Numerical-control constant-torque electric spanner

A constant-torque, electric technology, applied in the field of hand-held constant-torque electric wrenches, can solve the problems of low measurement and control accuracy, the final pre-tightening force cannot be directly measured, etc., to achieve high tightening accuracy and meet the tightening effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

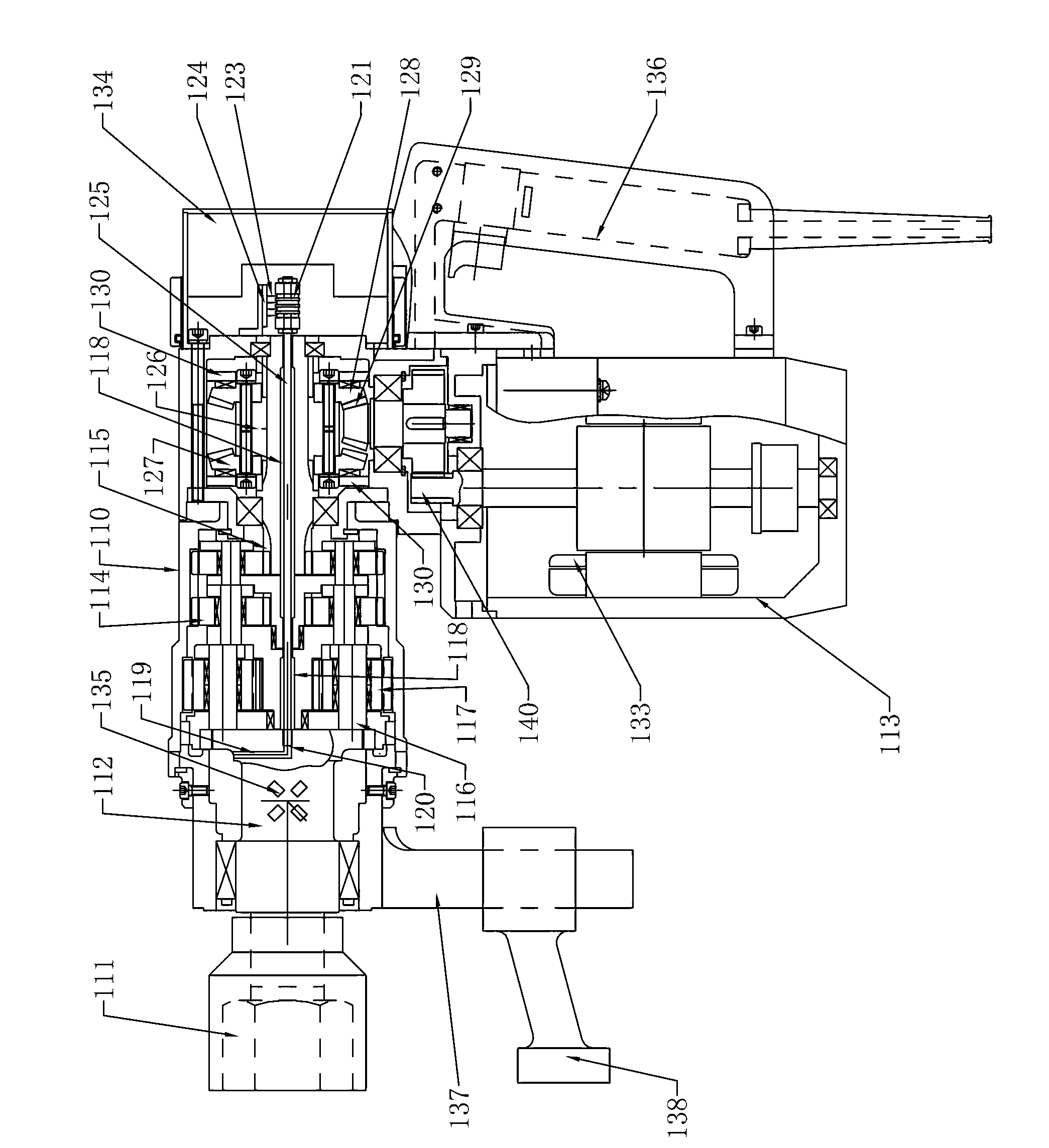

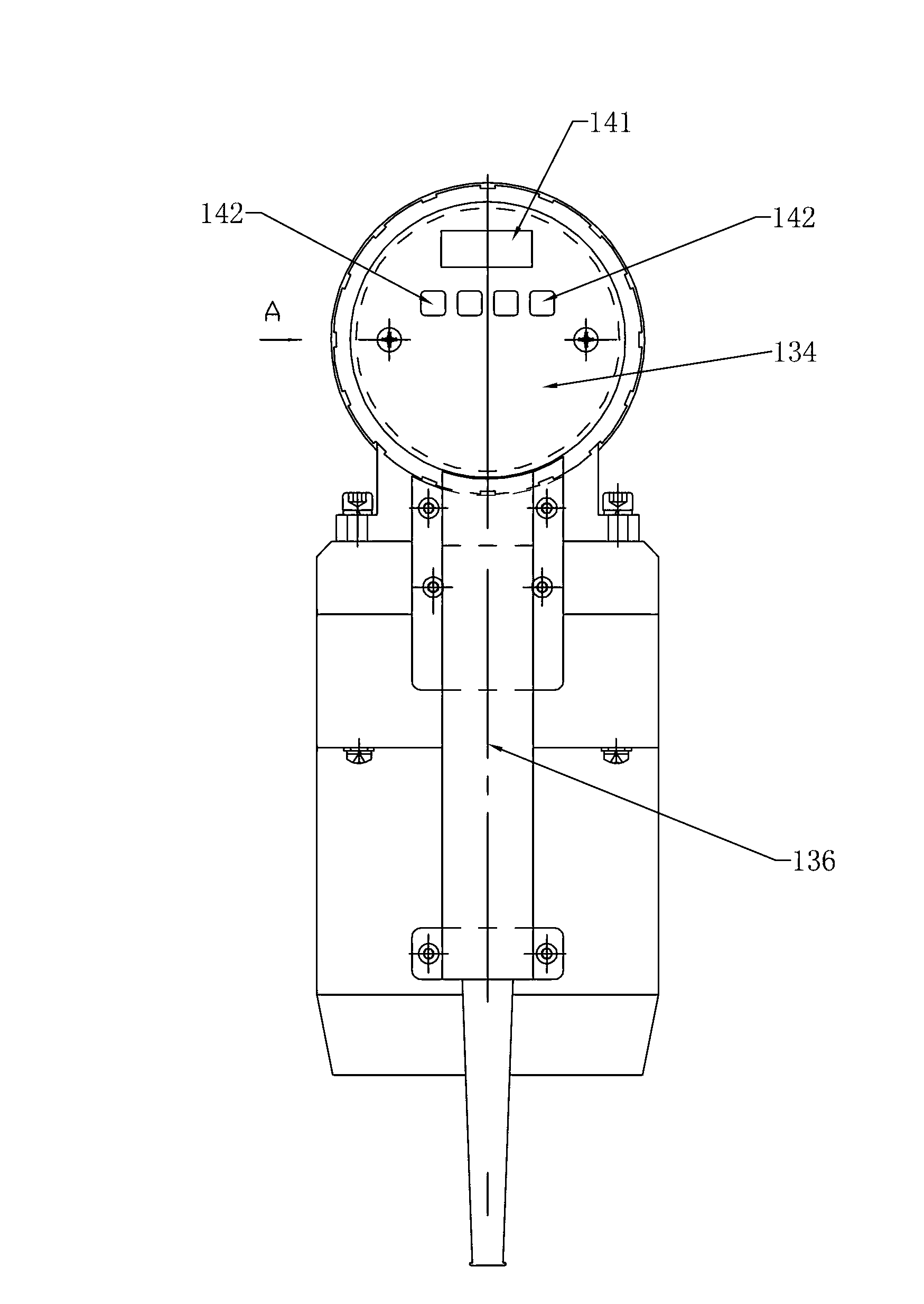

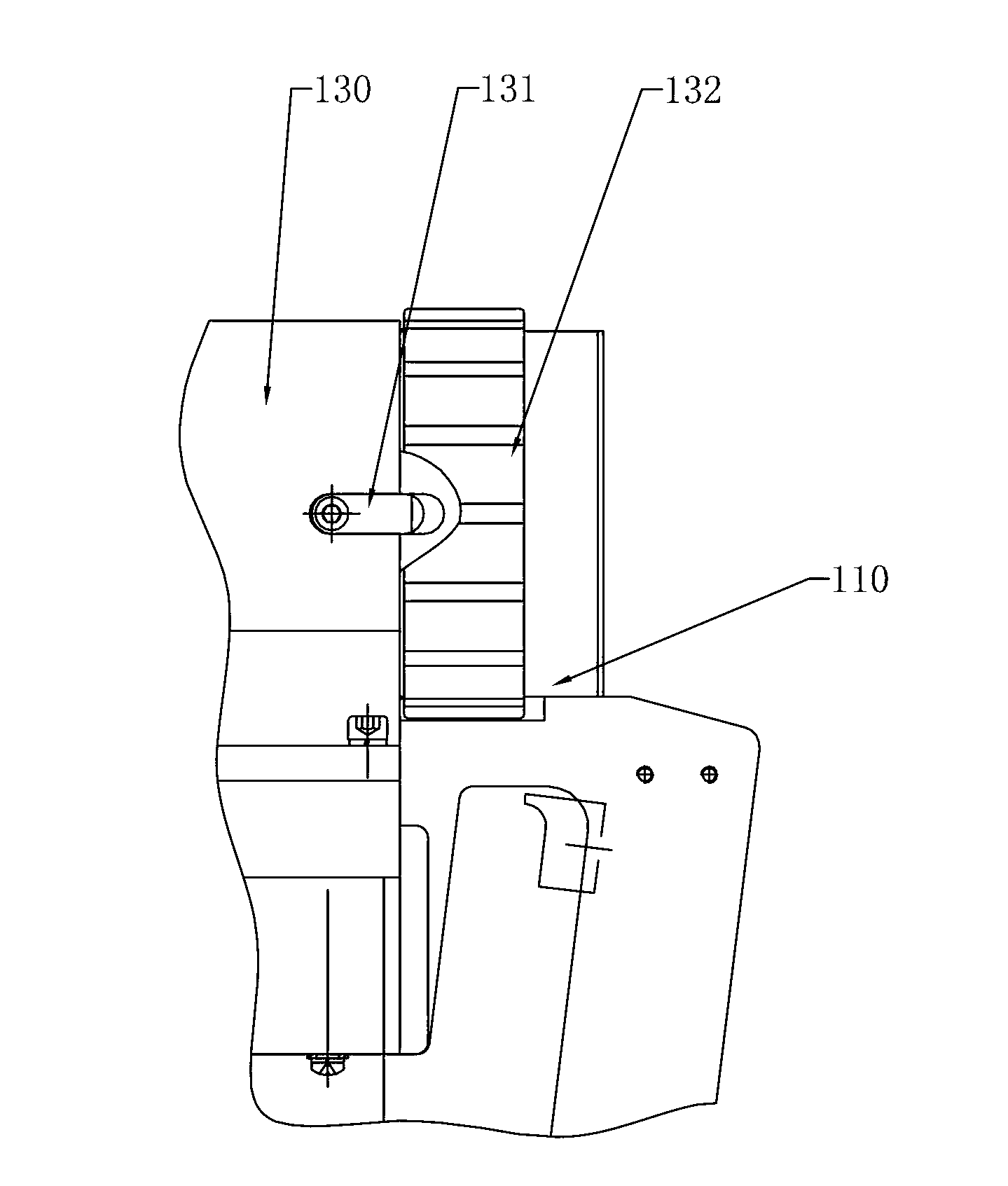

[0034] Such as figure 1 As shown, the digital control constant torque electric wrench of the present invention includes a housing 110, a sleeve 111, an elastic shaft 112, a speed reduction mechanism, a motor 113 and an electric control system. The output shaft of the motor 113 is connected to the input end of the deceleration mechanism, and the output end of the deceleration mechanism is connected to the elastic shaft 112. The other end of the elastic shaft 112 is fixedly connected to the sleeve 111. A sensor is pasted on the elastic shaft 112. The sensor is a strain gauge. 135, the strain gauge 135 is connected with the electric control system. In this embodiment, the elastic shaft adopts a solid cylindrical shaft, on which there are pasted strain gauges for measuring 45° shear stress. Piece matching group, two groups of symmetrical distribution. The elastic body can also adopt structures such as thin-walled tubes or four-piece rectangular beams. The elastic body can be ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com