Spinneret plate

A spinneret and spinneret hole technology, applied in spinneret assemblies, textiles and papermaking, etc., can solve the problems of not meeting the technological requirements, difficulty in spinning, too many tows, etc., and achieve better spinning effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] A spinneret according to the present invention will be further described in detail through specific examples below.

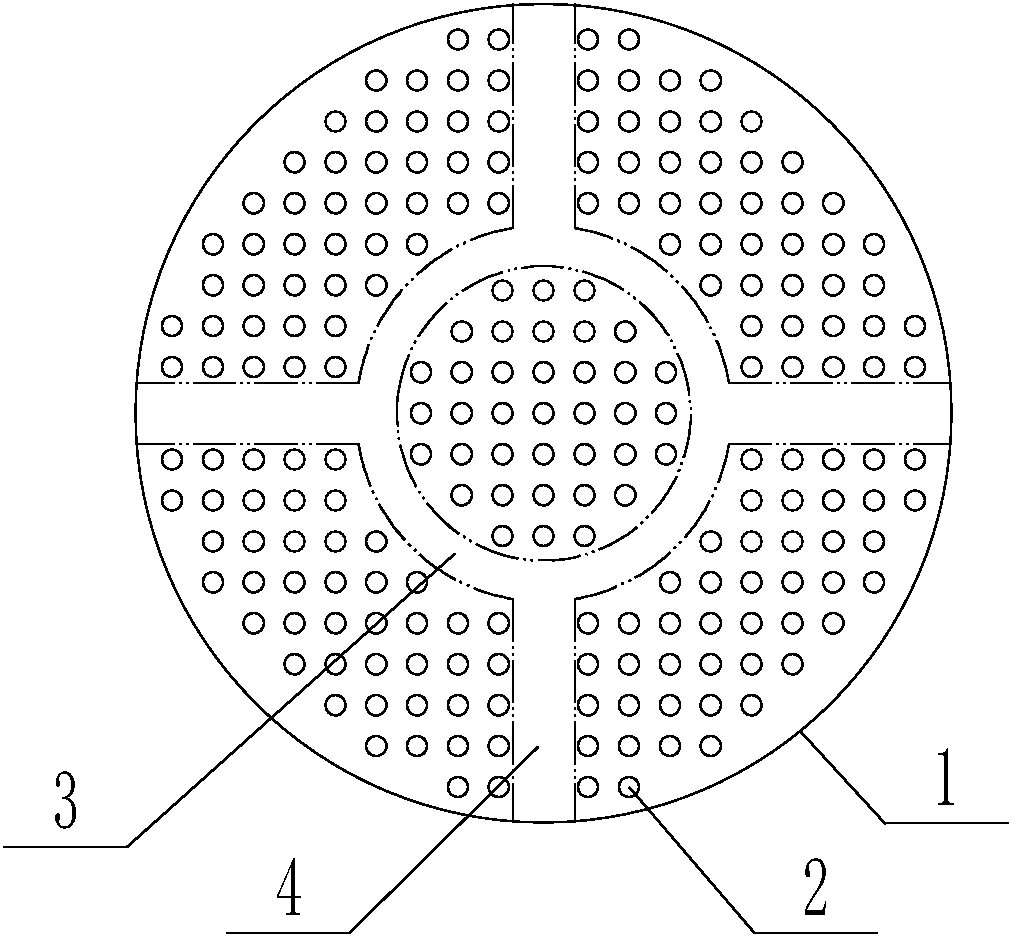

[0010] like figure 1 As shown, a spinneret includes: a spinneret body 1, a spinneret hole 2 is arranged on the spinneret body 1, and an annular ring with the center of the spinneret as the center is arranged on the spinneret body 1. The air passage 3, the spinneret body 1 is also provided with four straight air passages 4, the four straight air passages 4 are evenly distributed along the circumferential direction of the spinneret body 1, and one end of each straight air passage 4 is connected with the annular air passage 3 The other end of the straight air passage 4 communicates with the outside of the spinneret body 1 .

[0011] The above-mentioned spinneret, by setting the straight air passage 4 and the annular air passage 3 on the spinneret body 1, since there are no spinneret holes in the area of the straight air passage 4 and the annular air pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com