Plate saw bench with guide device

A guide device and panel saw technology, which is applied in the direction of guide protection, sawing components, sawing equipment, etc., can solve the problems of easy deflection of the plate, low cutting precision, high cost, etc., and achieve high processing precision and high cutting precision , to prevent the effect of deflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

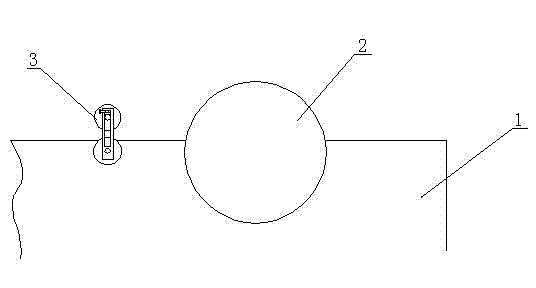

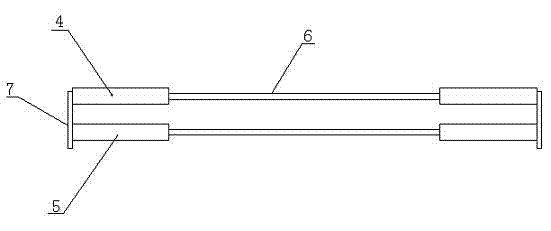

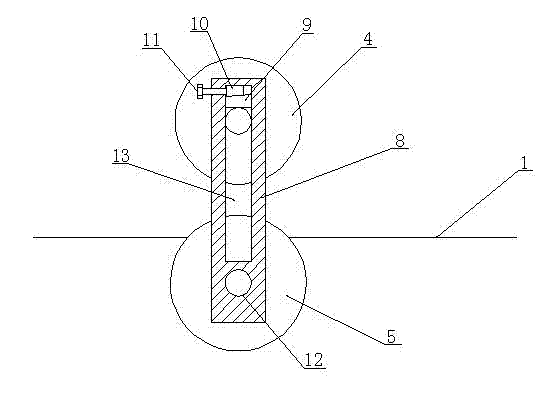

[0011] As shown in the figure, a panel saw table with a guide device includes a workbench 1, a circular saw 2 and a driving motor. The middle part of the top surface of the workbench 1 is provided with a circular saw installation groove, and the circular saw 2 is vertically arranged. In the circular saw installation slot, and connected with the drive motor. There is also a guide device 3 on the workbench 1. The guide device 3 is mainly composed of two rubber pressure wheels 4, two rubber support wheels 5, two synchronous shafts 6 and two locking mechanisms 7. The two rubber support wheels 5 Symmetrically arranged on both sides of the workbench 1, the lower part of the rubber support wheel 5 is embedded in the support wheel mounting groove provided on the top surface of the workbench 1, and the two rubber pressure wheels 4 are respectively arranged on the top of the two rubber support wheels 5. A rubber pressure wheel 4 and two rubber support wheels 5 are respectively connected...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap