Battery module

A technology for battery modules and battery cells, applied in the direction of battery, secondary battery, battery temperature control, etc., can solve the problems of uneven temperature, shorten the life of battery cells, troublesome fixing operation, etc., achieve uniform cooling state, prevent leakage Different, the effect of realizing longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

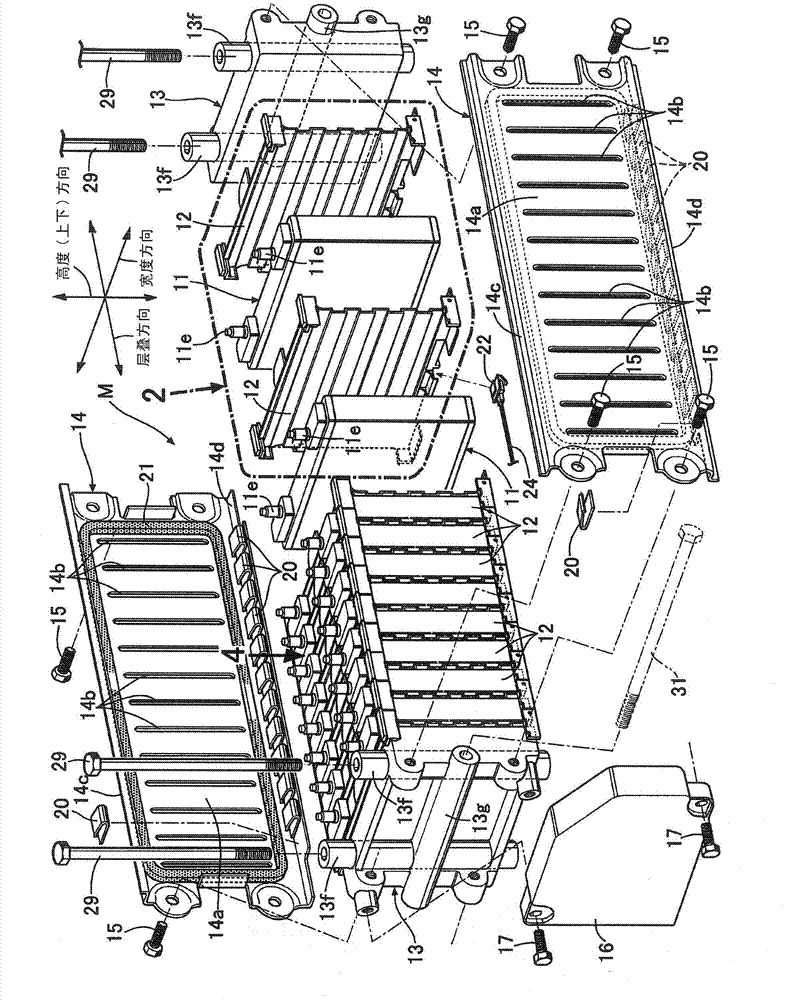

[0051] Below, according to Figure 1 to Figure 11 , the embodiment of the present invention will be described.

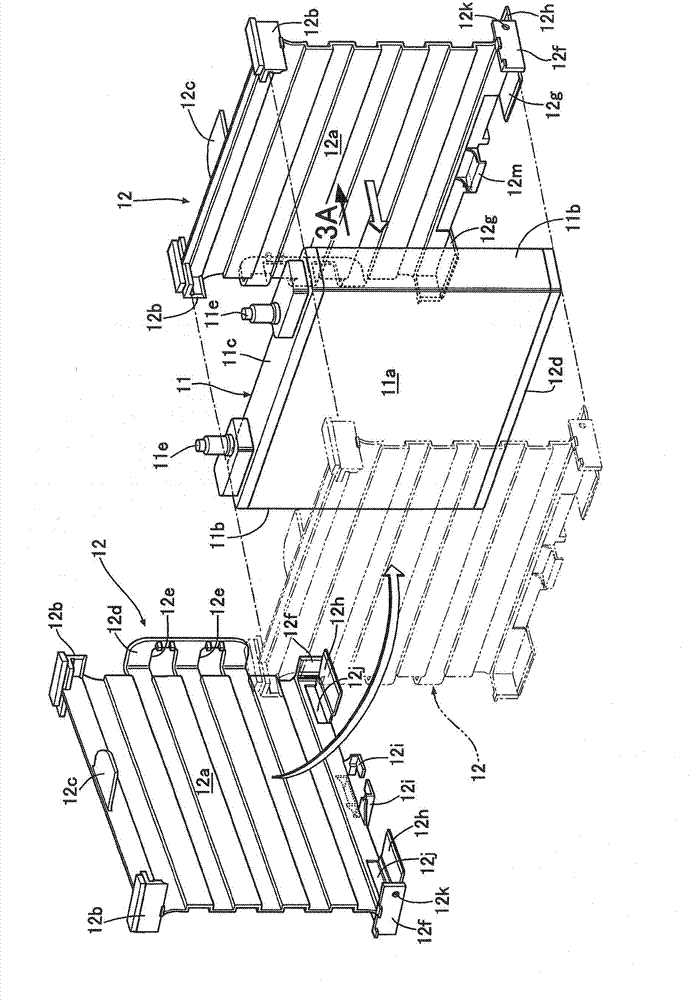

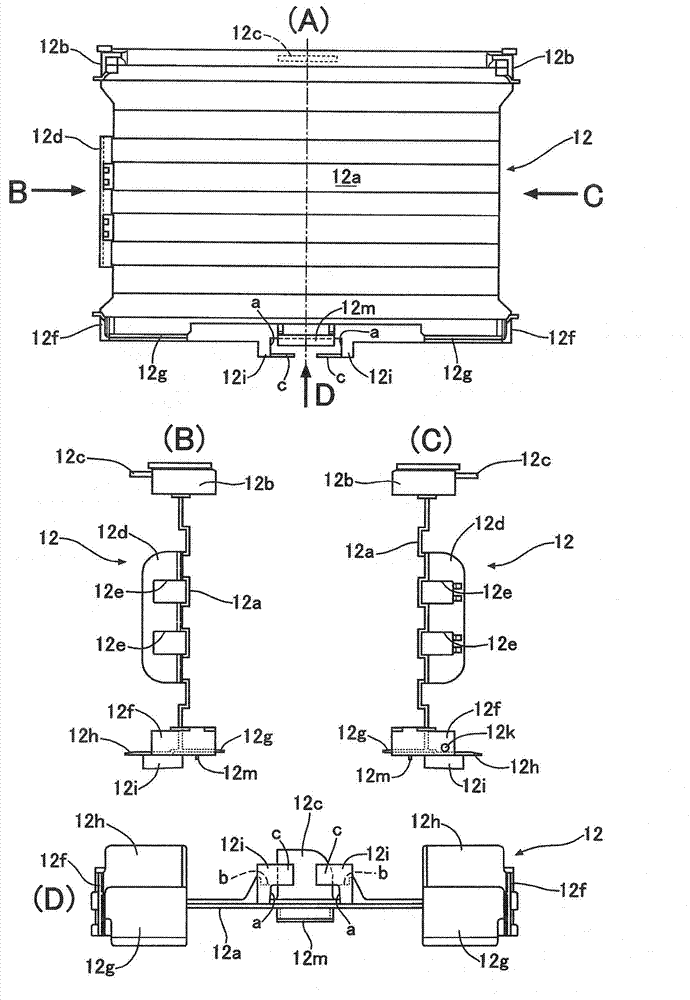

[0052] Such as figure 1 As shown, the battery module M for a hybrid vehicle includes, for example, a plurality of battery cells 11 . . . constituted by lithium-ion batteries. The rectangular parallelepiped battery unit 11 has: a pair of horizontally long rectangular main cooling surfaces 11a, 11a; a pair of side surfaces 11b, 11b sandwiched between the pair of main cooling surfaces 11a, 11a; Between the top surface 11c and the bottom surface 11d between 11a and 11a, a pair of terminals 11e and 11e protrude from the top surface 11c. A plurality of battery cells 11 ... are stacked in a state in which holders 12 ... of the same shape made of synthetic resin are sandwiched between the main cooling surfaces 11 a ....

[0053] It should be noted that, in this specification, the direction in which a plurality of battery cells 11 are stacked ... The direction is defined...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com