Construction method of template with no split bolt hole

A technology of pulling bolt holes and pulling bolts, which is applied in the construction, building structure, construction material processing and other directions, can solve the problems of inputting a large number of new templates for beam-slab template and reducing the number of turnover of templates, so as to achieve reliable and reliable template rigidity. The effect of improving the turnover rate and the simple fixing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

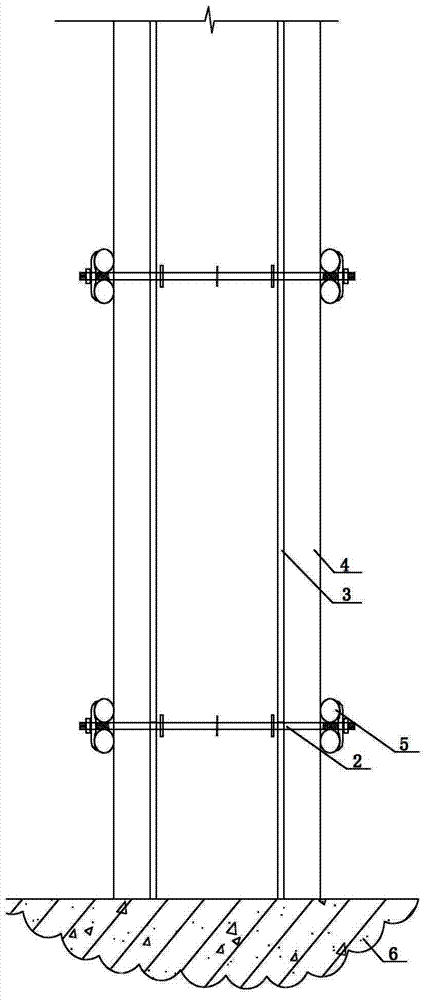

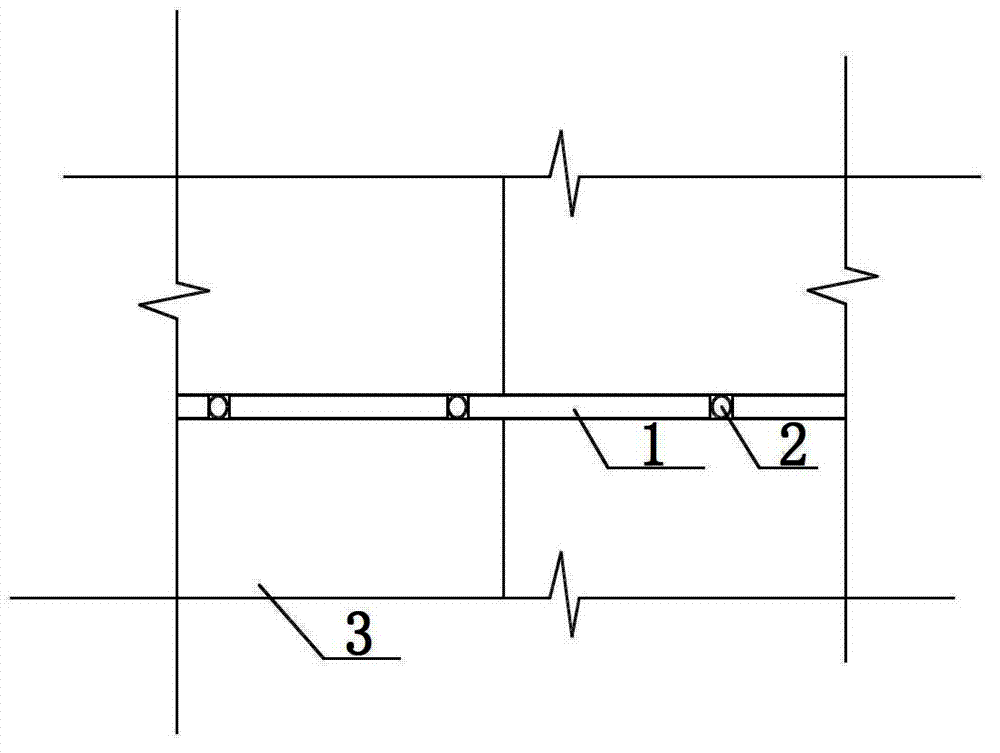

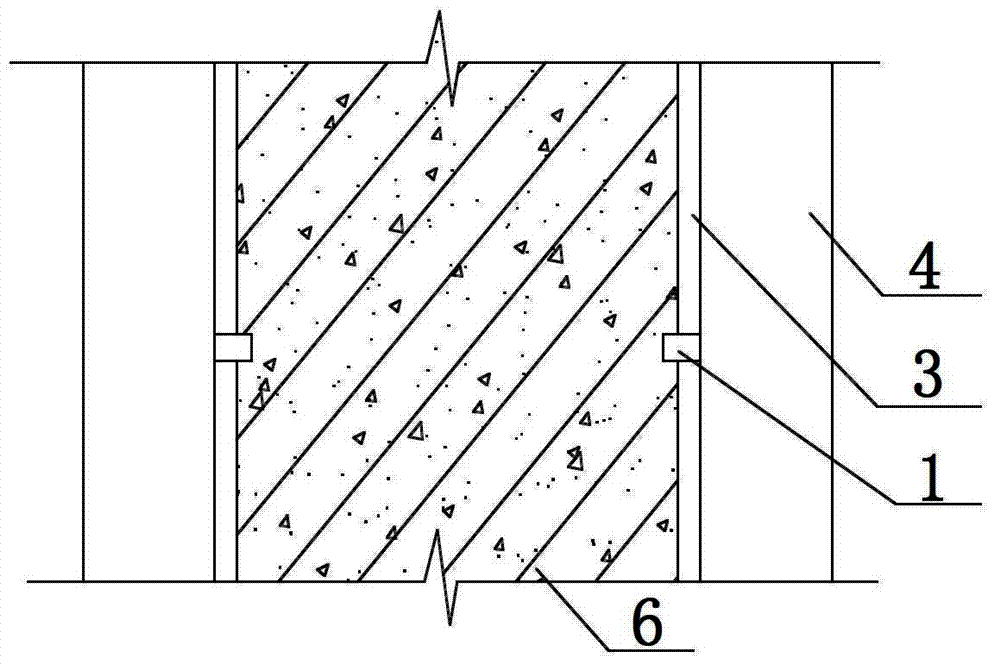

[0025] (1) A plurality of exterior wall formworks are placed longitudinally in turn to form the first layer of exterior wall formwork 3, and the adjacent two exterior wall formworks of the lower exterior wall formwork are spliced with nails, and then the adjacent two exterior wall forms Set wooden squares at the vertical joints between the templates and fix them with nails; (2) place small formwork strips 1 and tension bolts 2 at intervals on the top of the lower exterior wall formwork; the distance between tension bolts 2 on the same floor is 200mm; (3) Repeat the steps (1) and (2) to build the upper exterior wall formwork layer by layer until reaching the installation height of the exterior wall formwork; (4) install the vertical wooden square 4 on the outside of the external wall formwork; Horizontal double steel pipes arranged in the horizontal direction are installed on the outside of the wall, the distance between the horizontal double steel pipes is the same as the ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com