Capable-of-turning-angle type fastening transmission device of box-type parts

A transmission device and active device technology, applied in the direction of transmission devices, belts/chains/gears, mechanical equipment, etc., can solve the problems of difficult fastening work, time-consuming and labor-intensive work, and achieve light weight, good adaptability, and convenient fastening Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

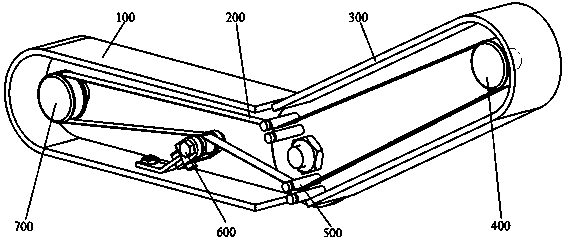

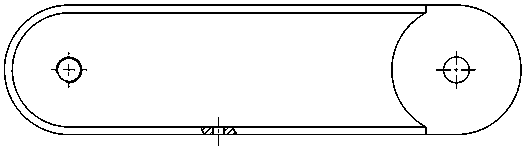

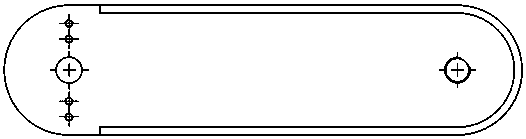

[0015] Specific implementation mode one: combine Figure 1 to Figure 6 Describe in detail the fastening transmission device for corner-type box parts, which is characterized by: including handle I (100) and handle II (300), elastic belt (200), active device (400), guide device (500), The tensioning device (600), the driven device (700); the handle I (100) and the handle II (300) are fastened and connected by bolts; the structure of the active device (400) and the driven device (700) Exactly the same, take the active device as an example: the active device (400) includes the pulley (401), deep groove ball bearing (402) and pin shaft (403), the pulley (401) and the outer ring of the deep groove ball bearing (402) Interference fit, interference fit between the inner ring of the deep groove ball bearing (402) and the pin shaft (403), the active device (400) is threadedly connected with the handle II (300) through the pin shaft (403); the guide device (500 ) includes the needle ro...

specific Embodiment approach 2

[0017] Embodiment 2: In combination with Embodiment 1, the fastening transmission device for corner-type box parts, its working principle is: use screws or magnetic adsorption to connect the sleeve with hexagonal holes or twelve-angle holes with the The pulley (401) of the driven device (700) is tightly connected, and the grooved circular plate with a shape of a word, cross, or four corners and hexagon is fastened to the pulley (401) of the driving device (400) by screws or magnetic adsorption. Connect the sleeve with the bolt and nut, and under the automatic adjustment of the tensioning device (600), use a wrench or a screwdriver to rotate the active device (400), and drive the driven device (700) to rotate through the elastic belt (200). Realize the tightening of bolts and nuts; when the bolts and nuts are tightened, the elastic belt (200) of the active device (400) will slip if the active device (400) continues to rotate, so as to avoid damage to the device due to excessive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com