All-wool lining suit front and complex chest lining processing process

A kind of processing technology, the technology of full fur lining, applied in the field of suit processing, can solve the problems of cracking, discomfort, inconsistency between the front body and the chest lining, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

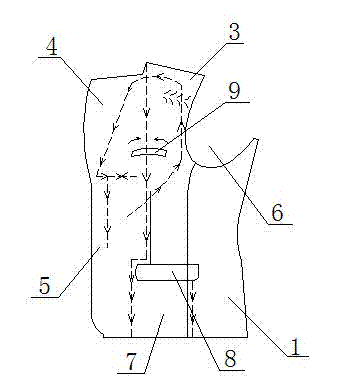

[0019] Such as figure 1 It is a structural schematic diagram of the present invention, a process for processing the chest lining of the front body of a full wool lining suit, comprising the following steps:

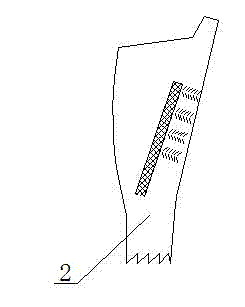

[0020] a. Put the front part 1 in the pre-shrinking box, adjust the temperature and humidity, take it out after one and a half to two and a half hours, and put the chest lining 2 in warm water at 50-70 degrees for 3-4 hours and take it out to dry Dry, match the pre-shrunk front body piece 1 and chest lining 2 according to the model and put them on the needle setting machine to re-line and staple, put the front body piece 1 and chest lining 2 according to the shoulder point 3, and take the breast dart 4 as the Put the front garment flat on the center line, straighten the strands, and push the dart 4 toward the placket to form a "C" shape.

[0021] b. Stitch from shoulder point 3, place a finger at the shoulder blade at 8cm-12cm below shoulder point 3, which is 0.4cm-0.6cm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com