filter device

A filtration device and fiber filtration technology, applied in the direction of filtration separation, gravity filter, loose filter material filter, etc., can solve the problems of difficult to press evenly, create gaps in the boundary, damage the filtration function, etc., and achieve the filtration operation. Excellent efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

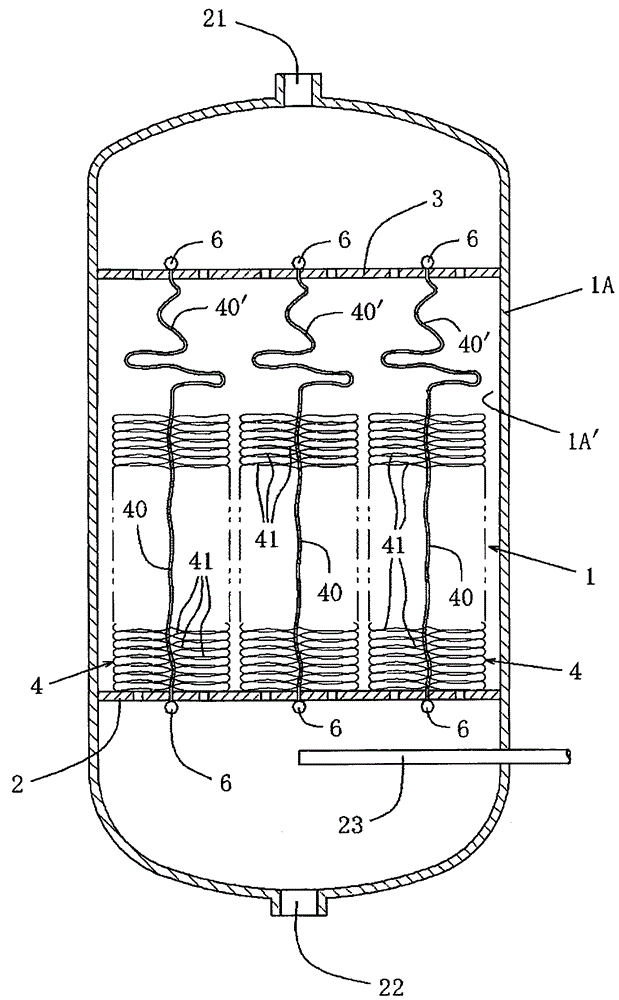

[0014] Accompanying drawing represents an embodiment of the filtering device of the present invention, and in the figure, 1 is filter chamber, and filter chamber 1 is that the inner wall 1A ' of filter bag 1A, perforated plate 2 and upper side perforated plate 3 are carried out to described filter tank 1A. Divided, the porous plate 2 is arranged in the filter tank 1A and constitutes a filter member support plate, and the upper porous plate 3 is arranged in the filter tank 1A opposite to the porous plate 2 . In addition, the filter tank 1A has an inlet for raw water (also used as an outlet for cleaning water and air) 21 on the upstream side, and an outlet for filtered water (also used as an outlet for cleaning water) 22 and a downstream side. Injection ports 23 for cleaning air are communicated with the filter chamber 1 (known).

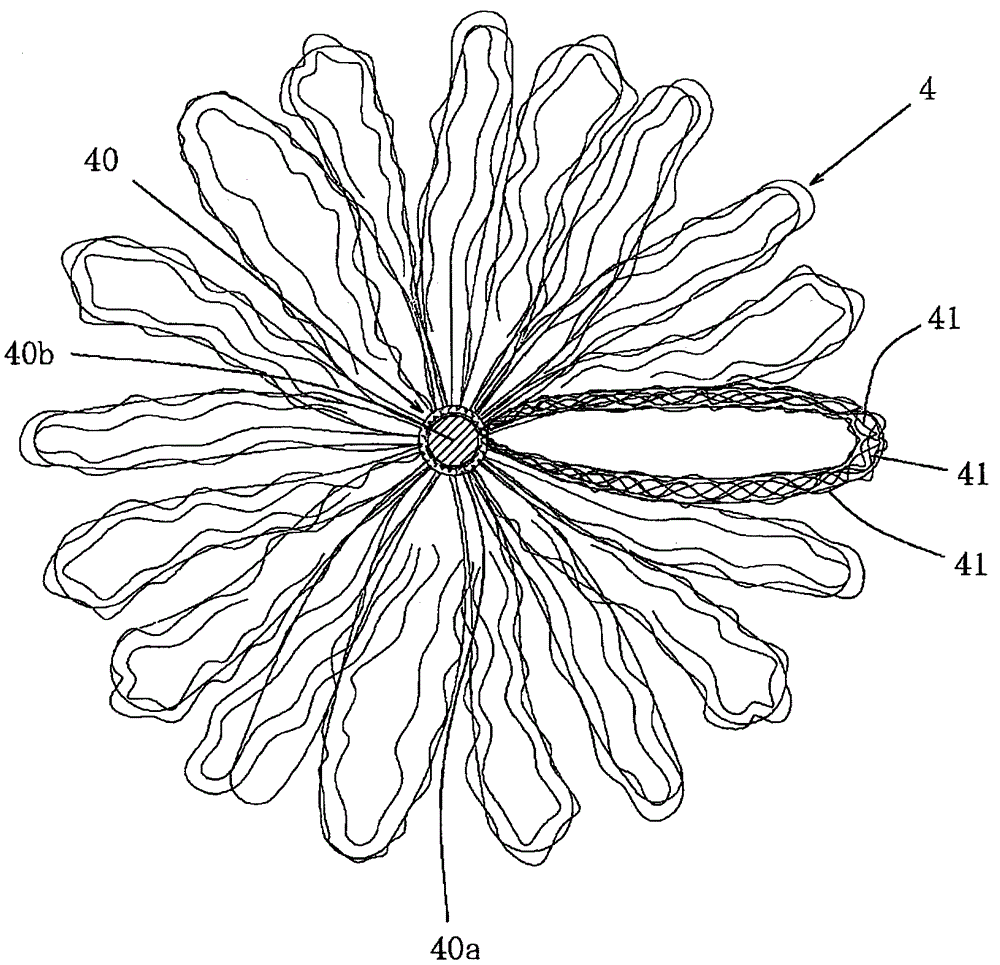

[0015] An appropriate number of fibrous filter members 4 are accommodated in the filter chamber 1 to perform filtering operations. The fibrous filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com