Photostudio with turntable driving mechanism

A driving mechanism and a technology for a studio, applied in the field of studios, can solve problems such as poor flatness of translucent plastic plates, and achieve the effect of accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

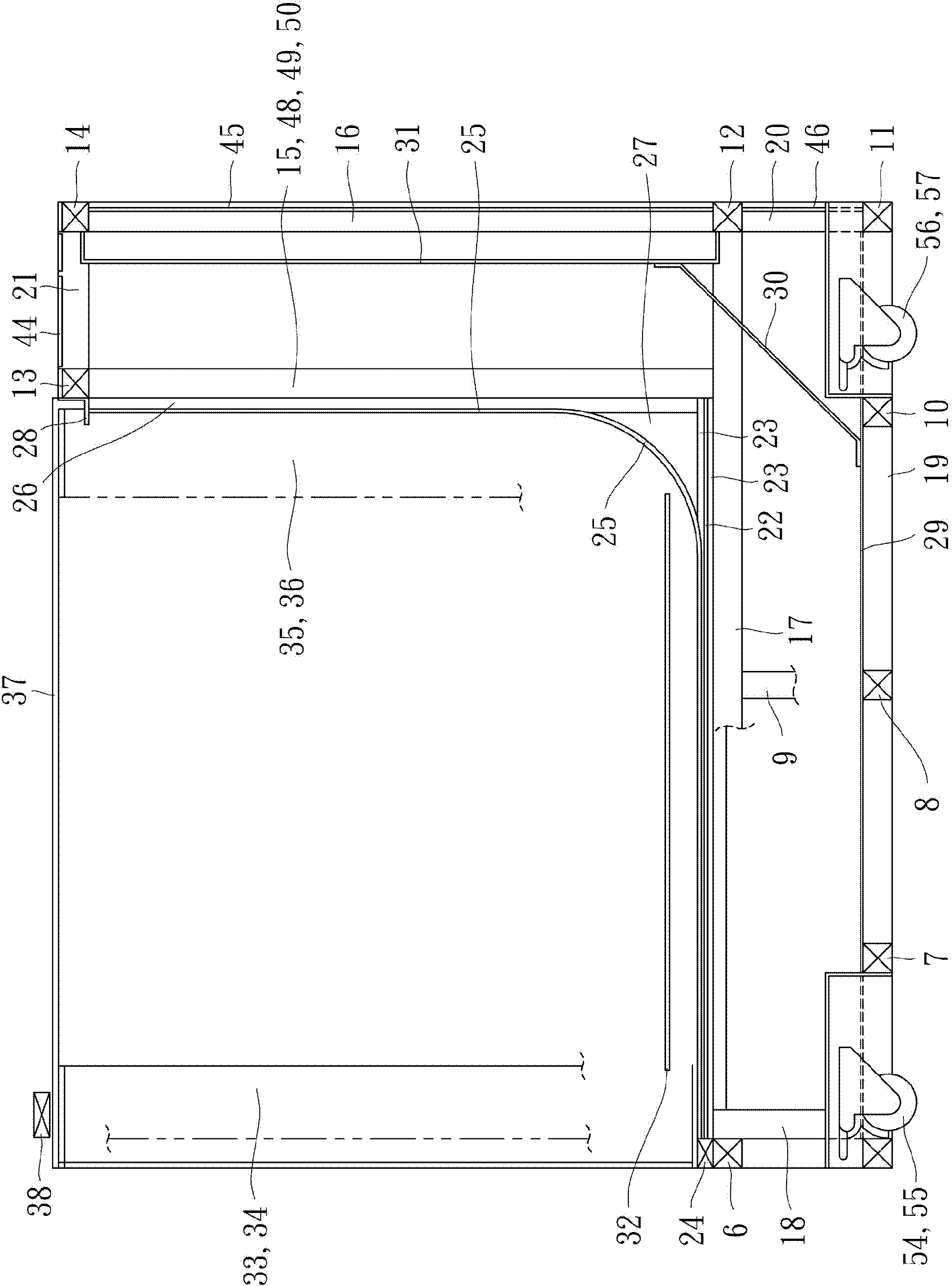

[0043] In order to have a further cognition and understanding of the features, purpose and functions of the present invention, a detailed explanation is given below with reference to the drawings.

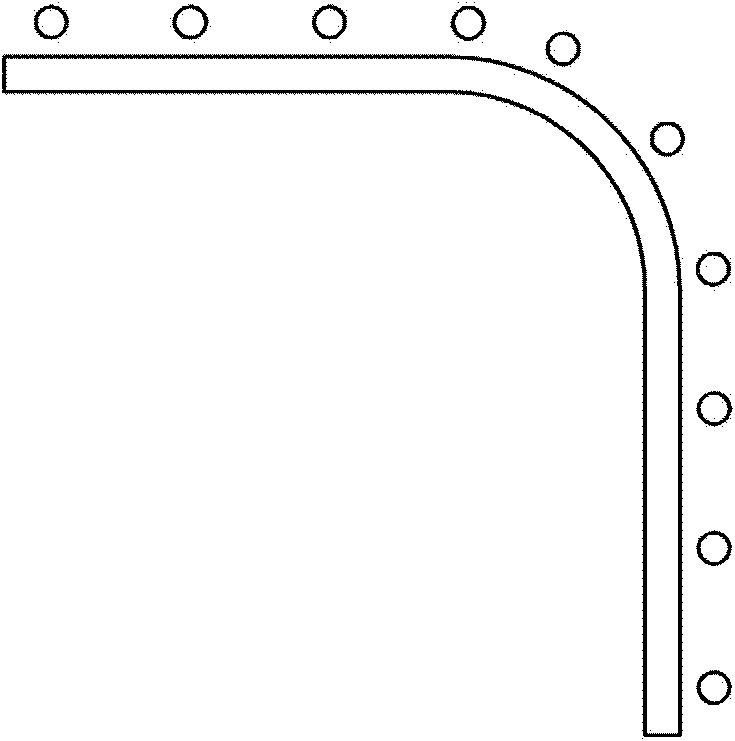

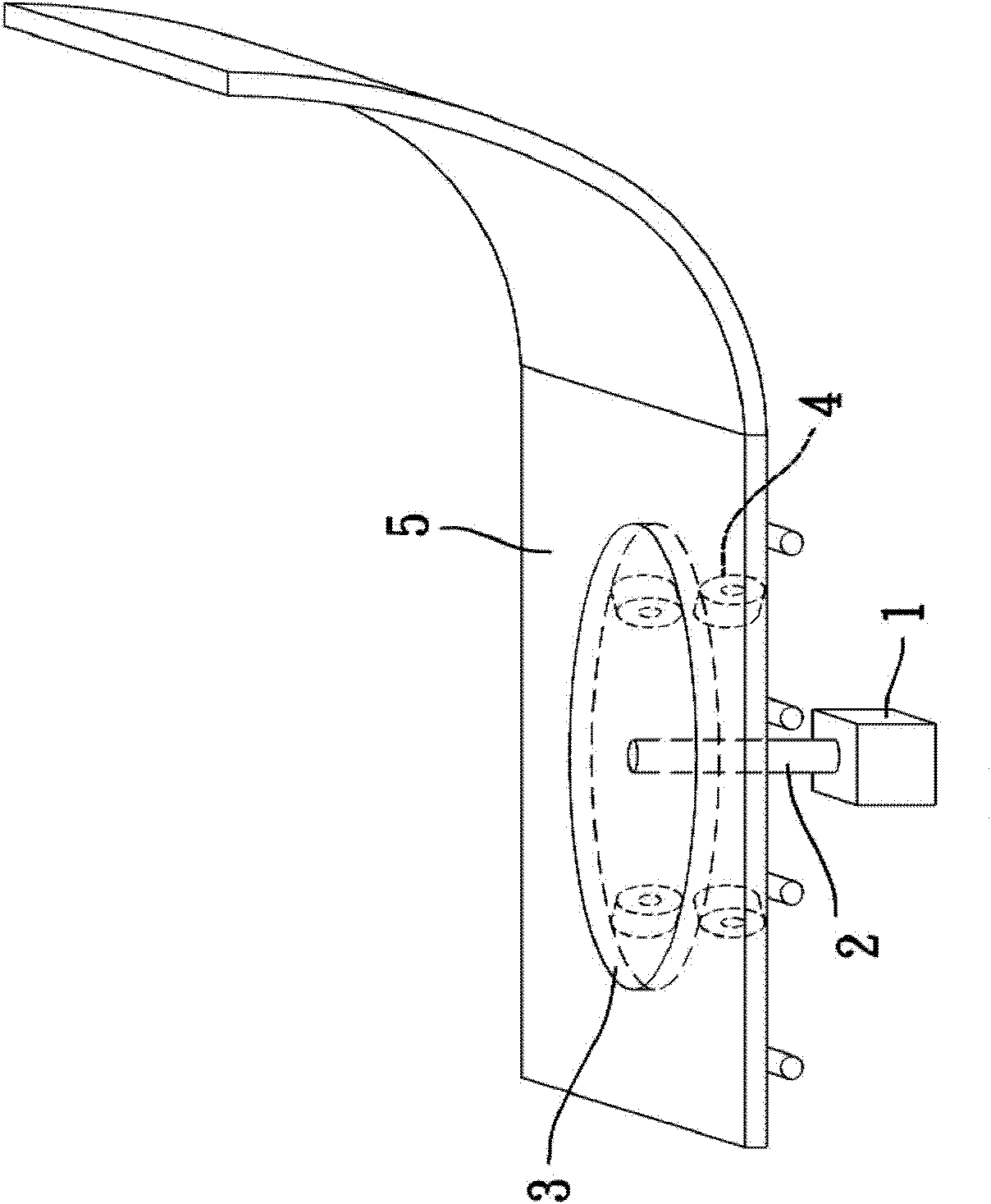

[0044] image 3Shown is a side view (Side View) of a studio with a turntable drive mechanism according to an embodiment of the present invention, which illustrates the main structure of the present invention, and aluminum extruded frames (Aluminum Frame) 6-21 constitute the photography The main support of the shed. The transparent glass plate 22 is embedded in the extruded aluminum frame 23 by side sliding, and is fixed front and rear by the extruded aluminum frames 24 and 15 . Moreover, the thinner translucent plastic sheet 25 is stuffed into the guide frame (Guiding Frame) 26, the guide block (Guiding Block) 27 and the aluminum extruded frame 23 from the top down to form a curved surface, while its horizontal part covers the The part above the transparent glass plate 22. Moreo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com