Control device for machine tool system and machine tool system

A control device and machine tool technology, applied in the field of machine tools, can solve the problem of high cost and achieve the effect of saving material expenses and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

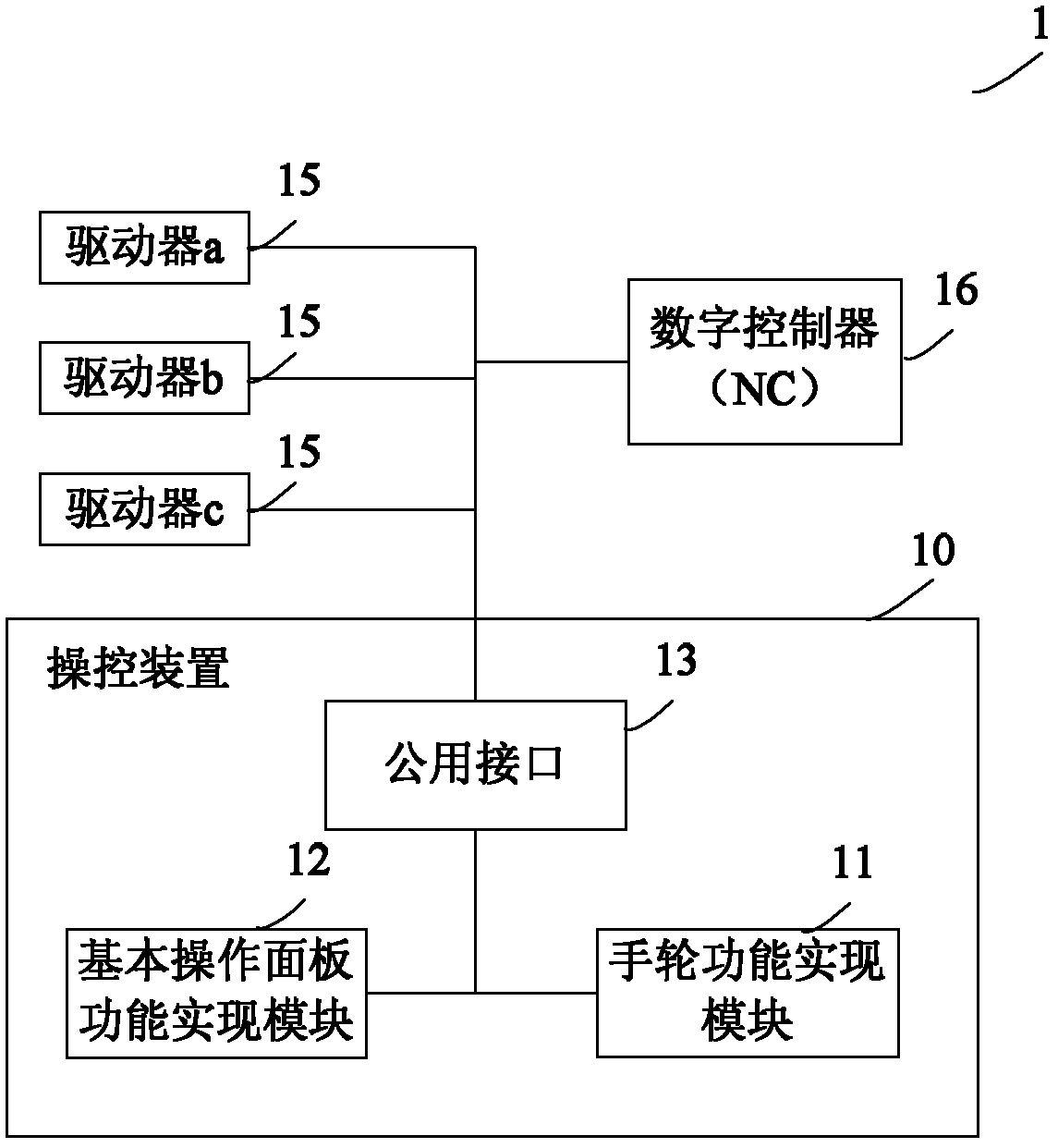

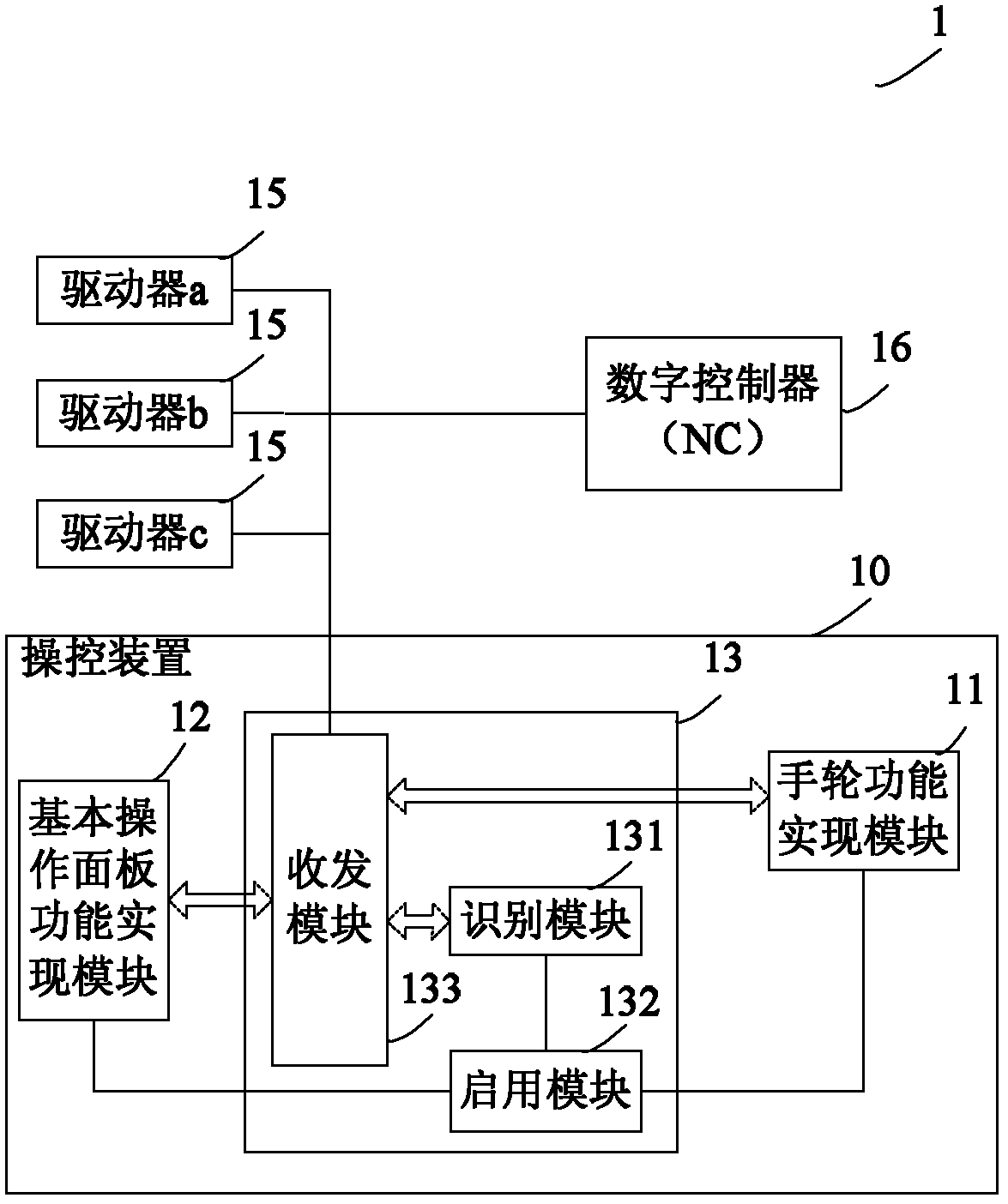

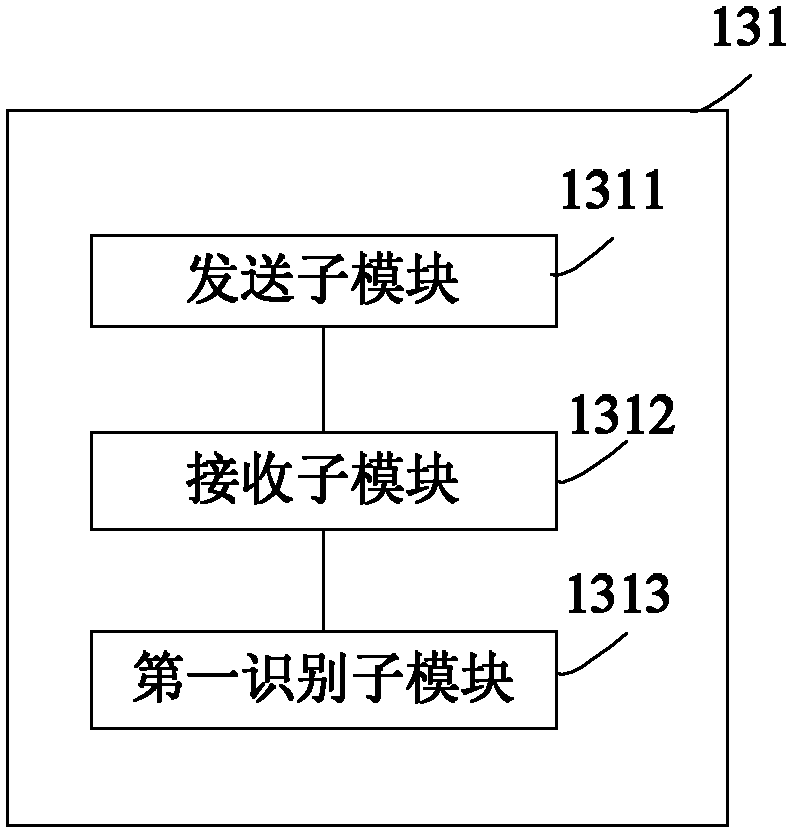

[0051] The inventors of the present invention have found the following through research:

[0052] 1. The basic operation panel (BOP) is a human-computer interaction panel, which does not store any data of the drive itself, and the BOP does not need to recognize different drives. For example, assuming that the three drivers in the machine tool system all contain the parameter P20, if you want to modify the value of P20 of the first driver, after connecting the BOP to the first driver, the BOP does not need to recognize that the connected one is the first driver. Several drives, it only needs to directly read and modify the value of P20. Therefore, it is not necessary to have a BOP for each drive in the machine tool system, that is, one BOP can be used to serve multiple drives;

[0053] 2. When using a single BOP to serve multiple drives, for example, when debugging the drives, you can connect the single BOP to each drive one after another to set parameters and debug for these ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com