Fuel tank filter pipe

An injection pipe, fuel tank technology, applied in the layout, power plant, vehicle components, etc. combined with the fuel supply of internal combustion engines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

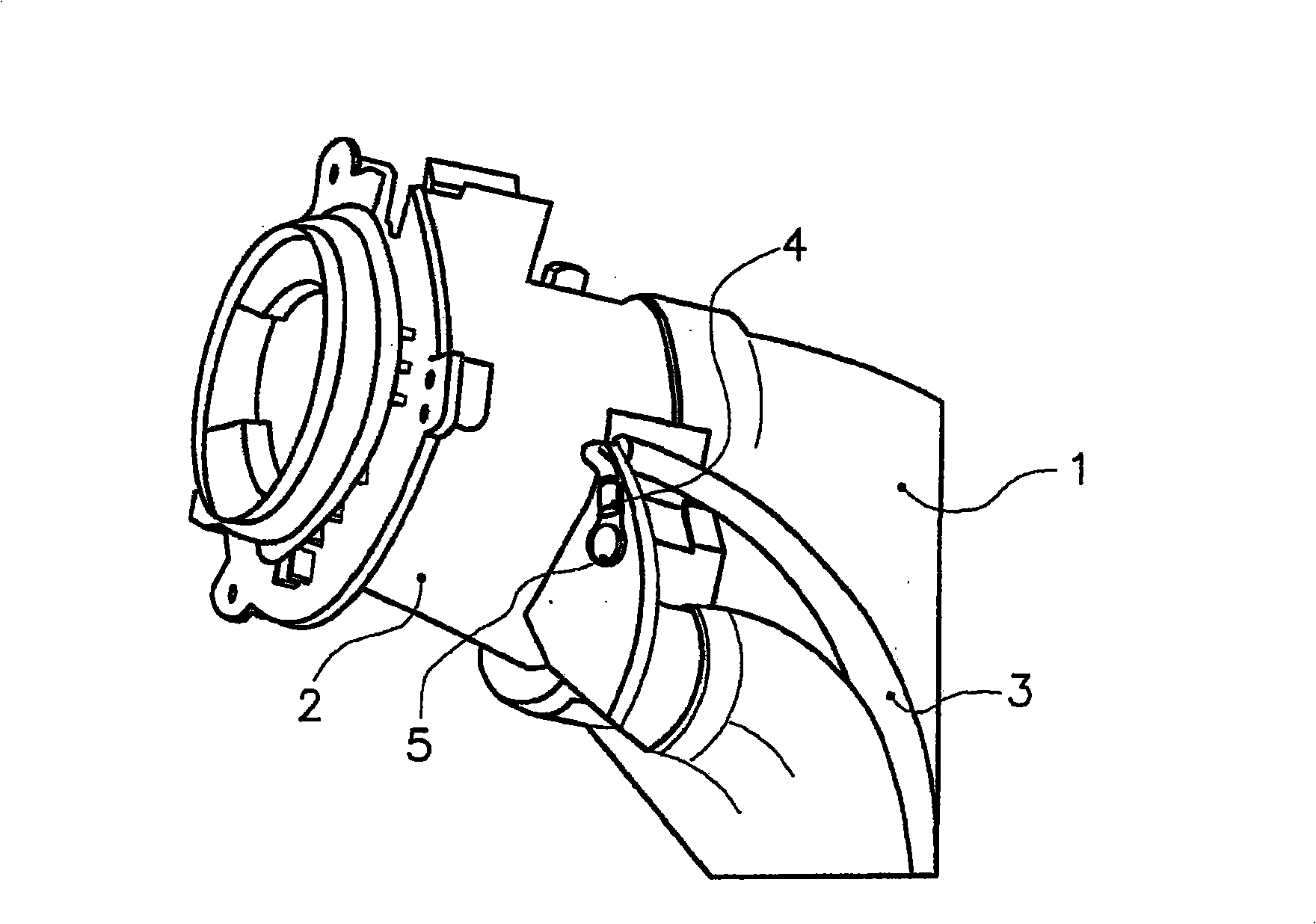

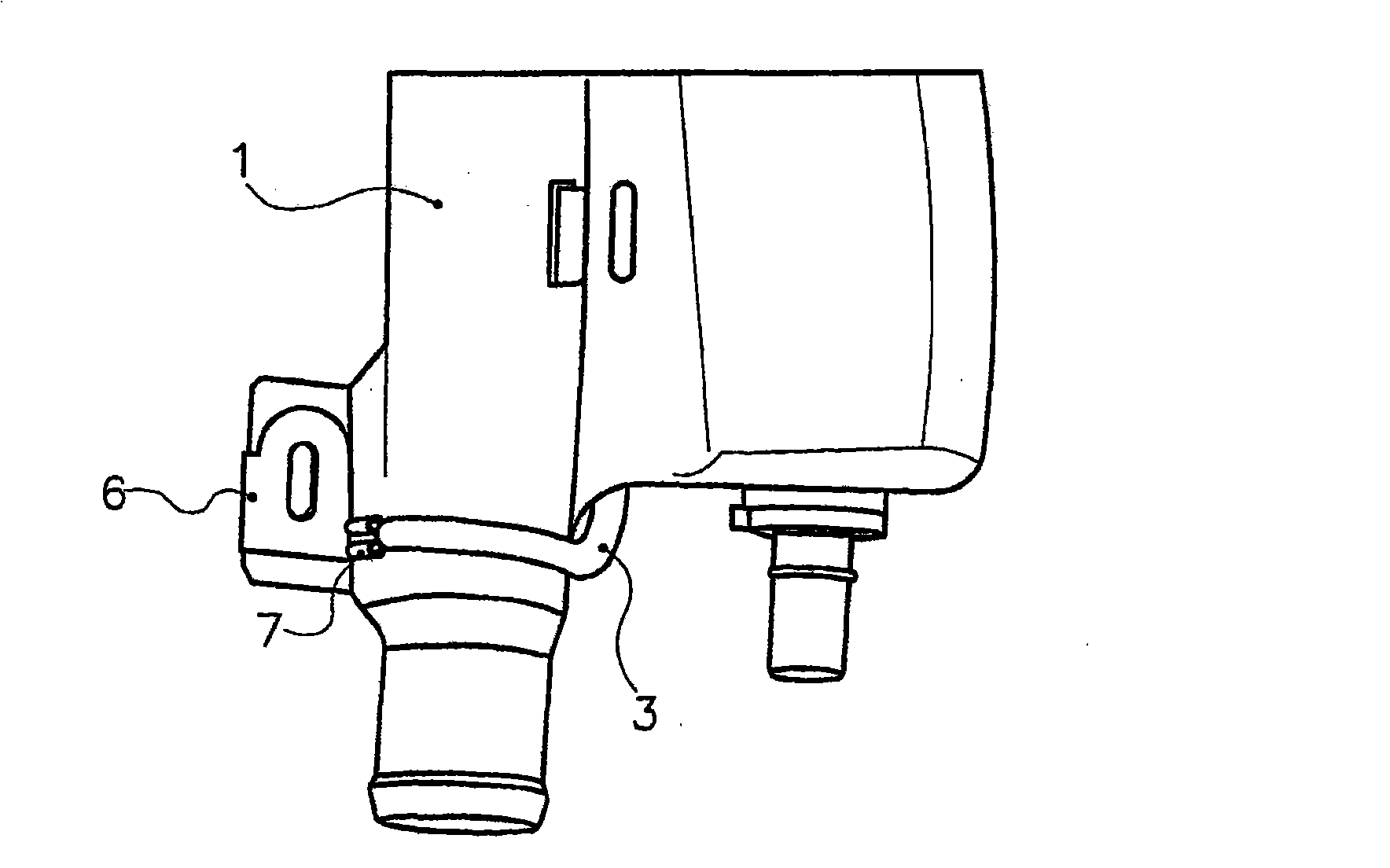

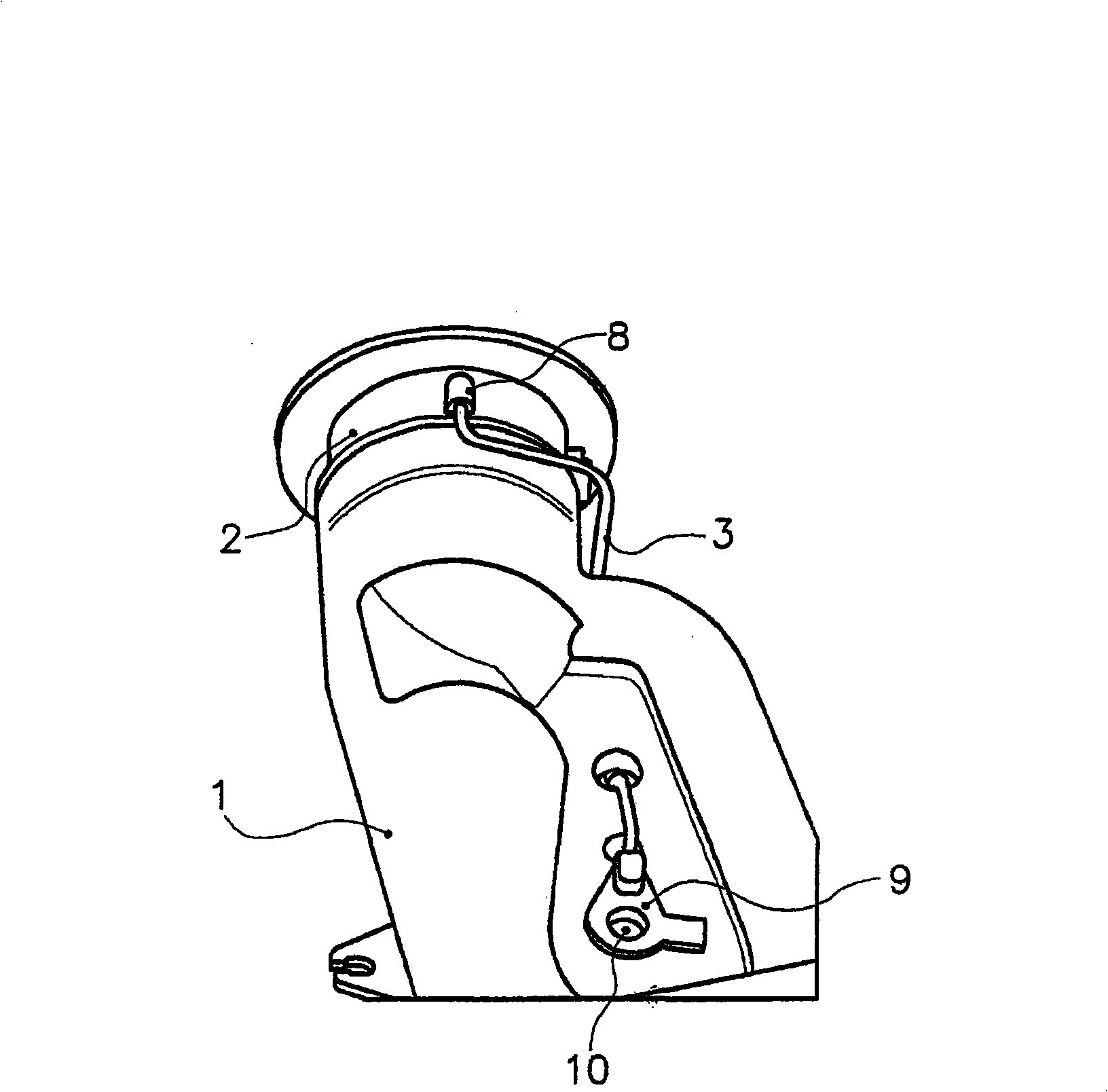

[0015] The term "fuel tank" is understood to mean a sealed tank capable of storing fuel under different and varying usage and environmental conditions. An example of such a tank is a fuel tank fitted to a motor vehicle.

[0016] The fuel tank is preferably made of plastic.

[0017] The term "plastic" is understood to mean any material comprising at least one synthetic resin polymer.

[0018] All types of plastics may be suitable. Especially suitable are plastics belonging to the class of thermoplastics.

[0019] The term "thermoplastic (plastic)" is understood to mean any thermoplastic polymer, including thermoplastic elastomers, and mixtures thereof. The term "polymer" is understood to mean homopolymers and copolymers (in particular binary and terpolymers). Examples of such copolymers are (without limitation) random copolymers, linear block and other block copolymers, and graft copolymers.

[0020] Any type of thermoplastic polymer or copolymer having a melting point bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com