Patents

Literature

102results about How to "Fixing method is simple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

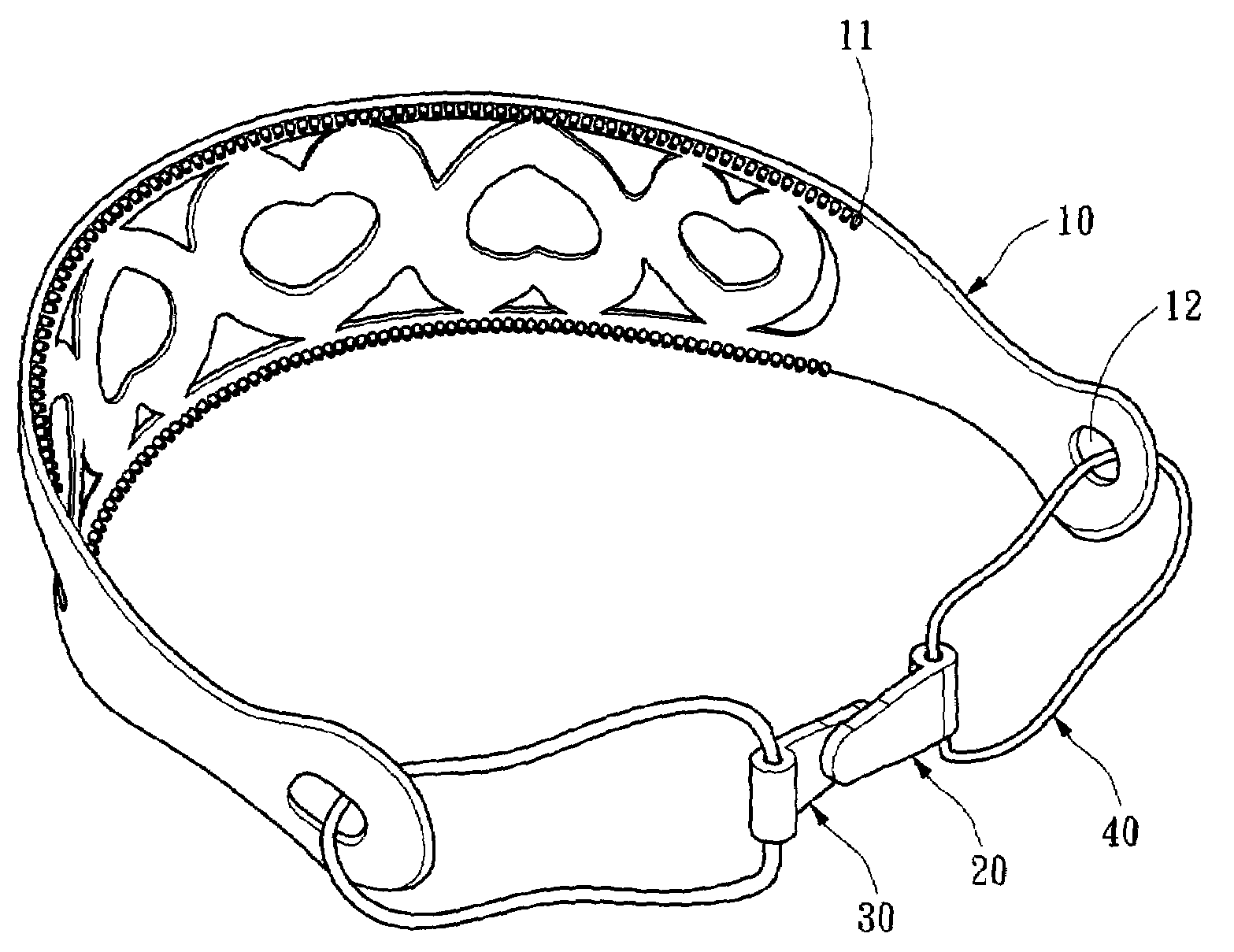

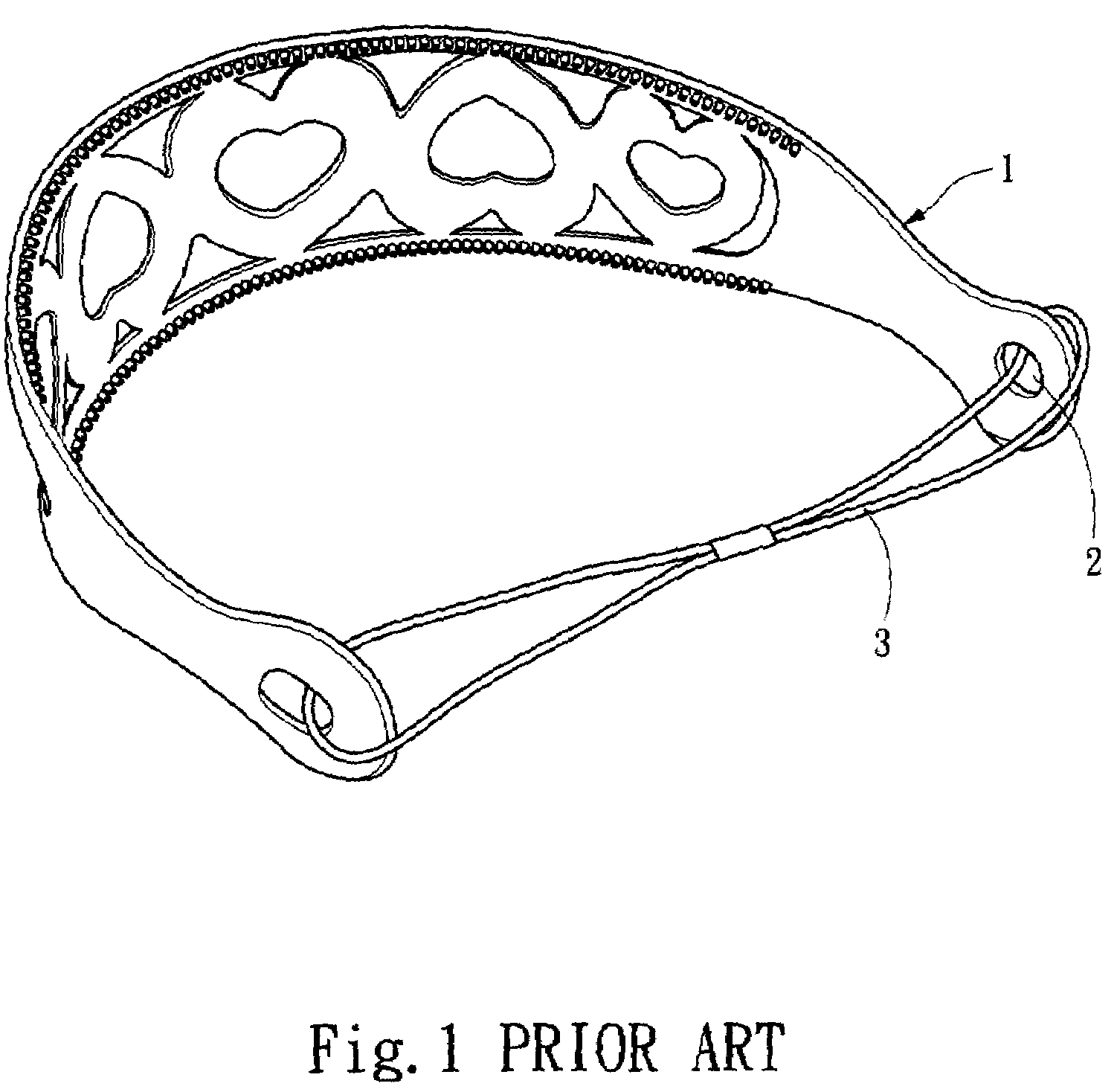

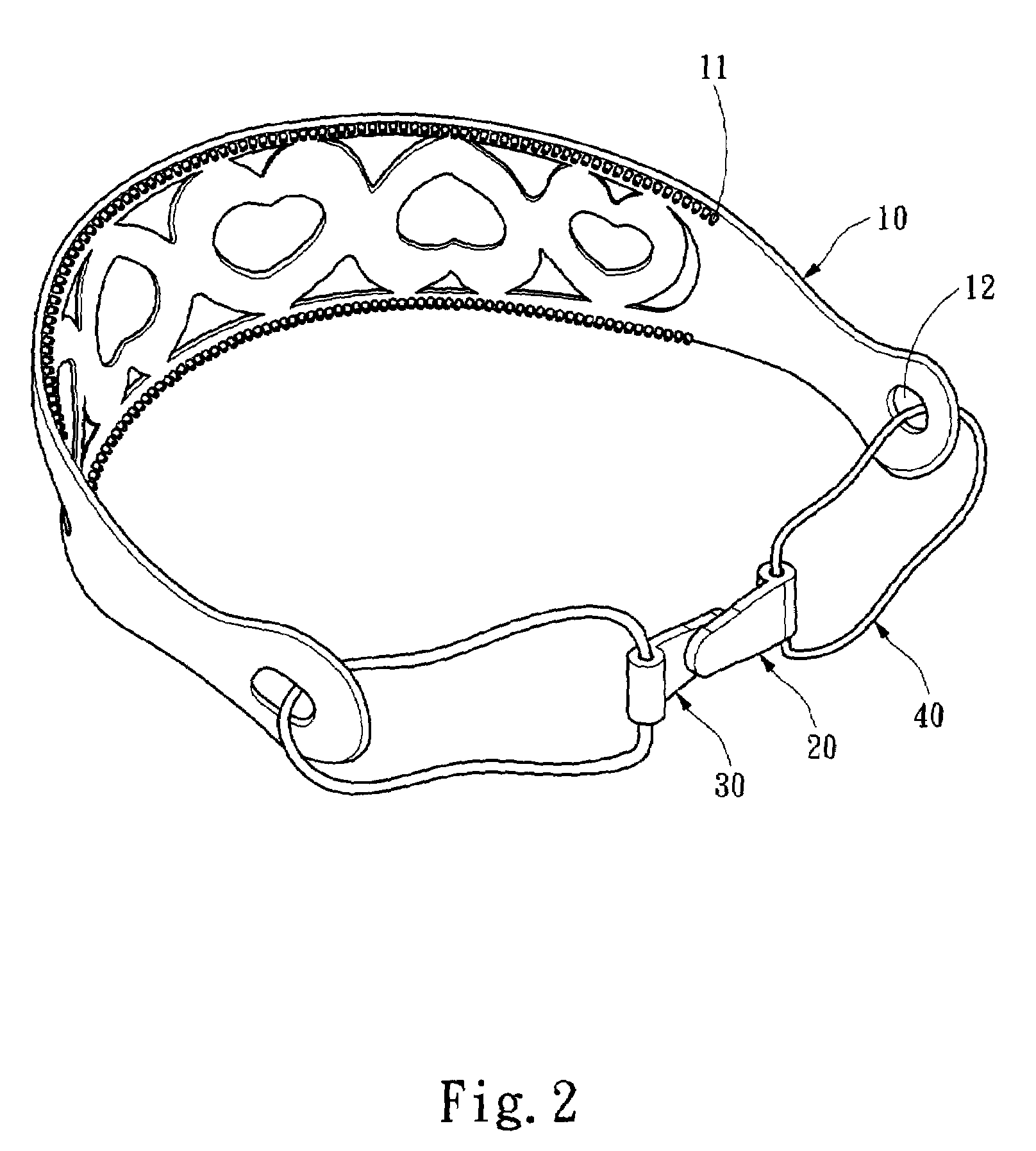

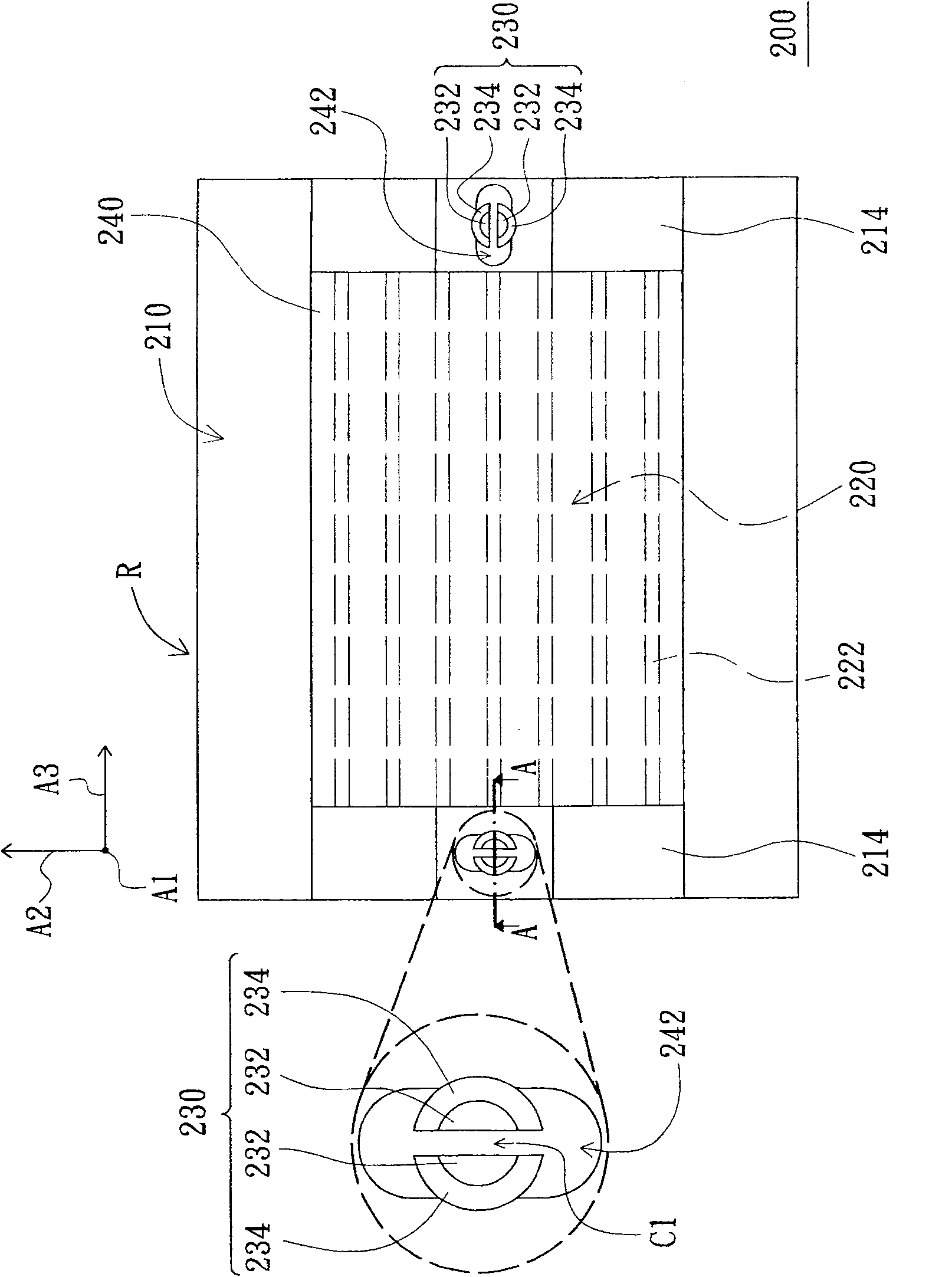

Hair hoop structure

InactiveUS20080302382A1Increase elasticityLabor-saving wearCurling devicesTravelling articlesEngineering

Owner:WANG JEN FU

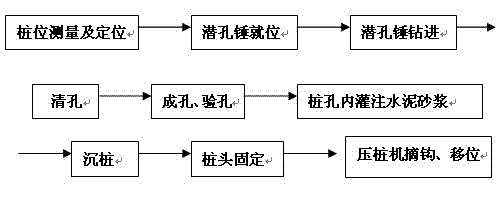

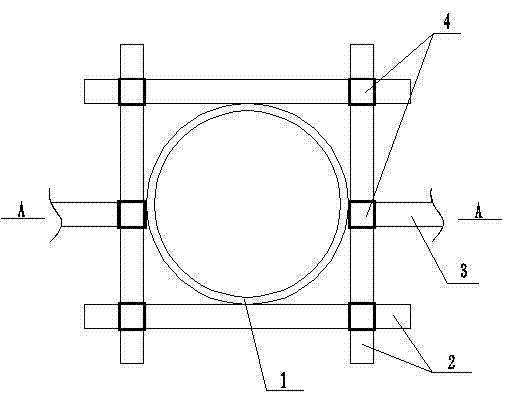

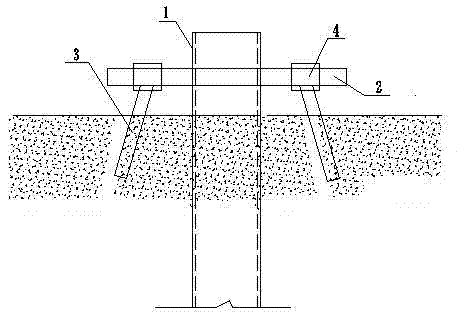

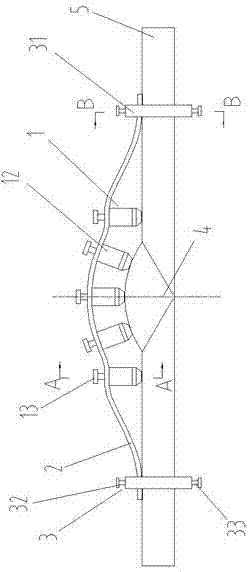

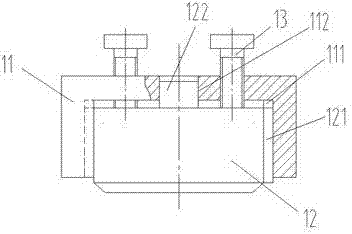

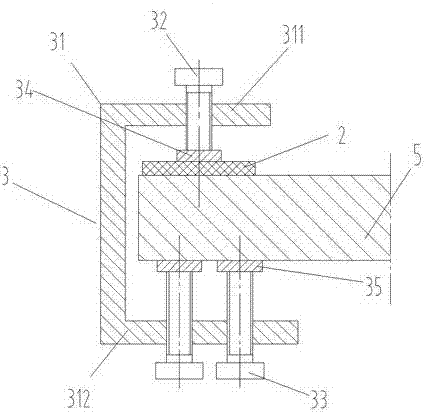

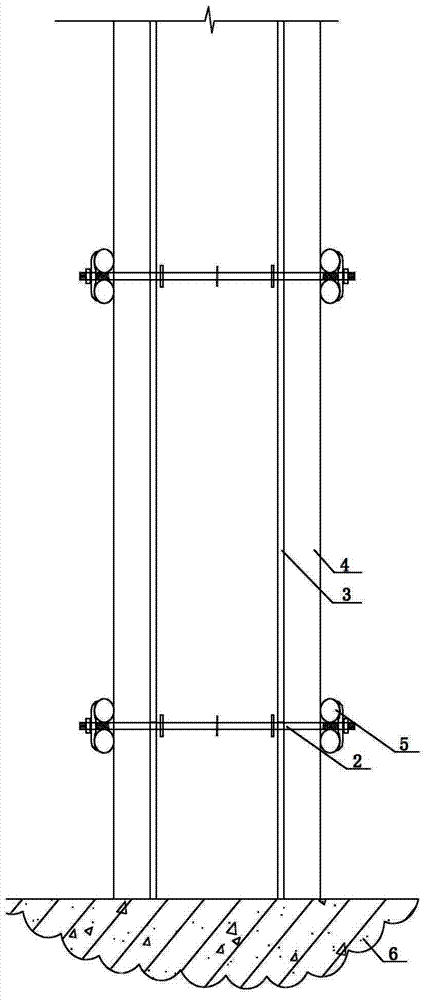

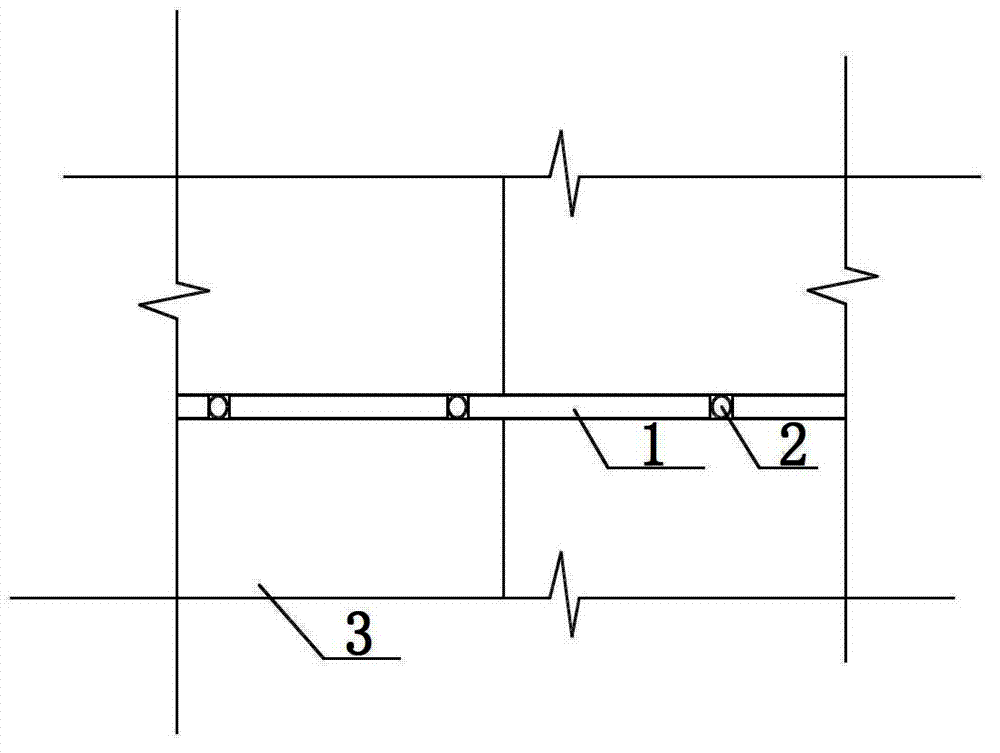

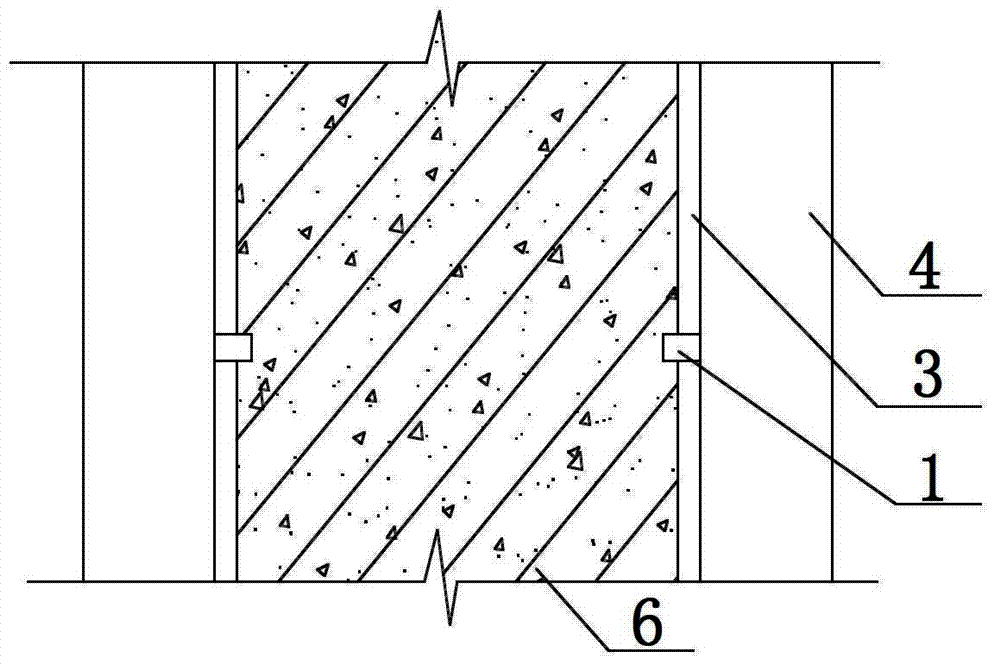

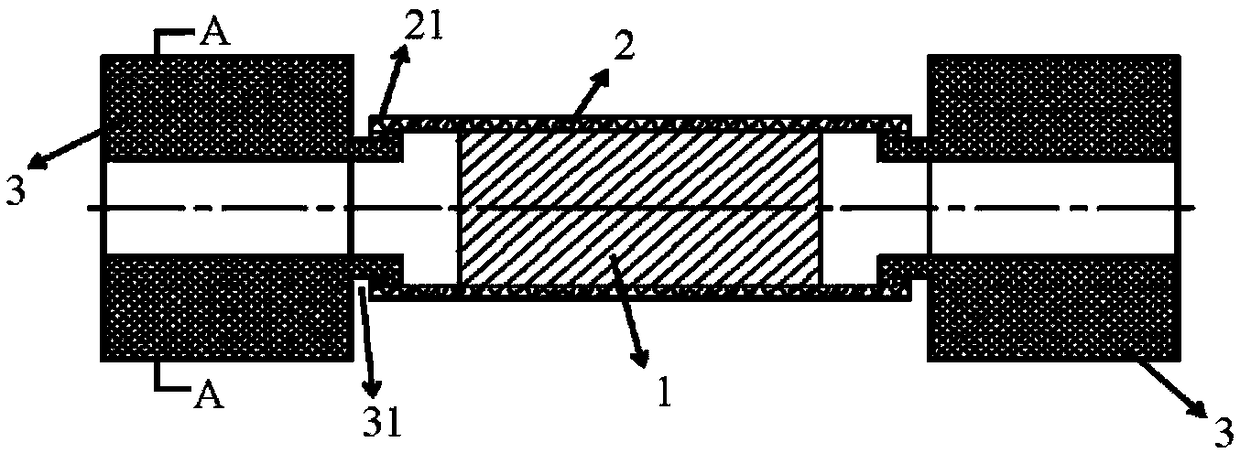

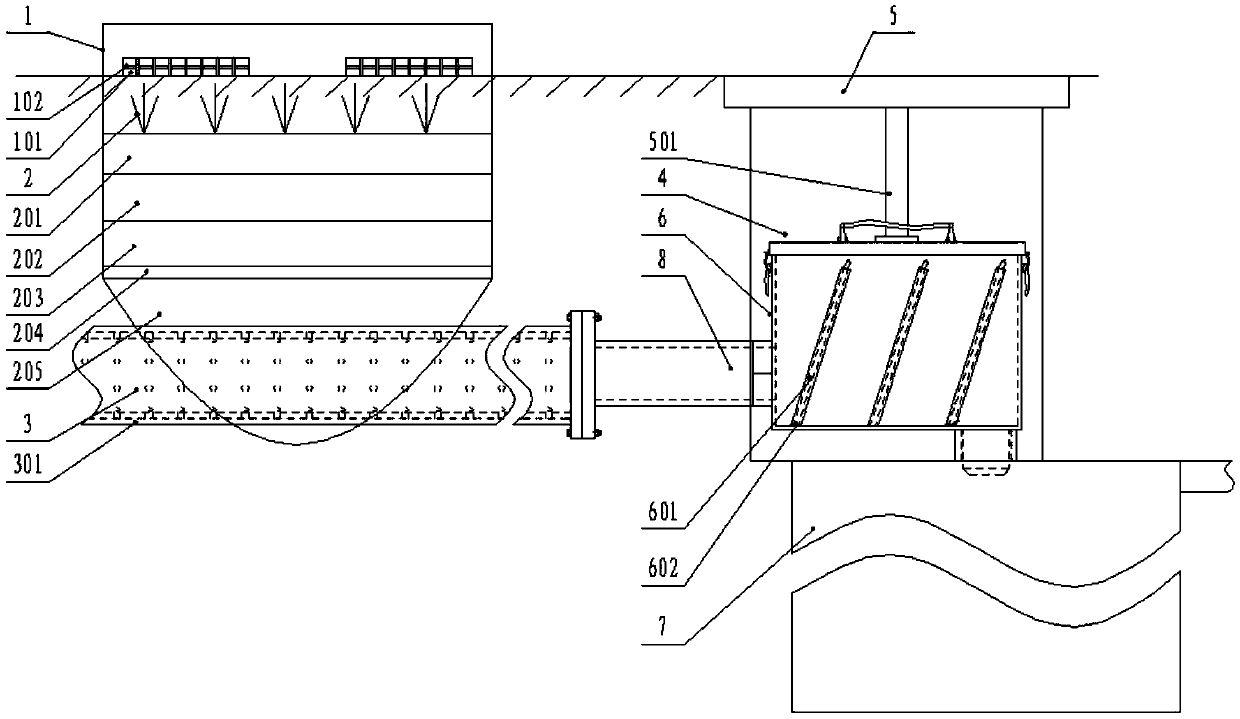

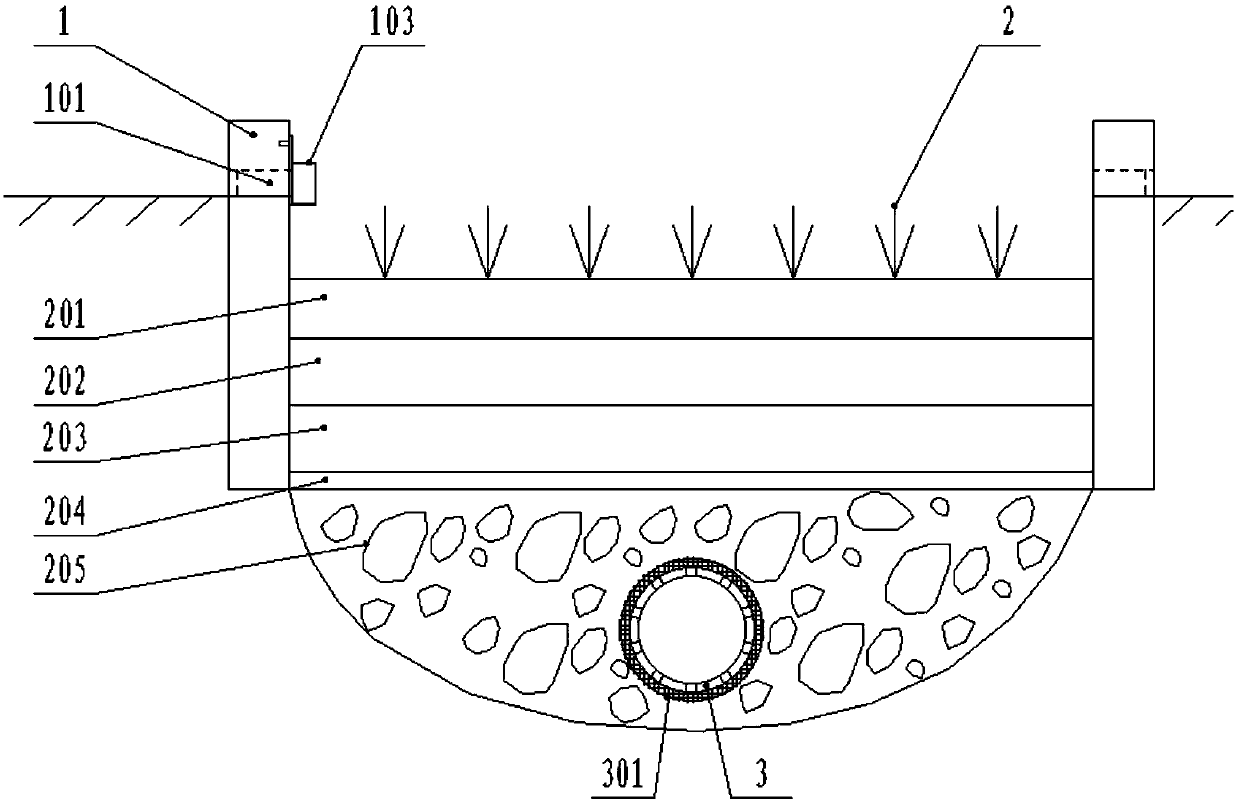

Prestressed pipe pile construction method under boulder group geological conditions

InactiveCN103290840AHigh selectivityPrevent buried drilling phenomenonBulkheads/pilesPre stressArchitectural engineering

The invention relates to a pipe pile construction method, in particular to a prestressed pipe pile construction method under boulder group geological conditions. According to the method, a down-the-hole hammer drilling process is adopted for guide hole construction; during pile sinking construction, first cement mortar is poured in a pile hole, and then a static pile driver is utilized to press a pipe pile into the pile hole; during pile head fixing construction, a #-shaped fixing frame formed by connecting fasteners is utilized to fix a pile head through a steel pipe at the position of an orifice of the pile hole, a splayed steel pipe is adopted to support two ends of the #-shaped fixing frame, the lower end of the steel pipe is embedded in a soil layer; and after the cement mortar is hardened and is integrated with surrounding rock stratums and the pipe pile, prestressed pipe pile construction is finished. According to the prestressed pipe pile construction method, a hole forming speed is quick, a construction period is short, and construction cost can be reduced by over 10%; by adopting a mode of pouring the cement mortar in the guide hole, pipe pile side pressure, end bearing capacity and the position of the pile side can be guaranteed, and side-direction stress safety of the pipe pile can be guaranteed; a pile head fixing head is simple, construction is convenient, verticality of the pipe pile is guaranteed, and bearing capacity of the prestressed pipe pile is also effectively improved.

Owner:二十二冶集团天津建设有限公司

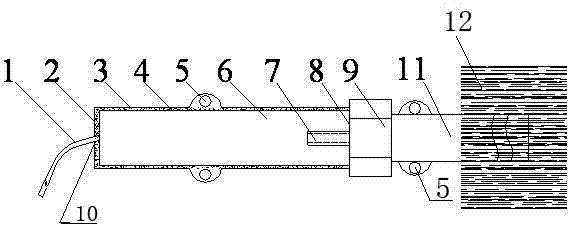

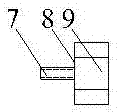

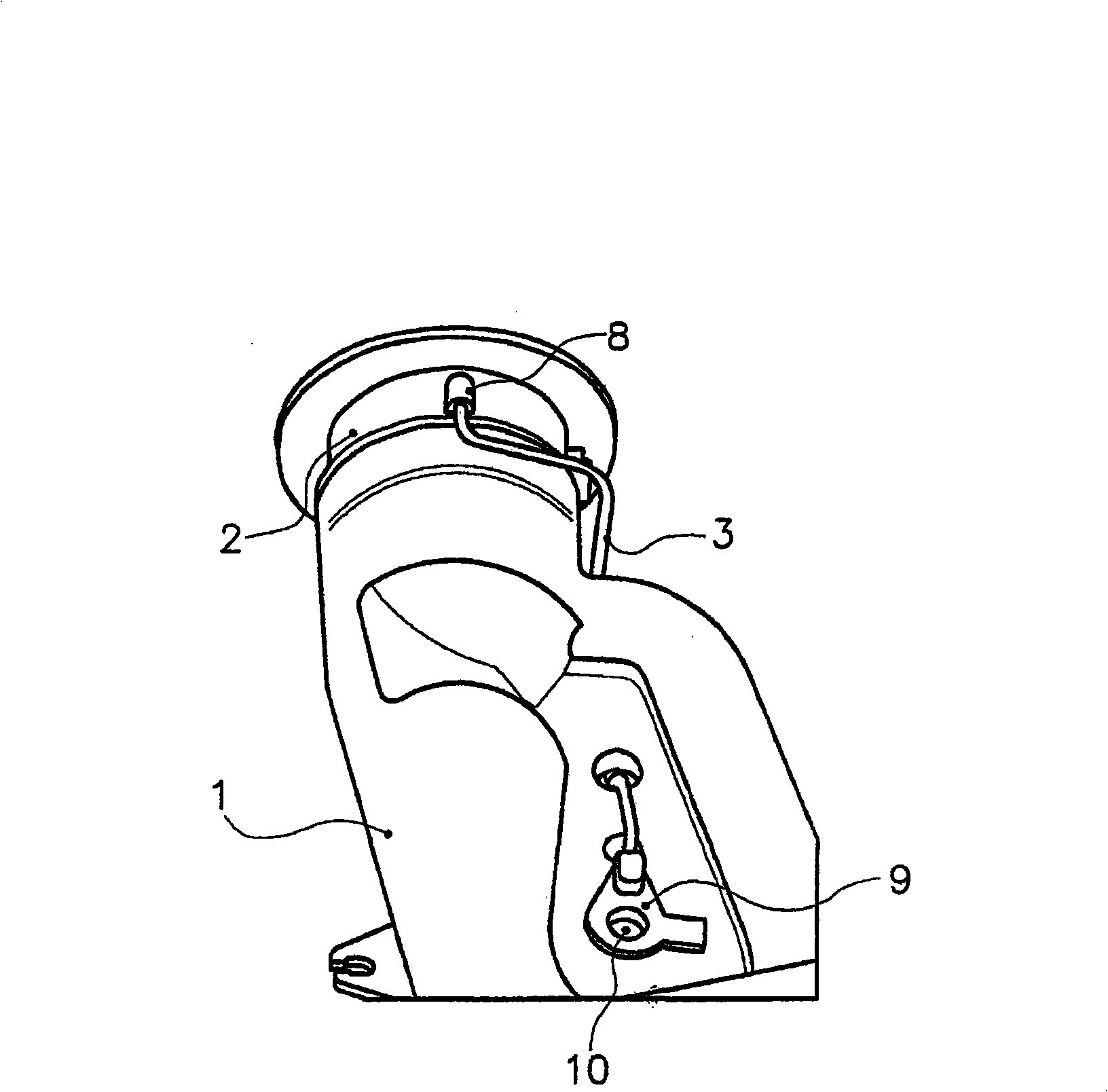

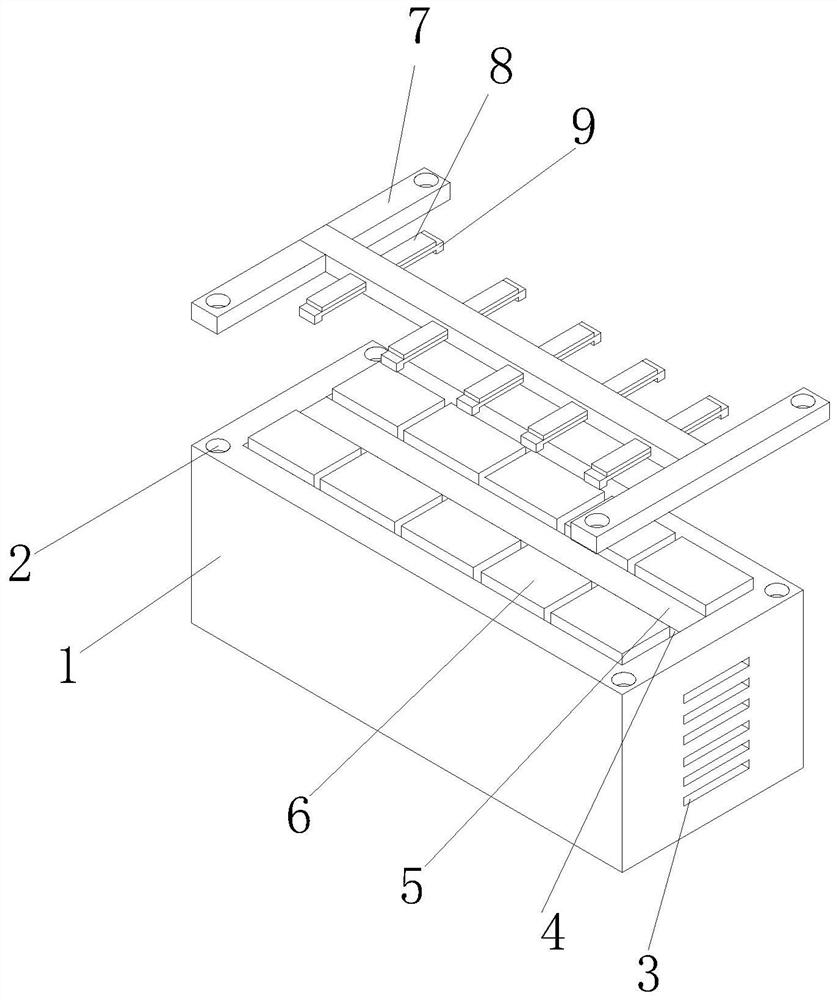

Method for rapidly fixing micro-quake sensor underground

InactiveCN104502957AReduce investmentFixing method is simpleSeismic signal receiversSeismic signal transmissionAcoustic waveEngineering

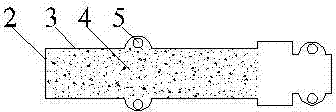

The invention provides a method for rapidly fixing a micro-quake sensor underground. The fixing method is characterized in that on the basis that an anchor rod (11) provided by the support way of an underground coal roadway driving working surface anchor rod (11) is taken as a carrier, the conventional buried type installation way is changed, and a sensor and the anchor rod (11) are fixedly connected integrally by rapidly fixing the micro-quake sensor device underground. The device comprises an outer cover and a connector, wherein the outer cover consists of a bottom plate (2), a cover body (3), an external sound wave insulating material (4) and closing holes (5), wherein the connector consists of a protruding shaft (7), a baffle plate (8) and a fixing bolt (9). By adopting the method, a series of problems of complex installation procedures, high time consumption, difficulty recovery and the like in the conventional micro-quake sensor installation way are solved. Rapid installation and detachment of the sensor are realized. Moreover, the cover body provided by the device can be used for fixing and protecting the sensor, and plays a role in insulating and eliminating noise.

Owner:GUIZHOU INST OF COAL SCI

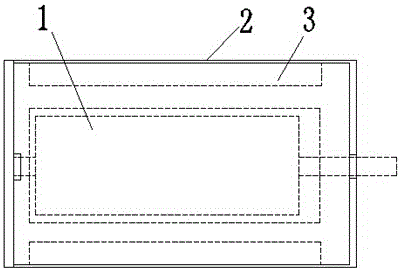

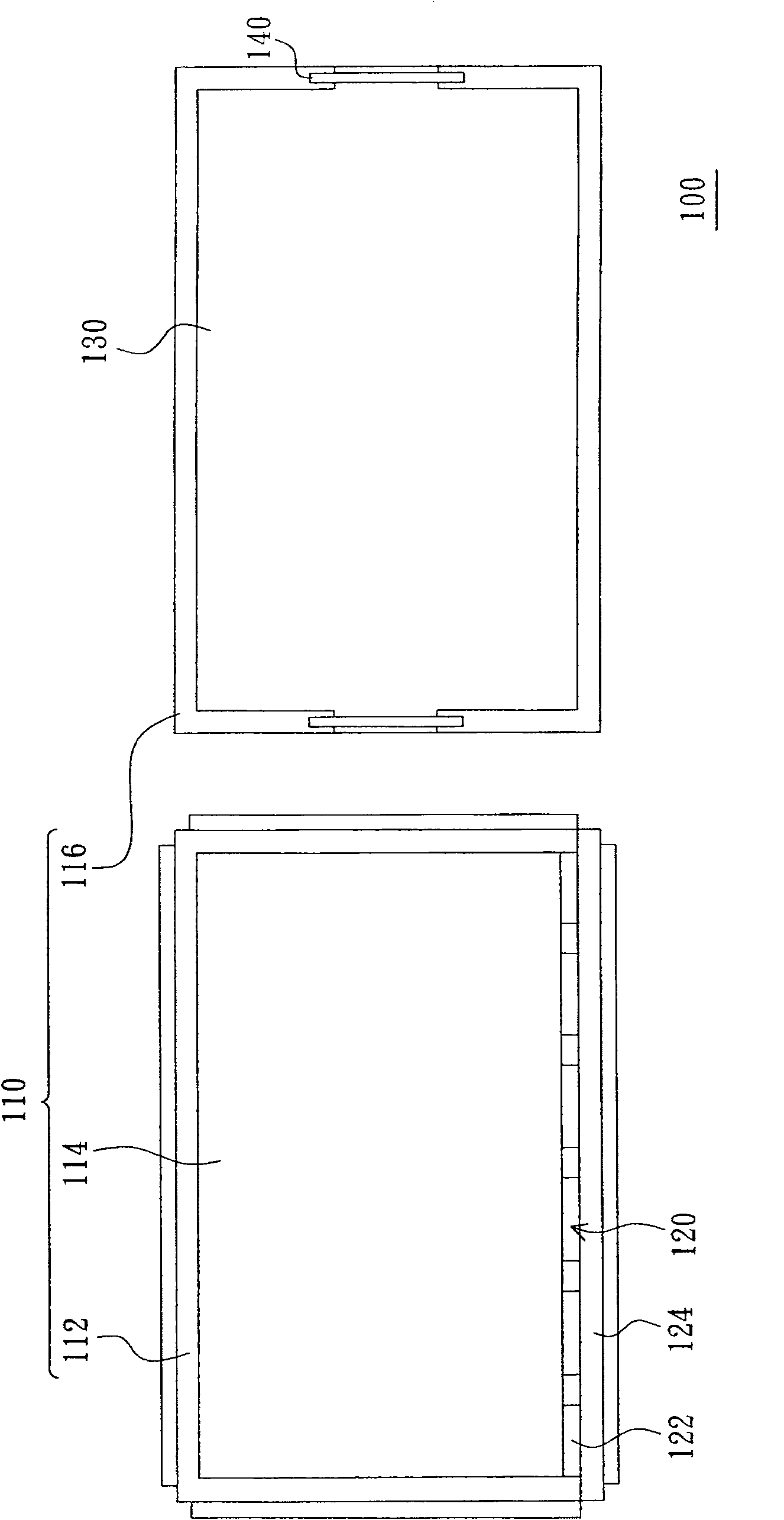

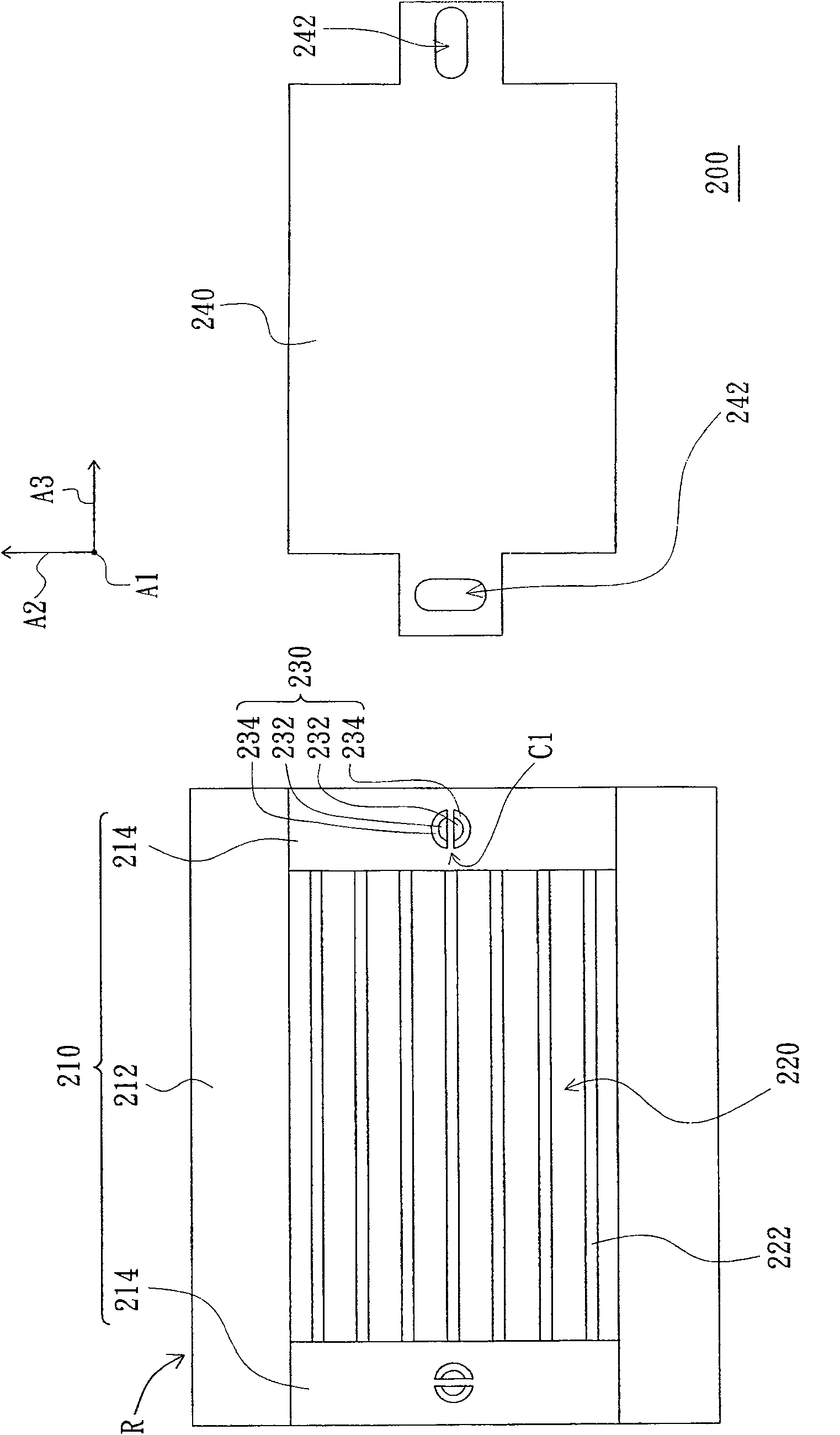

Backlight module and optical film immobilizing method

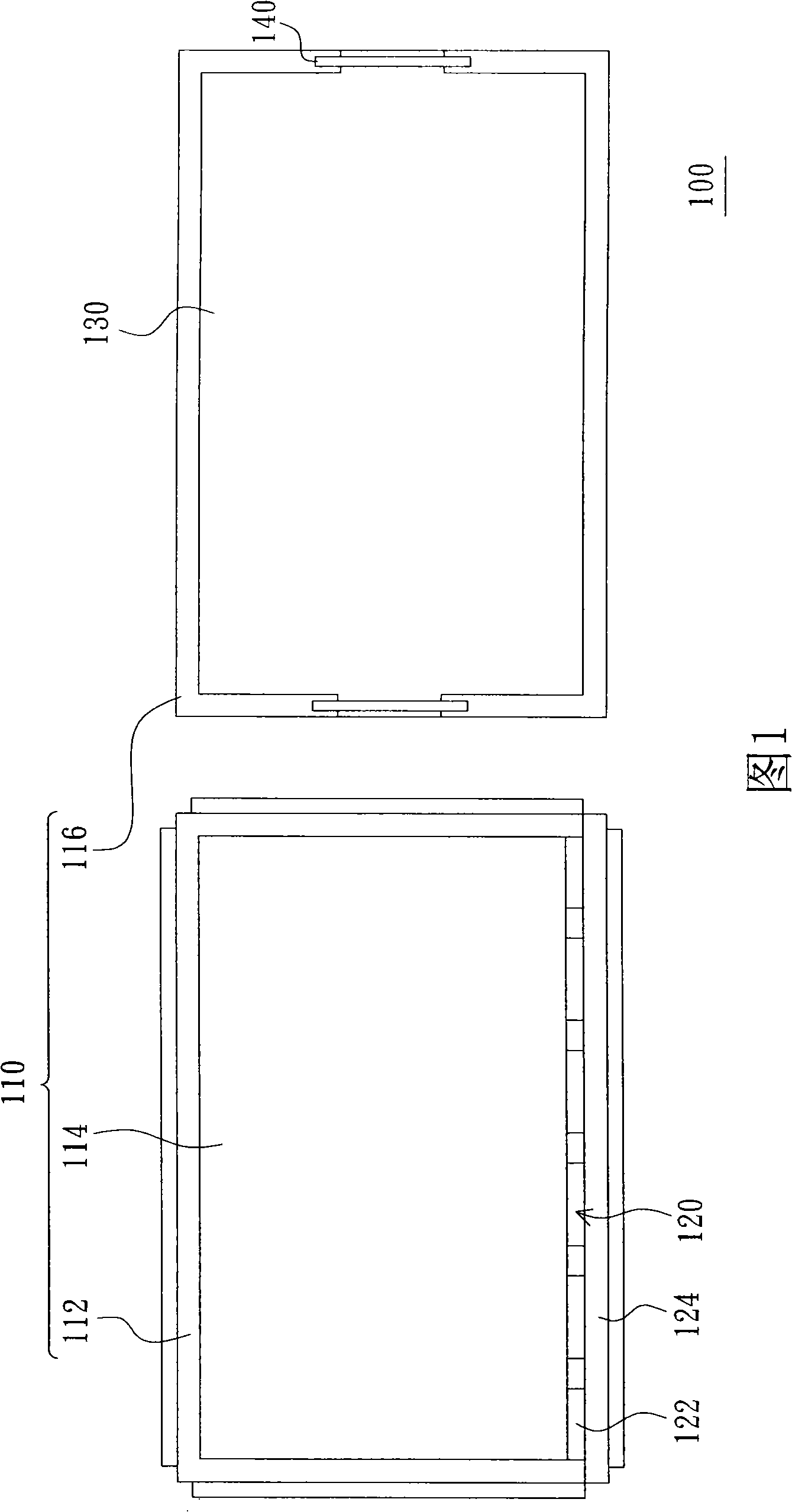

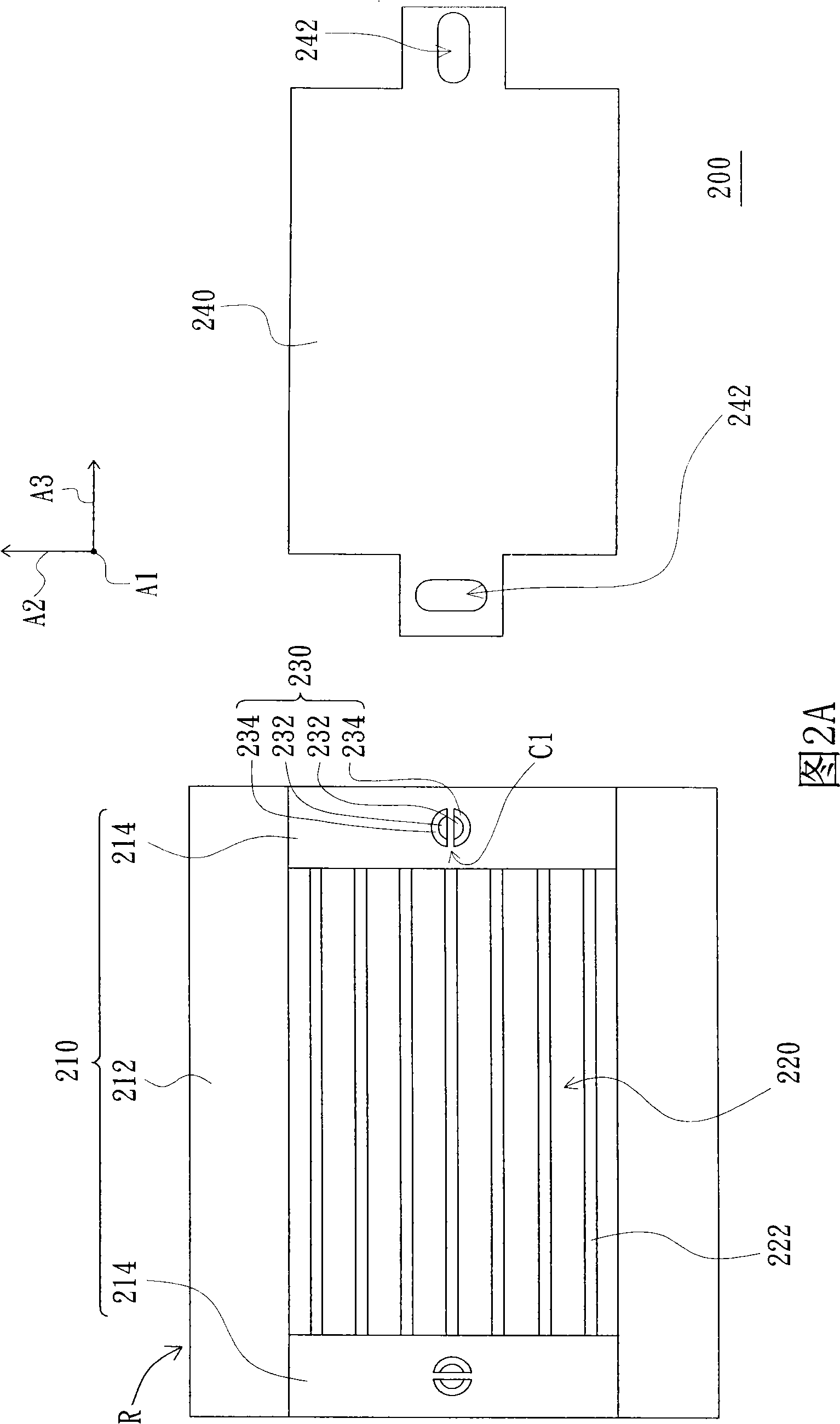

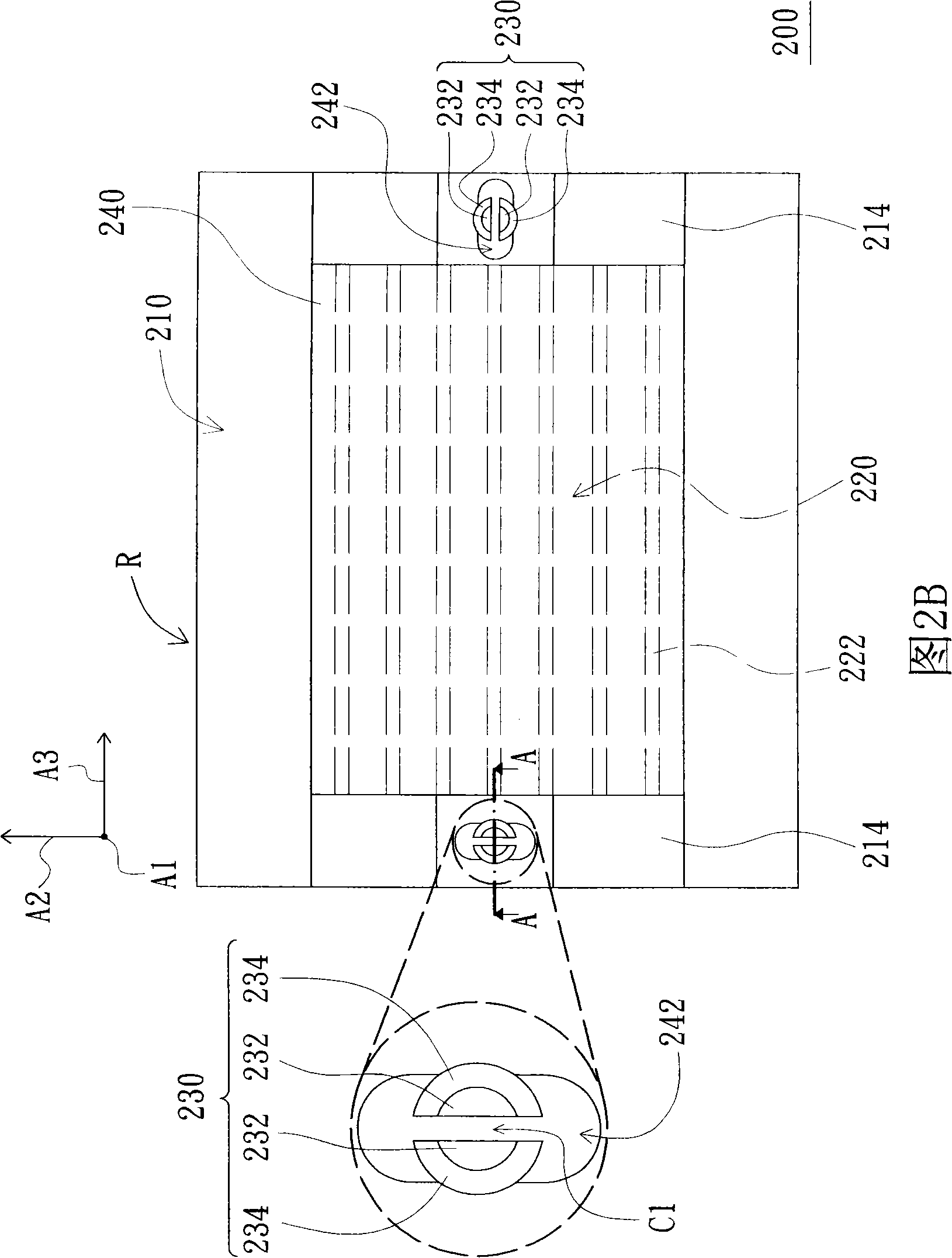

ActiveCN101308287AFixing method is simpleSimplify the assembly processLighting support devicesNon-linear opticsComputer moduleEngineering

The invention discloses a fixing method for a backlight module and an optical patch; the backlight module comprises a base, a light source, a plurality of fixed components and an optical patch. The light source is arranged on the base and can emit light. Each fixed component has a pair of flexible connectors arranged on the base and a pair of clipping fasteners which are respectively arranged on the flexible connectors. The flexible connectors of each fixed component maintain the gaps, and the flexible connectors of each fixed component can make flexible deformation by narrowing the gaps. The optical patch is arranged on the base and has a plurality of fixed holes. The light passes through the optical patch. The flexible connectors of each fixed component pass through one of the fixed holes; each fixed hole is limited between each clipping fastener of the corresponding fixed component and the base, so that the optical patch is restricted in moving on a first axis, a second axis and a third axis; the first axis, the second axis and the third axis are perpendicular to each other.

Owner:AU OPTRONICS CORP

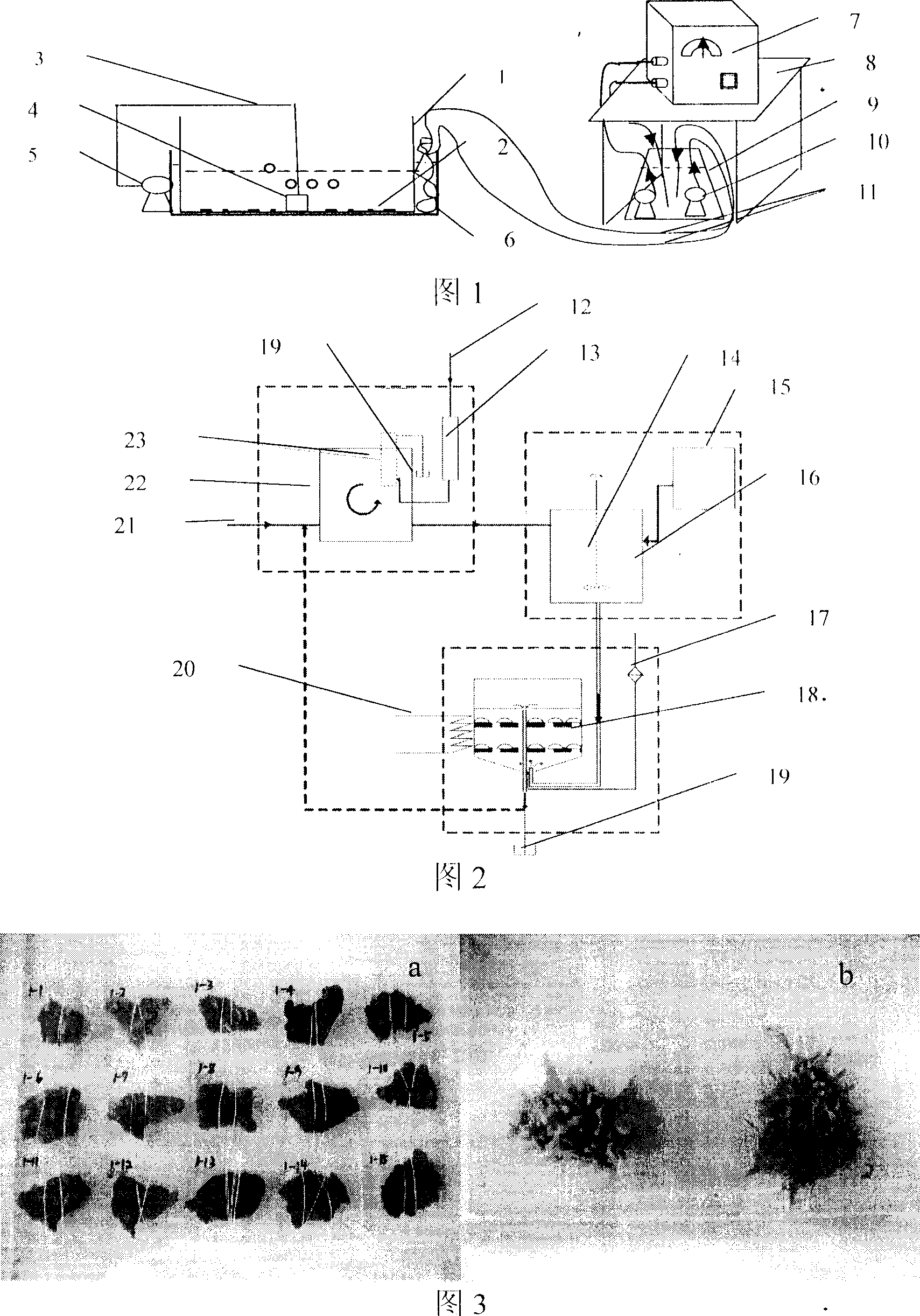

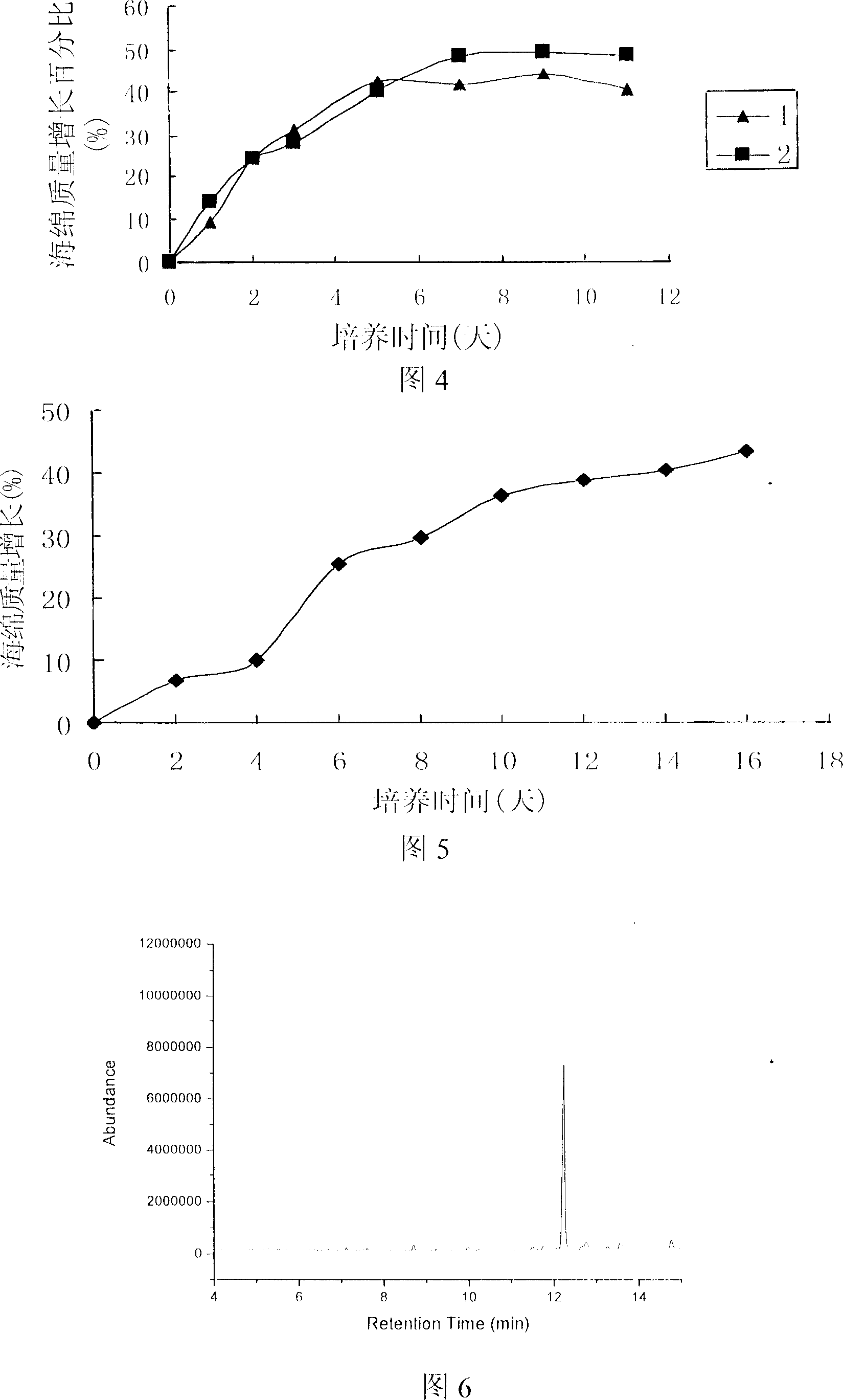

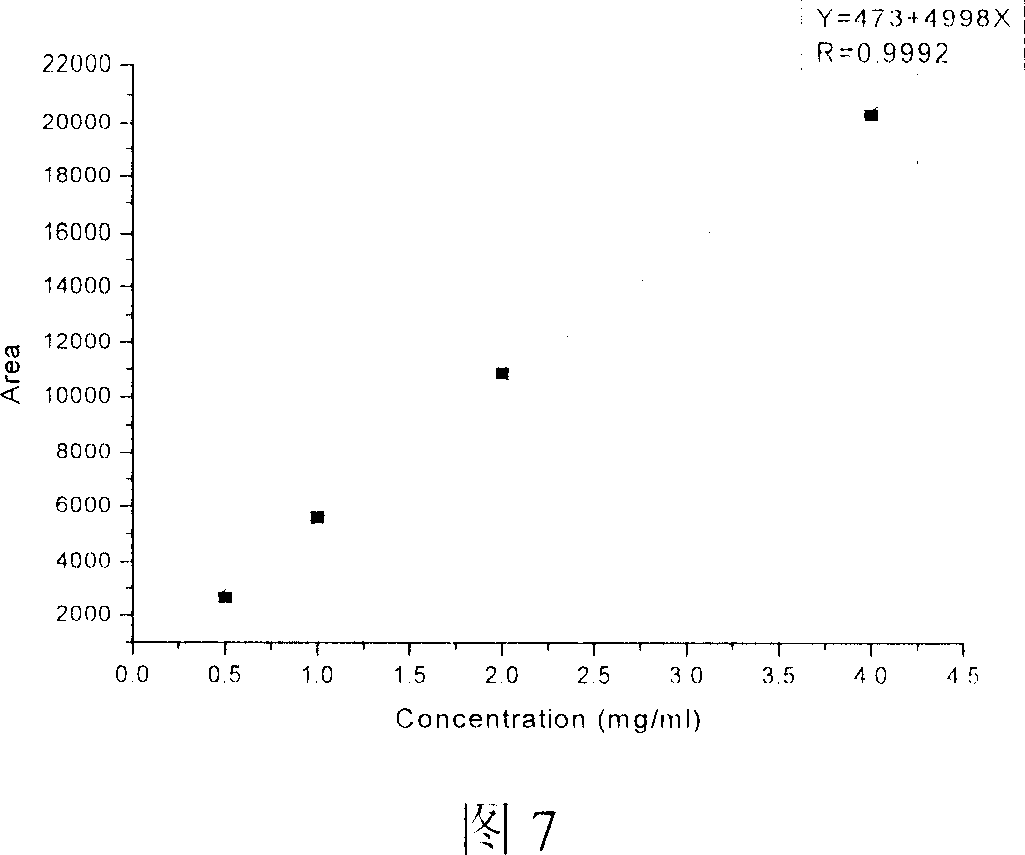

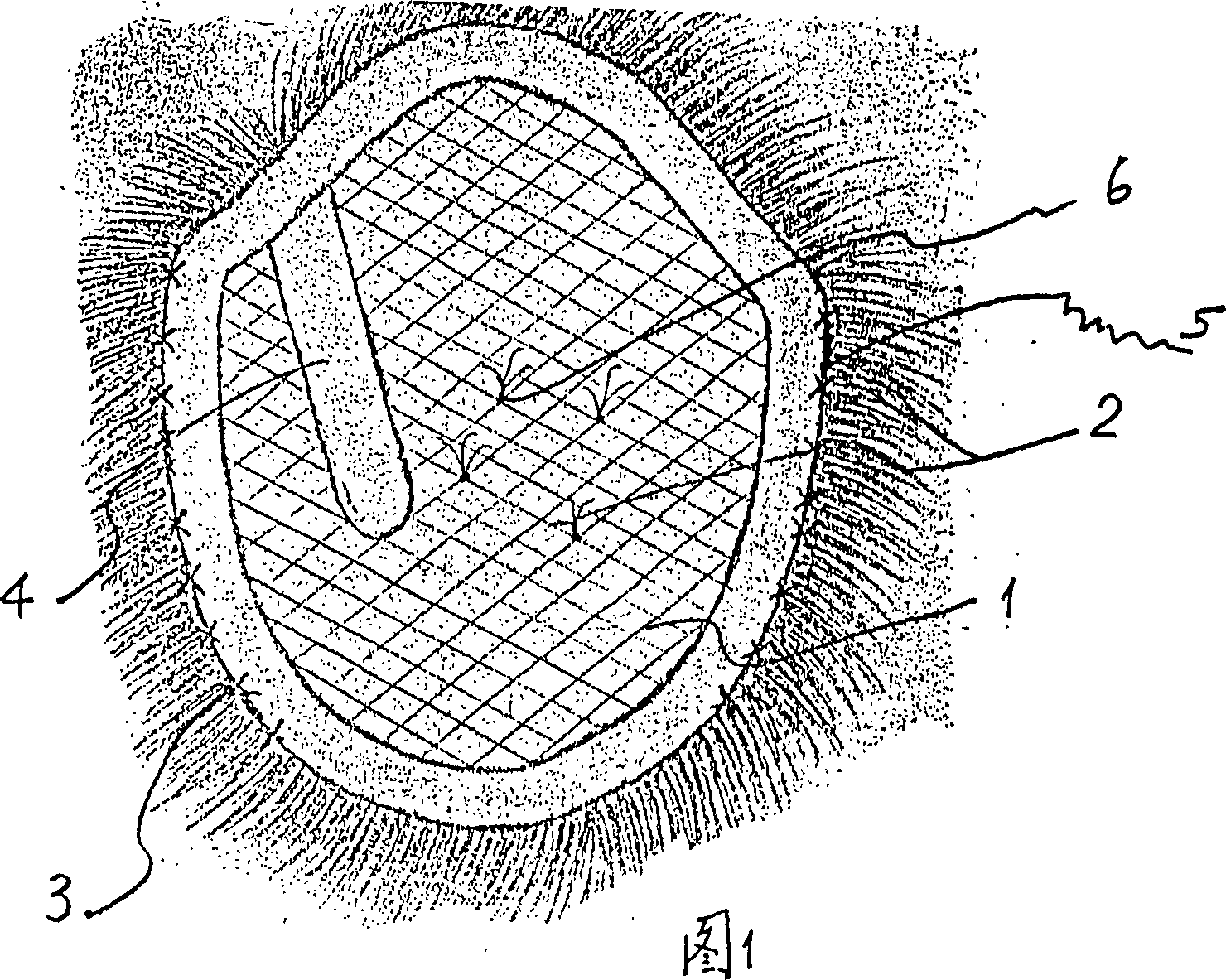

Laboratory artificial cultivating method for intertidal zone marine sponge

InactiveCN101099452ATechnical integrityEasy to makeAnimal cellsClimate change adaptationTemperature controlSurface ocean

The present invention relates to a method for making intertidal sponge undergo the process of artificial cultivation under the laboratory condition to obtain biomass. Said method includes the following steps: collecting sponge in intertidal zone, cleaning impurity and dirts from sponge surface in laboratory, cutting sponge into small blocks, making temporary culture in culture vessel, then fixing the small block sponge on the carrier, placing it into a culture device to make temperature-controlled photophobic culture, adding bait algae as main body food, making culture for 10-20 days, so that the biomass maxmum value of primary sponge growth can be obtained.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

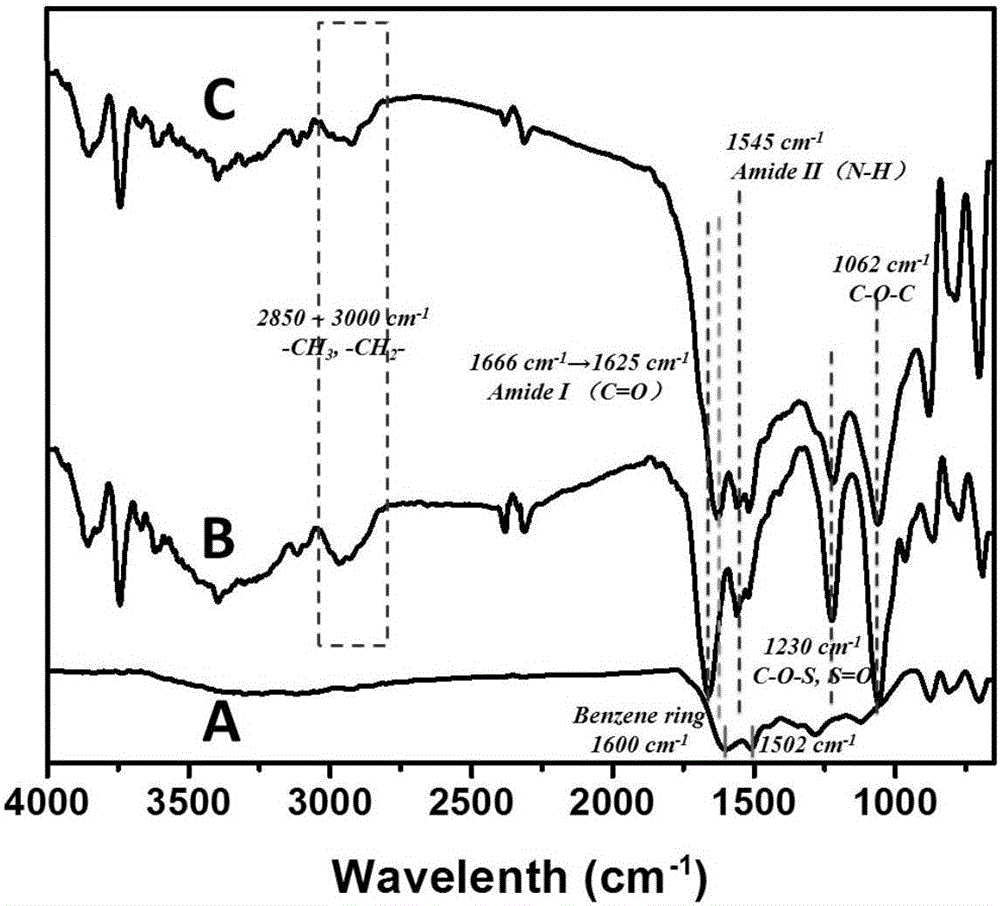

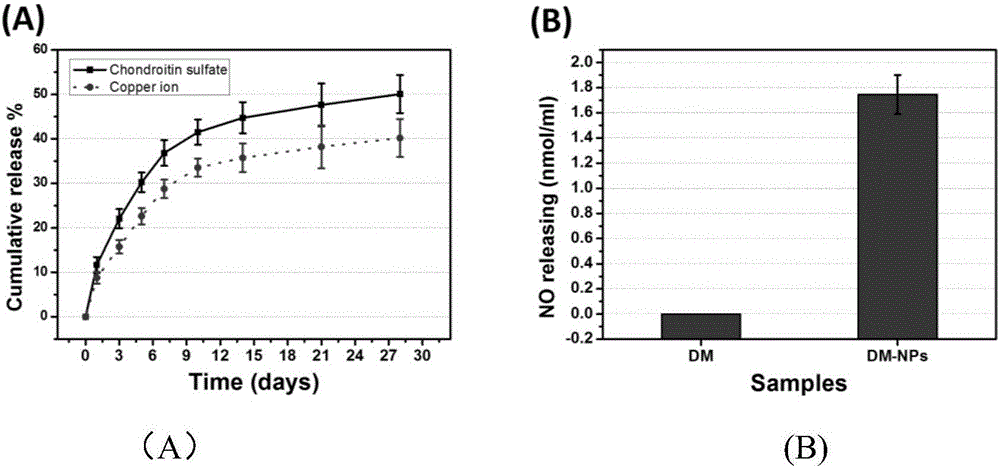

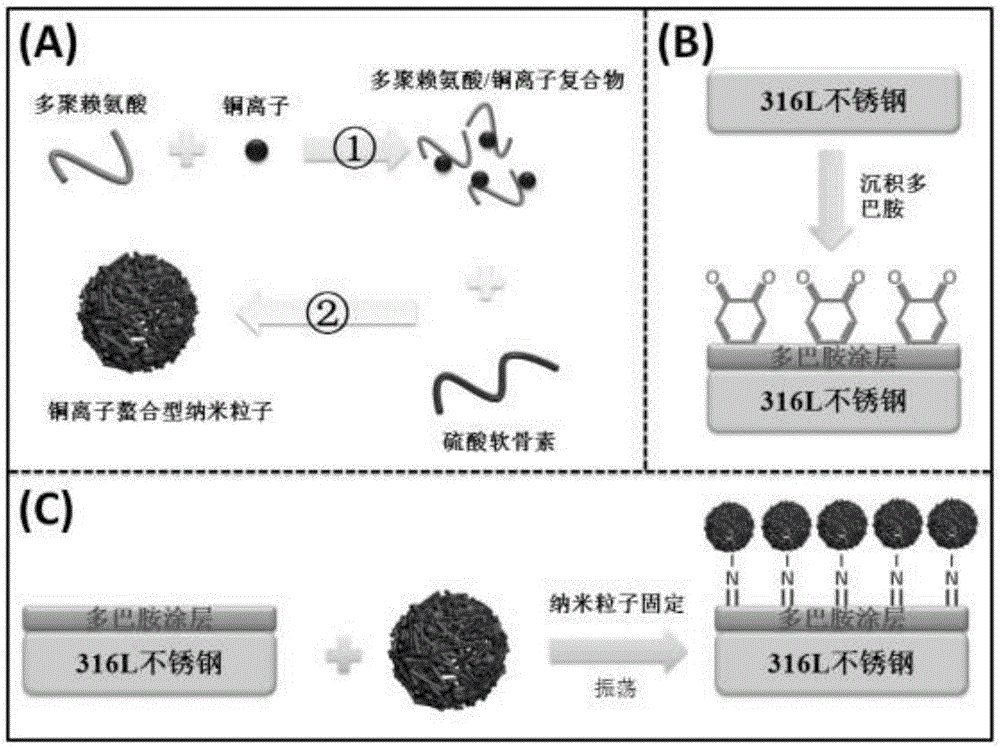

Preparation method of copper ion chelated nano particle biological coating

InactiveCN105925173ANormal biological functionHigh activitySurgeryPolyamide coatingsEndothelial regenerationPhysical chemistry

The invention discloses a preparation method of a copper ion chelated nano particle biological coating. The preparation method comprises the following steps: at first, chelating PLL and copper ions to obtain a PLL / copper ion compound; utilizing the characteristic that PLL and chondroitin sulfate can carry out electrostatic interaction to mix PLL / copper ion compound with chondroitin sulfate so as to form copper ion chelated nano ions; then preparing a DM coating on the surface of 316L stainless steel, utilizing the characteristic that DM and primary amino group can carry out Schiff base reactions to fix nano particles containing amino groups onto the surface of a sample so as to establish a multifunctional surface that can prevent coagulation and proliferation and promote endothelial regeneration. By establishing a nano particle coating, which has multiple biological functions, on the surface f 316L stainless steel, the anti-coagulation and anti-proliferation functions of stainless steel are prominently enhanced, and at the same time, the performance of repairing endothelial injury is strengthened.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

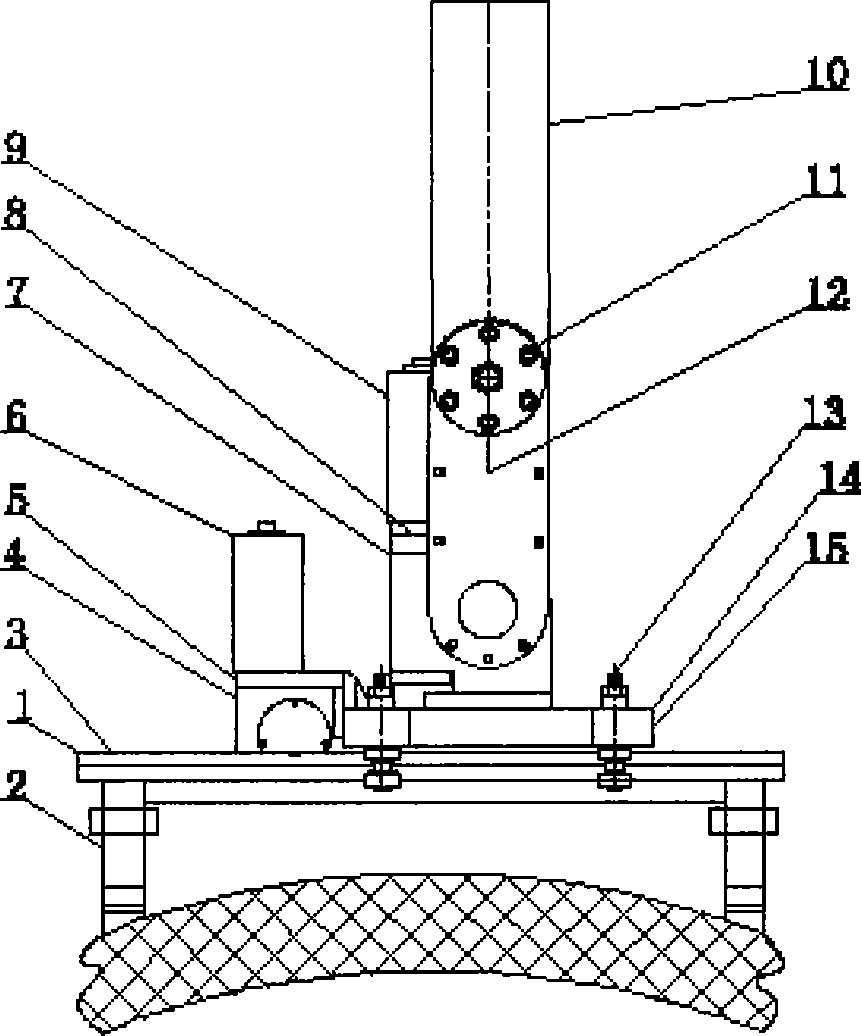

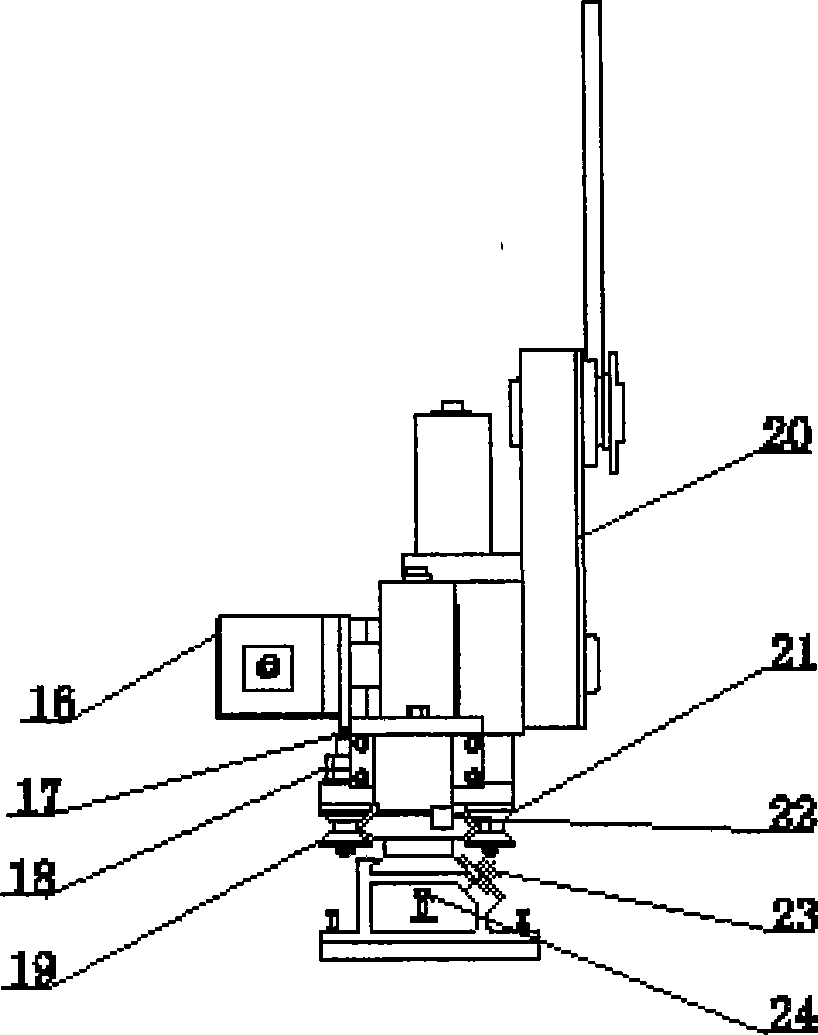

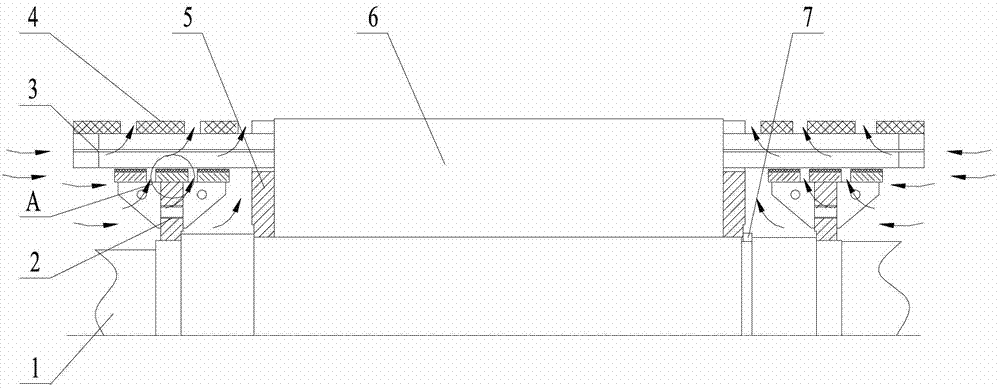

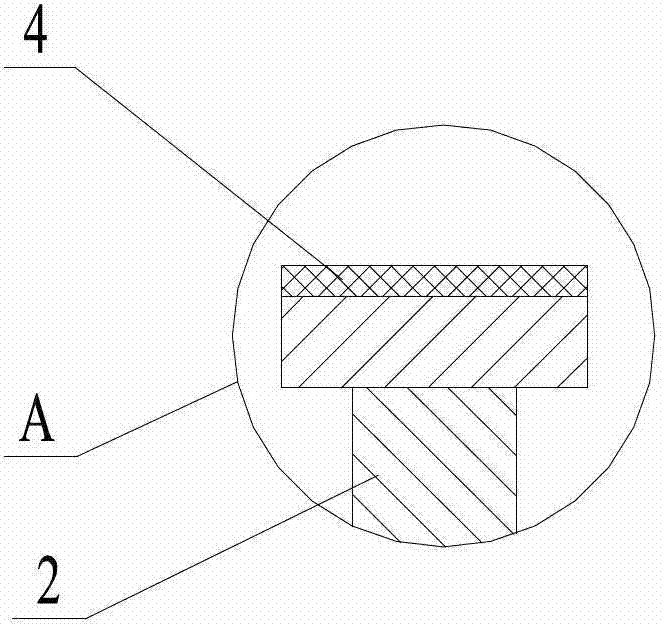

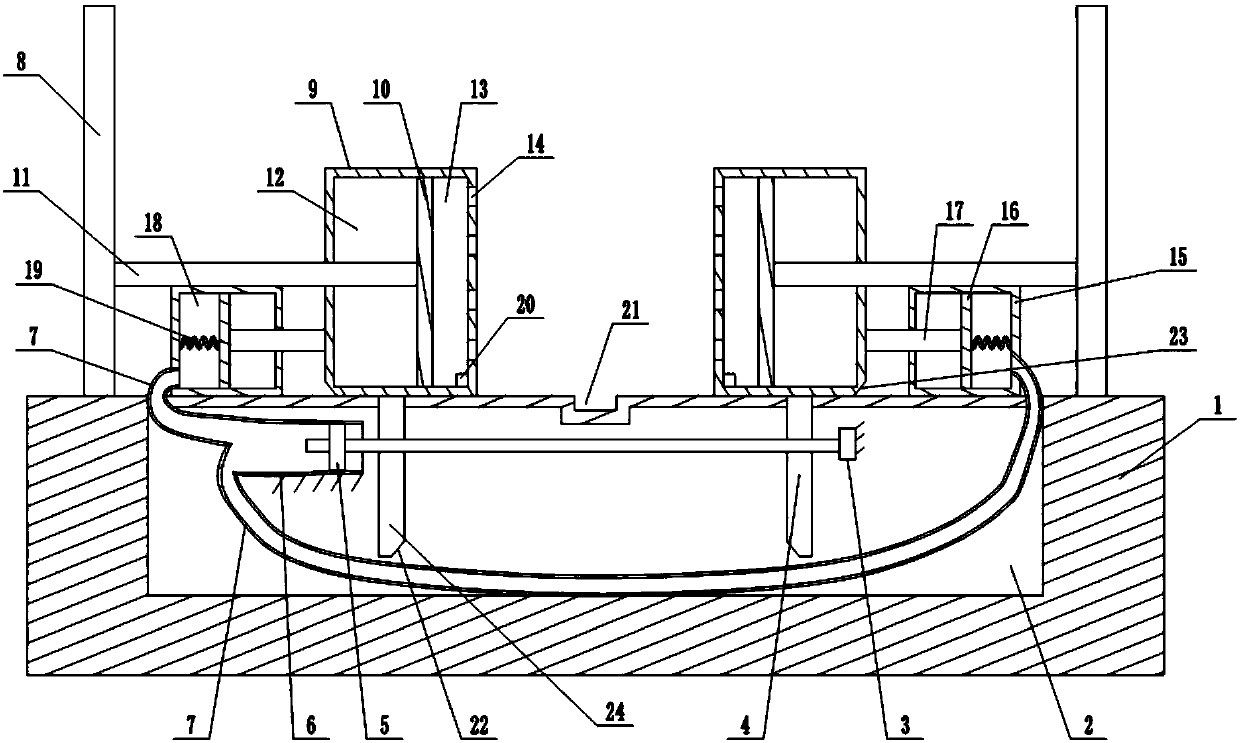

Hydraulic concrete cutting system

InactiveCN101480816AAchieve rotationReliable stopStone-like material working toolsHydraulic motorReinforced concrete

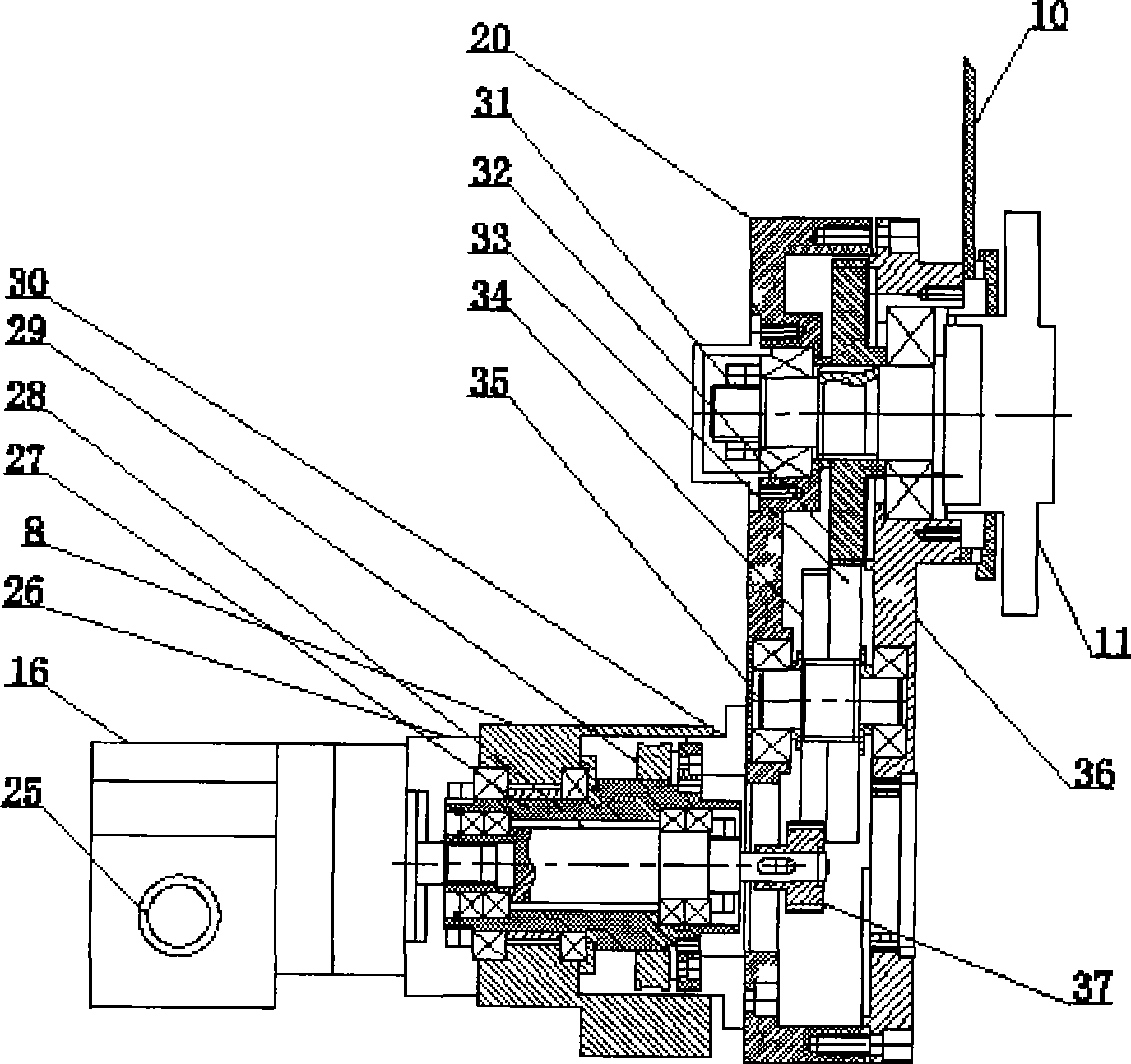

The invention belongs to a building reinforced concrete cutting apparatus, in particular to a hydraulic concrete cutting machine. The hydraulic concrete cutting machine is characterized by comprising a hydraulic supply source, an electric cabinet, a guide way component (1), a cutting feed component (4), a rotation component (7), a speed reducing component (12), a base component (14) and a hydraulic motor (16); the guide way component (1) is fixed on a guide way supporting frame (2); the base component (14) and the cutting feed component (4) are respectively installed at two sides of the guide way component (1); the rotation component (7) and the speed reducing component (12) are vertically connected and fixed above the base component (14); the hydraulic motor (16) is arranged at one end of the rotation component (7) and communicated with the hydraulic supply source through a hydraulic oil pipe; and the electric cabinet controls the operation of the cutting machine through a control cable. The invention adopts the cable control of the electric cabinet to automatically cut, is safe, has high efficiency, low cutting cost, convenient operation, no dust during operation and no repair for cutting processing.

Owner:舒汉平

Special equipment for measuring positions of bottom claw threaded hole and crankshaft hole of cylinder block

InactiveCN102338605AEasy to measureEasy to masterMechanical depth measurementsEngineeringCylinder block

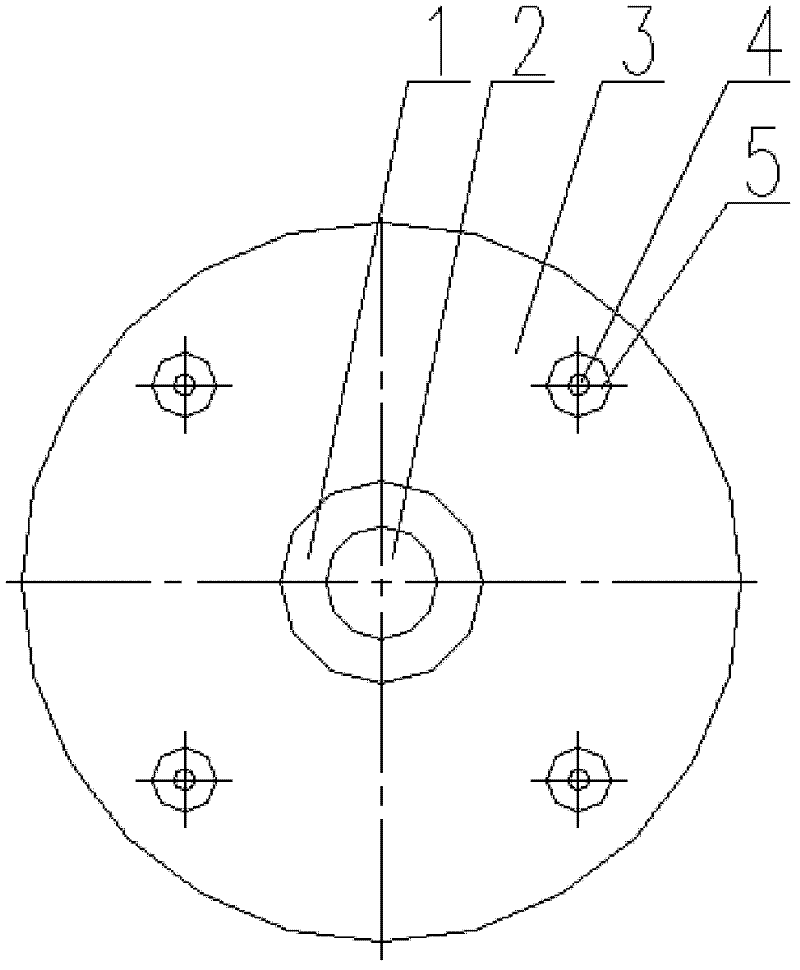

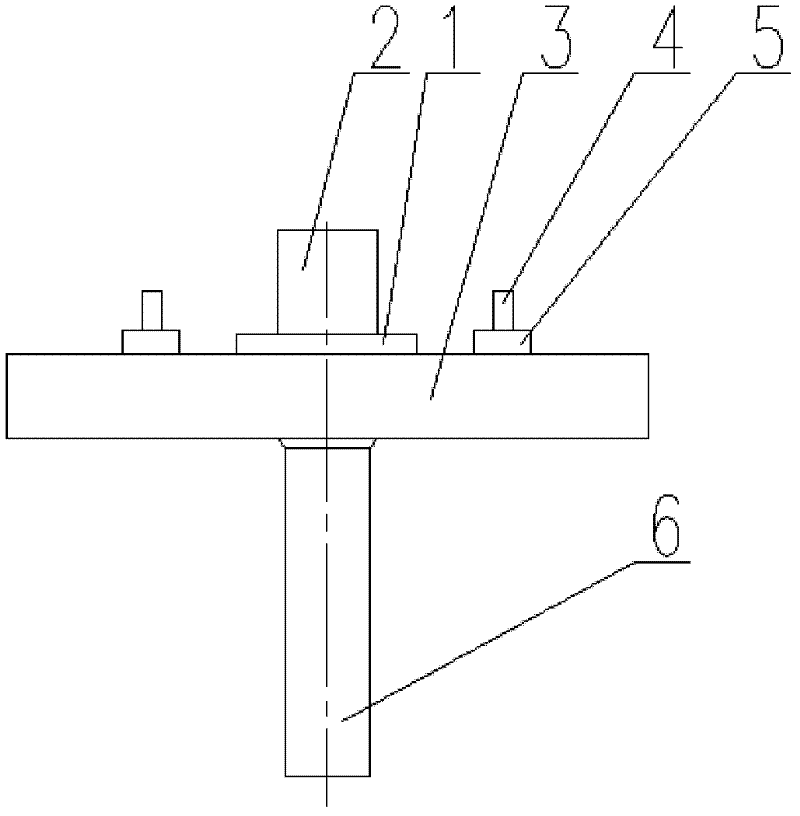

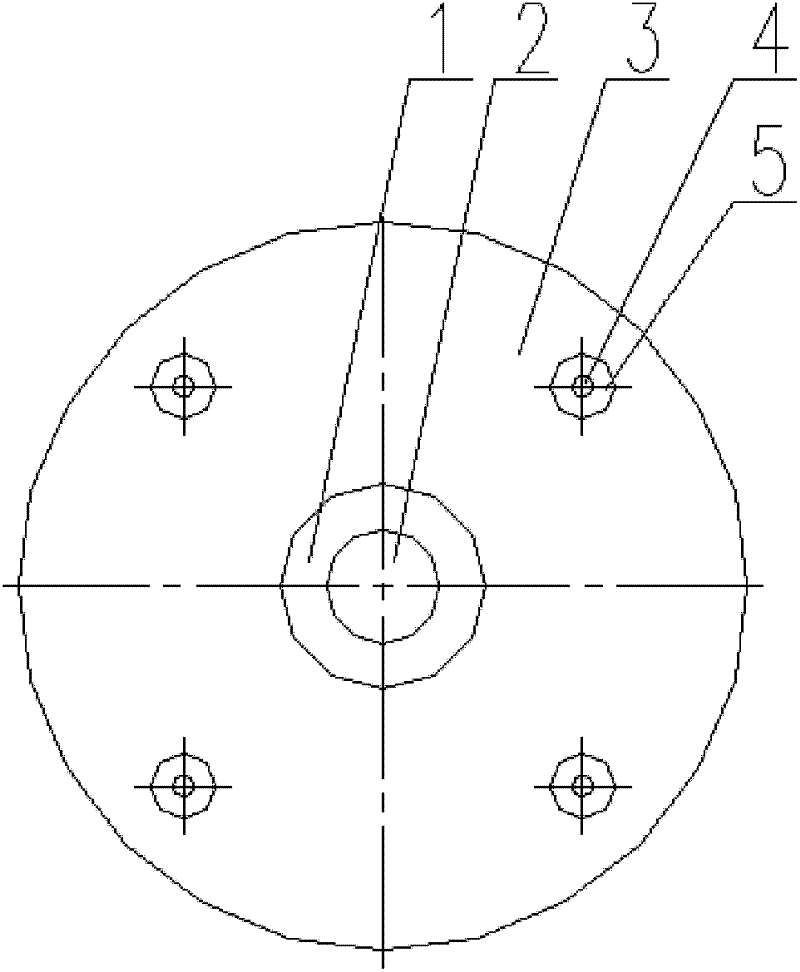

The invention relates to special equipment for measuring positions of bottom claw threaded holes and crankshaft holes of a cylinder block; the special equipment comprises a detecting circular table, bottom claw threaded hole detecting columns, a crankshaft hole detecting column and a handle, wherein the crankshaft hole detecting column is manufactured at the axial upward axis of the detecting circular table; a crankshaft hole detecting circular table is radially manufactured on the detecting circular table which is coaxial with the crankshaft hole detecting column; the axial upward bottom claw threaded hole detecting columns are uniformly distributed at the periphery of the crankshaft hole detecting column on the detecting circular table; a bottom claw threaded hole detecting circular table is radially manufactured on the detecting circular table which is coaxial with the bottom claw threaded hole detecting columns; and the cylindrical handle is manufactured in the axial downward axis position of the detecting circular table. The measurement method of the special equipment for measuring the positions of the bottom claw threaded holes and crankshaft holes of the cylinder block is simple and comprises steps of aligning the bottom-side handle at the cylinder body and then aligning the bottom claw threaded hole detecting columns and the crankshaft hole detecting column on the detecting surface at the cylinder block.

Owner:TIANJIN BAOLAI PRECISION MACHINERY

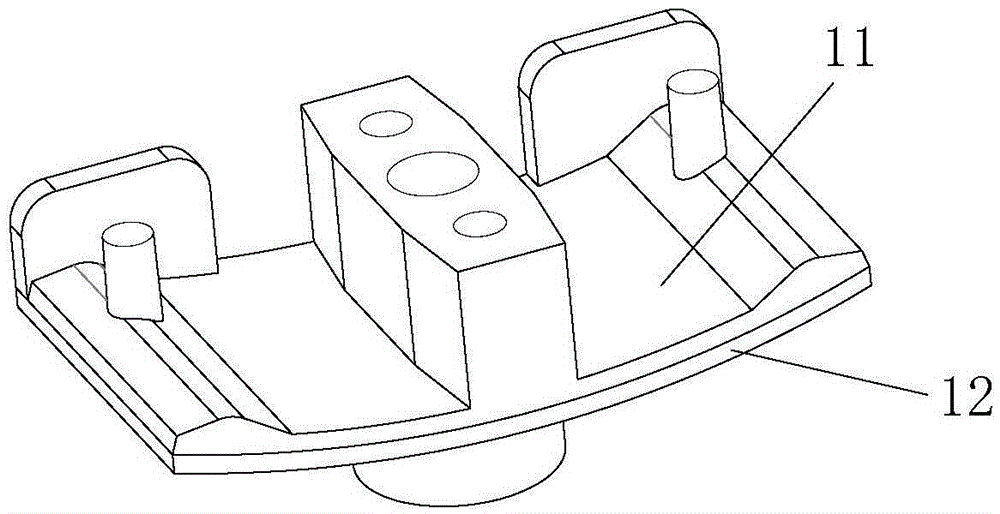

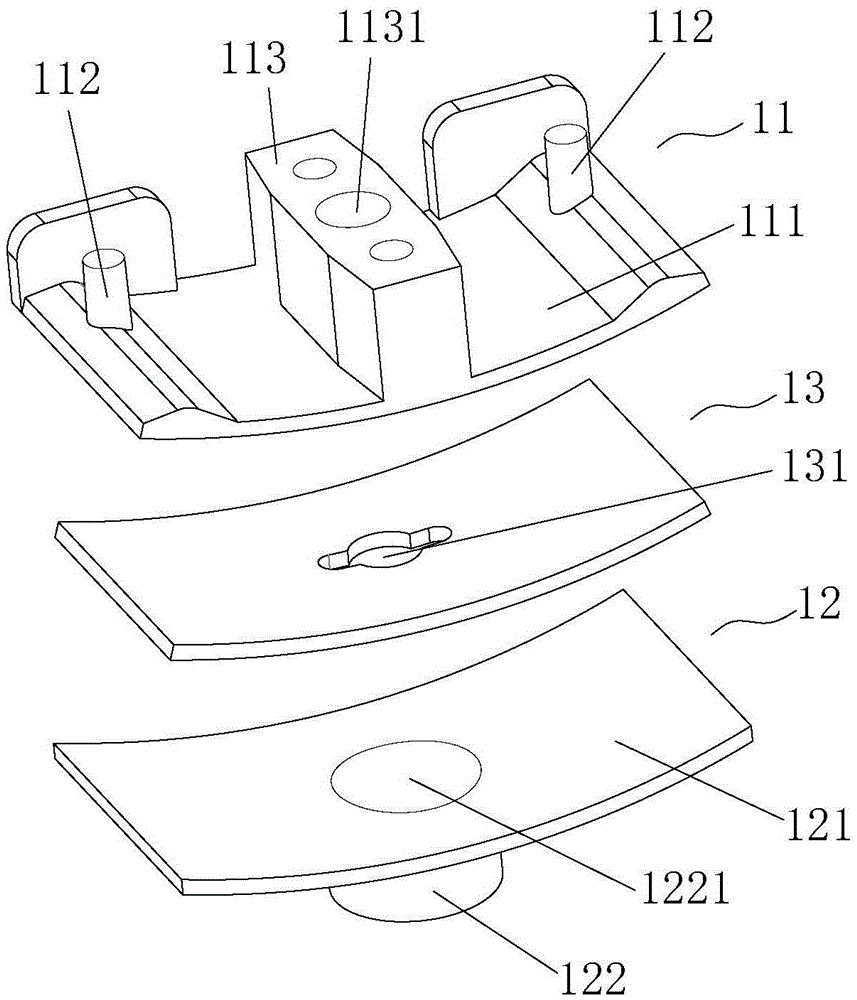

Sensor device for detecting welding line by ultrasonic guided waves and fixing method

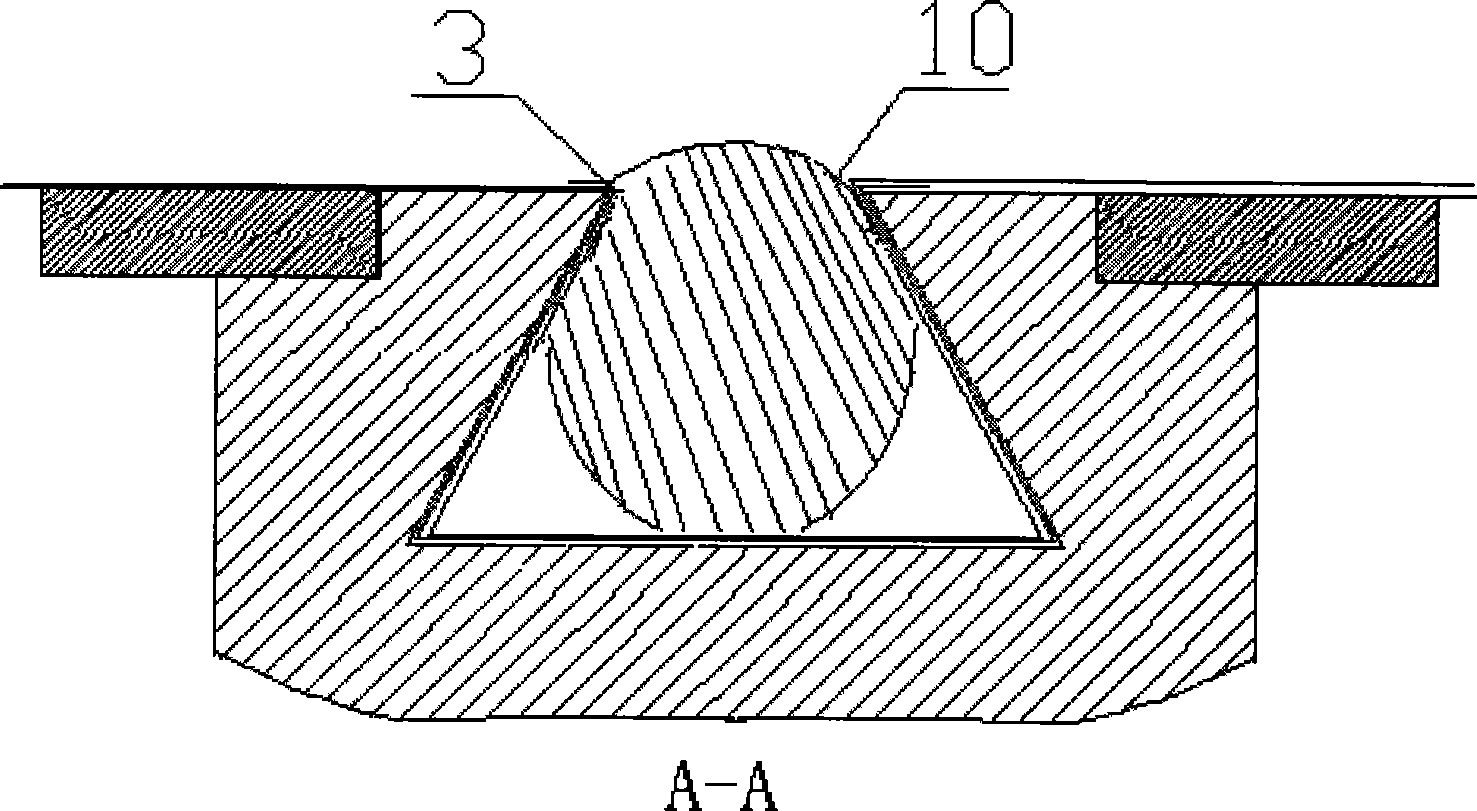

InactiveCN103901112AIncrease the lengthEnhanced echo strengthMaterial analysis using sonic/ultrasonic/infrasonic wavesFar distanceEngineering

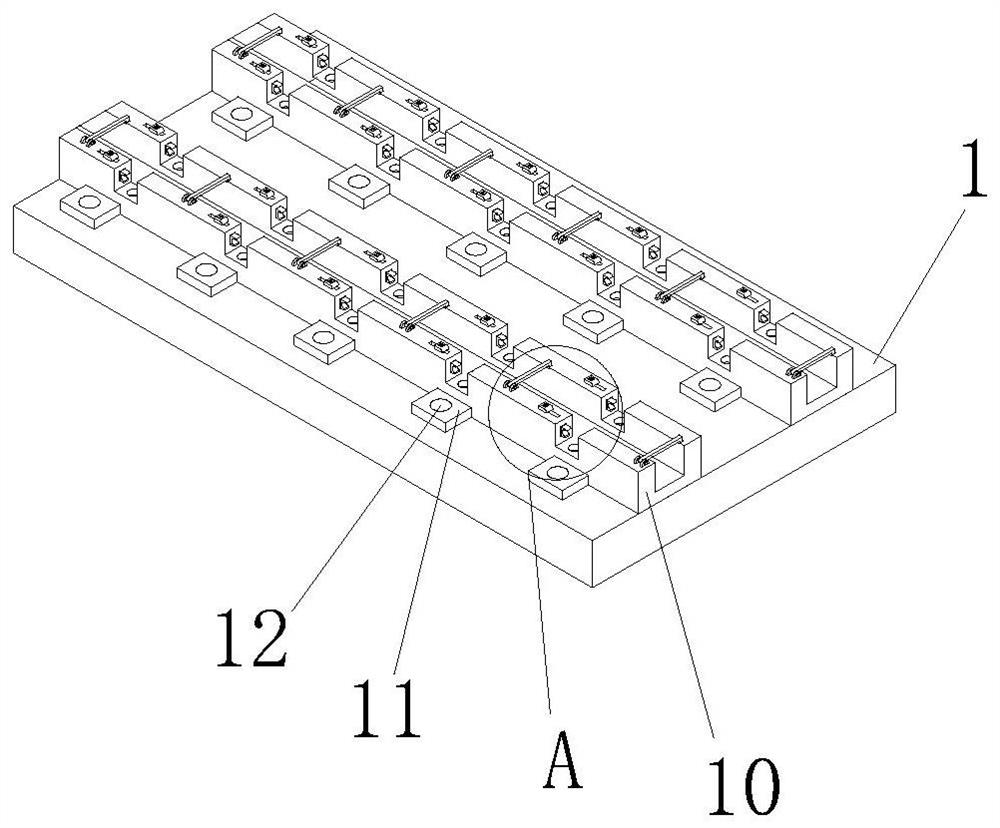

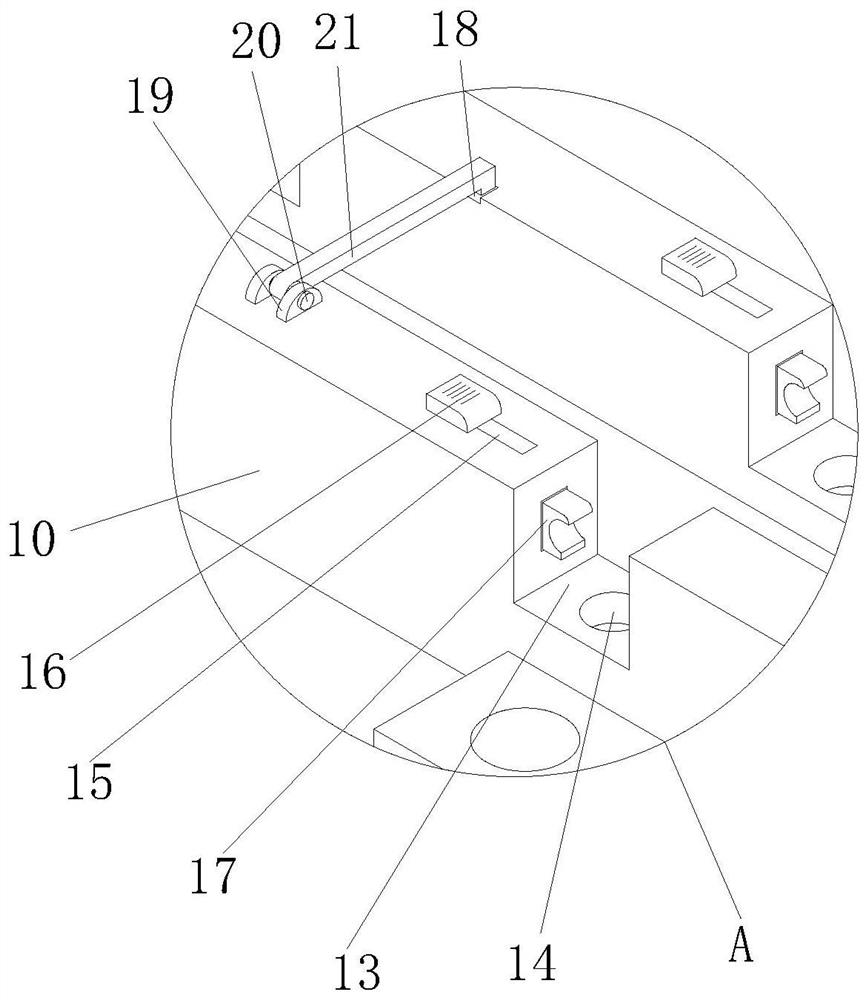

The invention discloses a sensor fixing device for detecting a welding line by ultrasonic guided waves. The sensor fixing device comprises a plurality of sensing units, a fixed belt and two clamping units, wherein the fixed belt is vertical to the welding line in the length direction; the plurality of sensing units which are side by side are symmetrically arranged on the welding line and welding plates at two sides of the welding line 4; the upper ends of the plurality of sensing units are fixed at the middle lower part of the fixed belt respectively; the lower ends of the plurality of sensing units are abutted against the arc-shaped convex welding line and the welding plates at the two sides of the welding line respectively; the clamping units are used for respectively fixing the two ends of the fixed belt on the welding plates; a sensor is embedded into a sensor clamp. The sensor fixing device is simple in structure, convenient to operate, stable, reliable and relatively strong in applicability; all the sensors mounted on the welding line and the welding plates at the two sides of the welding line are not limited by the shape and the size of the welding line, the strength of receiving echoes is enhanced and the length of the measureable welding line is greatly improved, so as to provide a reliable way for efficiently detecting the far-distance welding line. The measurement range is enlarged, and the detection efficiency and the detection precision are improved.

Owner:镇江天颐装备科技有限公司

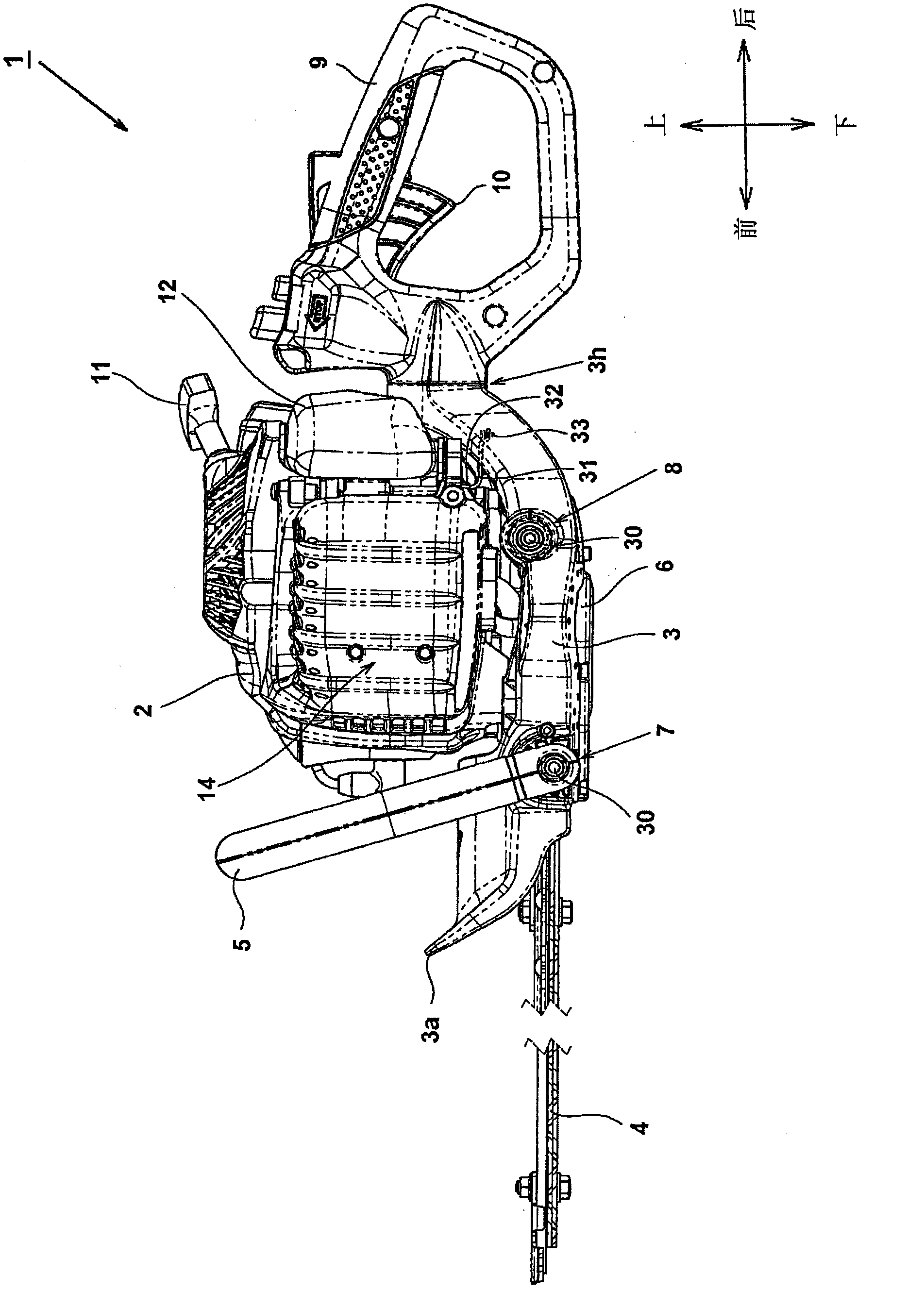

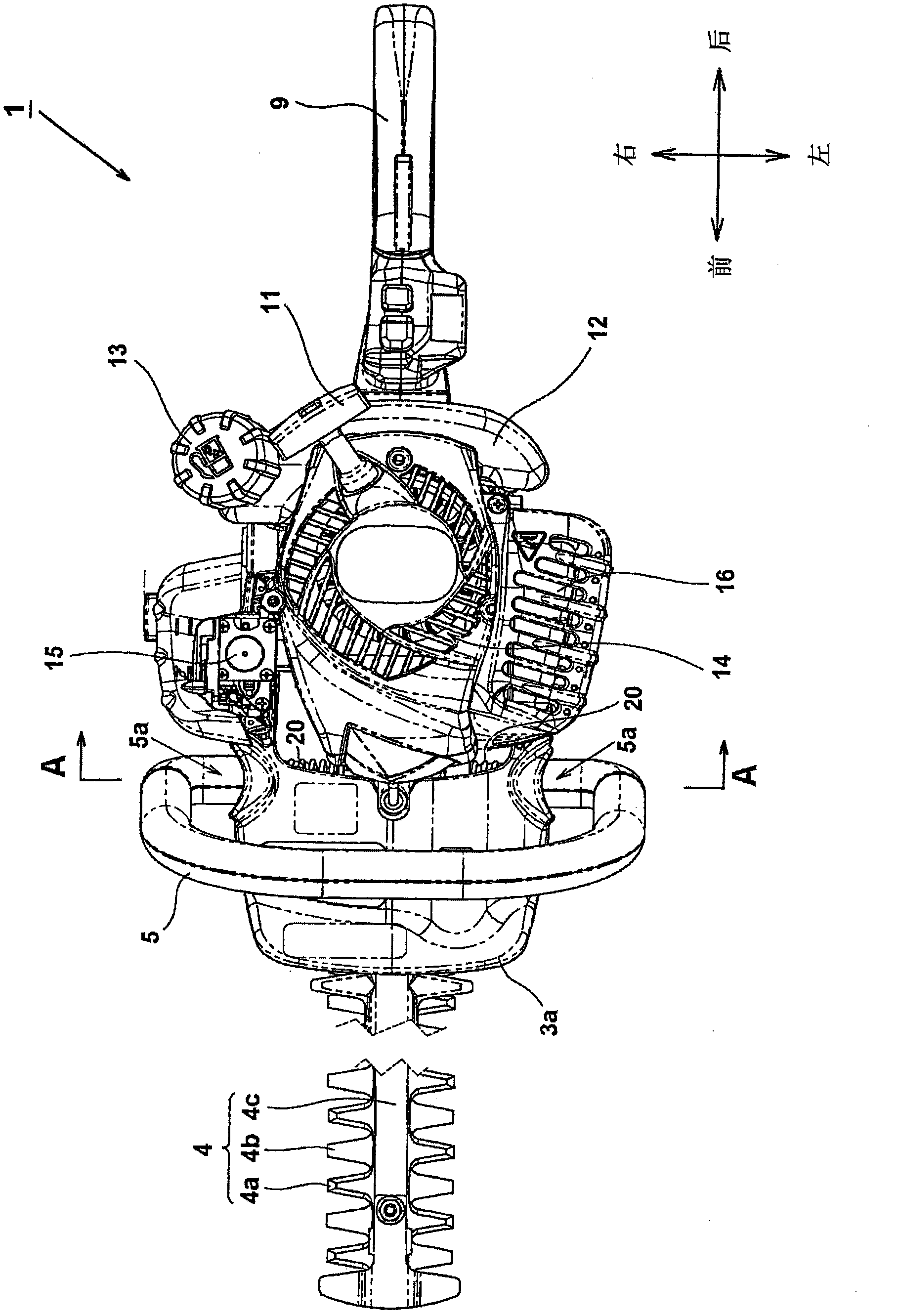

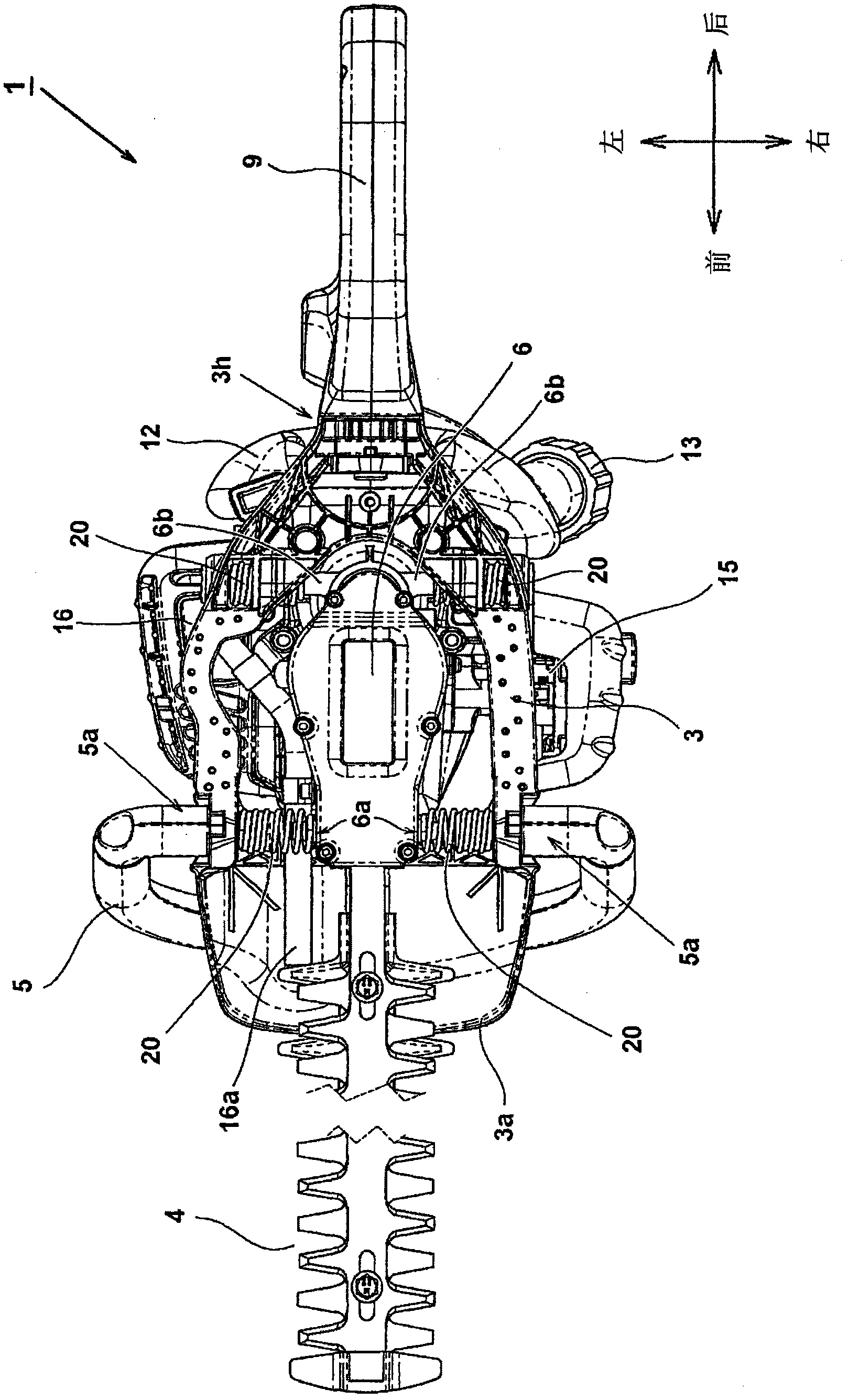

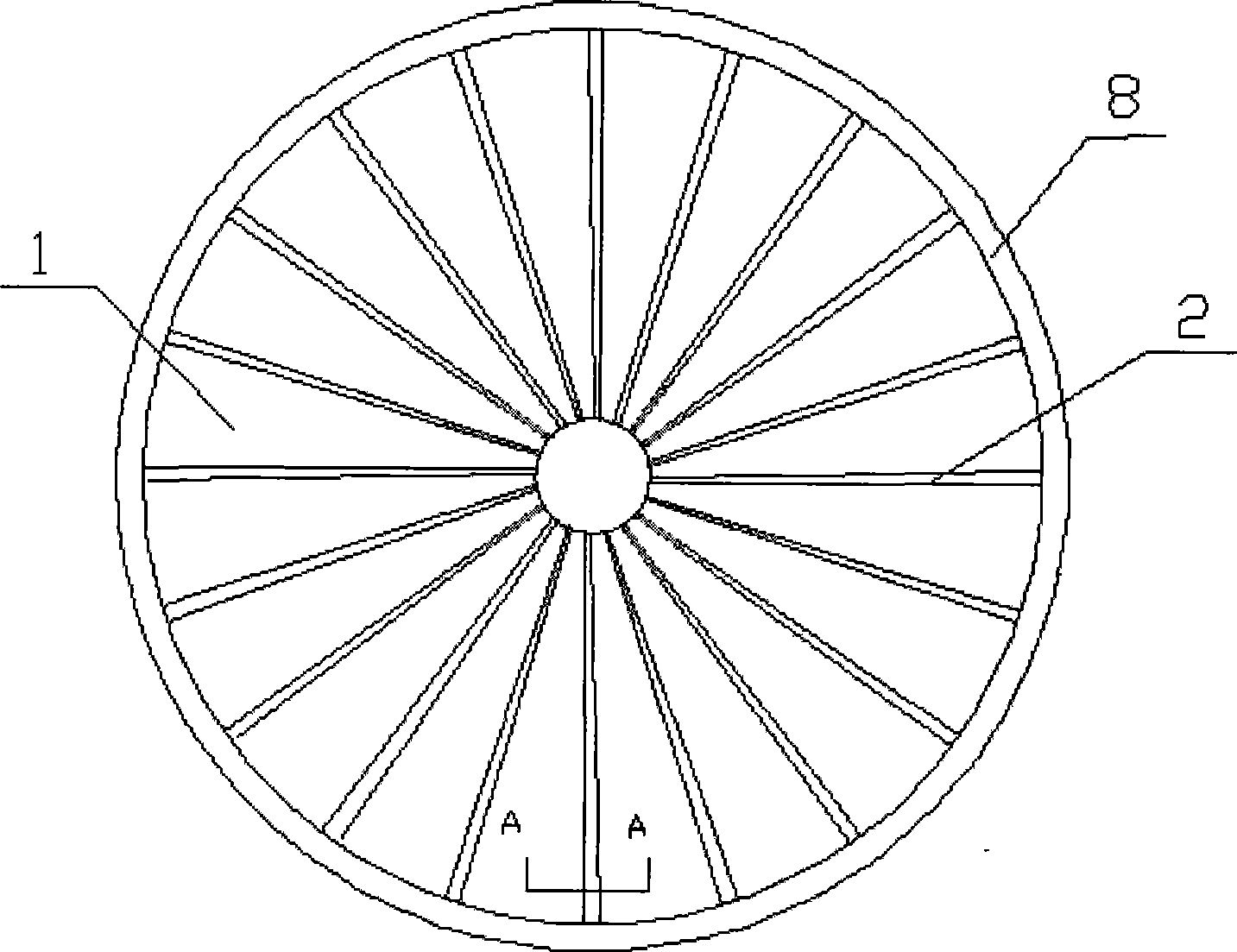

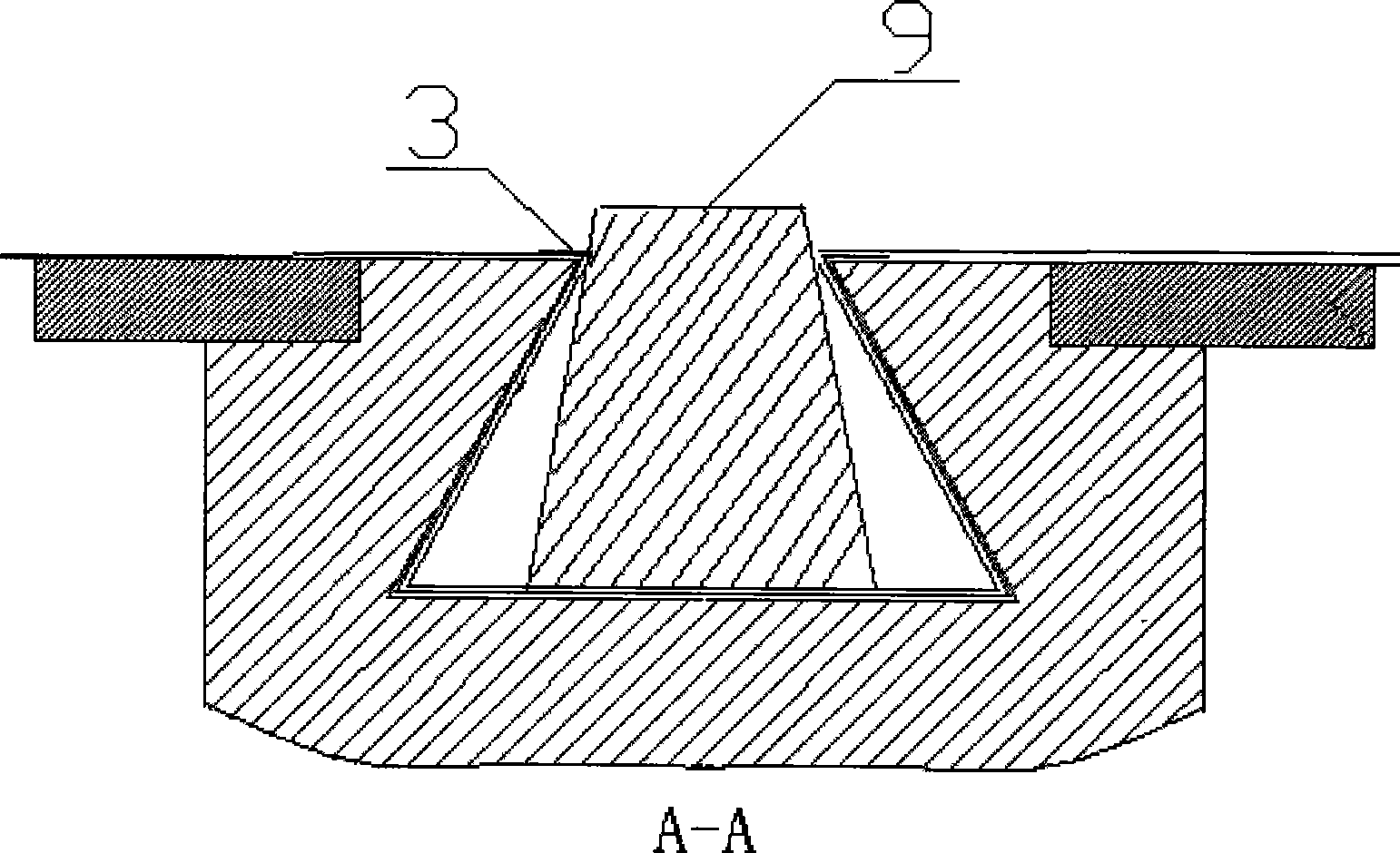

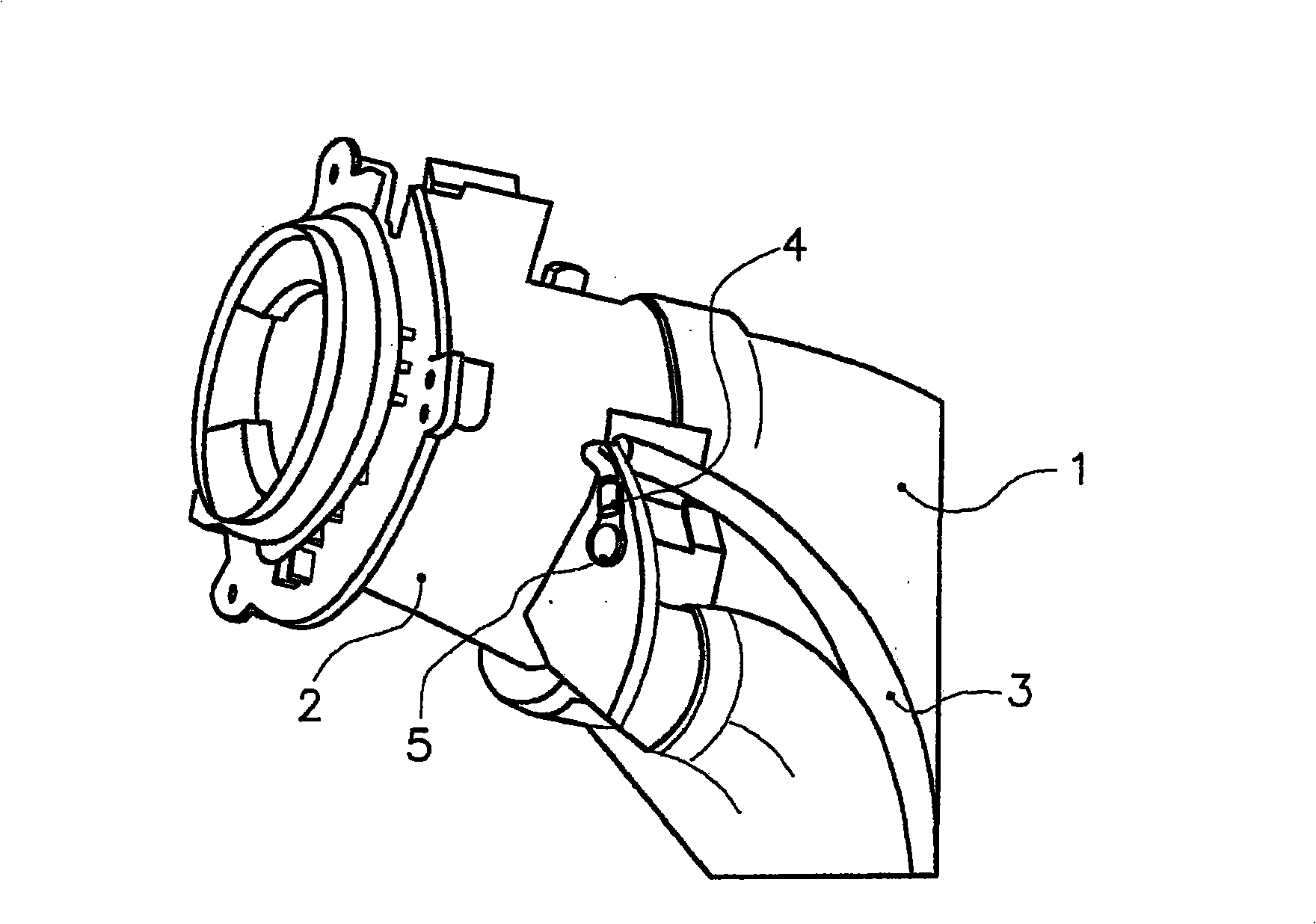

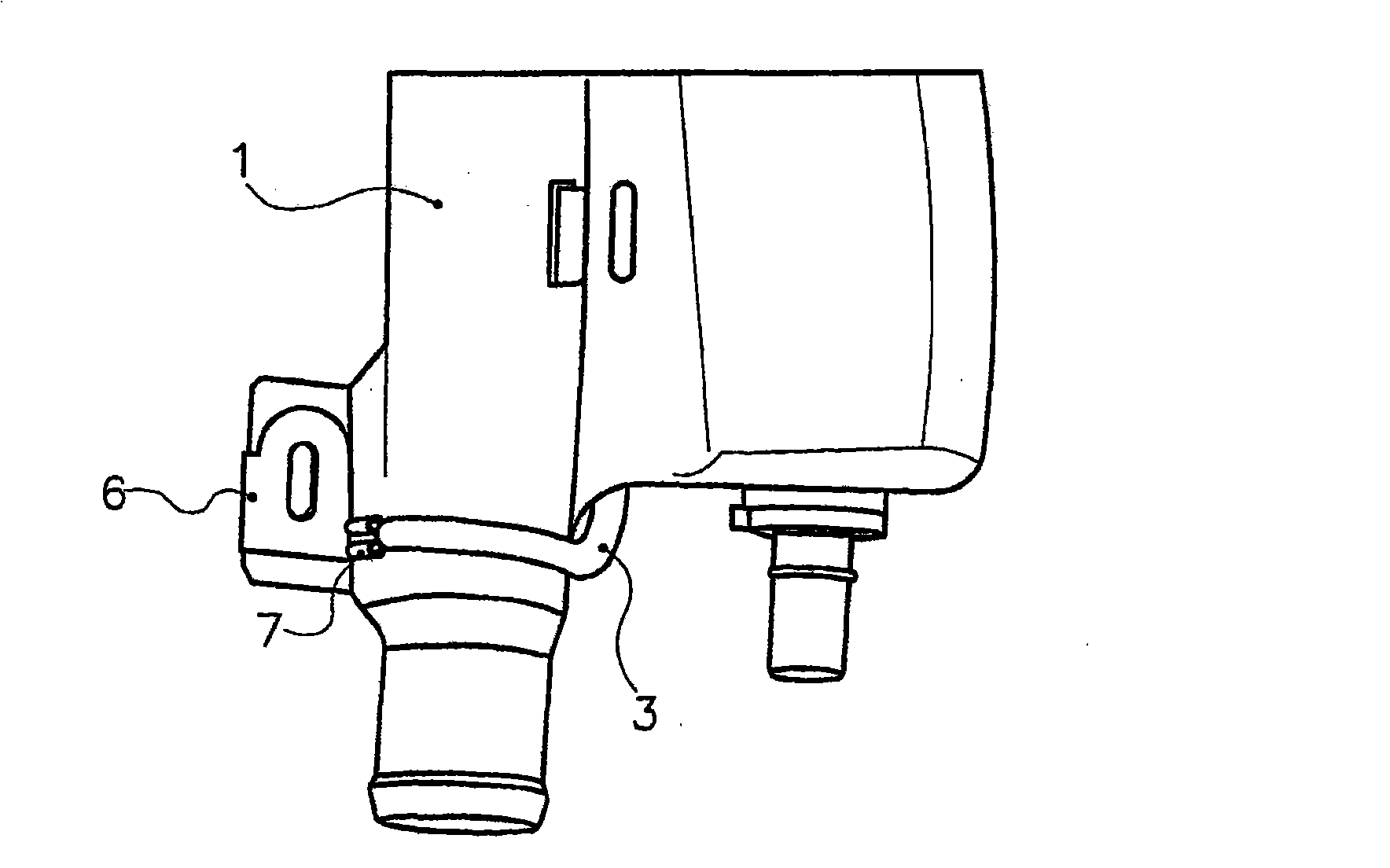

Portable working machine

ActiveCN102428838AFixing method is simpleReduce manufacturing costCuttersCutting implementsMechanical engineeringEnergy transformation

Owner:HITACHI KOKI CO LTD

Fixing device of filter disk filter cloth

ActiveCN101468266ANo breakageLow priceStationary filtering element filtersMoving filtering element filtersEngineeringBottom pressure

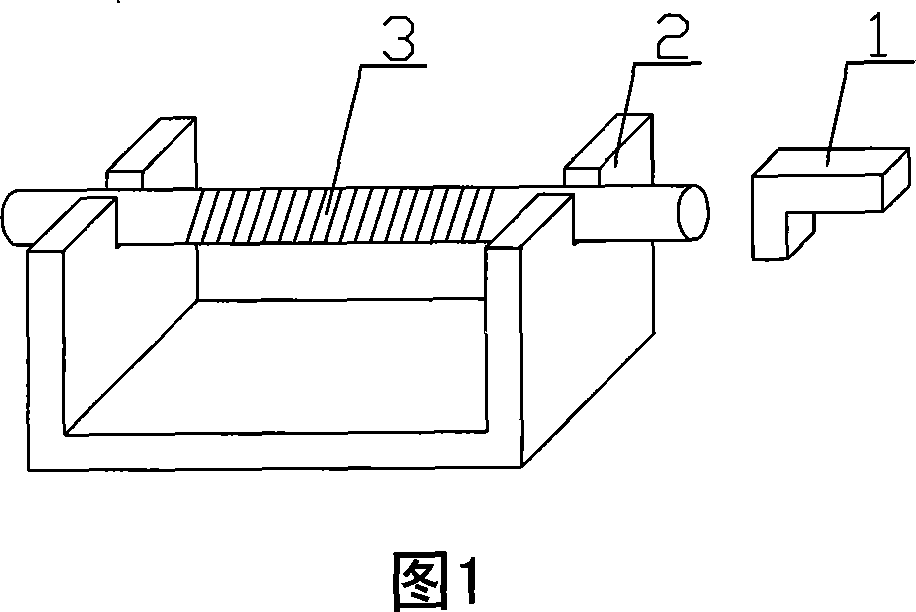

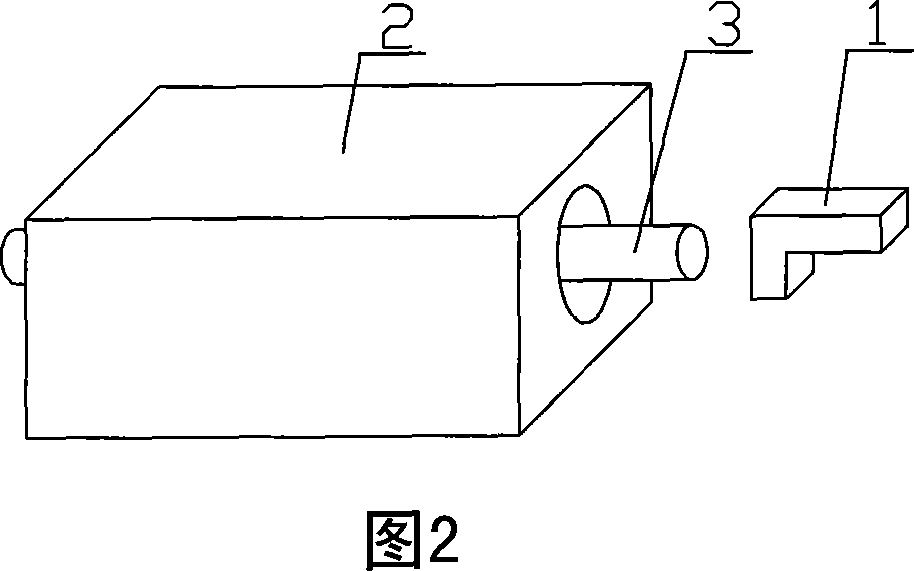

The invention provides a device for fixing filtering cloth on a filter plate surface, which comprises the filter plate surface (1), a linear pressure cloth groove (2), a round pressure cloth groove (8) and the filtering cloth (3), wherein the filter plate surface (1) is provided with the filtering cloth (3) of which the joint part is positioned in the linear pressure cloth groove (2), a bottom pressure strip (5) presses on the joint part of the filtering cloth (3), a trapezoidal pressure tank (4) is positioned above the bottom pressure strip (5), and the trapezoidal pressure tank (4) is connected with the bottom pressure strip (5) through a bolt (6). The device can well fix the filtering cloth on the filter plate surface, solve the technical problems in the prior art that the product yield is decreased, the quality is reduced, the production cost is increased, the installation is difficult, the energy source is wasted and the like because of the ageing and the deformation of rubber strips.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

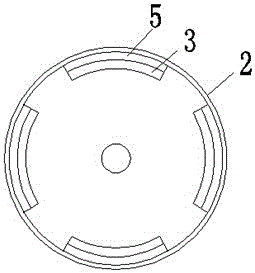

End-part cooling structure for rotor winding of bipolar wound rotor motor

The invention provides an end-part cooling structure for a rotor winding of a bipolar wound rotor motor. Rotor pressing rings are arranged at both ends of a rotor punching plate; the rotor pressing ring at one end is positioned by a shaft shoulder; the rotor pressing ring at the other end is positioned by an arc key; the arc key is placed in a shaft groove; a rotor coil is placed inside the rotor punching plate; a rotor bracket heating sleeve is arranged on a shaft; the end parts of the rotor coil are bound by weftless tapes; the thickness of each weftless tape is calculated by a centrifugal force; and the end parts of the rotor coil need to be sectionally bound in the axial direction. According to the invention, under the premise that a motor power, a power factor, the vibration and the like meet the requirements, a rotor pressing ring and rotor bracket separated structure is adopted, so that more wind energy can pass through the rotor coil, the weftless tapes are reasonably arranged, a part installation fixing and manufacturing method is also optimized and the heat dissipation condition at the end parts of the rotor winding is greatly improved.

Owner:SEC ELECTRIC MACHINERY

Clamping and cleaning device for automobile part machining

InactiveCN107838702AAffect fixed effectsHigh precisionPositioning apparatusGrinding work supportsEngineeringSlide plate

The invention relates to the field of automobile parts, and discloses a clamping and cleaning device for automobile part machining. The clamping and cleaning device comprises a working table, guide columns, a sunken part, a notch, first cylinders and second cylinders, wherein first sliding plates divide the first cylinders into first communicating parts and first moving parts; a plurality of air holes are formed in one end, which is close to the sunken part, of each first moving part; second sliding plates are connected into second cylinders in a sliding manner; second push rods are fixed on the second sliding plates; the second push rods extend out of the second cylinders, and are connected to the first communicating parts in a sliding manner; the second sliding plates divide the second cylinders into second communicating parts and second moving parts; a motor and a main air pipe are mounted in the notch; the main air pipe communicates with two branch pipes; and the two branch pipes are respectively connected with the different second communicating parts. The clamping and cleaning device can realize dual fixing on a workpiece and clean the workpiece twice, so that the workpiece machining precision can be improved, and fragments produced during workpiece machining also can be cleared away; and the workpiece machining quality is improved.

Owner:宁波江北清锐汽车零部件有限公司

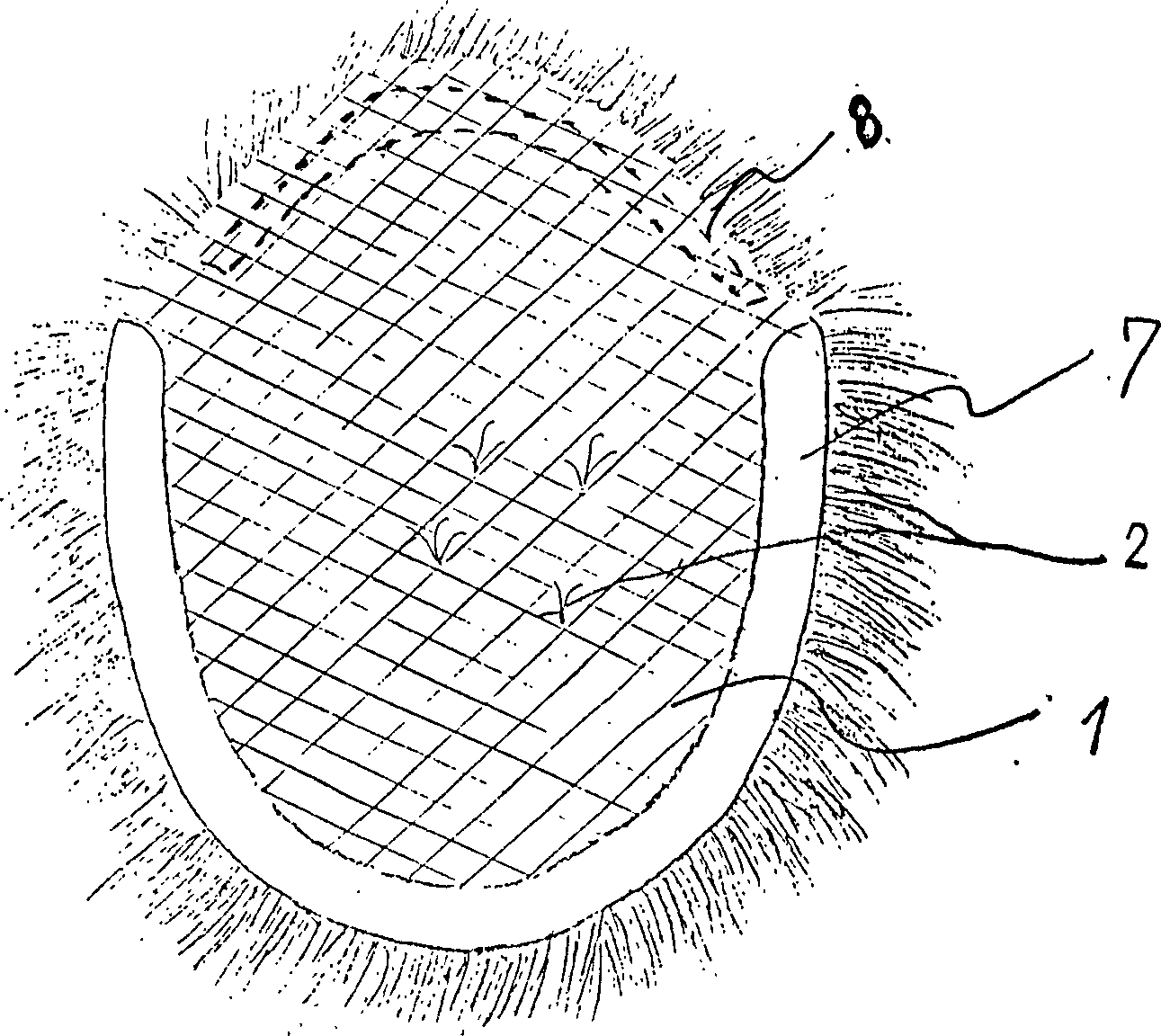

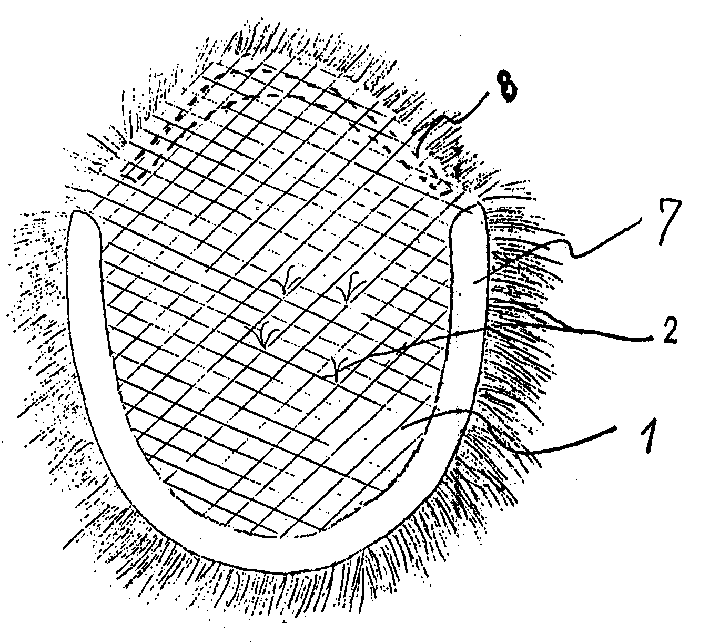

Flexible plastic bald-repairing decorative wig and its making method

InactiveCN1428110AFixing method is simpleThe fixing method is firmHair accessoriesToupeesHair rootsFibre treatment

The present invention relates to a decorative plastic bald wig and its production method. Said method includes the following steps: defining mould and taking smaple, pouring to make mould, duplicating mould and forming, hair fibre treatment, braiding hair fibre and bonding double-face glue, etc. It is characterized by hair fibre hair root treatment, it can make the hair fibre whose root color is head skin colour be braided on the transparent wig lining, and its knotted position is not black, after the wig is fixed, it can be made into various required styles.

Owner:朱惠芳

Construction method of template with no split bolt hole

InactiveCN102777031AEasy to installFixing method is simpleBuilding material handlingStructural engineeringUltimate tensile strength

The invention discloses a construction method of a template with no split bolt hole. The construction method includes the following steps: (1) sequentially placing a plurality of external wall templates along the longitudinal direction to form a lower-layer external wall template; (2) placing small template strips and split bolts at the top of the lower-layer external wall template at intervals; (3) repeating the step (1) and the step (2) to construct upper-layer external wall templates layer by layer until the upper-layer external wall templates are as high as the installation of the external wall templates; (4) installing a vertical wood square on the outer sides of the external wall templates; (5) installing horizontal double steel pipes arranged along the horizontal direction on the outer side of the vertical wood square; (6) adjusting the evenness and verticality of the external wall templates; (7) pouring wall concrete; (8) loosening the split bolts when the wall concrete achieves the template removing strength, taking down the double steel pipes, dismantling the external wall templates and removing the small template strips; (9) cutting off the exposed portion of the split bolts at the bottom of a groove formed at the position where the small template strips are removed; and (10) trowelling the groove through waterproof mortar. By means of the construction method, rigidity of the template is reliable.

Owner:CHINA CONSTR SIXTH ENG DIV CORP

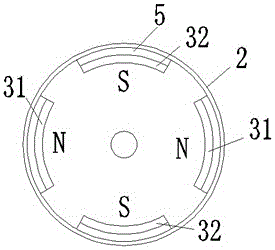

High-power automobile starter and stator magnetic steel fixing method

InactiveCN105703494ASimple production processEasy to manufactureMagnetic circuit stationary partsMagnetic circuit characterised by magnetic materialsMagnetic tension forceRubidium

Owner:丁培远

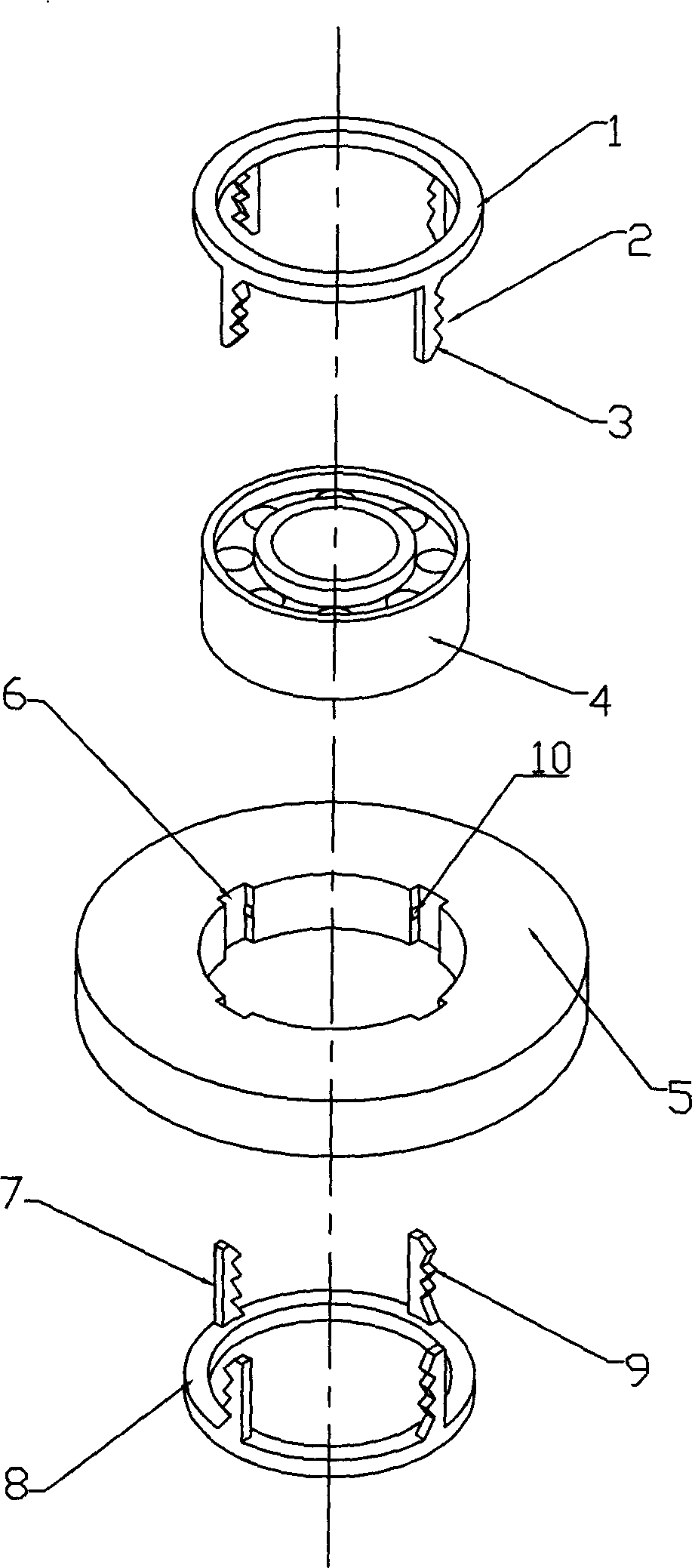

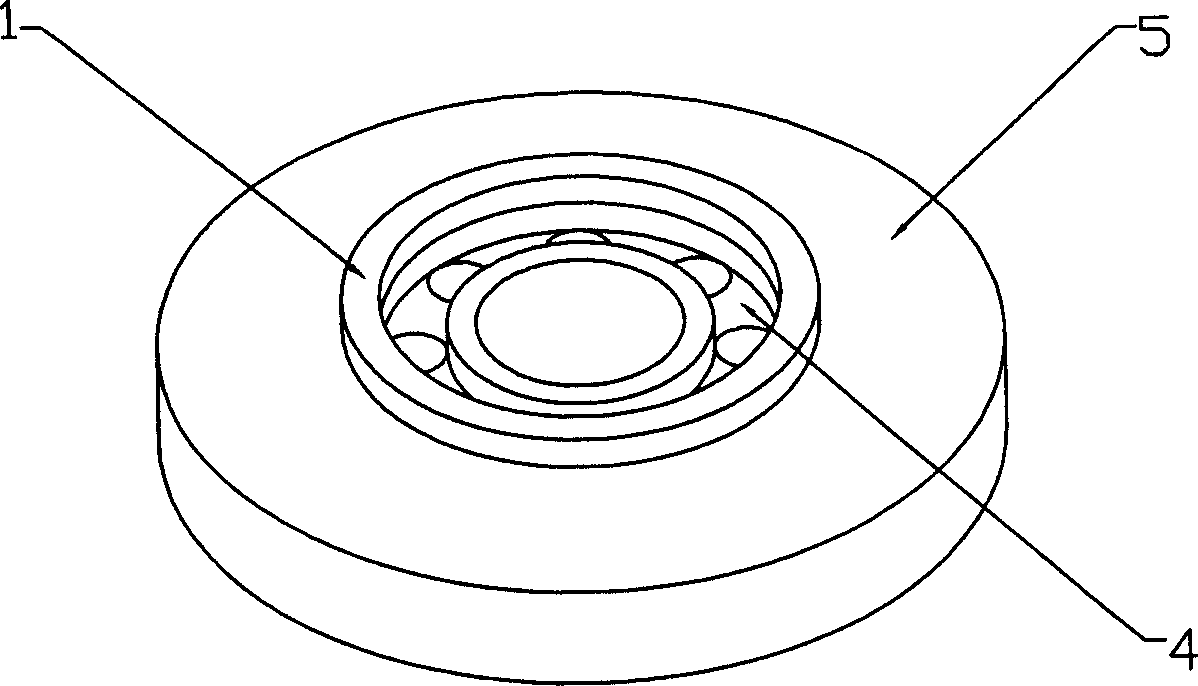

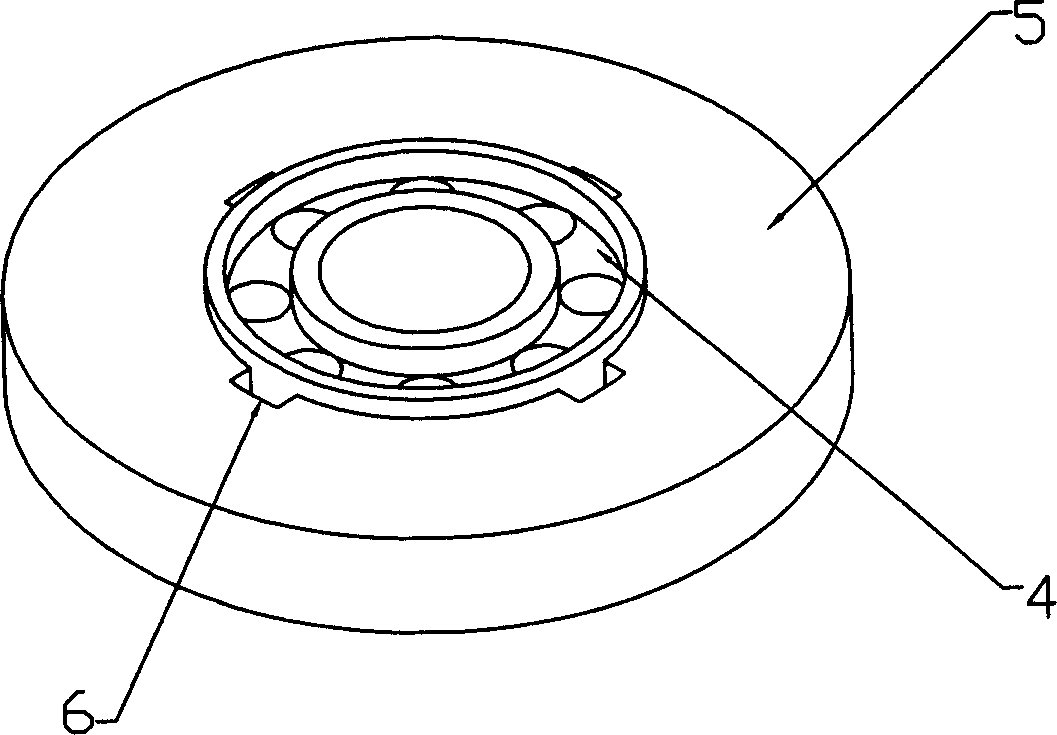

Fixing and connecting method for bearing and wheels

InactiveCN1880787AThe fixing method is simple and convenientLow costWing suspension devicesBearing unit rigid supportEngineeringMechanical engineering

Owner:陈卓逵

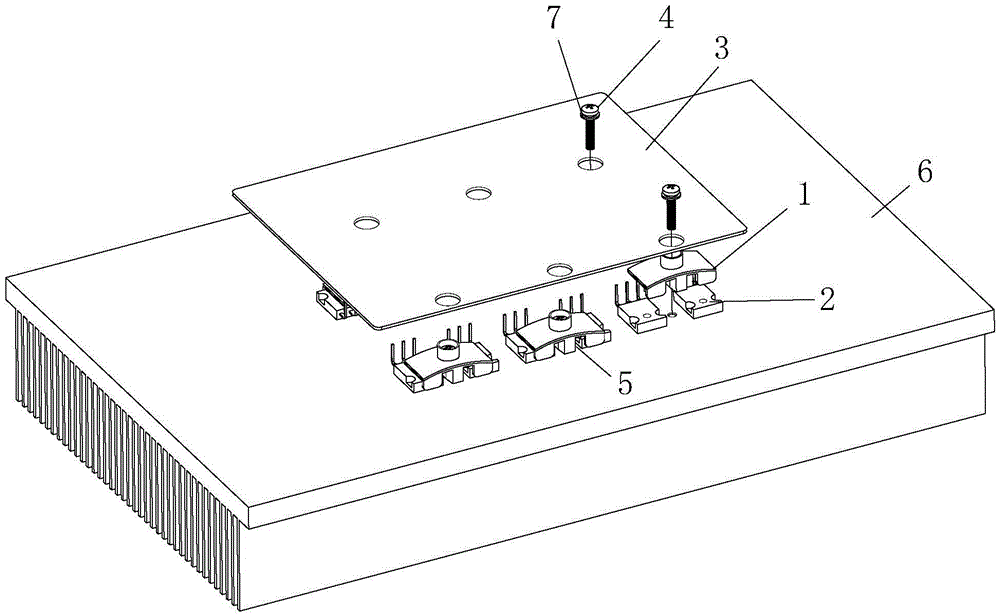

Fixing structure and fixing method for MOS transistor

InactiveCN105470221AFlat and tight fitFixing method is simpleSemiconductor/solid-state device detailsPrinted circuit aspectsEngineeringTransistor

The invention discloses a fixing structure and a fixing method for an MOS transistor. The MOS transistor pin is welded on a PCB; the fixing structure comprises a fixing part that is positioned in an accommodating space formed by the MOS transistor and the PCB; one end of the fixing part extends out of the PCB while the other end of the fixing part is connected with the MOS transistor in a buckling manner; the fixing structure also comprises a screw; the fixing part is connected with a radiator through the screw; the upper end of the screw is clamped at one end, extending out of the PCB, of the fixing part while the lower end of the screw penetrates from one end, extending out of the PCB, of the fixing part, and the screw extends out of one end, buckled with the MOS transistor, of the fixing part to be rotated into the radiator; the fixing part adopts an arc-shaped structure, and can be deformed in a central axial direction of the screw; and when the screw penetrates through the fixing part to be rotated into the radiator, the fixing part is deformed from the arc-shaped structure into a flat-plate structure for pushing against the MOS transistor on the radiator. The fixing structure can fix two MOS transistors at the same time, so that the working efficiency is improved; and when the screw penetrates through the fixing part to be rotated into the radiator, the fixing part is deformed for applying action force on the MOS transistor to enable the MOS transistor to be smoothly and tightly laminated with the radiator so as to improve the radiating effect.

Owner:上海兆能电力电子技术有限公司

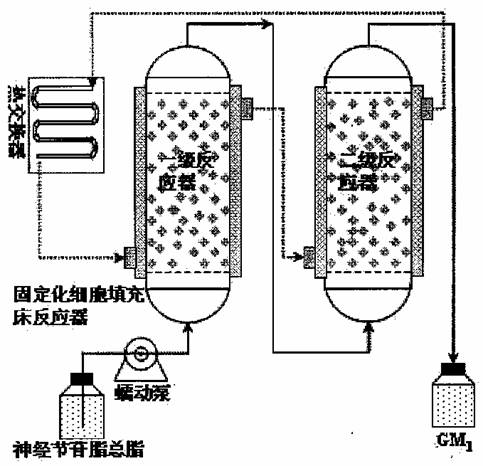

Immobilized microbial cell method for converting ganglioside

ActiveCN102154416ARealize continuous operationContinuous operationMicroorganism based processesOn/in organic carrierMicroorganismMetabolite

The invention discloses an immobilized microbial cell method for converting ganglioside, which can specifically convert ganglioside so as to generate monosialoganglioside (GM1) and solves the problem that acid hydrolysis has low conversion rate and easily generates inactive monosialoganglioside and simultaneously solves the problem that in an non immobilized microbial cell method, medium components or microbial metabolite impurities are easily mixed into the monosialoganglioside. After cells are fixed with fibroin gel, a columnar type reaction bed is filled; the ganglioside to be converted reversely flows through a packed column and is converted into GM1.

Owner:SHANDONG NEWTIME PHARMA

Horizontal plug-in type lead storage battery mounting assembly

InactiveCN111725464AEasy to fixFixing method is simpleSecondary cellsCell component detailsEngineeringStructural engineering

The invention relates to the technical field of storage battery mounting assemblies. The invention further discloses a horizontal plug-in type lead storage battery mounting assembly which comprises abattery box, bolt holes are formed in four corners of the upper surface of the battery box, heat dissipation grooves are formed in the left surface and the right surface of the battery box, the heat dissipation grooves are communicated with the interior of the battery box, the interior of the battery box is of a hollow structure, a clamping device is arranged in the battery box, a placement grooveis formed in the top of the battery box, a partition plate is fixedly connected in the placement groove, and a battery is placed in the placement groove. According to the device, when a user puts a battery on the U-shaped frame, a moving block slides leftwards, an L-shaped rod drives calipers to slide leftwards, the moving block is loosened, and the calipers are ejected rightwards through a spring, so that the calipers are mutually clamped with a clamping block after being ejected, the battery is firmly fixed, and the device is firmer in battery fixing, simple in battery fixing method, and the operation can be completed by one person.

Owner:方勐

Fixing method for needle selecting device driving coil

InactiveCN101051547AFixing method is simpleImprove cooling effectElectromagnetsCooling effectElectrical and Electronics engineering

The invention discloses method for fixing drive coil of needle-gating device. Drive coil of controlling movement of blade in the needle-gating device is installed in the coil holder, and is connected to the coil holder fixedly. The method includes steps: fabricating the coil holder with flute on surface in advance; placing drive coil to the flute in the coil holder; filling jelly into the flute. Advantages of the method are: simple and easy of implementation, obvious cooling effect, and increasing service life of drive coil.

Owner:吴圣旺

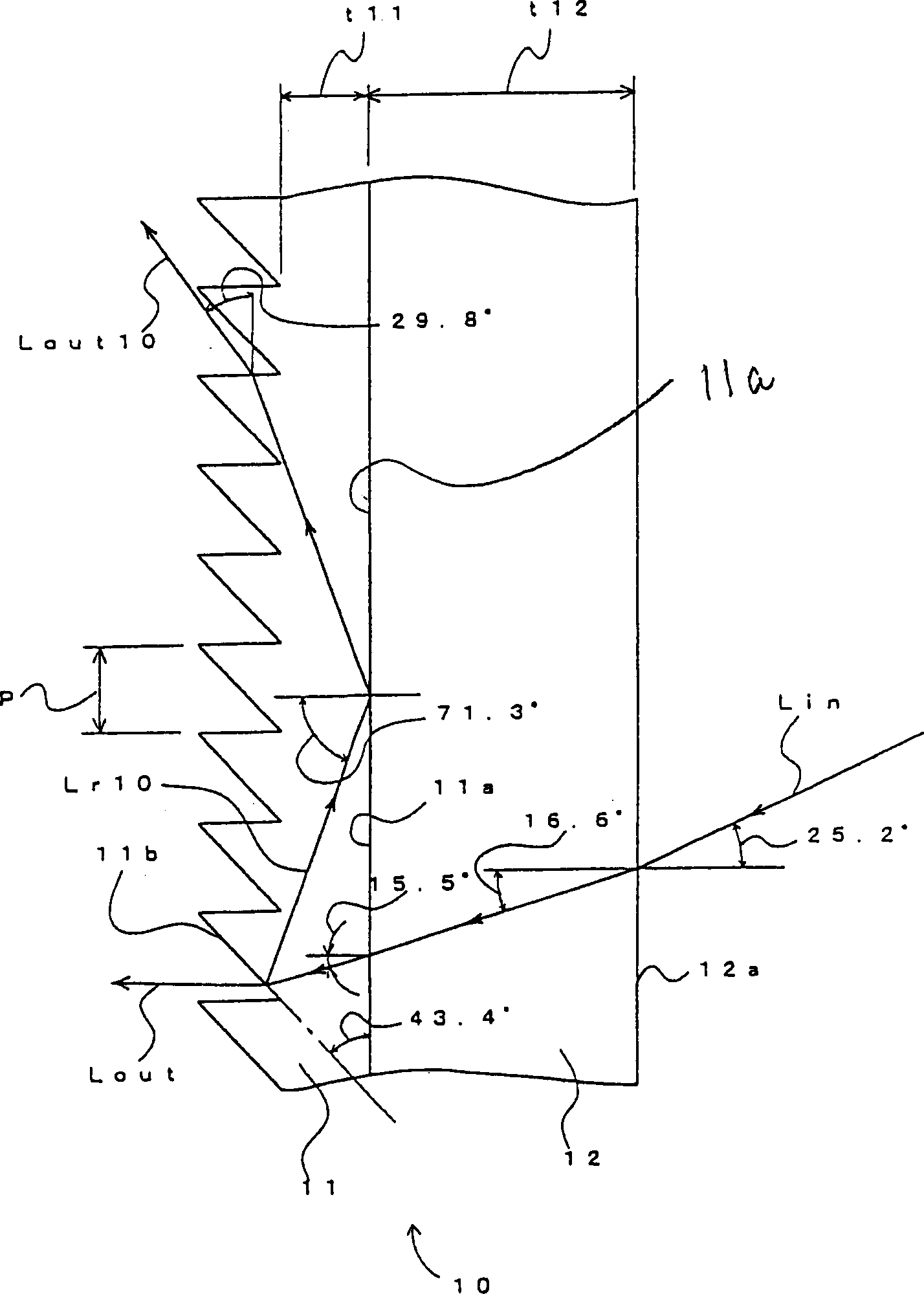

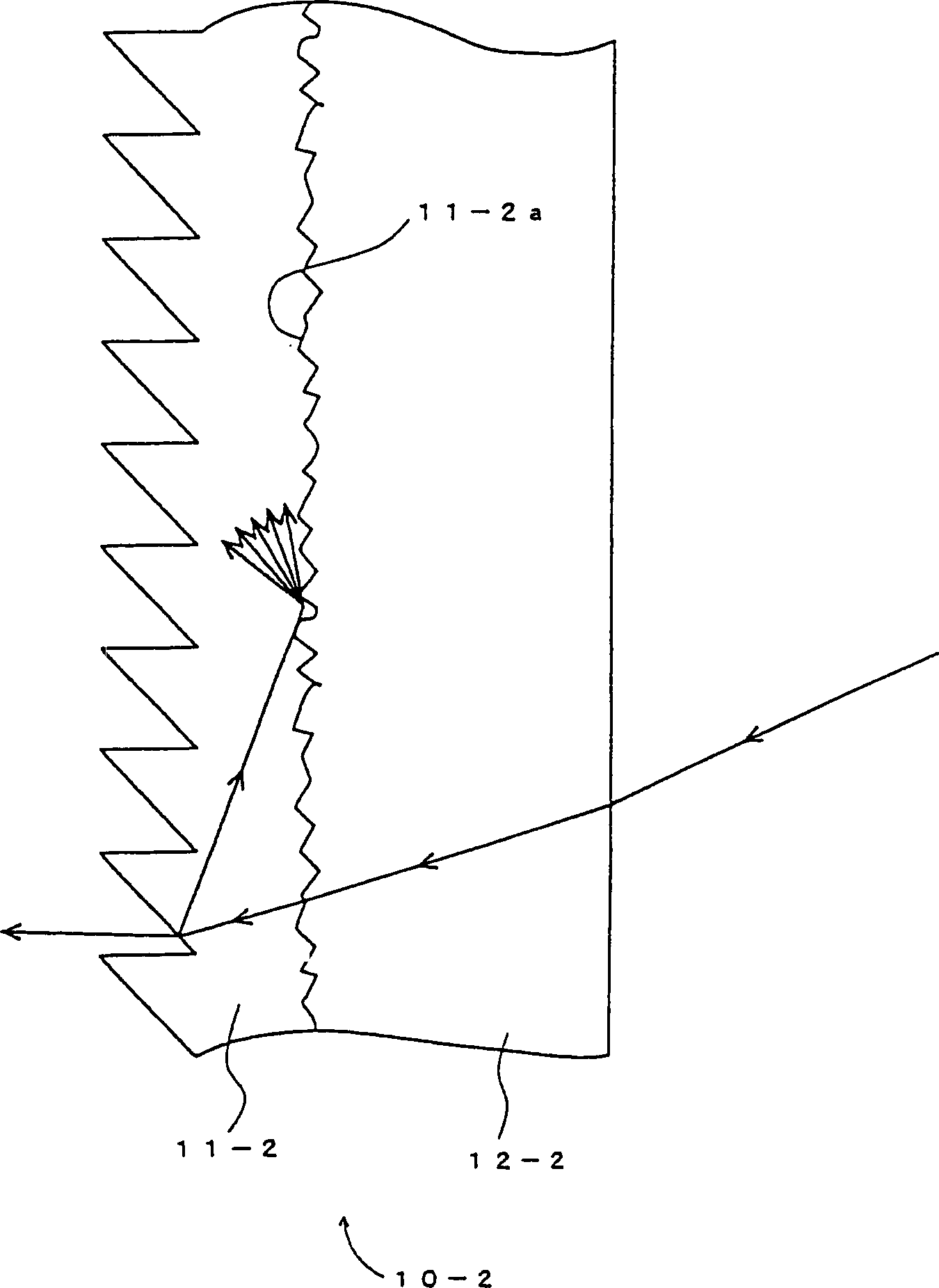

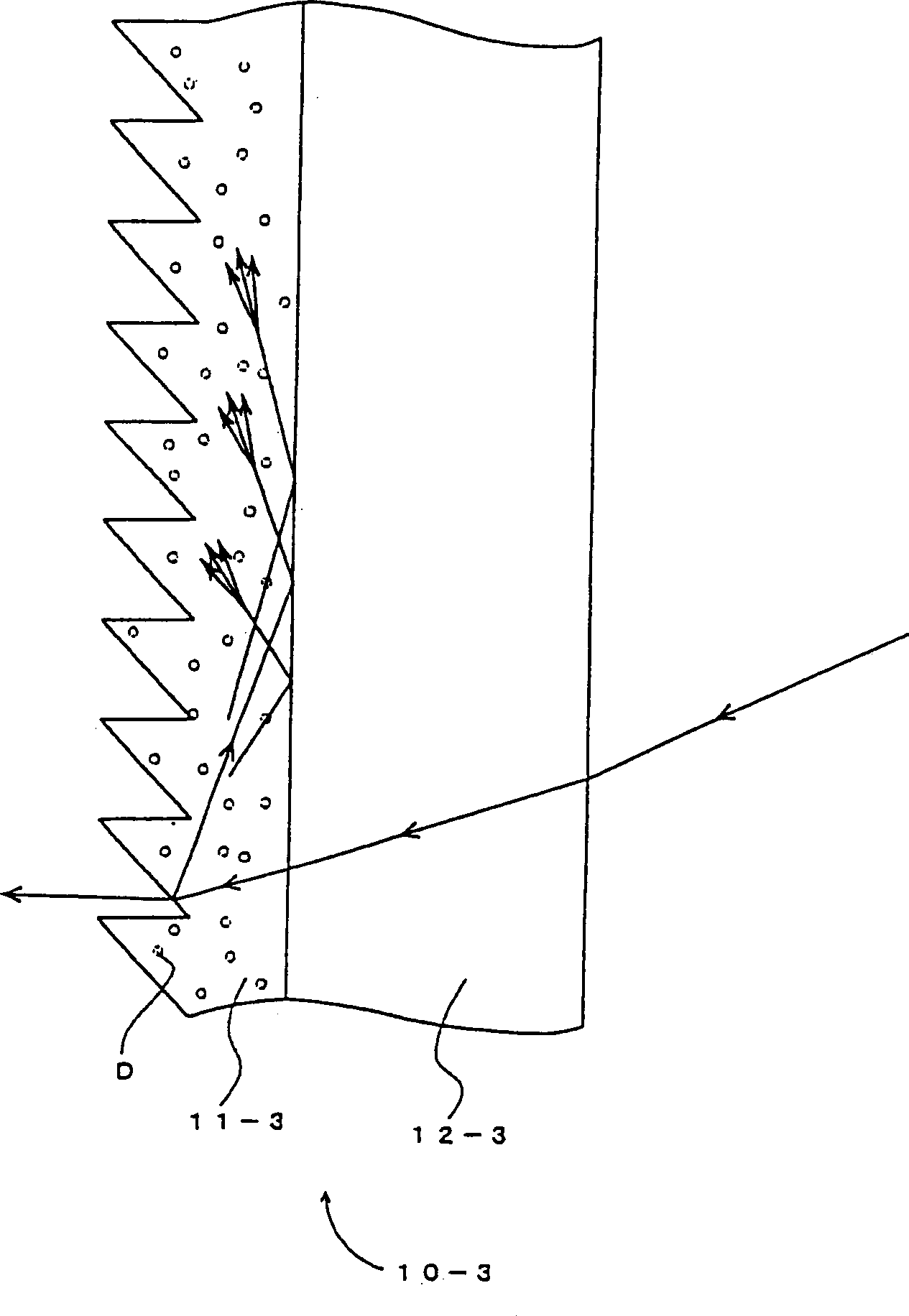

Fresnel lens

InactiveCN1387053AFixing method is simpleDouble image is not obviousProjectorsLensFresnel lensProjection screen

The invention discloses a Fresnel lens sheet used in a rear projection screen and a transmission projection screen using the Fresnel lens sheet. The Fresnel lens sheet is characterized in that it has at least a lens layer forming a Fresnel lens and a layered structure with a base material layer, and a total reflection surface is provided on the outgoing light side instead of the incident light side, and the lens is composed of When light is incident on either the side of the lens layer or the side of the base material layer, a part of the projected light transmitted from the lens layer to the base material layer is totally reflected. The effect is that regardless of the thickness of the lens layer, it is possible to obtain a Fresnel lens sheet that can reduce double images and can be easily fixed so that double images are not conspicuous.

Owner:DAI NIPPON PRINTING CO LTD

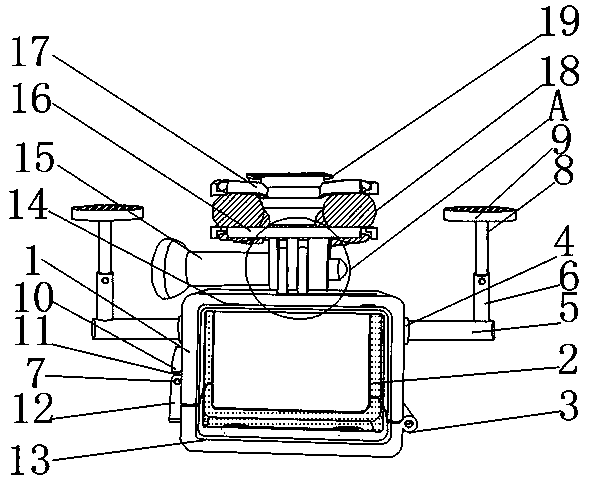

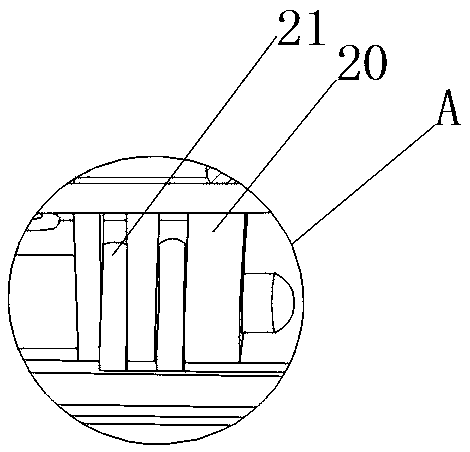

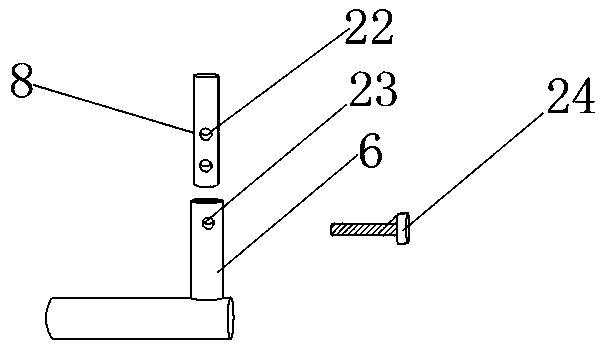

Anti-shake camera support for unmanned aerial vehicle

An anti-shake camera support for an unmanned aerial vehicle includes a bracket body and a first support bracket, and the first support bracket is located above the bracket body. A silica gel protective pad is fixedly installed inside the bracket main body, a first rotating shaft is installed on one side of the silica gel protective pad, a second rotating shaft is installed on one side of the bracket main body close to the upper part of the first rotating shaft, a pillar is installed inside the second rotating shaft, and a sleeve is fixedly installed on the outer wall of the pillar close to theupper part of the bracket main body. The anti-shake camera support of the unmanned aerial vehicle employs a silica gel protective pad, a circular magnetic block and a transparent protective shell, and the camera can be prevented from being damaged by the support due to friction. The support is practical and can prevent the bracket from jitter in the operation of the unmanned aerial vehicle from affect the effect of photographing and recording, and has good stability, can protect the camera head of the camera, has the effect of water-proof and dust-proof, is suitable for different working conditions, and brings a better use prospect.

Owner:HARBIN UNIV OF SCI & TECH

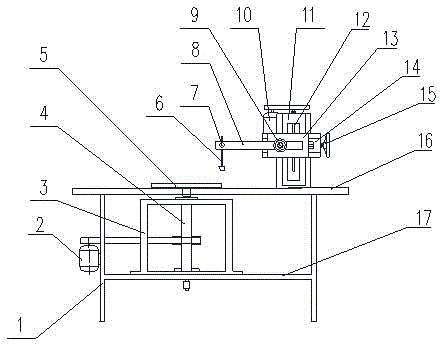

Novel vacuum-assisting mold absorption mold repairing device

InactiveCN104400897AConvenient position controlEasy accessAuxillary shaping apparatusVacuum assistedDrive motor

The invention discloses a novel vacuum-assisting mold absorption mold repairing device, which belongs to the technical field of daily ceramic equipment. The novel vacuum-assisting mold absorption mold repairing device comprises a stander, a worktable, a mold rotating mechanism and a mold repairing mechanism, wherein the worktable is connected to the upper end of the stander, and an installation plate is arranged in the middle part of the stander; the mold rotating mechanism comprises a hollow main shaft, a main shaft base, a mold holder and a driving motor; the main shaft base is fixed on the installation plate; the upper part of the hollow main shaft penetrates the main shaft base and the worktable, the lower part of the hollow main shaft penetrates the main shaft base and the installation plate, the upper part and the lower part of the hollow main shaft are respectively fixedly installed on the main shaft base through a bearing, the mold holder is installed on the upper end part of the hollow main shaft, the lower end part of the hollow main shaft is communicated with a vacuum pipe, and a belt pulley is installed in the middle part of the hollow main shaft; the driving motor is installed on the stander, and the belt pulley is connected with the driving motor through a belt; the mold repairing mechanism comprises a mold repairing cutter and a cutter support, the cutter support is fixed on the worktable, and the mold repairing cutter is installed on the cutter support. The novel vacuum-assisting mold absorption mold repairing device is simple in structure, convenient to use, good in mold fixing and mold repairing effects and capable of alleviating the labor intensity of workers.

Owner:李金盛

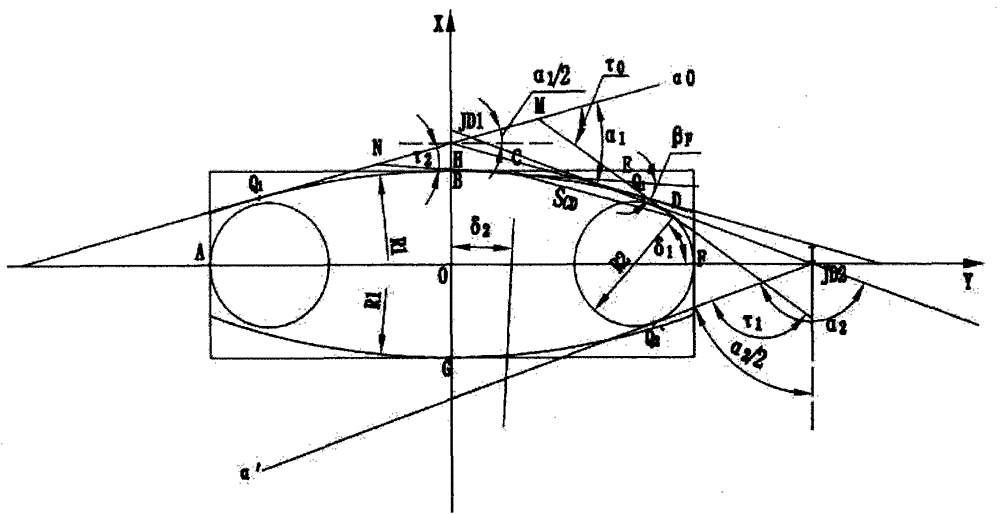

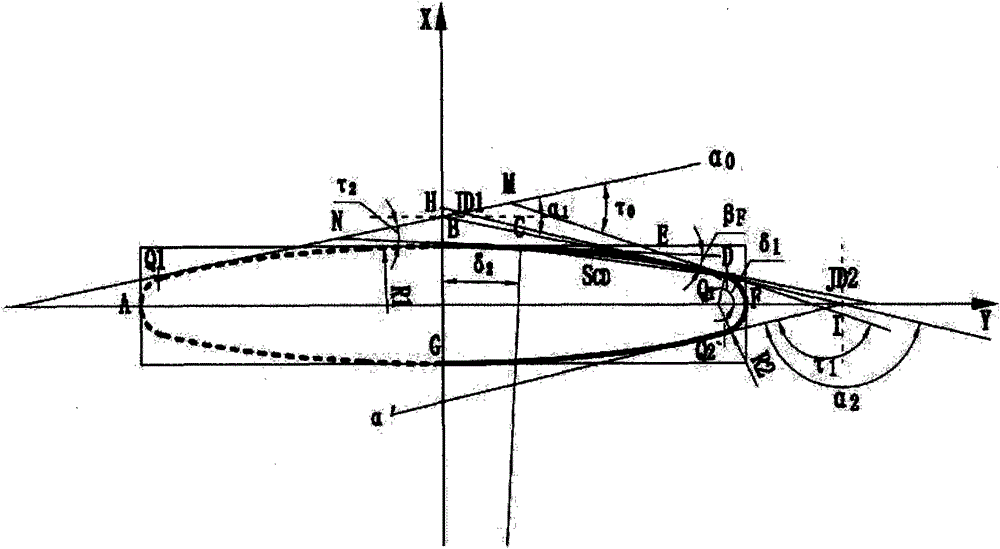

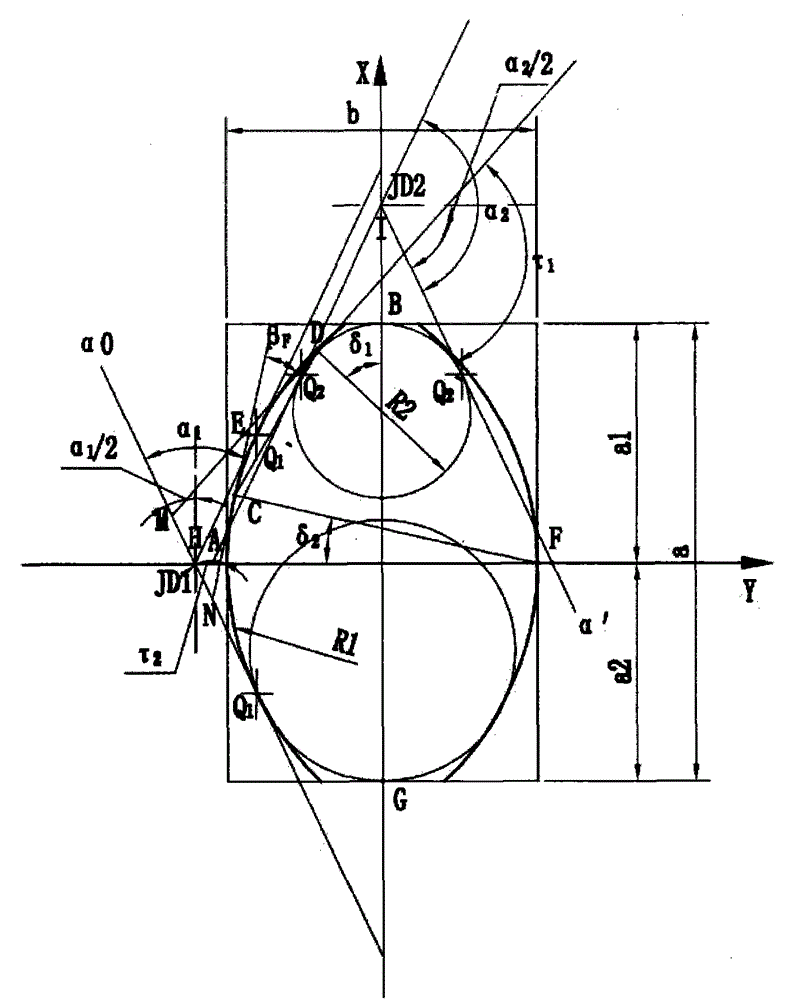

Computer aided design method for egg-shaped shell line form

ActiveCN104794255ADesign calculation changesDesign calculation method changesSpecial data processing applicationsGraphicsComputer Aided Design

The invention discloses a computer aided design method for an egg-shaped shell line form, relates to the technical field of egg-shaped curve computer aided design and provides a reliable and generally-applicable computer aided design method for the egg-shaped shell line form. The design method comprises the steps that a rectangle is established according to the geometric dimension requirement of an egg-shaped shell to be designed, a computer software Excel table is adopted for calculating the parameters and coordinates of a middle easement curve, the calculation result data of the coordinates of the middle easement curve are imported point by point in a CAD fundamental figure, and the egg-shaped shell line form is formed. By means of the computer aided design method, the egg-shaped shell line form can be easily designed, and the shell line form of an egg-shaped container and an egg-shpaed curve formed through a design method for the structural line form of an egg-shaped component can be easily designed.

Owner:王开明

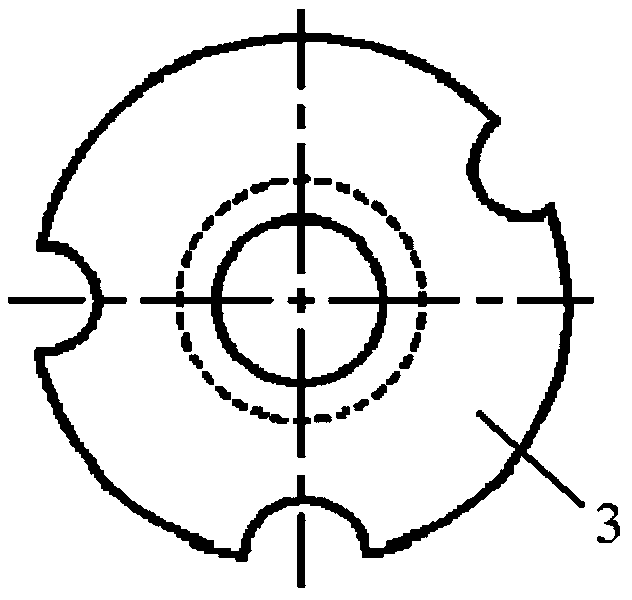

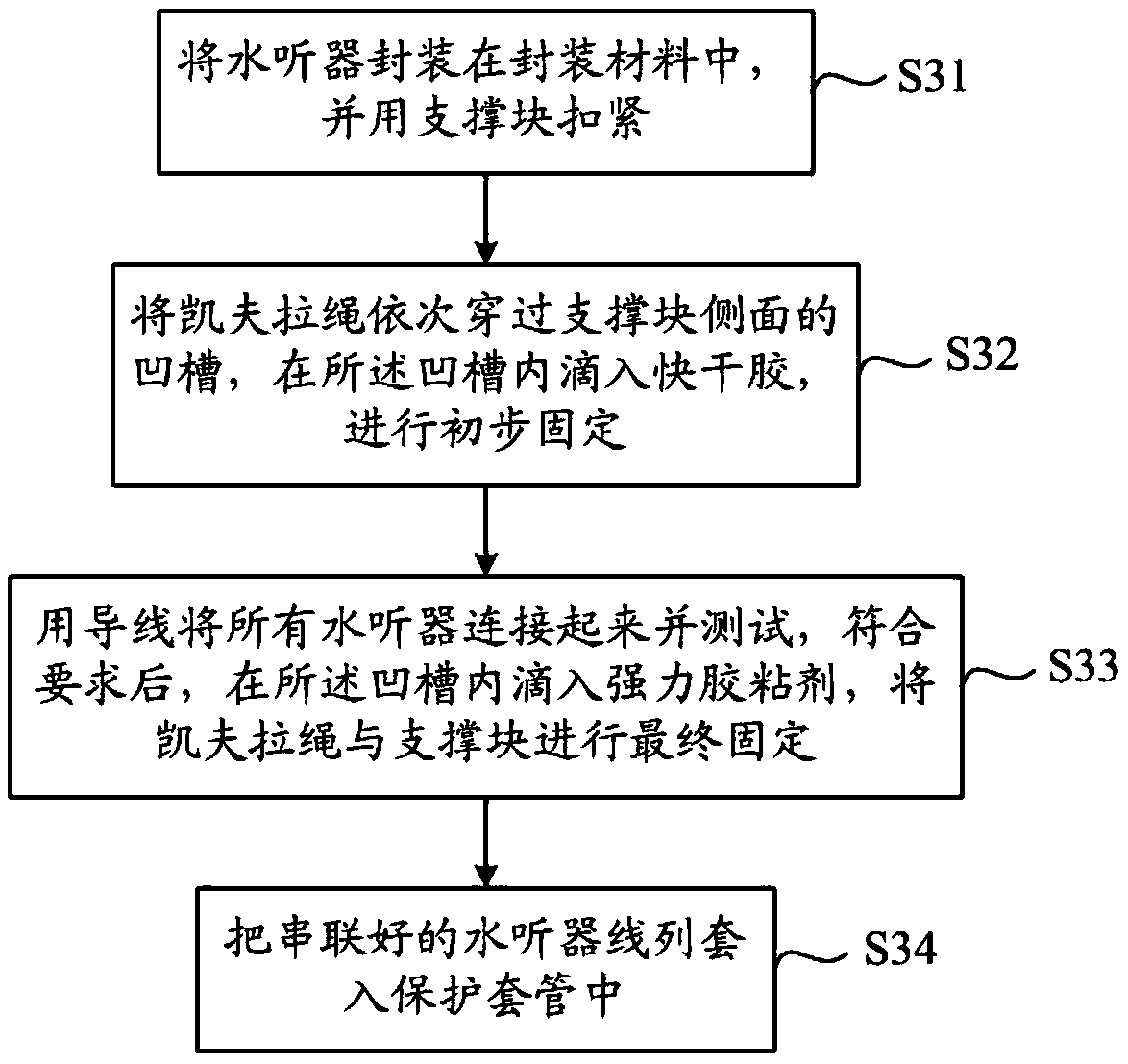

Fixing device and fixing method of hydrophones in array cable

ActiveCN108769870AFixing method is simpleEasy to operateTransducers for subaqueous useHydrophoneTransducer

The invention discloses a fixing device and a fixing method of hydrophones in an array cable, and belongs to the technical field of underwater acoustic transducers. The fixing device comprises an encapsulating material for encapsulating the hydrophones, and a support block, wherein both ends of the encapsulating material are arranged as a clamp structure; and one end of the supporting block is provided with a card slot that is flexibly connected with the clamp. The fixing method comprises: encapsulating the hydrophones in the encapsulation material and fastening with the support block; sequentially passing the Kevlar rope through the groove on the side of the support block, dripping the quick-drying glue into the groove for preliminary fixing; connecting all the hydrophones by wires for testing, dropping the quick-drying glue into the groove after the requirements are met to finally fix the Kevlar rope and the support block; and embedding serially connected hydrophone line arrays in the protective sleeve. The fixing method is simple and easy to operate, and the encapsulating material is caught in the card slot of the supporting block by the clamp, so that the hydrophone may be disassembled for replacement or maintenance by taking out the clamp from the card slot, thereby reducing the difficulty of repairing a fault during cable forming process.

Owner:HAIYING ENTERPRISE GROUP

Backlight module and optical film immobilizing method

ActiveCN100590494CFixing method is simpleSimplify the assembly processLighting support devicesNon-linear opticsComputer moduleEngineering

The invention discloses a fixing method for a backlight module and an optical patch; the backlight module comprises a base, a light source, a plurality of fixed components and an optical patch. The light source is arranged on the base and can emit light. Each fixed component has a pair of flexible connectors arranged on the base and a pair of clipping fasteners which are respectively arranged on the flexible connectors. The flexible connectors of each fixed component maintain the gaps, and the flexible connectors of each fixed component can make flexible deformation by narrowing the gaps. Theoptical patch is arranged on the base and has a plurality of fixed holes. The light passes through the optical patch. The flexible connectors of each fixed component pass through one of the fixed holes; each fixed hole is limited between each clipping fastener of the corresponding fixed component and the base, so that the optical patch is restricted in moving on a first axis, a second axis and a third axis; the first axis, the second axis and the third axis are perpendicular to each other.

Owner:AU OPTRONICS CORP

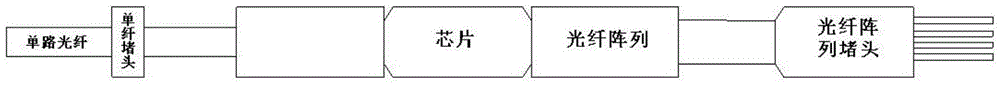

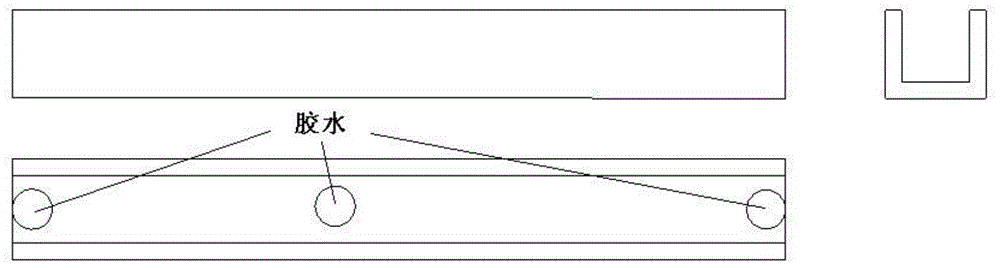

A method for fixing bare components of optical splitters after coupling and alignment during packaging

ActiveCN103995333BFixing method is simpleTroubleshoot calibration issuesFibre mechanical structuresCouplingEngineering

The invention relates to the technical field of optical fiber communication component manufacturing, in particular to a fixing method of an optical branching device naked device during packaging after coupling aligning. According to the method, the shortcomings in an existing optical branching device packaging technology are overcome, the fixing method of the optical branching device naked device during packaging after coupling aligning is optimized, optical device correcting is well achieved, insertion loss is lowered, and the technical problem that due to unqualified packaging, insertion loss is too high, and packaging needs to be carried out again is avoided in the packaging technology.

Owner:湖南省康普通信技术有限责任公司

Submerged green space structure for sponge city

InactiveCN109098256AImprove filtering effectAvoid affecting water qualityArtificial islandsSewerage structuresFiltrationWater storage tank

The invention provides a submerged green space structure for a sponge city. The submerged green space structure for the sponge city is characterized in that the submerged green space structure comprises a water storage tank and a connecting water pipe; the size of road traffic stone is 1 meter by 0.7 meter by 0.1 meter, the road traffic stone with the top 30 centimeters above the ground is fixed adjacent to the ground, and four circular blind holes are opened on the inner side; a filter box is a rectangular box structure with the top fixed with a top cover by snap connection; two eyebolts arefixed on the top cover through bolt connection; a wire rope is wound and fixed between rings of the two eyebolts; the right end of a bottom face is provided with a cylinder communicated with the innerportion of the filter box. The submerged green space structure for the sponge city has the advantages of maintaining a high level of water quality through a perforated pipe into the water storage tank by multi-layer filtration, greatly reducing the maintenance and repair frequency caused by the accumulated blockage of sediments, allowing a maintenance well to provide conditions for easy maintenance and repair when the filter box is maintained for too long, ensuring the filter box to be taken out and put in simply and conveniently, and being simple and feasible in fixing method.

Owner:丁文铃

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com