Flow line production system used for shaping stator coil

A technology of stator coil and production system, applied in the field of assembly line production system, can solve the problems of large space occupied by station appliances, high grounding rate of stator coil, frequent transfer, etc., so as to release production space, improve production efficiency, and solve the problem of frequent transfer. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

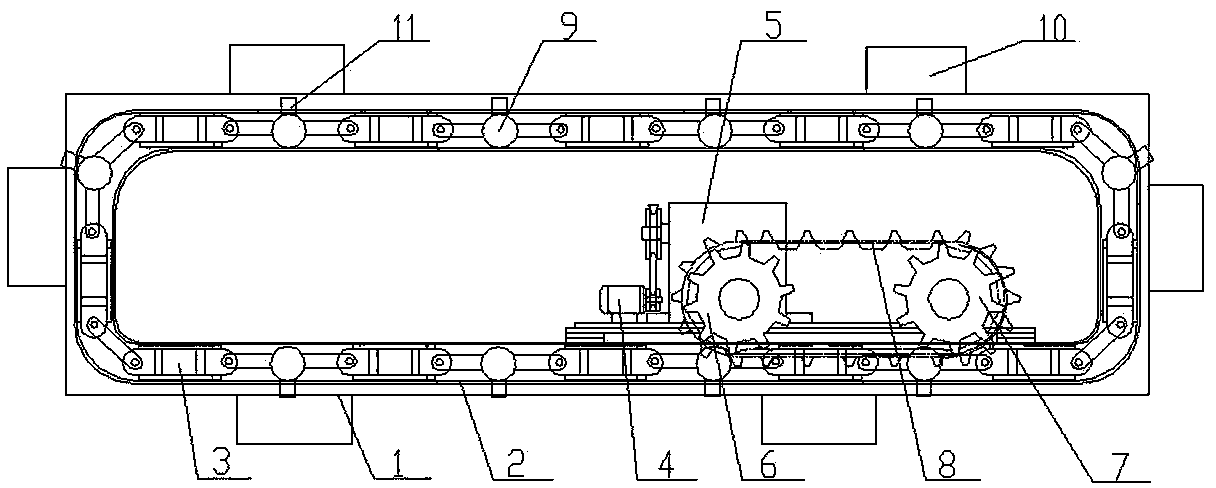

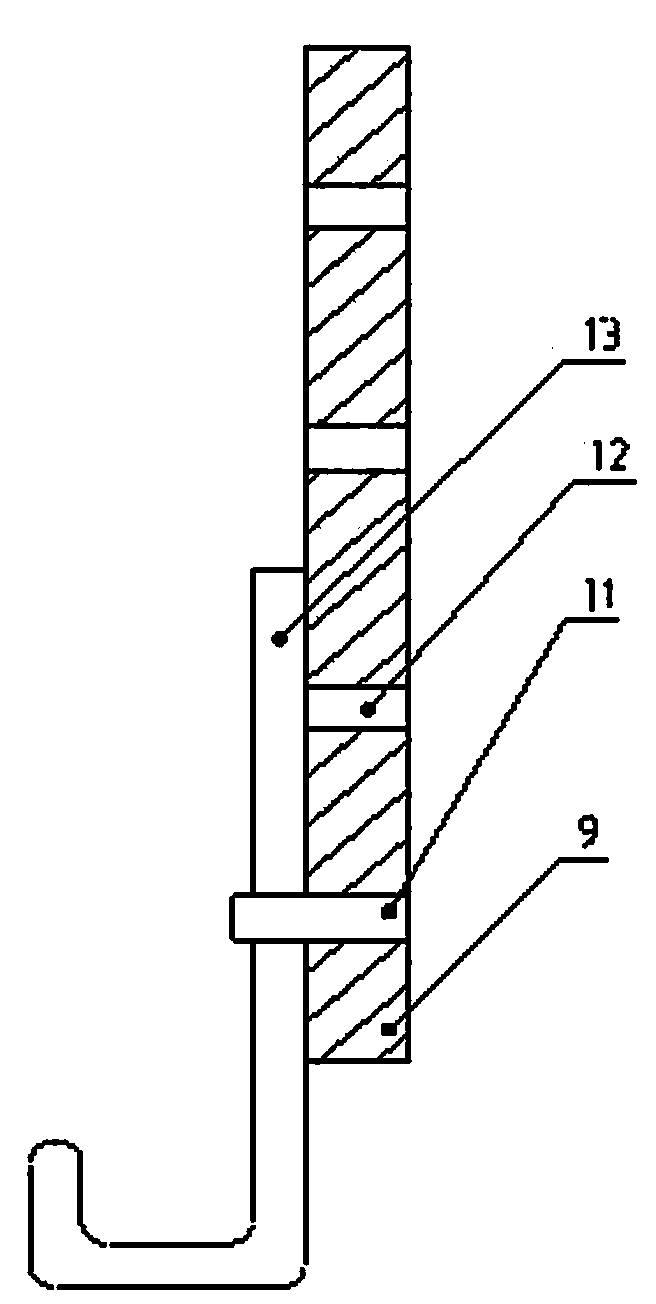

[0012] An assembly line production system for stator coil forming, including a bracket 1 and several operating tables 10, the top of the bracket 1 is fixed with an end-to-end rail 2, and the operating table 10 surrounds the outside of the rail 2; the rail 2 is equipped with The main transmission device controls the transmission chain 3 that rotates, and several adjustment vertical rods 9 are vertically fixed on the transmission chain 3; several horizontal positioning holes 12 are arranged on the adjustment vertical rod 9, and one end of the horizontal positioning hole 12 is movable. Adjust the positioning pin 11 outside the vertical rod 9, and one end of the positioning pin 11 is fixed with a hook 13.

[0013] During specific implementation, the main transmission device includes a motor 4 fixed on the bracket 1, a speed reducer 5 connected to the motor 4, a first transmission gear 6 fixed on the output shaft of the speed reducer 5, and a motor supported on the bracket. The sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com