Novel vacuum-assisting mold absorption mold repairing device

A vacuum-assisted and mold-repairing technology, applied in auxiliary molding equipment, ceramic molding machines, manufacturing tools, etc., can solve the problems of easy contact and defect of the model, deformation of the blank, cracking, etc., to solve the problem of uneven mold repair strength, mold repair Precise, easy-to-pick results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

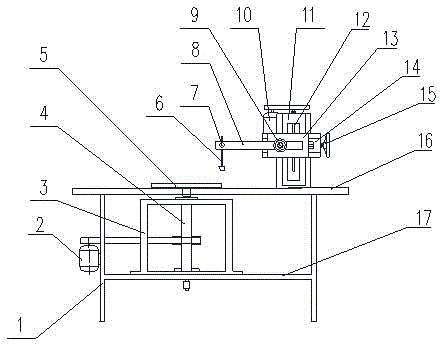

[0018] The present invention will be further described in detail below through specific embodiments.

[0019] Such as figure 1 As shown, a new type of vacuum-assisted mold repairing device includes a frame 1, a workbench 16, a mold rotating mechanism and a mold repairing mechanism. The workbench 16 is connected to the upper end of the frame 1, and the workbench 16 has a through hole for installation. The middle part of frame 1 has mounting plate 17, has through hole on the mounting plate 17; Rotary mold mechanism comprises main shaft 4, mold base 5; Die base 5 is positioned at the top of workbench 16, and through hole is arranged on mold base 5; Main shaft is Hollow, the main shaft is connected with the mold base, and the hollow part of the main shaft communicates with the through hole on the mold base.

[0020] In order to better fix the main shaft, the mold rotating mechanism of the present invention is also provided with a main shaft support 3 , and the main shaft support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com