Bridge crane

An overhead crane and rope technology, which is applied in the directions of walking overhead cranes, cranes, and trolley cranes, can solve the problems of danger, rope slack, and time-consuming hoisting mechanism, and achieves reduction in size and accurate lifting work. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

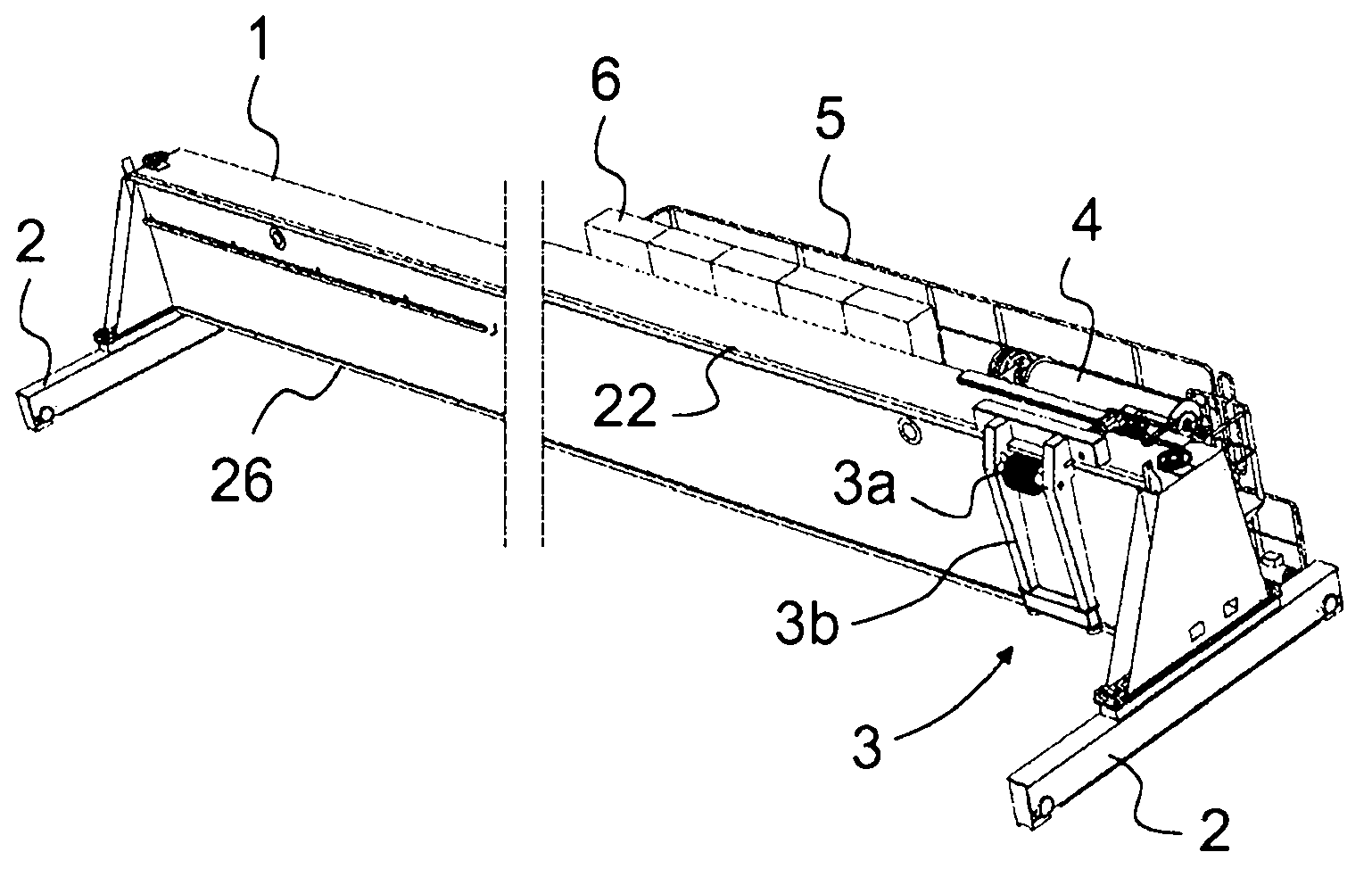

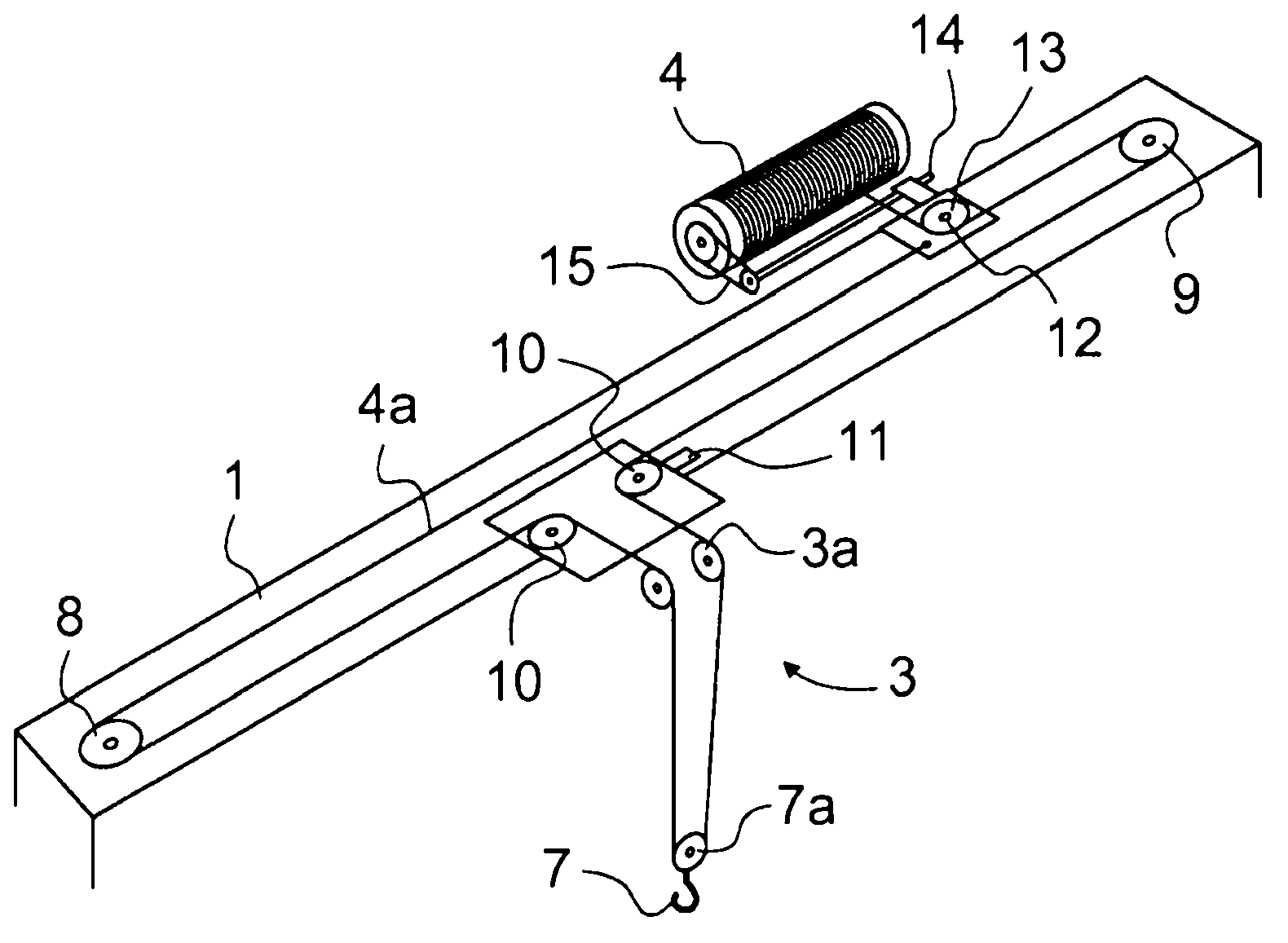

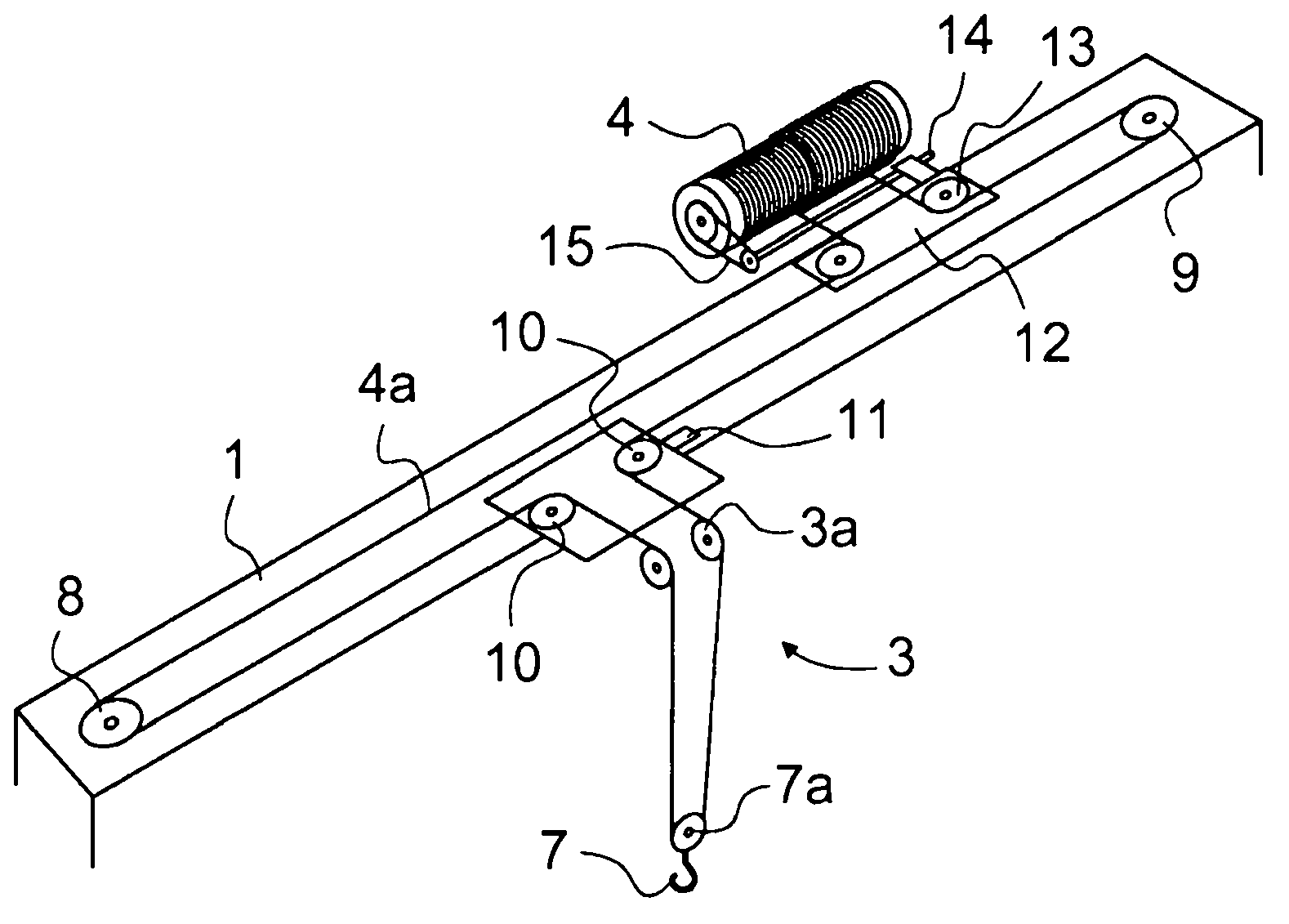

[0014] figure 1 An oblique top view of a simplified and segmented bridge crane according to the invention is shown, without the hoisting rope, the hook and some other parts belonging to the solution, which will be described below. Bridge cranes are also known as torsion bridge cranes and they comprise a main girder 1 at both ends of which are end carriages 2 provided with at least rails Wheels and traveling mechanism. The hoisting block 3 is fitted in conjunction with the first side of the main girder on which the block travels in a lateral direction with respect to the direction of travel of the main girder 1 . The hoisting block 3 comprises a pulley 3a for hoisting the ropes and a frame part provided with legs 3b which rests in the longitudinal direction of the main girder on guide rails 22 and 26 which are at the top of the main girder 1 and on the bottom edge of the first side of the main girder 1. to combine Figure 7 The structure of the guide rail and hoisting block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com