Fixing method of lining stainless steel plate for underground rescue cabin

A technology of stainless steel plate and fixing method, which is applied in the fields of earth drilling, safety devices, mining equipment, etc. It can solve the problems of complex process and impact on appearance, and achieve the effects of simple fixing method, reduced maintenance cost and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but do not limit the present invention in any way.

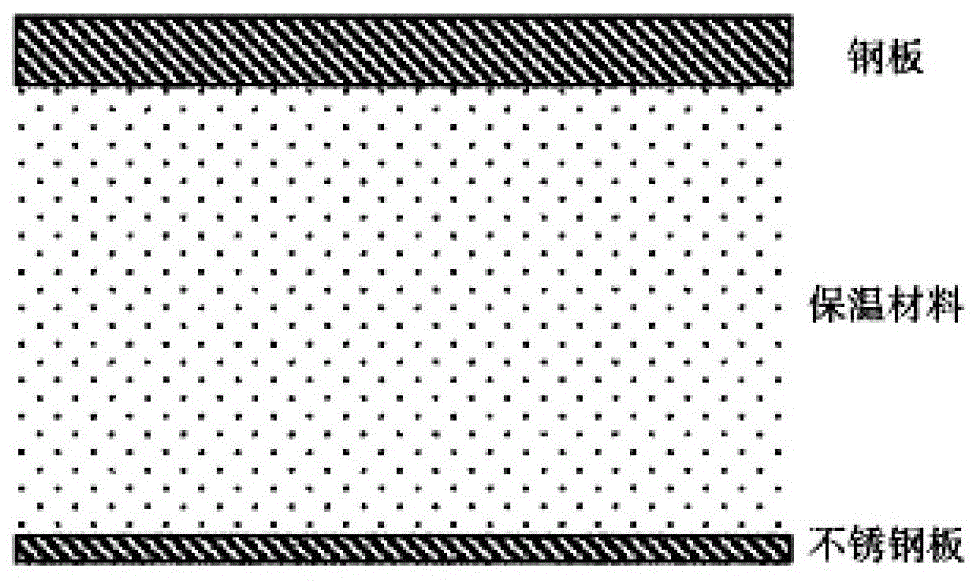

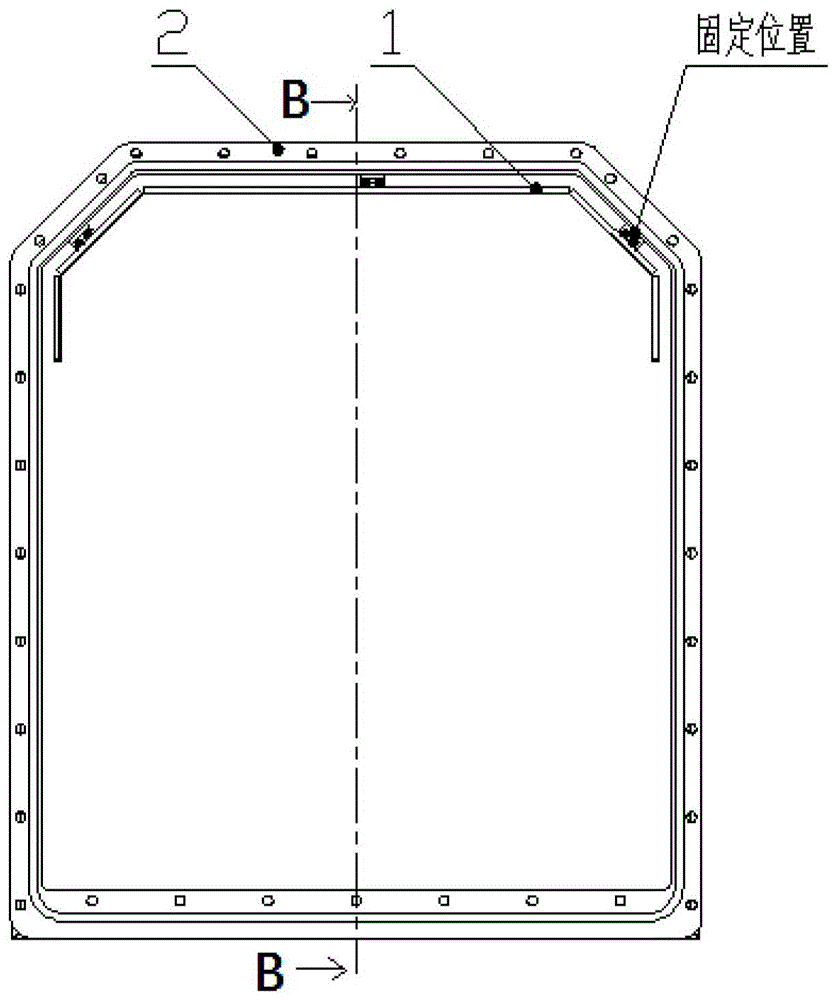

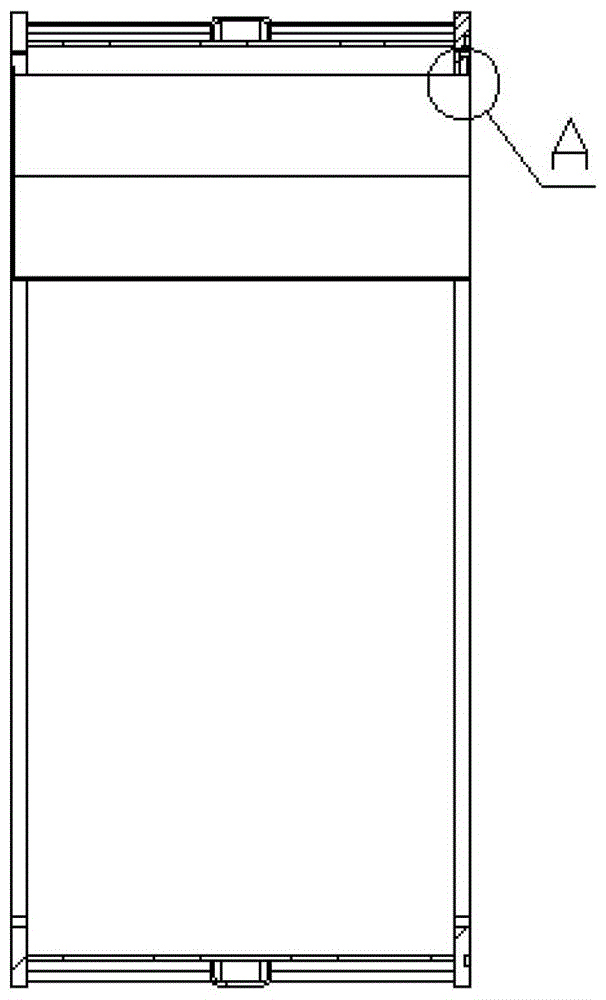

[0025] A method for fixing a stainless steel plate lining an underground rescue cabin. The method includes the following steps: after the cabin section of the rescue cabin is welded, a rigid fixing block 4 is welded at the bottom of the flange plate 2 on the end surface of the cabin section. The welding must be firm. Then lay the insulation layer. After the insulation layer is laid, the non-metallic fixed block 3 is fixed on the rigid fixed block 4 by screws. The material of the non-metallic fixed block 3 is a laminated glass cloth plate to reduce the heat transfer inside and outside the cabin during use. Save refrigerant. Then the connecting piece 5 is welded to the inner stainless steel plate 1, and finally the connecting piece 5 is fixed on the non-metallic fixing block 3 with screws, so as to realiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com