Hydraulic concrete cutting system

A concrete and hydraulic technology, applied in the field of reinforced concrete cutting equipment for construction, can solve the problems of inability to cut at any angle, single function of the driving mechanism, inconvenient installation, etc., and achieve the effects of reliable output speed, light design, and reliable and fast installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

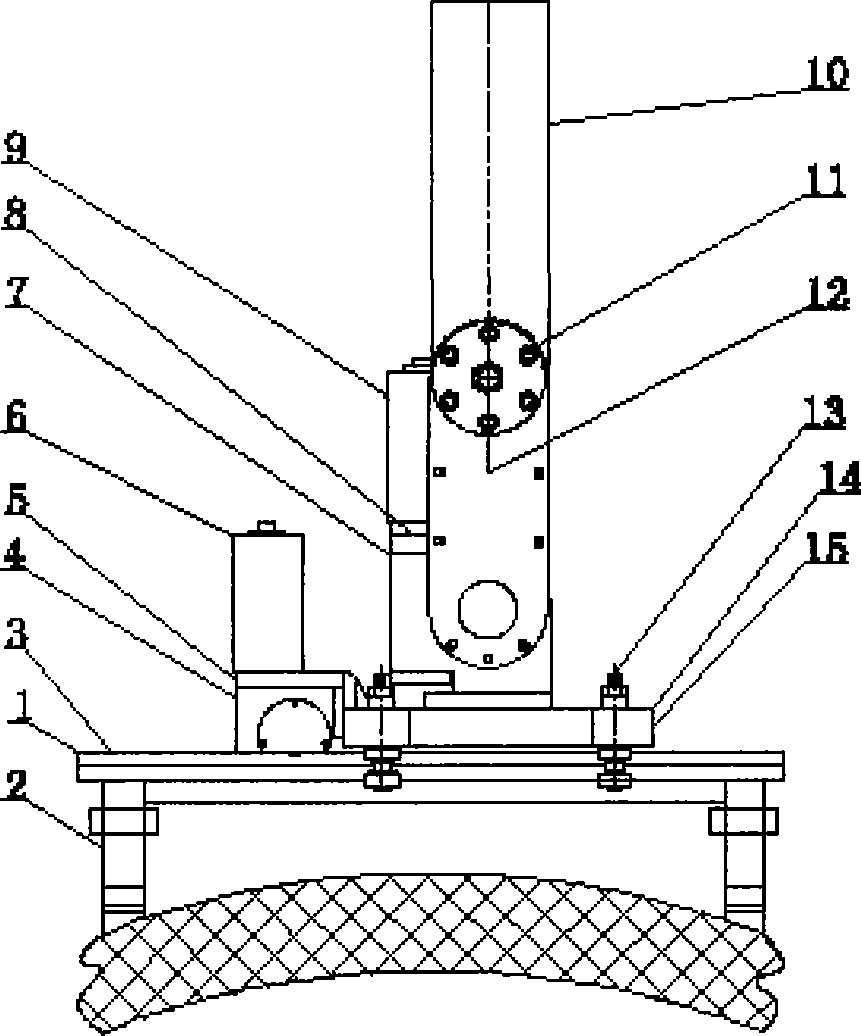

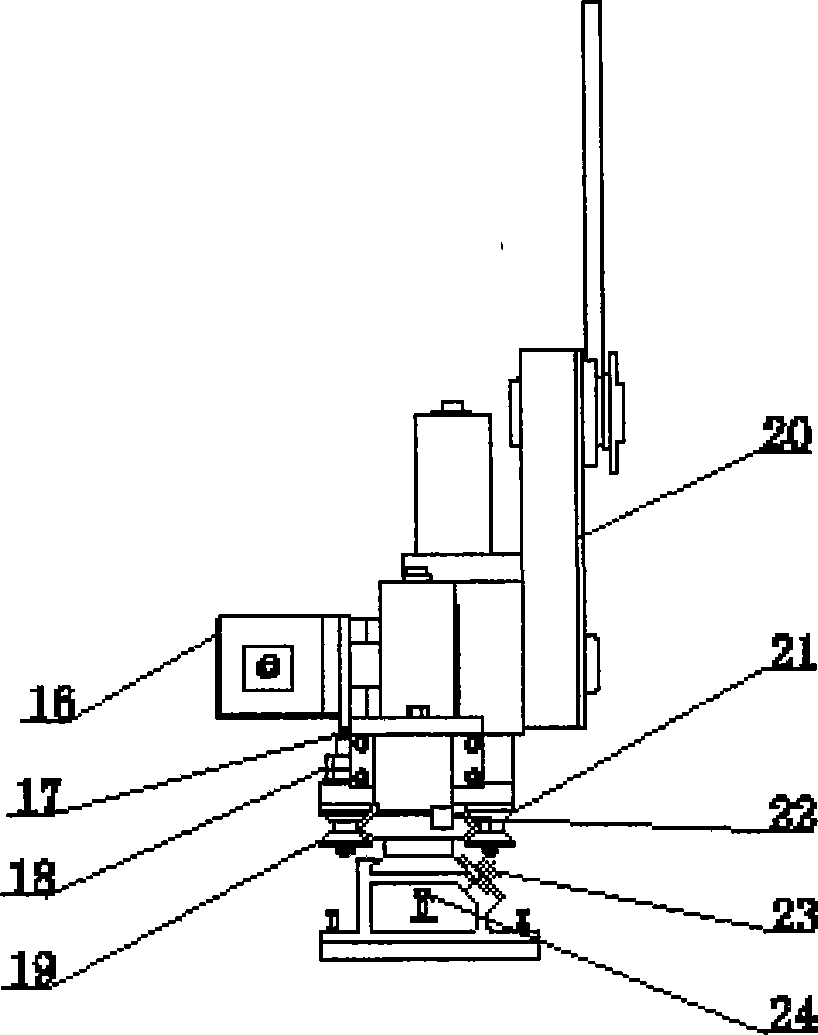

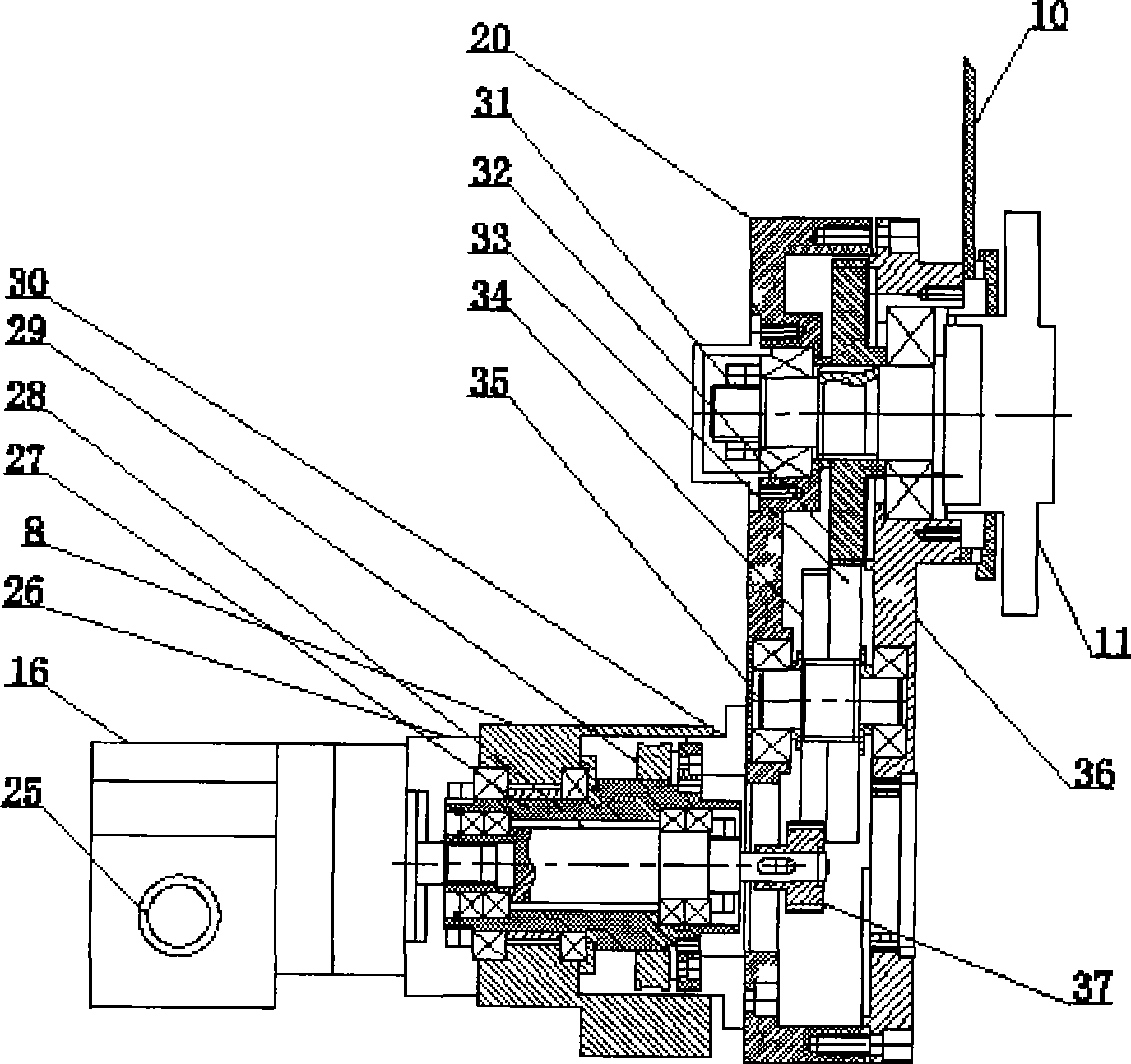

[0036] Example figure 1 , figure 2 As shown in the figure, the equipment is a kind of equipment manufactured comprehensively by mechanical, electrical and hydraulic technologies. It is mainly composed of a hydraulic supply source, an electric control box, a guide rail assembly 1, a knife feed assembly 4, a rotating assembly 7, a deceleration assembly 12, a base assembly 14, and a hydraulic motor 16. The guide rail assembly 1 is fixed on the guide rail support frame 2, the knife feed assembly 4 is fixed on one side of the base assembly 14, the rotation assembly 7 and the deceleration assembly 12 are connected at a vertical angle and fixed above the base assembly 14, and the cutting saw blade is connected on the deceleration assembly 14. On the assembly 12; the hydraulic motor 16 is at one end of the rotating assembly 7 and communicates with the hydraulic supply source through the oil pipe; the electric control box controls the operation of the cutting machine through the cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com