A method for fixing bare components of optical splitters after coupling and alignment during packaging

An optical splitter and fixing method technology, applied in the direction of fiber mechanical structure, etc., can solve problems such as large insertion loss, reduce insertion loss, reduce waste of manpower and material resources, and solve the effect of optical device calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are only used to illustrate the present invention, but can not be used to limit the scope of the present invention.

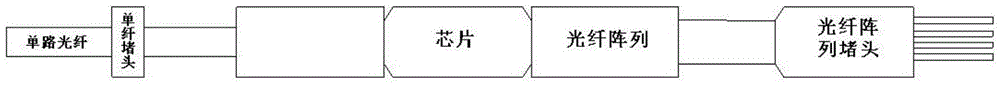

[0026] The invention provides a method for fixing the bare components of the optical splitter after coupling and alignment during packaging. The method is divided into the following steps:

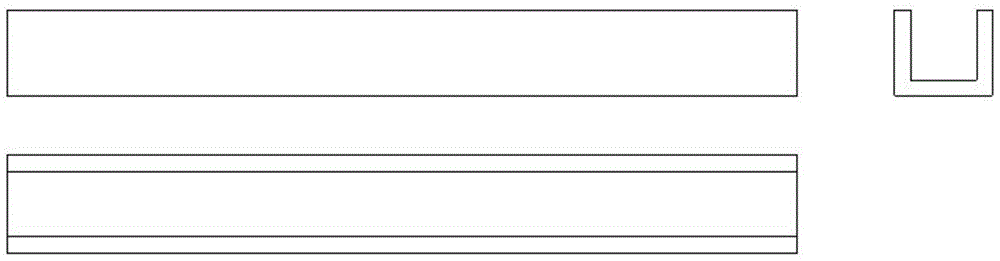

[0027] Making a silicone tube with a C-shaped opening, the inner diameter of the raw material for making the silicone tube with a C-shaped opening is greater than the outer diameter of the chip;

[0028] Thread the optical fibers at the input and output ends of the bare component of the optical splitter into empty pipes with sealed steel pipe plugs;

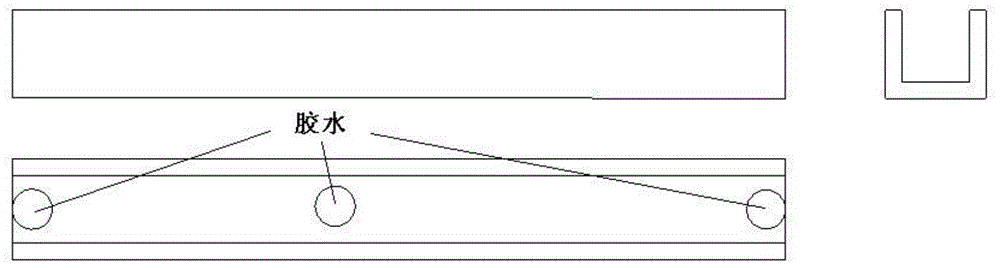

[0029] Apply appropriate amount of silica gel to the places where the plugs are placed at both ends of the lower cover of the packa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com