Spinneret plate

A spinneret and spinneret hole technology, which is applied in the field of fiber production, can solve the problems of failing to meet technological requirements, spinning difficulties, and too many tows, and achieve the effect of good spinning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] A spinneret of the present invention will be further described in detail below through specific embodiments.

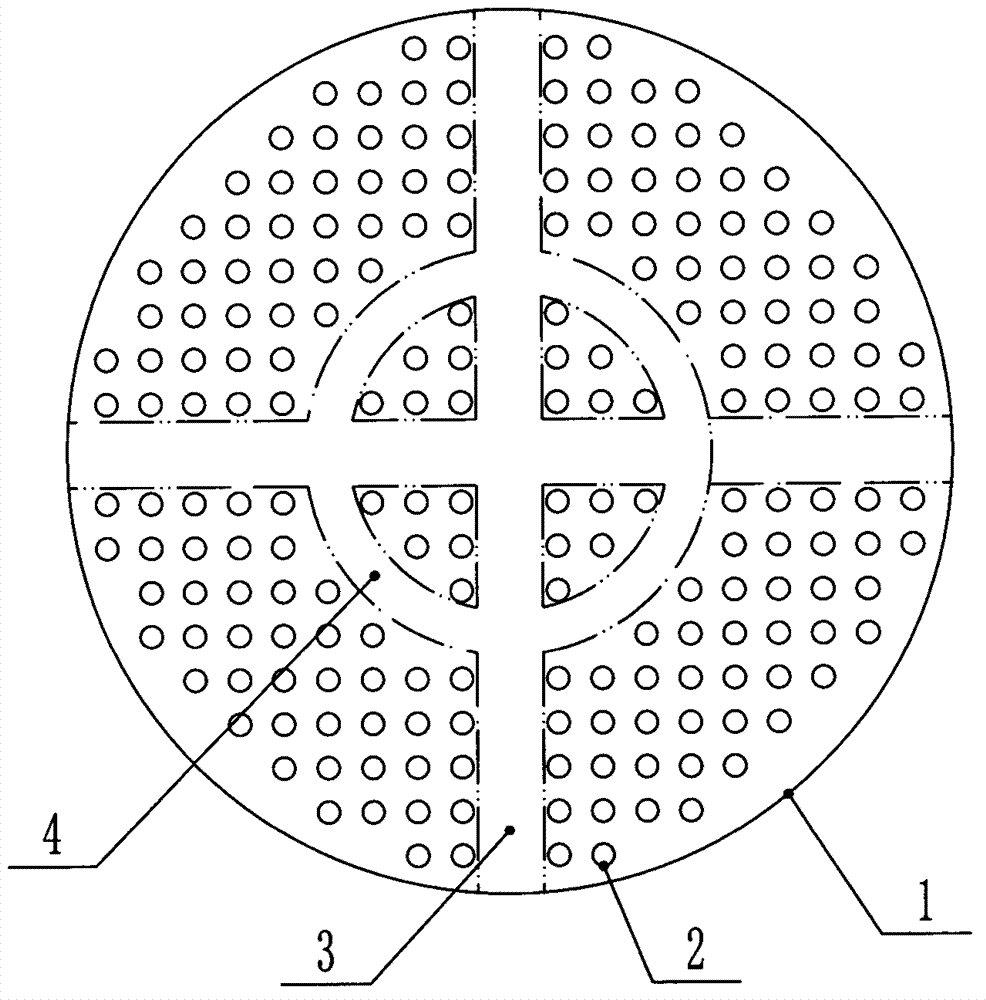

[0009] like figure 1 As shown, a spinneret includes: a spinneret body 1, a spinneret body 1 is provided with a spinneret hole 2, and the spinneret body 1 is provided with a spinneret leading from the periphery of the spinneret to the spinneret The cross-shaped ventilation channel 3 in the middle of the plate and the annular ventilation channel 4 with the center of the spinneret as the center of the circle.

[0010] The above-mentioned spinneret, by setting the cross-shaped air passage 3 and the annular air passage 4 on the spinneret body 1, because there is no spinneret hole 2 in the cross-shaped air passage 3 and the annular air passage 4 area and communicate with each other, it is also There is no tow to block the passage of the cooling air, and the cooling air can enter the middle of the spinneret from the periphery of the spinneret through the air duct, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com