Sensor device for detecting welding line by ultrasonic guided waves and fixing method

A sensor device, ultrasonic guided wave technology, applied to measuring devices, material analysis using sound waves/ultrasonic waves/infrasonic waves, instruments, etc., can solve problems such as manual fixation, inability to ensure that the bottom of the sensor is tightly pressed, and affecting the effect of weld flaw detection, etc. , to achieve the effects of convenient operation, simple and easy fixing method, and improved detection efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with drawings and embodiments.

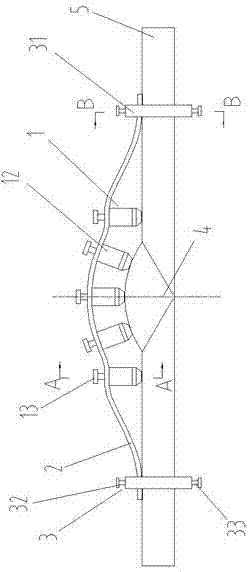

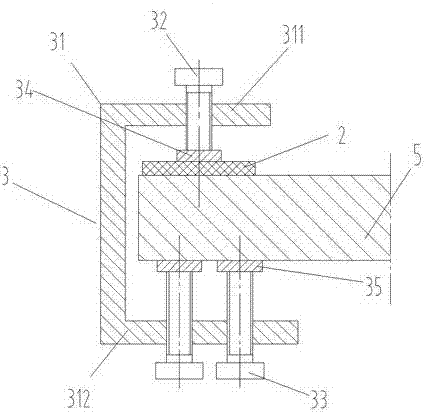

[0027] like Figure 1 to Figure 5 As shown, this embodiment is used to detect the butt weld 4 of two welding plates 5, including five sensing units 1, fixing belts 2 and two clamping units 3, along the length direction of the fixing belt 2, five are arranged side by side The sensing units 1 are arranged symmetrically on the welding seam 4 and the welding plates 5 on both sides of the welding seam 4, the upper ends of the five sensing units 1 are respectively fixed under the middle part of the fixing belt 2, and the lower ends are against the arc-shaped protruding welding seam 4 and the welding plate 5 on both sides of the weld. The length direction of the fixing belt 2 is perpendicular to the welding seam 4 , and the clamping unit 3 fixes both ends of the fixing belt 2 on the welding plate 5 respectively.

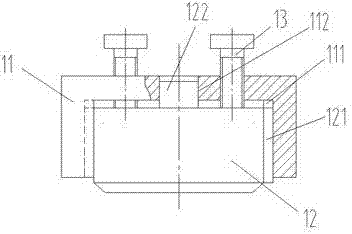

[0028] The sensor fixture 11 is in the shape of a groove with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com