Air flotation assembly for large-scale precise rotary table

An air-floating, precision technology, applied in the direction of bearings, shafts and bearings, mechanical equipment, etc., can solve the problems of shortening the life of rotating devices, prone to failure, and unable to carry objects to move smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, the present invention is described in further detail:

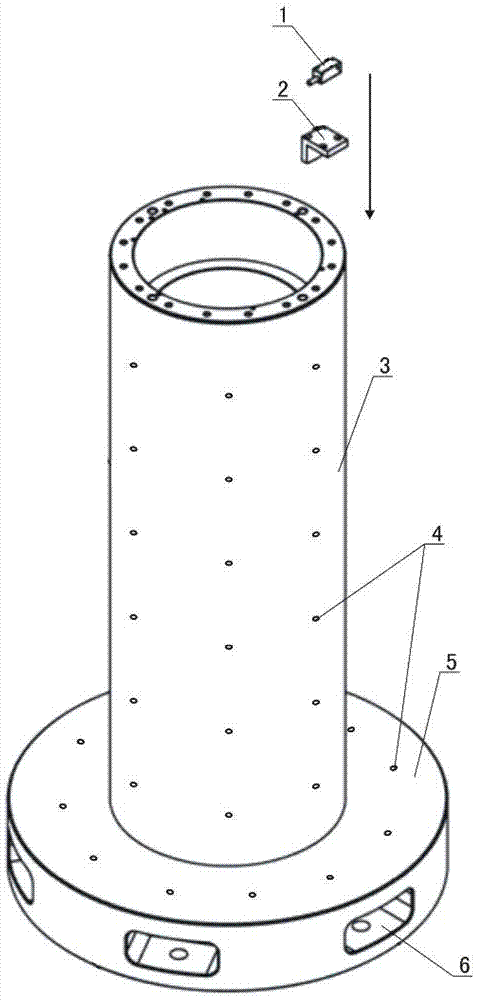

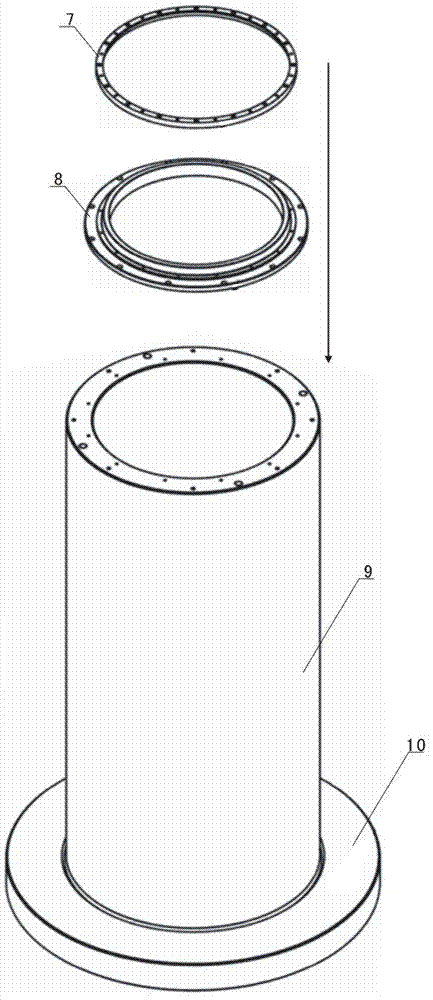

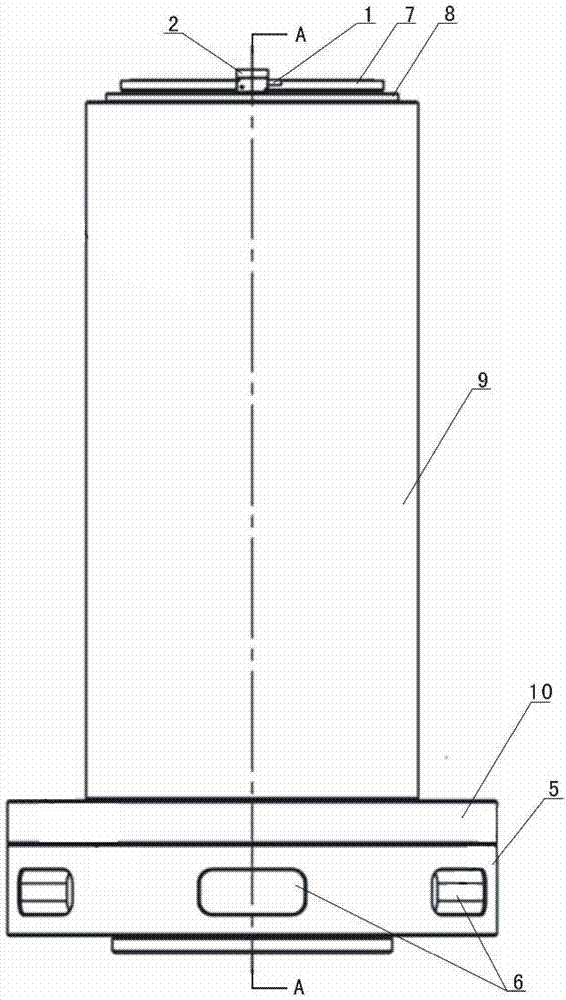

[0022] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the present invention includes an air bearing bracket, a reading bracket 2, a reading head 1, an air bearing sleeve, a grating connecting ring 8 and a ring grating 7, the air bearing sleeve is sleeved on the air bearing bracket, and the The air flotation support includes a vertical tube 3 and a seat 5 arranged at the bottom of the vertical tube 3, the reading bracket 2 is installed on the upper end of the vertical tube 3, and the reading head 1 is installed on the reading bracket 2; the air flotation bushing includes a base 10 and the shaft tube 9 arranged on the base 10, the grating connecting ring 8 is installed on the upper end of the shaft tube 9, the ring grating 7 is installed on the upper end of the grating connecting ring 8, and the grating connecting ring 8 and the ring grating 7 are ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com