastening mechanism and inclined plane, which is applied in the directions of packaging item types, sensors, diagnosis, etc., can solve the problems of simple and labor-saving assembly process, and achieve the effect of easy assembly and elimination of hidden dangers of biological safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

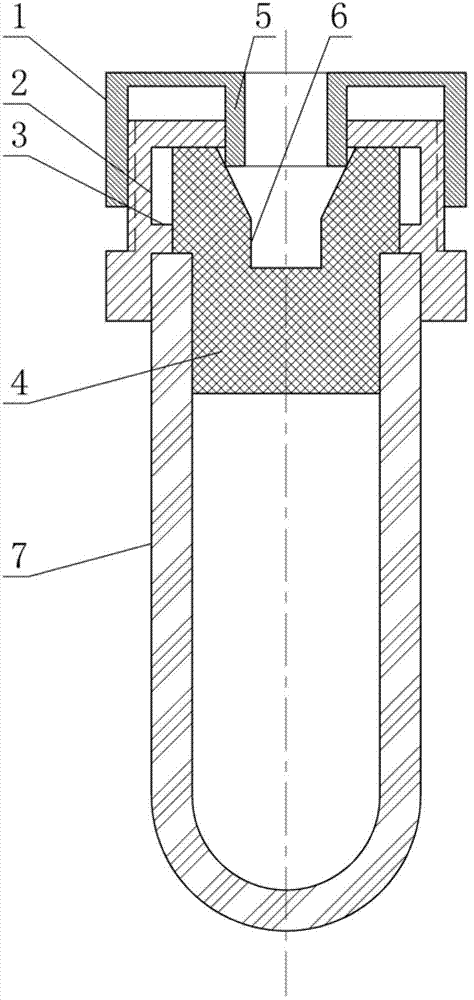

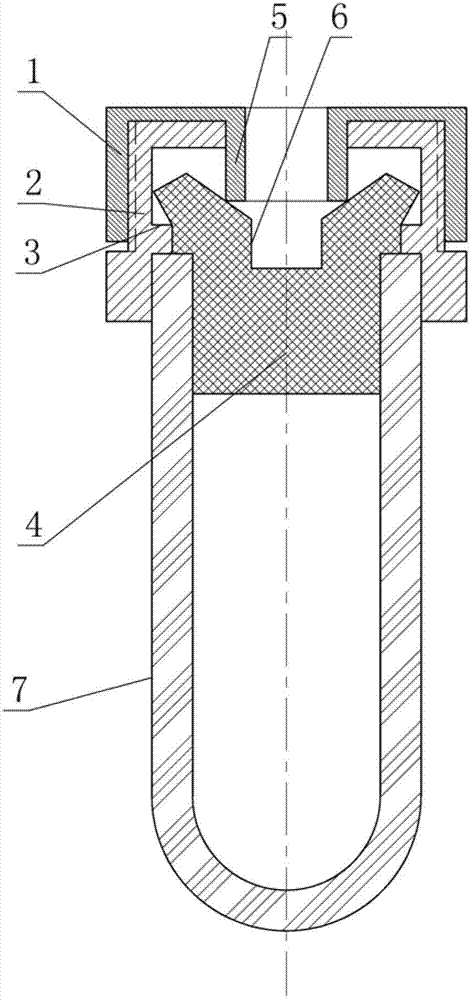

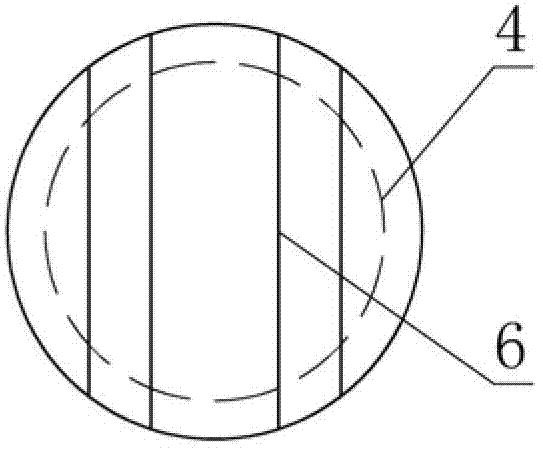

[0018] The loading type inclined-plane expansion type cap fastening mechanism is composed of a fastening cap 1, a splash-proof cap 2, a clasp 3, a rubber plug 4, a pressure cylinder 5, an expansion wing 6 and a test tube 7.

[0019] Wherein, the upper end of the rubber plug 4 has a pair of expansion wings 6 with inclined planes, and the material of the two expansion wings 6 and the rubber plug 4 are both butyl rubber and integrated as a whole. The slopes of the two expansion wings 6 are arranged opposite to each other. The outer sides of the two expansion wings 6 are cylindrical sides and coaxial with the rubber plug 4, and the rubber plug 4 is plugged into the upper port of the test tube 7 and forms an interference fit relationship with the test tube 7. The bottom outer edges of the two expansion wings 6 are between the inner and outer edges of the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com