Patents

Literature

41results about How to "Reliable stiffness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

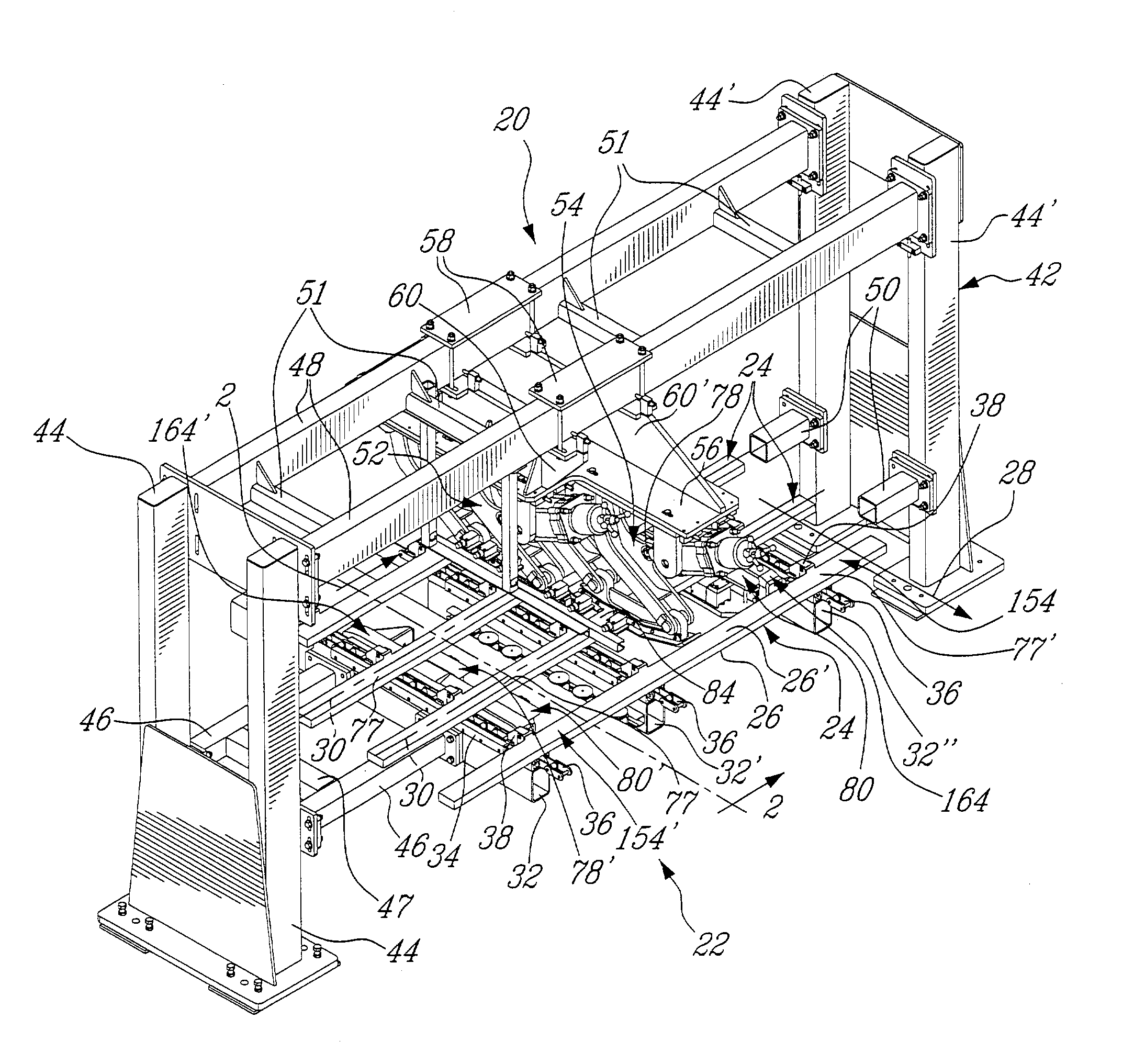

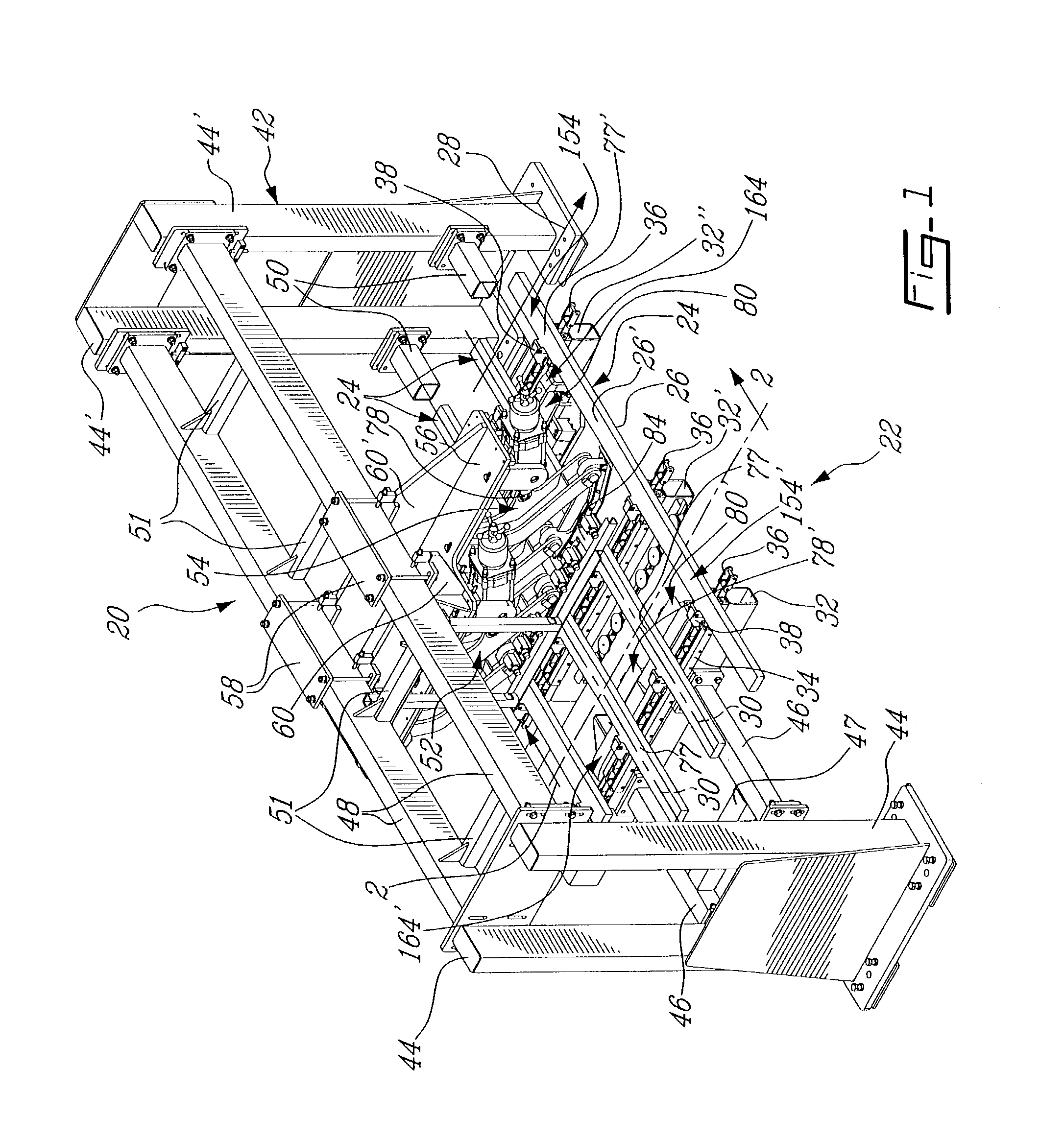

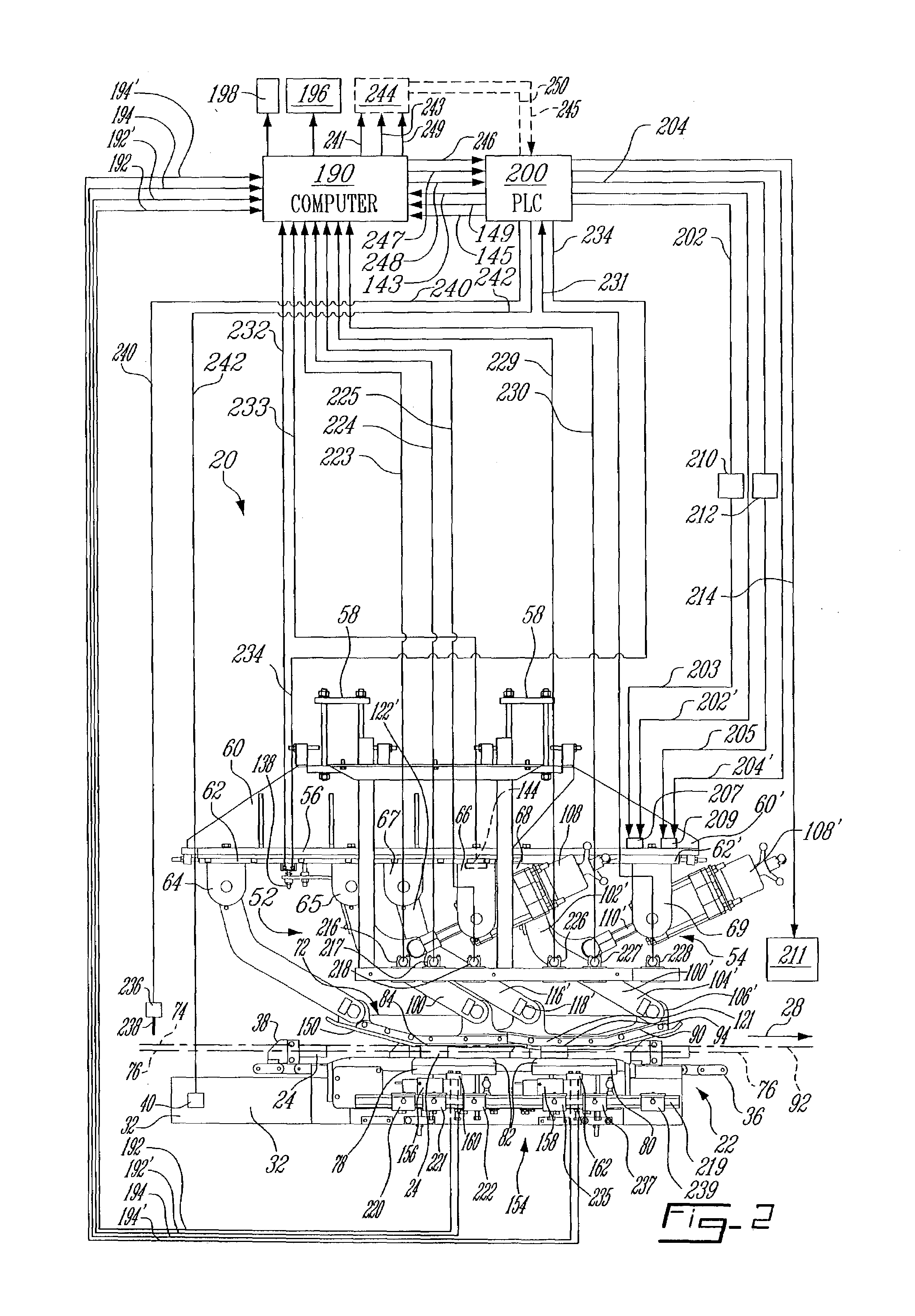

Apparatus and method for testing stiffness of articles

ActiveUS7194916B2Reliable stiffness estimationCompact implementationMaterial strength using steady bending forcesWood testingEngineeringLoad cell

Owner:CENT DE RES & DEV IND DU QUEBEC

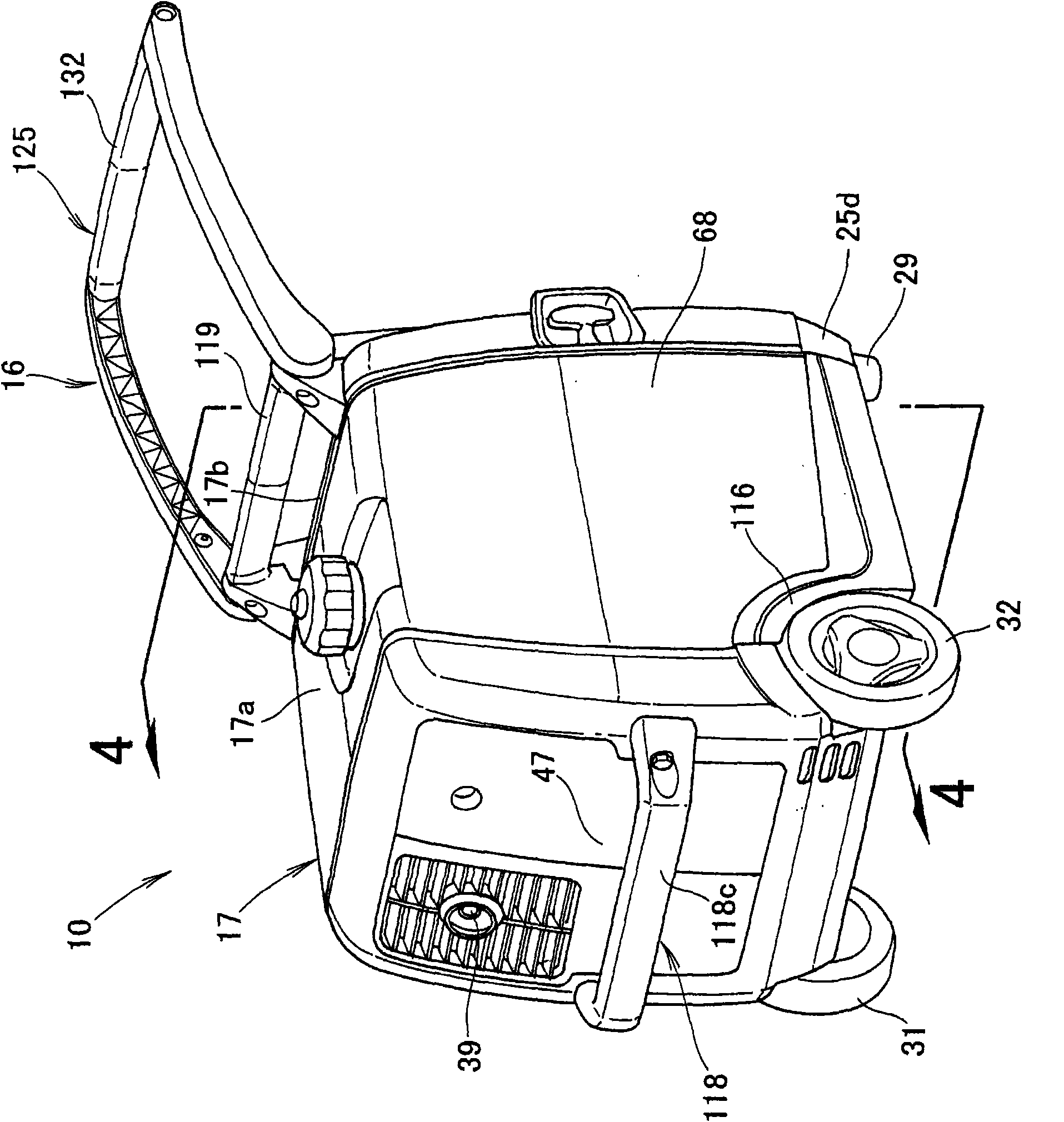

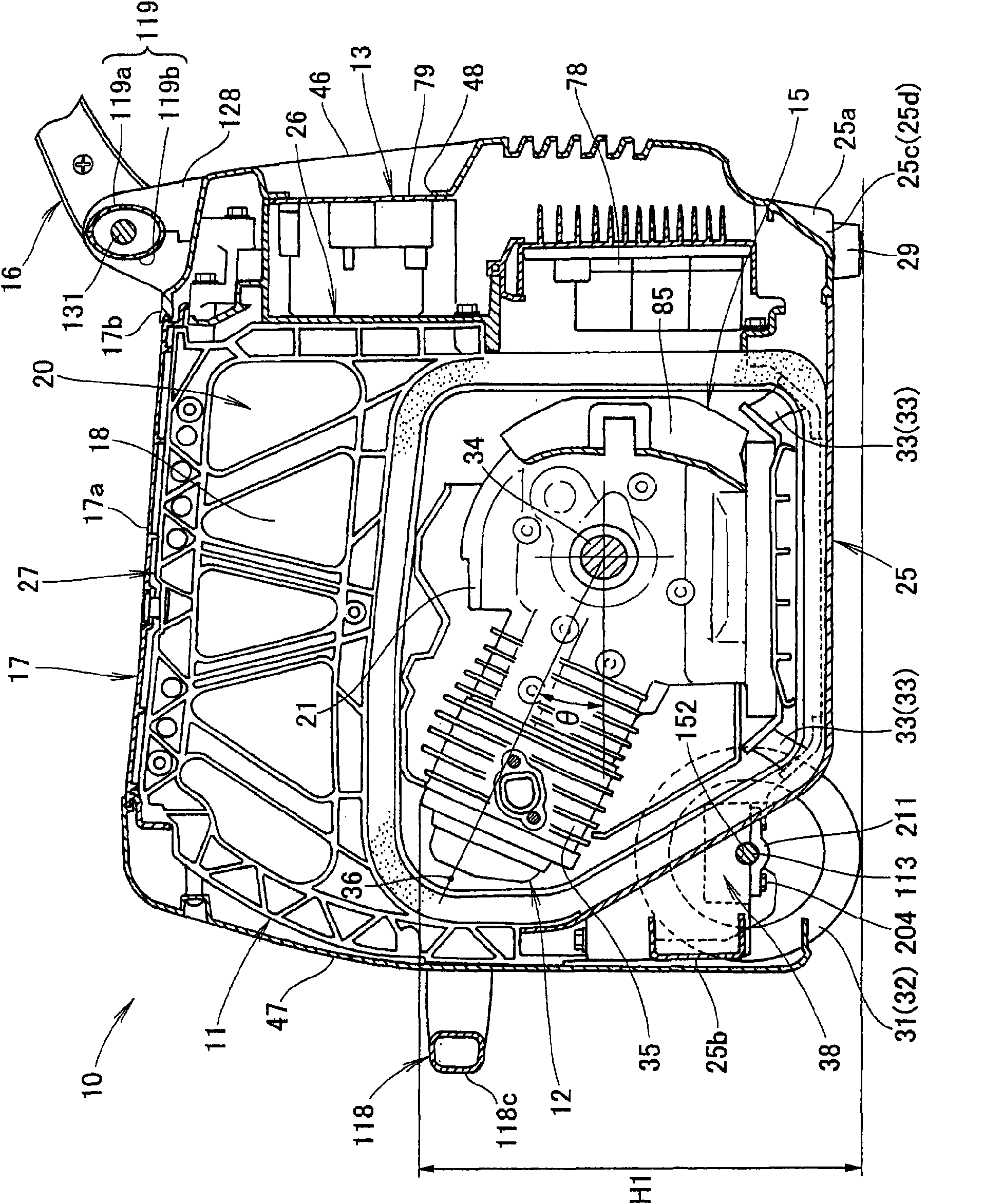

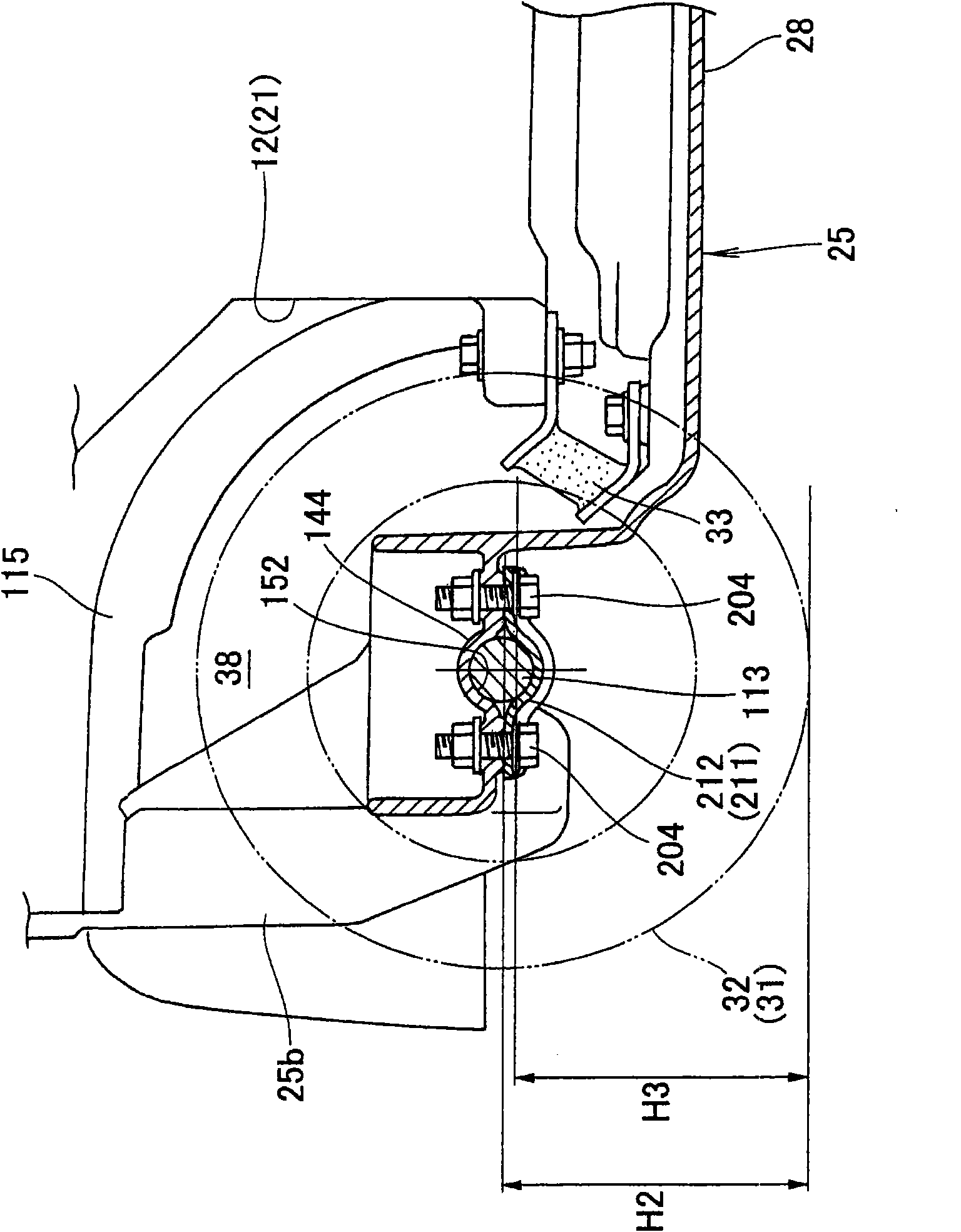

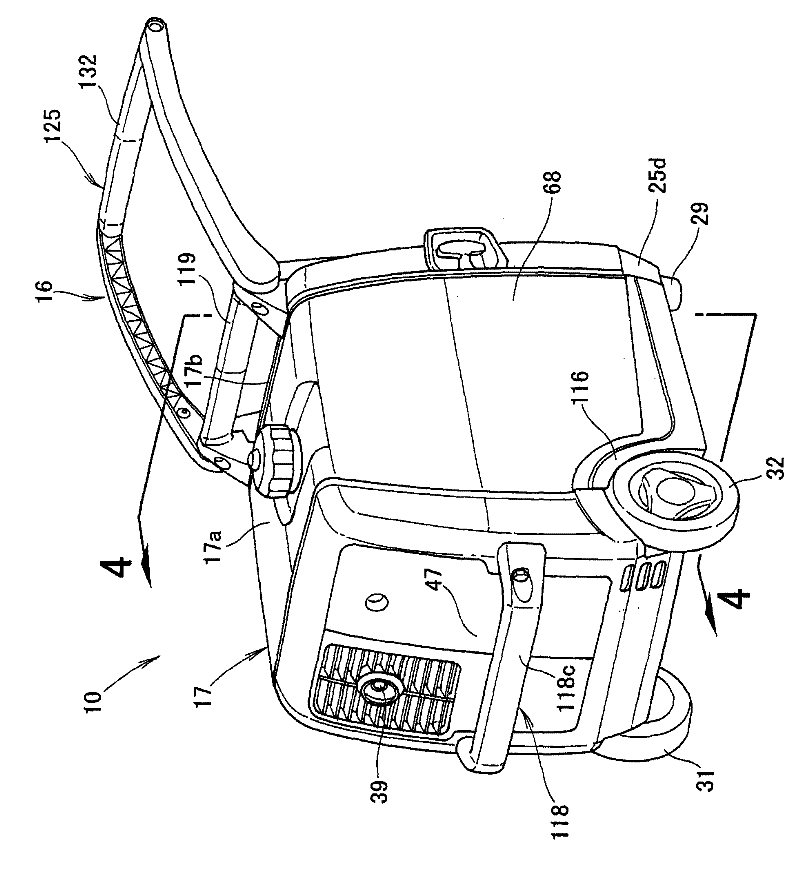

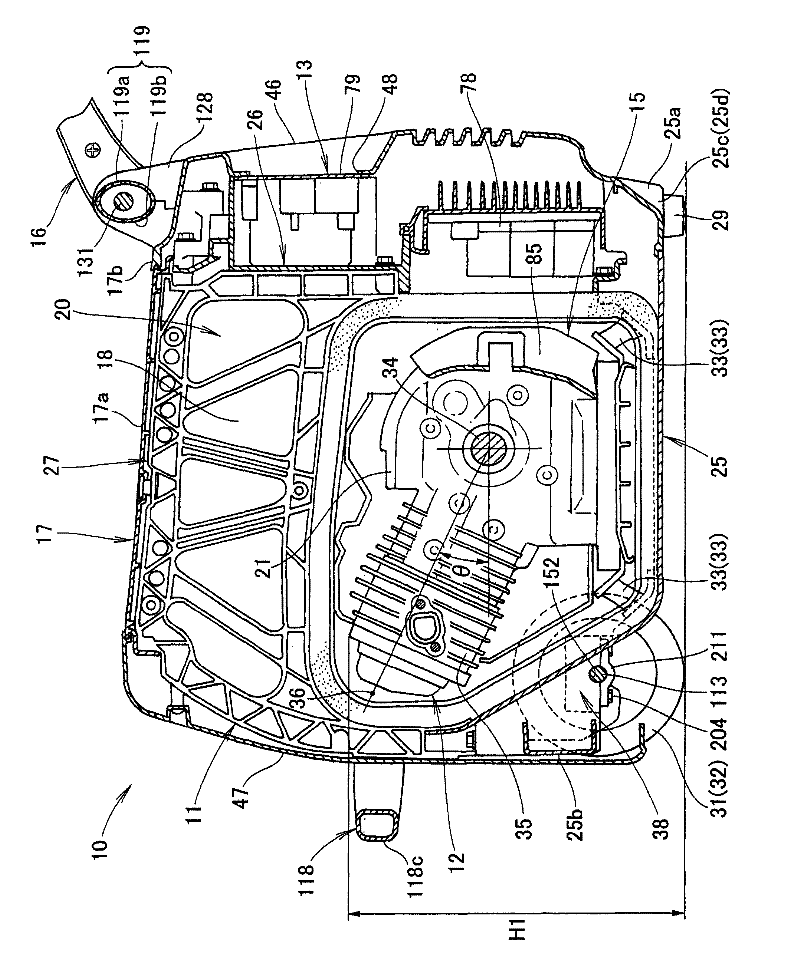

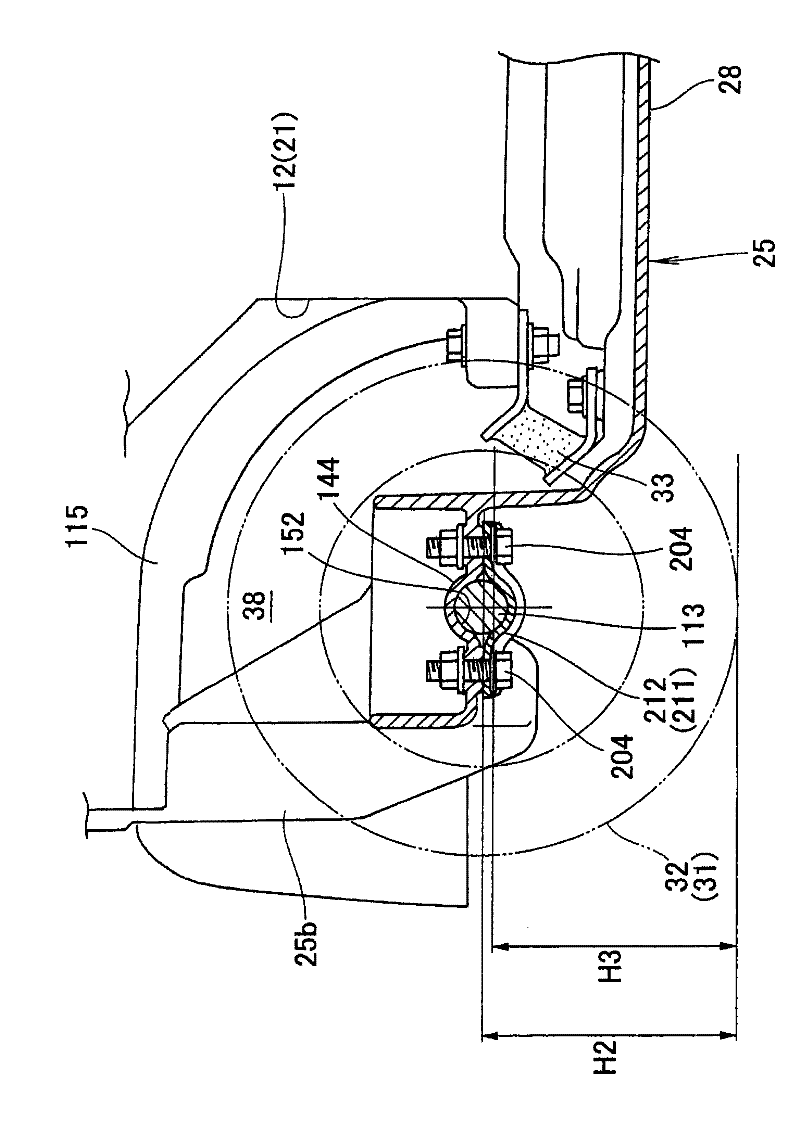

Engine generator

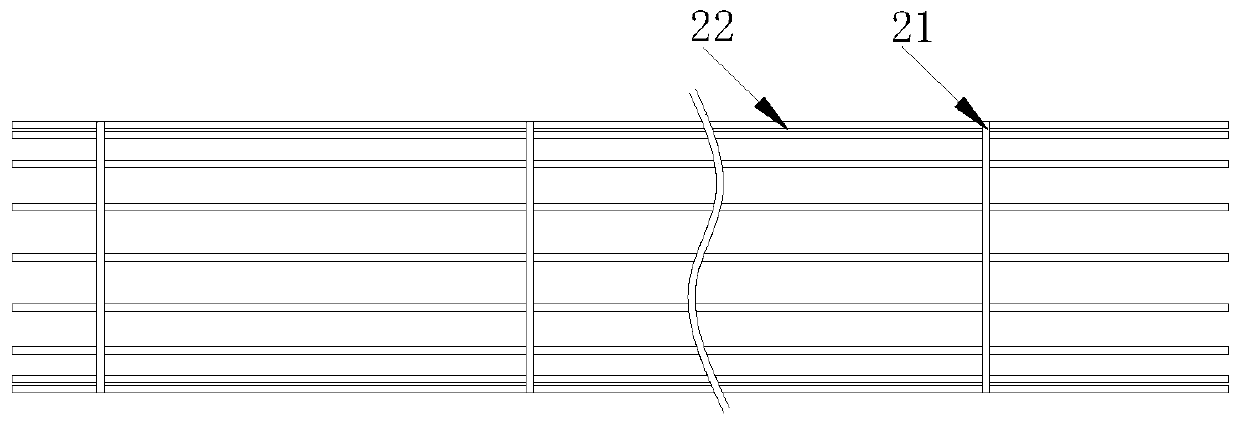

The invention relates to an engine generator accommodating an engine (21) and a generator (22) inside a case (17). A first stationary handle (118) that extends in the width direction is mounted in the rear section of the case. A second stationary handle (119) is mounted on the upper front part of the case. A draw handle (125) is provided so as to swing in the vertical direction in relation to the second stationary handle. The second stationary handle is manually grasped and the engine generator is moved. The first and second stationary handles are grasped and the engine generator is lifted. The draw handle is pulled to move the engine generator.

Owner:HONDA MOTOR CO LTD

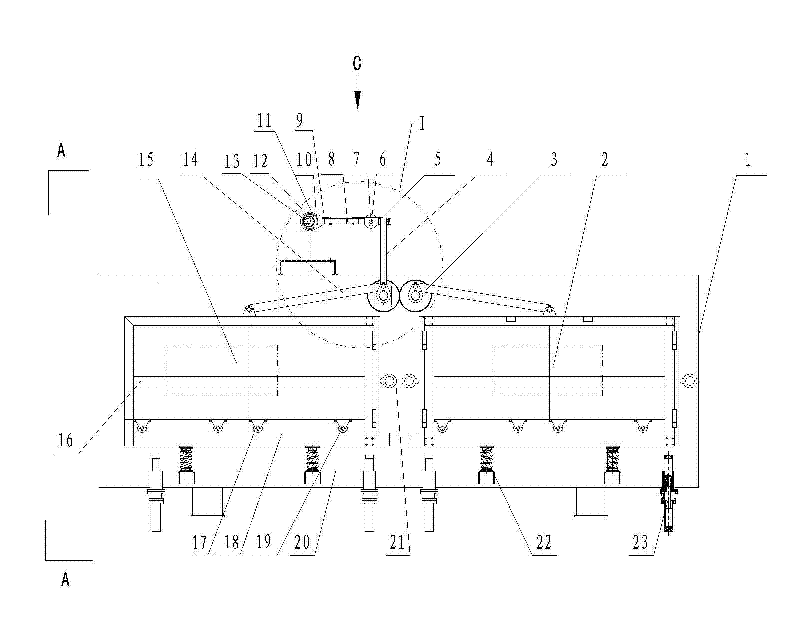

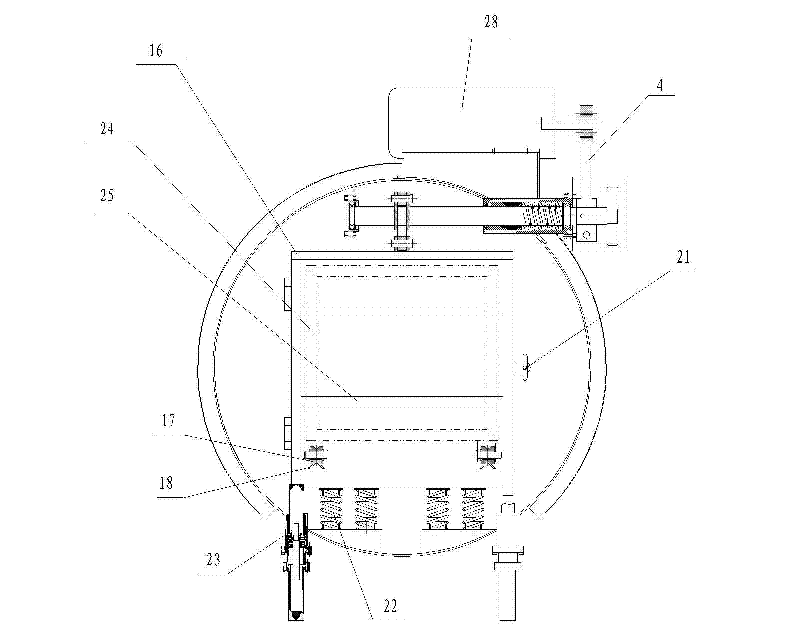

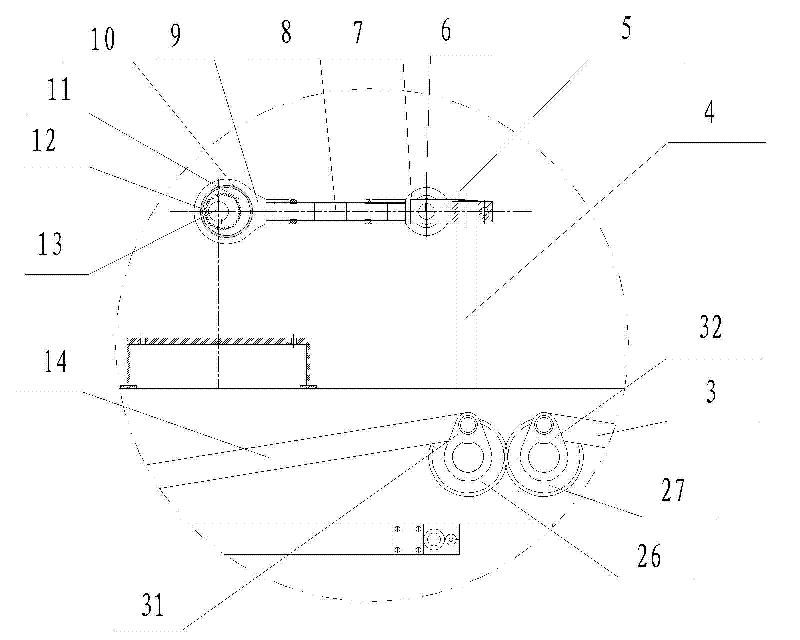

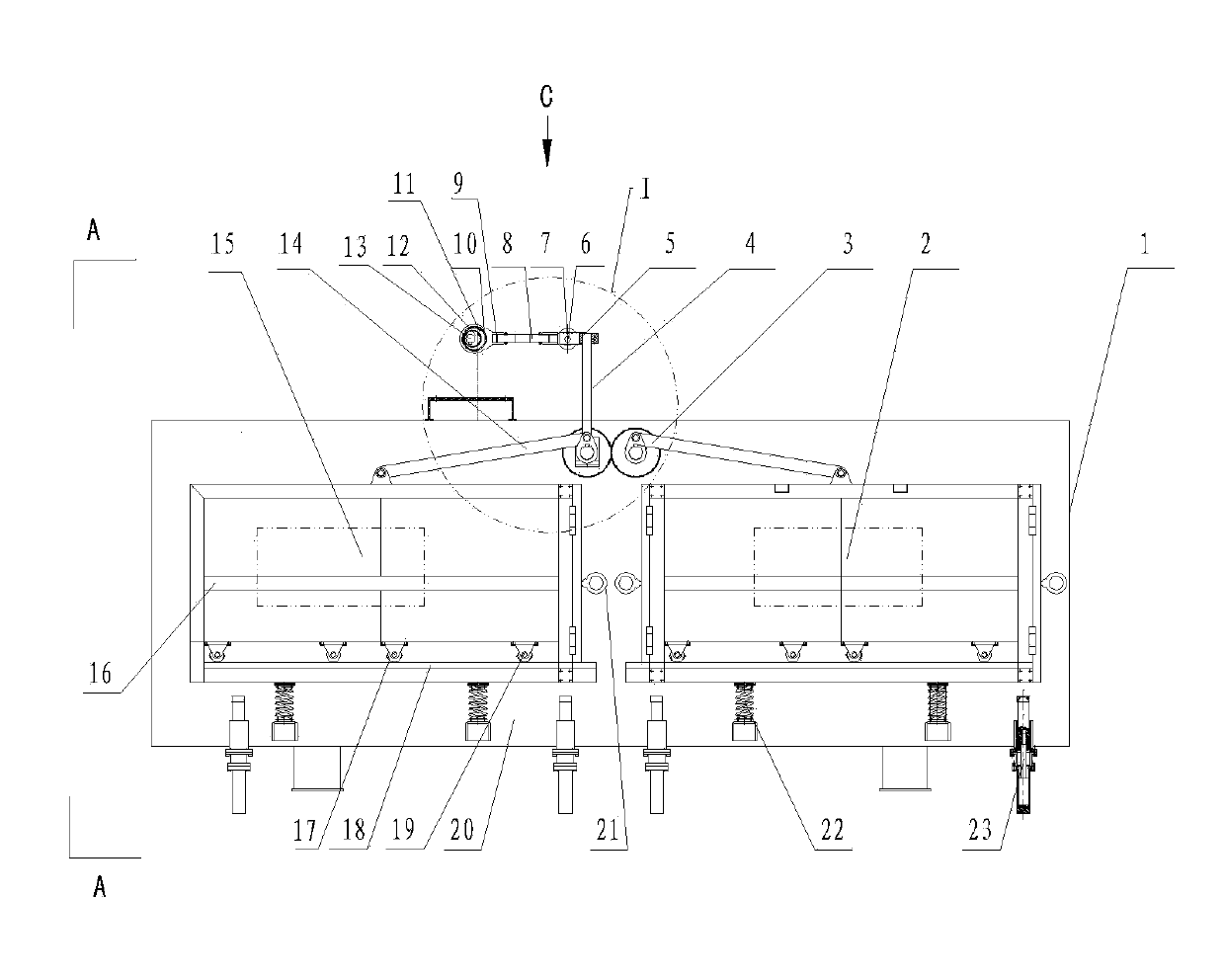

Cooling and sterilizing process for protein preparation and special horizontal type shaking table thereof

ActiveCN102247609AProcess parameters are easy to controlGood antibacterial effectLavatory sanitoryHeatGear wheelReducer

The invention relates to a cooling and sterilizing process for a protein preparation and a special horizontal type shaking table thereof. In the prior art, a sterilizing device for the protein preparation has the defects of poor stability and difficult control of parameters. The special shaking table comprises a cycloidal pin wheel speed reducer, a driving motor and a shaking table, wherein an eccentric outer gear, an eccentric inner gear, a gear shaft sleeve and a left gear base are fixedly arranged on the cycloidal pin wheel speed reducer and an output shaft of the driving motor; the left gear base is connected with one end of a regulating lead screw; the other end of the regulating lead screw is connected with a right bearing base; a shaking amplitude adjustment device is connected with the bearing base and one end of a shaking oscillating bar; the other end of the shaking oscillating bar is connected with one end of a rotating shaft of the shaking oscillating bar; and the other end of the rotating shaft of the shaking oscillating bar is connected with the shaking table by a transmission device in a shaking table cylinder body. The special horizontal type shaking table has a reasonable and compact structure, is reliable in strength, rigidity and toughness of key positions, small in assembly stress of parts and high process performance, process parameters are easy to control, and the optimal bacteriostatic effect can be achieved.

Owner:华原谷道生物科技西安有限公司

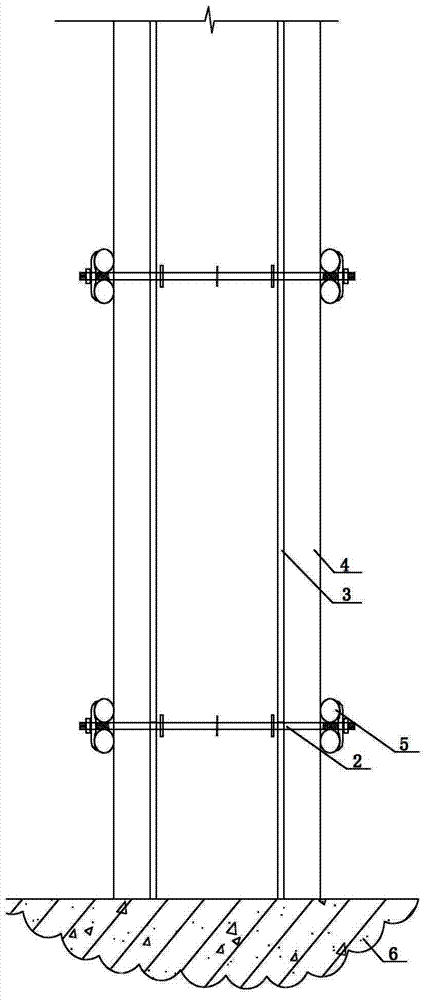

Construction method of template with no split bolt hole

InactiveCN102777031AEasy to installFixing method is simpleBuilding material handlingStructural engineeringUltimate tensile strength

The invention discloses a construction method of a template with no split bolt hole. The construction method includes the following steps: (1) sequentially placing a plurality of external wall templates along the longitudinal direction to form a lower-layer external wall template; (2) placing small template strips and split bolts at the top of the lower-layer external wall template at intervals; (3) repeating the step (1) and the step (2) to construct upper-layer external wall templates layer by layer until the upper-layer external wall templates are as high as the installation of the external wall templates; (4) installing a vertical wood square on the outer sides of the external wall templates; (5) installing horizontal double steel pipes arranged along the horizontal direction on the outer side of the vertical wood square; (6) adjusting the evenness and verticality of the external wall templates; (7) pouring wall concrete; (8) loosening the split bolts when the wall concrete achieves the template removing strength, taking down the double steel pipes, dismantling the external wall templates and removing the small template strips; (9) cutting off the exposed portion of the split bolts at the bottom of a groove formed at the position where the small template strips are removed; and (10) trowelling the groove through waterproof mortar. By means of the construction method, rigidity of the template is reliable.

Owner:CHINA CONSTR SIXTH ENG DIV CORP

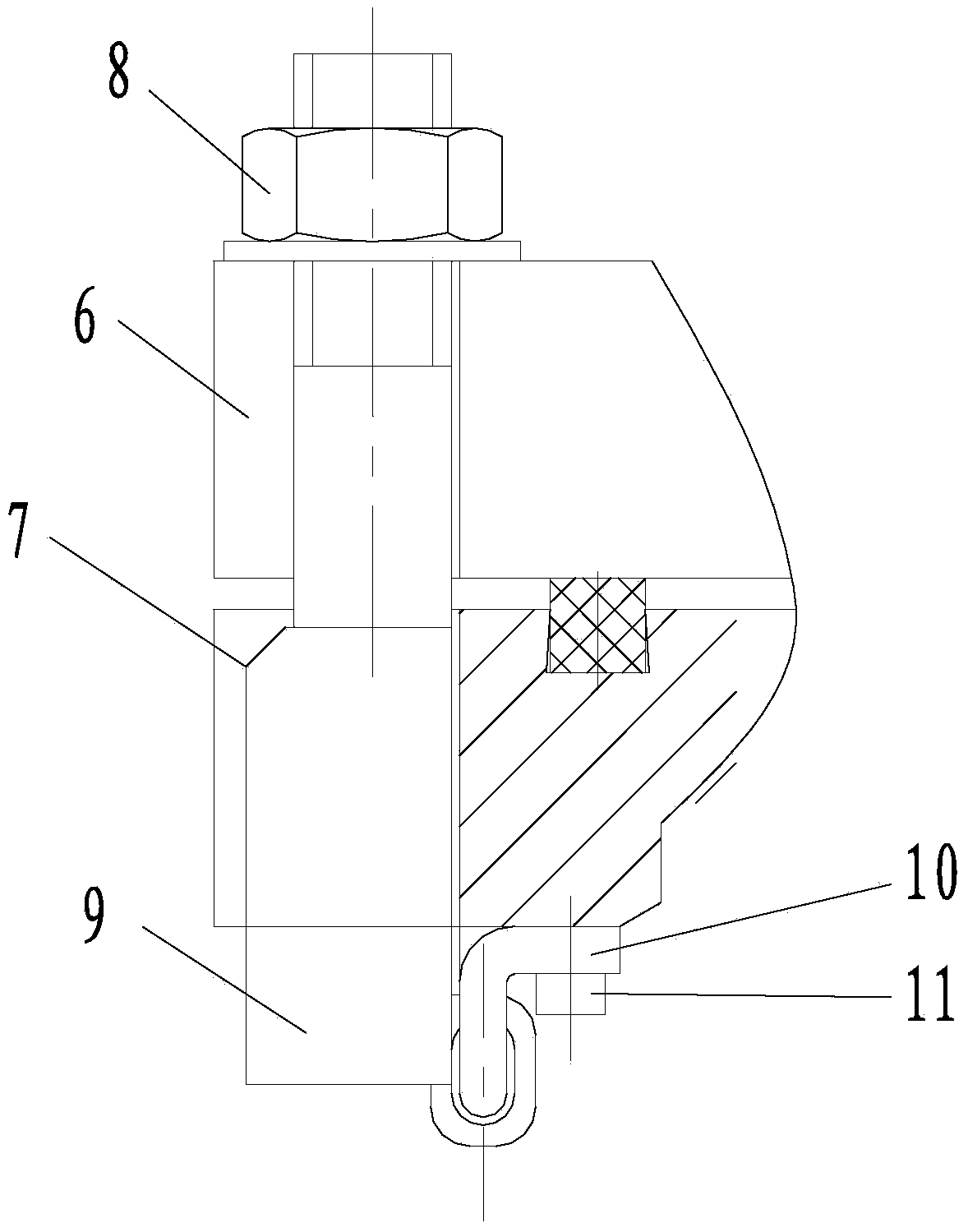

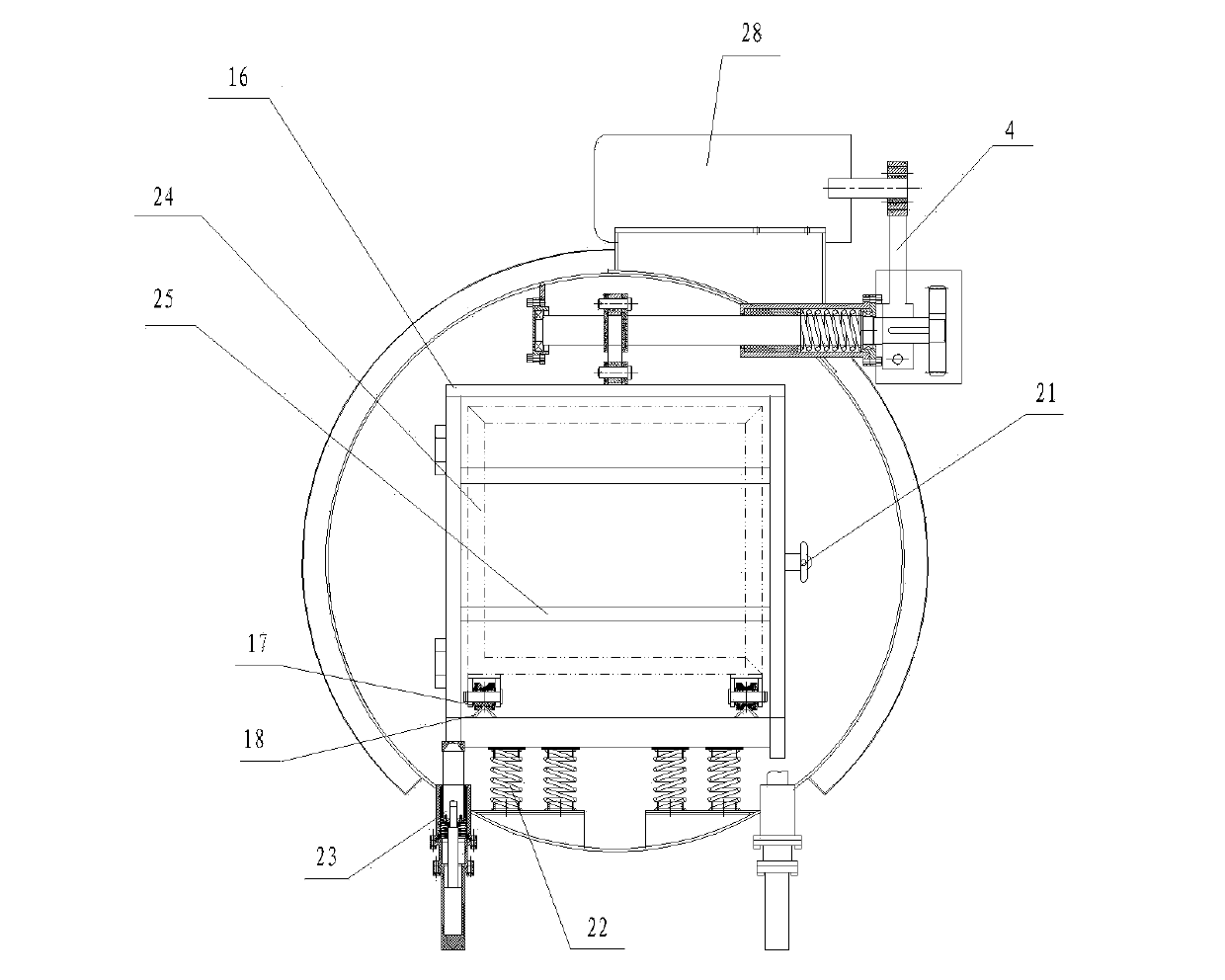

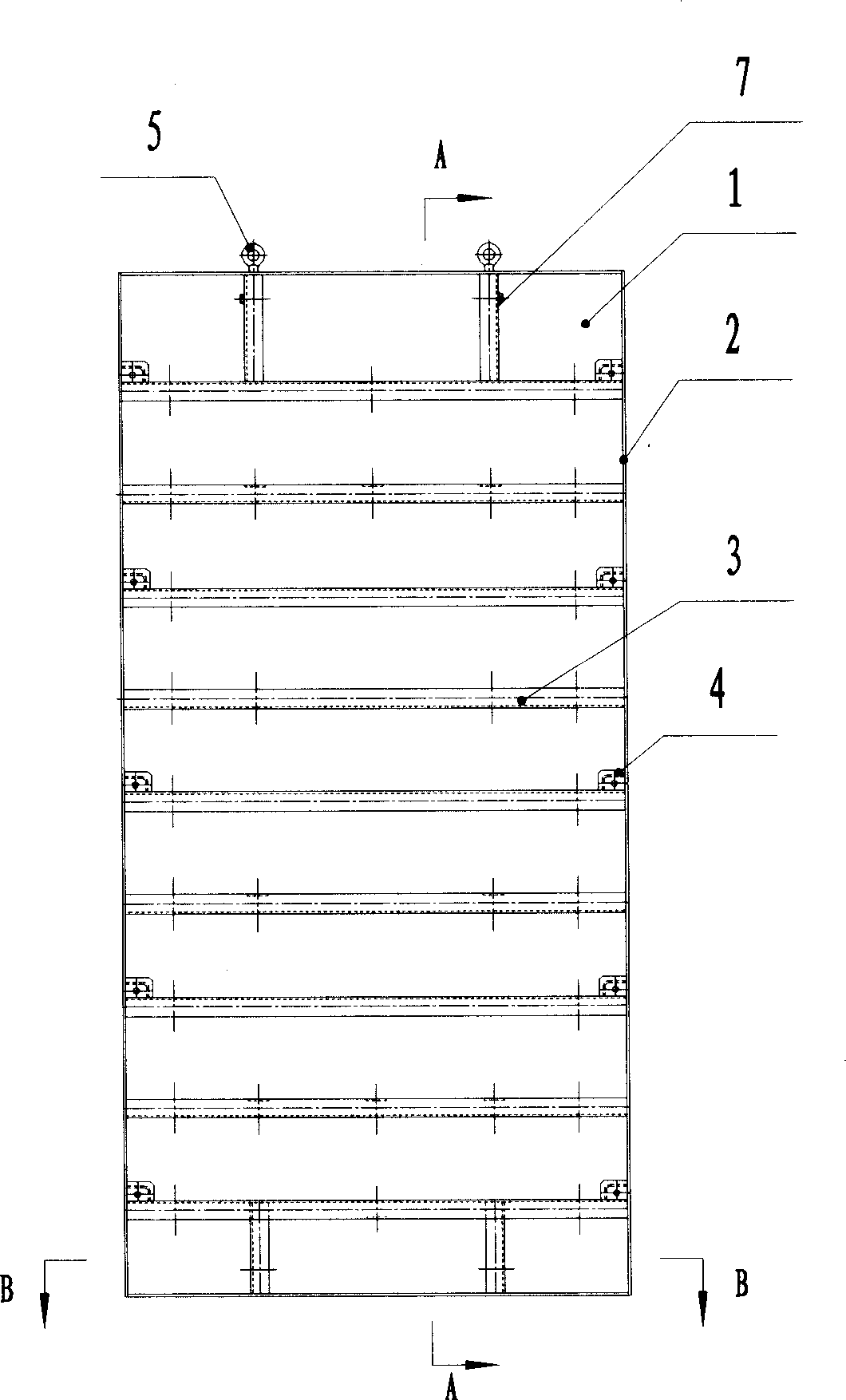

Quick-opening manhole

ActiveCN103436432AReliable strengthReliable stiffnessBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringFlange

The invention provides a quick-opening manhole, wherein a turning-locking bolt is annularly arranged between a manhole and a manhole cover; the turning-locking bolt comprises a bolt part, a boss part and a hanger; the boss part is arranged under the bolt part; the boss part is wider than the bolt part; the hanger is arranged at the lower end of the boss part; a connection part is arranged between the hanger and the manhole flange; a manhole cover lifting device comprises an upper lifting rod, a rotary assembly and a lower lifting rod; the rotary assembly comprises a rotary disk, an oval disk, a rotary shaft and a handle; the rotary shaft is arranged between the oval disk and the rotary disk; the handle is connected with the rotary disk; hollow oval disk is respectively connected with the upper lifting rod and the lower lifting rod in a sliding mode; the upper lifting rod is connected with a rotary suspension arm; and the lower lifting rod is connected with the manhole cover. Through the quick-opening manhole, the strength and rigidity for locking the manhole cover are very reliable; and the quick-opening manhole is simple to operate with safety, convenience and reliability.

Owner:江阴德尔热能机械有限公司

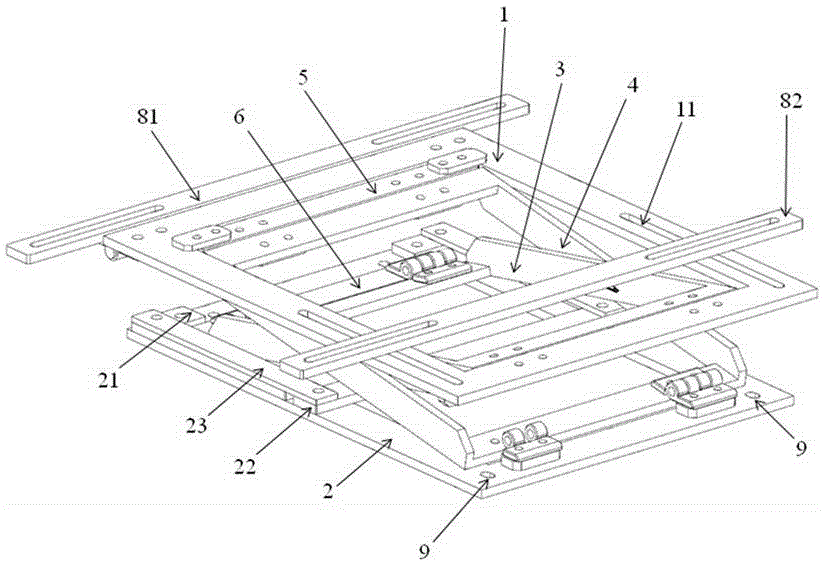

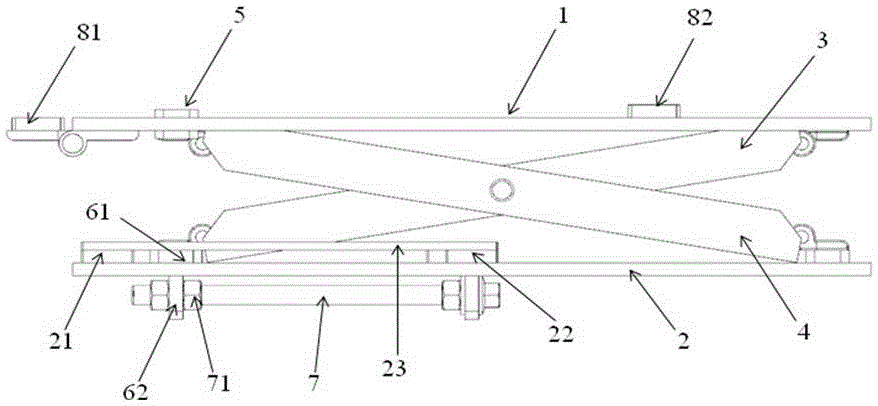

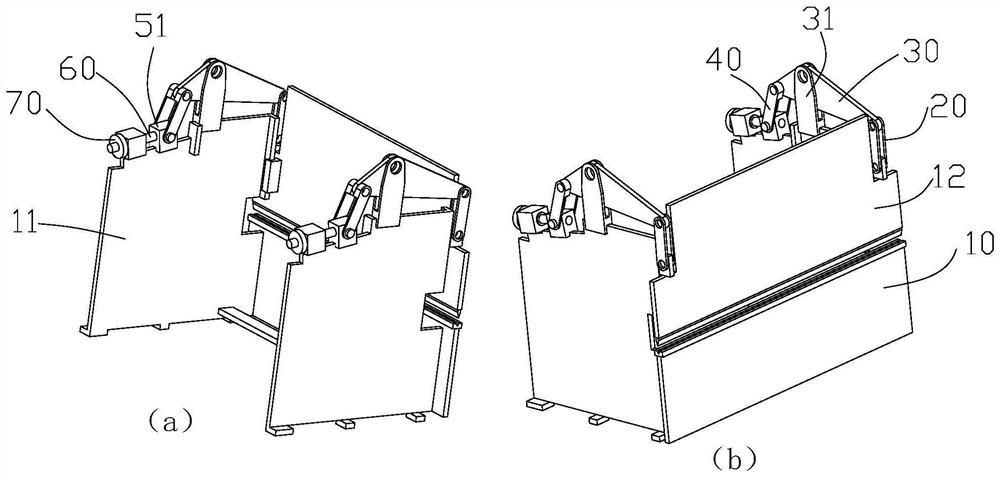

Seat lifting mechanism

ActiveCN106427701APrecise Vertical AdjustmentLarge lifting height rangeSeat suspension devicesEngineeringSeat lift mechanism

The invention relates to scissors lifting gears, and especially relates to a seat lifting mechanism. The seat lifting mechanism comprises an upper bracket, a lower bracket, a first support bar, a second support bar, an upper sliding block, a lower sliding block and a transmission rod. The transmission rod is fixedly connected to the bottom of the lower bracket, the first support bar and the second support bar are hinged in a center crossing way, the upper end of the first support bar is hinged to the upper bracket, the lower end of the first support bar is hinged to the lower sliding block, the lower sliding block is connected to the lower bracket in a sliding way, the upper end of the second support bar is hinged to the upper sliding block, the lower end of the second support bar is hinged to the lower bracket, the upper sliding block is connected to the upper bracket in a sliding way, the lower sliding block comprises a lower bracket connection portion and a transmission rod connection portion, the lower bracket connection portion is connected to the lower bracket in a sliding way, the transmission rod is provided with a transmission part, and the transmission part is used for connecting the transmission rod connection portion to the transmission rod in a sliding way. The accurate vertical adjustment can be guaranteed, the lifting height range is great, and the reliable stiffness and bearing capacity are guaranteed.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

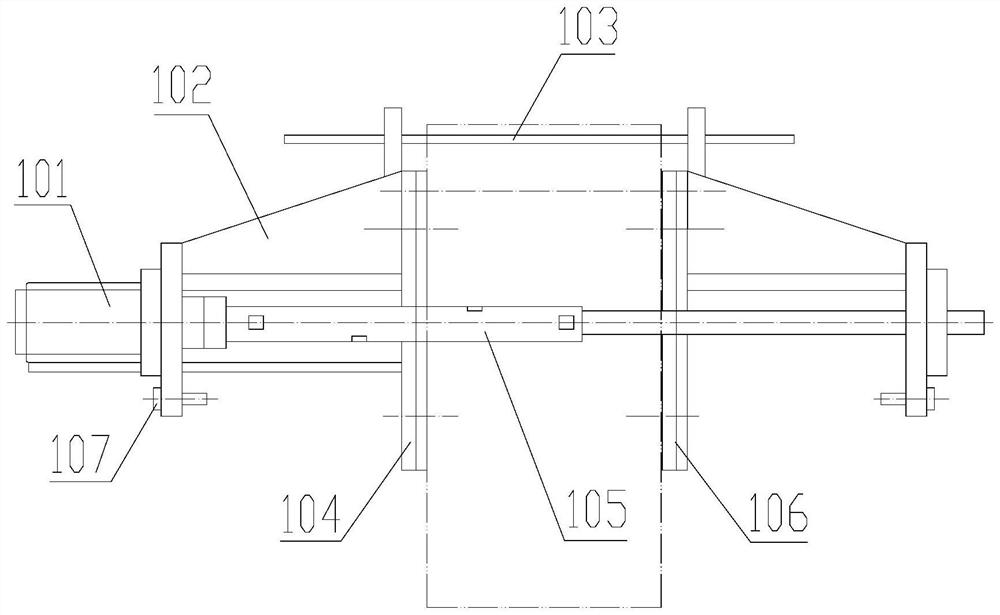

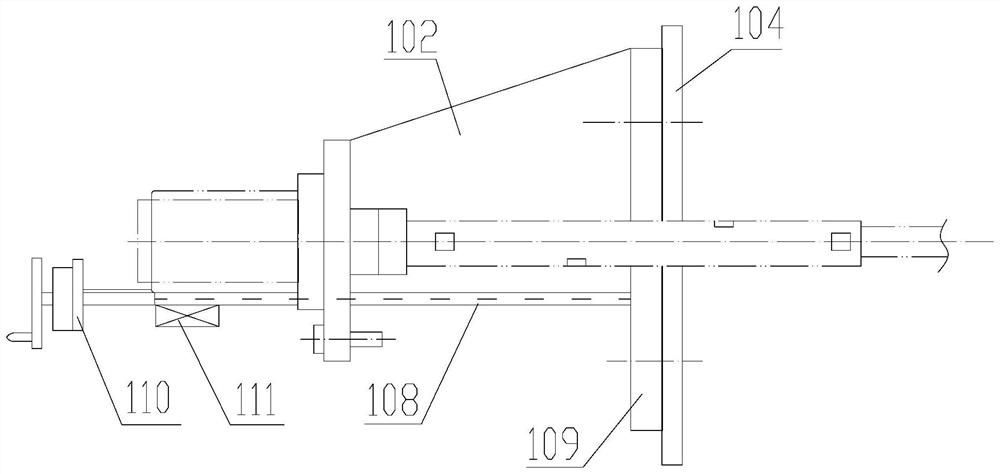

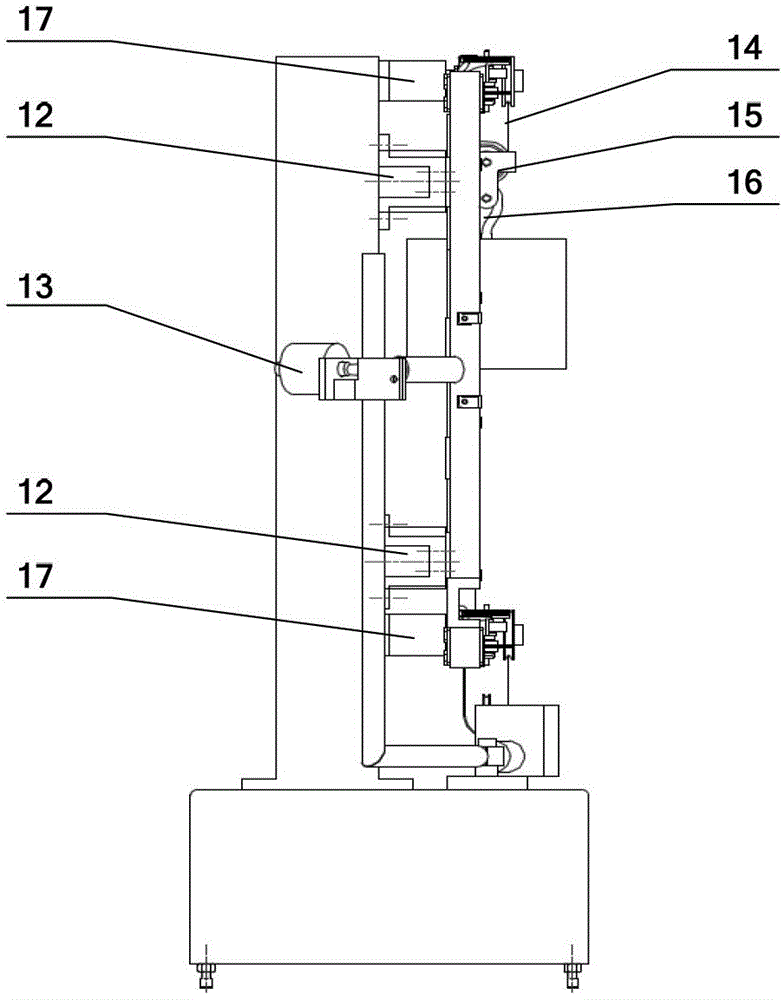

Precise and rapid repairing device for main shaft hole of steel tube rolling mill

PendingCN114160833AStability Oriented ServicesReliable stiffnessAutomatic control devicesBoring barsReamerIndustrial engineering

The precise and rapid repairing device is characterized in that the bottom face of a base where a steel tube rolling mill spindle is located serves as the horizontal reference, and the two end faces of the spindle hole serve as the installation reference and the fixing position of the repairing device; comprising a first support and a second support, the first support is provided with a datum plate matched with the two end faces of a spindle hole, a base plate tightly attached to the datum plate and connected with the datum plate through bolts, a supporting bottom plate is arranged perpendicular to the base plate, a feeding mechanism is arranged on the supporting bottom plate, and the feeding mechanism controls the horizontal moving direction of a reamer power mechanism; and the reamer power mechanism drives the hinge rod. The original datum point, the original line and the original plane of the restoration serve as the installation datum of boring equipment, multiple three-dimensional positioning is achieved, portability and flexibility are achieved, shaft hole repairing can be carried out even without disassembling the whole base, damage to the restoration is avoided, stability and reliability are achieved, disassembling, assembling and moving are convenient, the application range is wide, one-time alignment is achieved, the machining precision is high, and the comprehensive cost is low.

Owner:江阴市南方不锈钢管有限公司

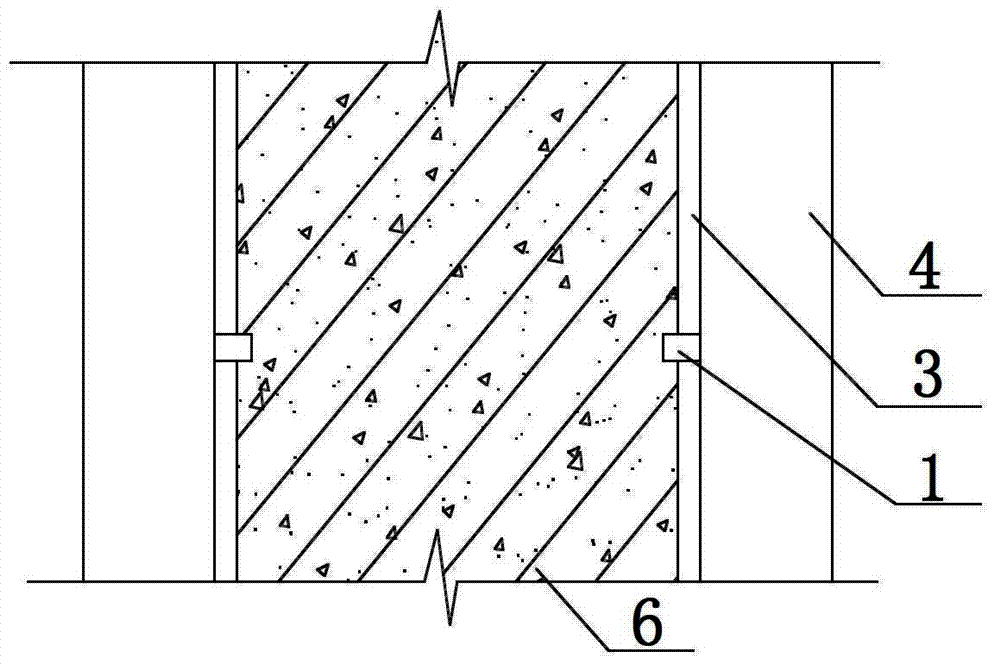

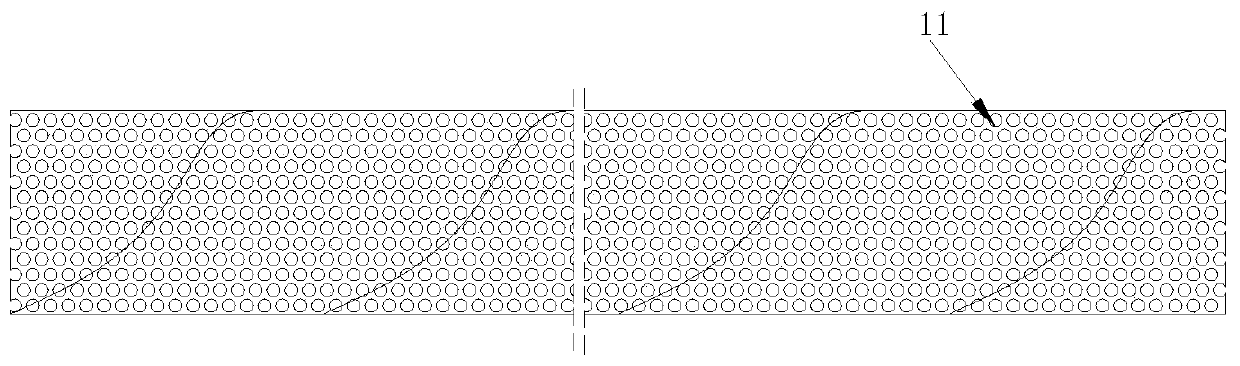

Construction method of foundation pit supporting water-stop continuous wall

The invention provides a construction method of a foundation pit supporting water-stop continuous wall. Over-lapped triaxial stirring piles and support piles arranged in a coaxial line according to fixed spaces, and reinforcing steel bar structures are arranged in a foundation pit so as to form a continuous wall body. The triaxial stirring piles are overlapped to form a triaxial stirring wall. Thesupport piles are constructed on a center line after the triaxial stirring wall is constructed; the triaxial stirring piles and the support piles are in the coaxial line; the pile diameter of each support pile is larger than the pile diameter of each stirring pile; and reinforcing steel bar structures are arranged in a matching way. The support piles are constructed by adopting a high-power longspiral drilling machine and a rotary drilling rig. Foundation pit supporting and water stopping are combined so as to form the continuous complete seamless water-retaining seepage-proofing undergroundcontinuous wall body with a certain strength and rigidity; the foundation pit supporting water-stop continuous wall is simple in structure, reliable in strength, high in water-retaining and seepage-proofing performances, simple in construction, low in cost, low in environment pollution, and particularly suitable for deep foundation pit engineering in the city. The invention is suitable to be applied as the construction method of the foundation pit supporting water-stop continuous wall.

Owner:辽宁省有色地质一〇五队有限责任公司

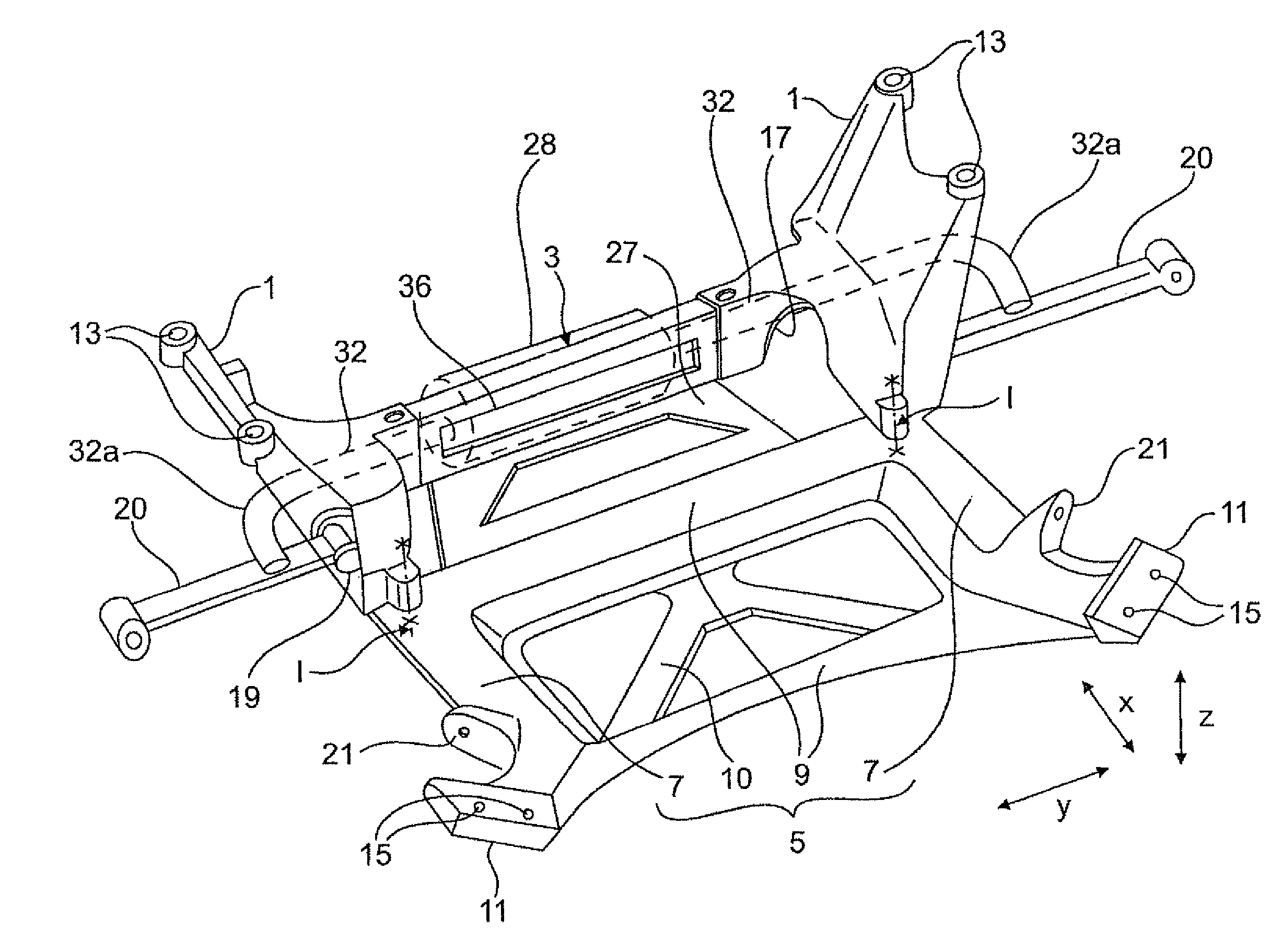

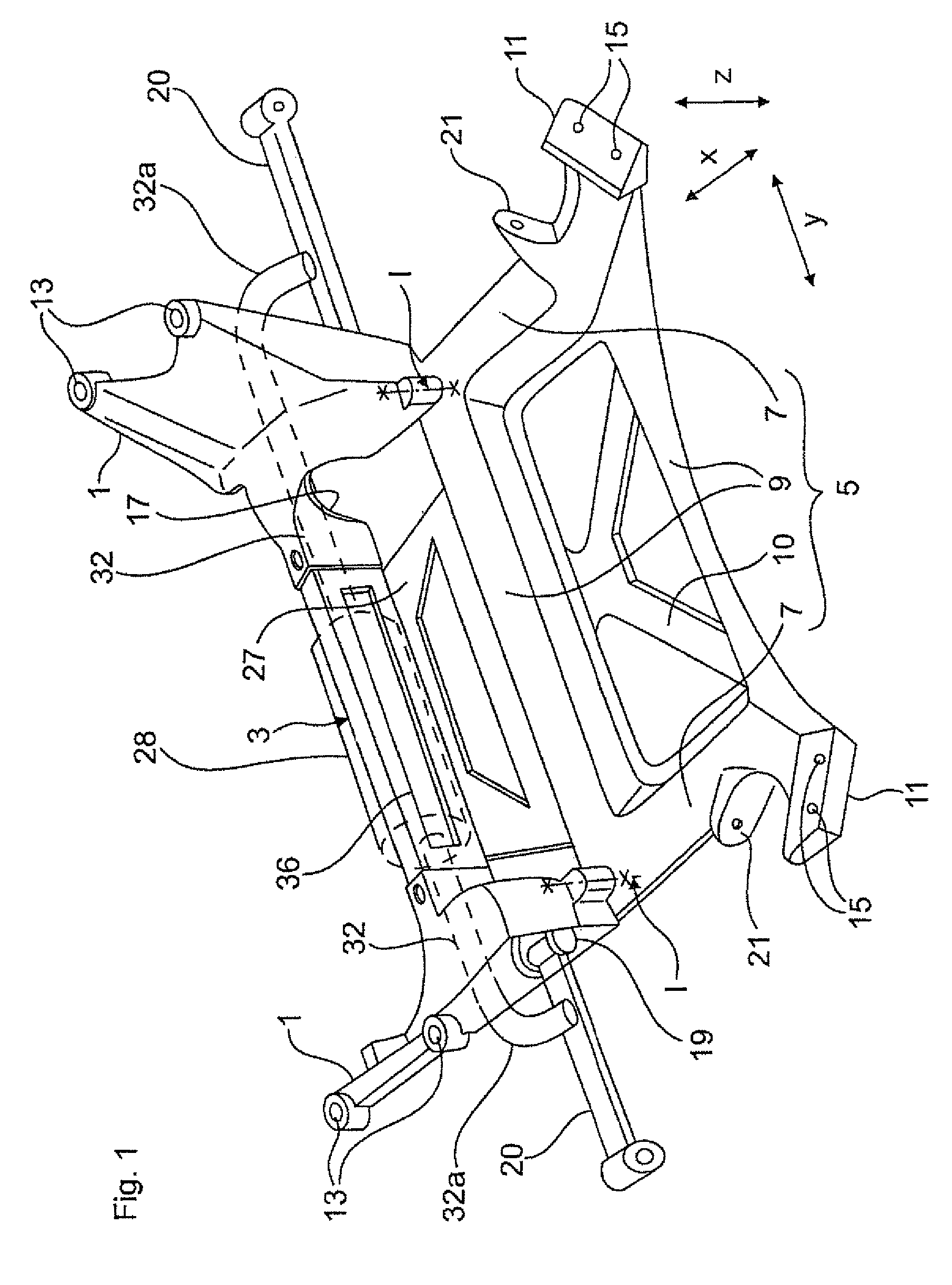

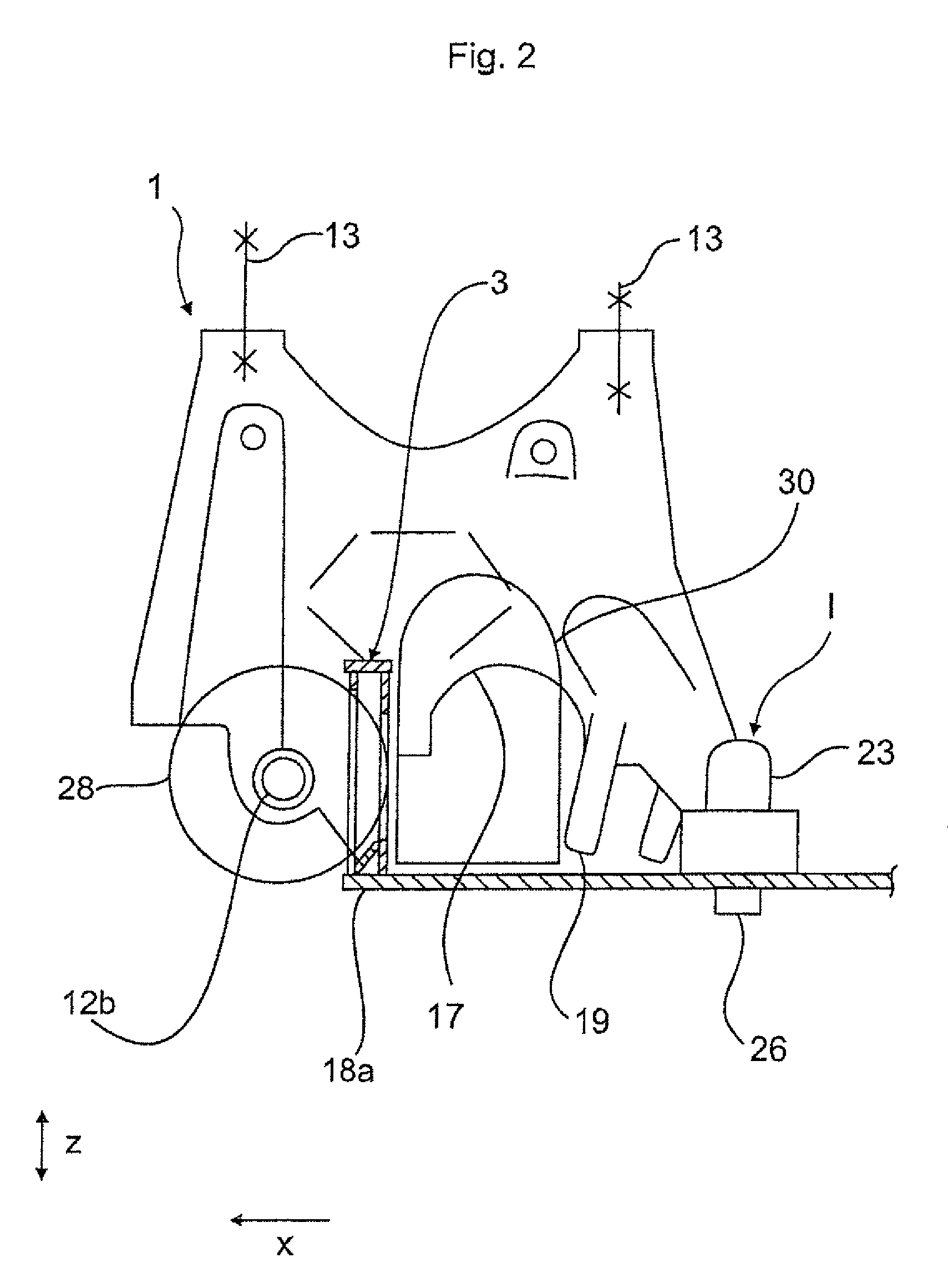

Subframe for a motor vehicle

ActiveUS9540046B2Increased bending stiffnessSimple and light structureUnderstructuresInterconnection systemsMobile vehicleVehicle frame

The invention relates to a subframe for a motor vehicle, comprising two front node elements (1) for connecting to a vehicle body, which node elements are spaced from each other in a vehicle transverse direction (y) and are connected to each other by means of a front subframe cross member (3), and comprising at least one functional part (28), in particular a rotary actuator, which extends adjacently to the subframe cross member (3) in a vehicle transverse direction (y), by means of which functional part a torsion can be applied to torsion springs that act on the vehicle wheel suspension. According to the invention, the subframe cross member (3) has an opening, which provides an additional installation space, in which the functional part (28) at least partially protrudes.

Owner:AUDI AG

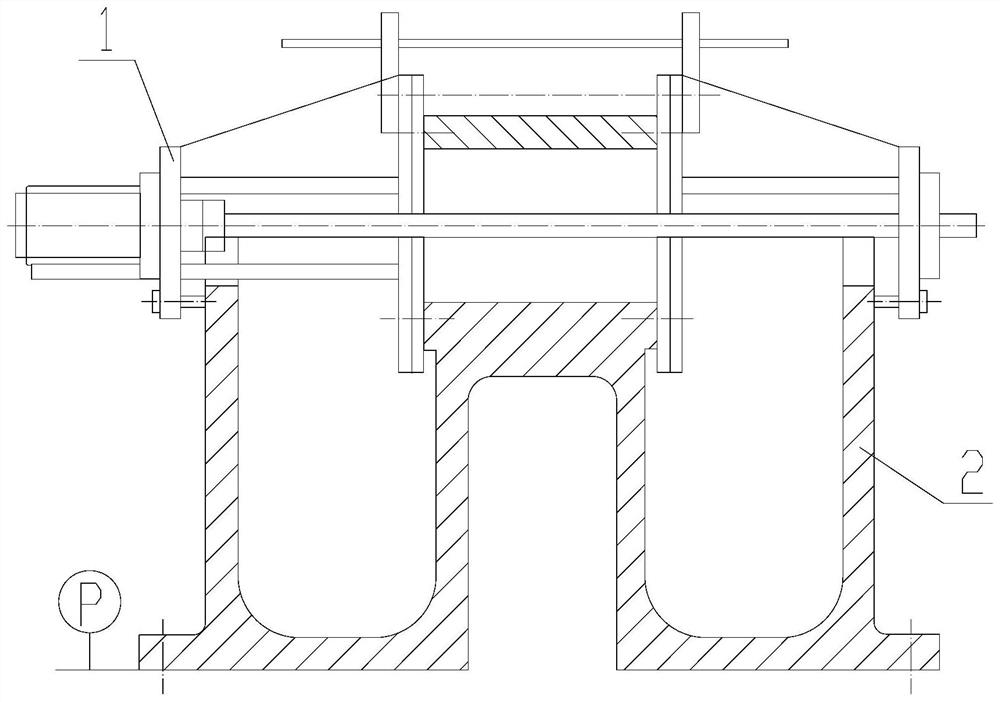

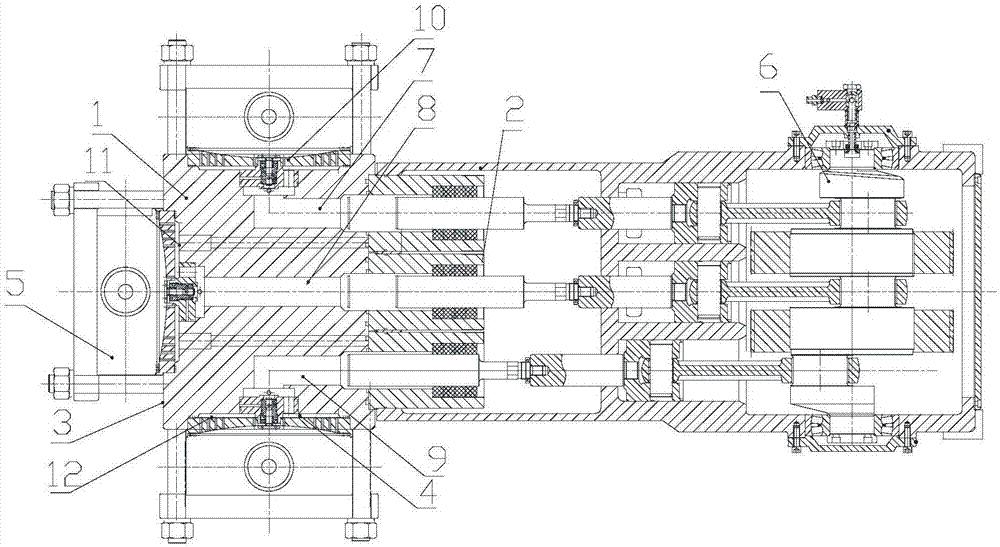

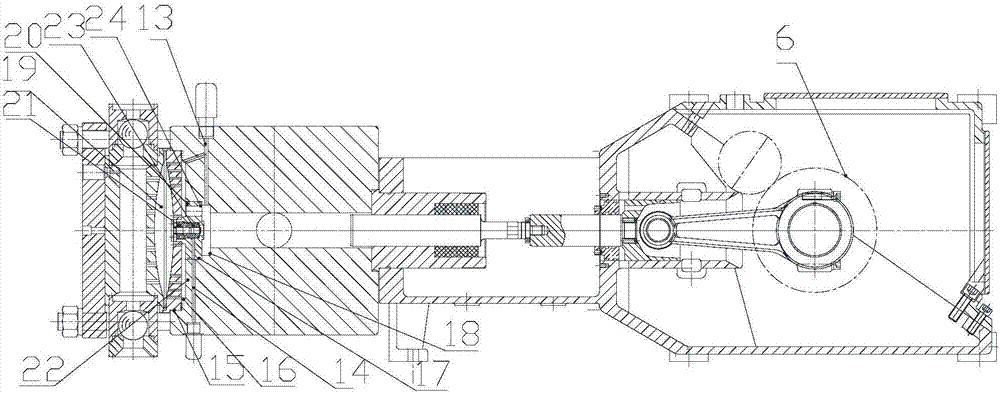

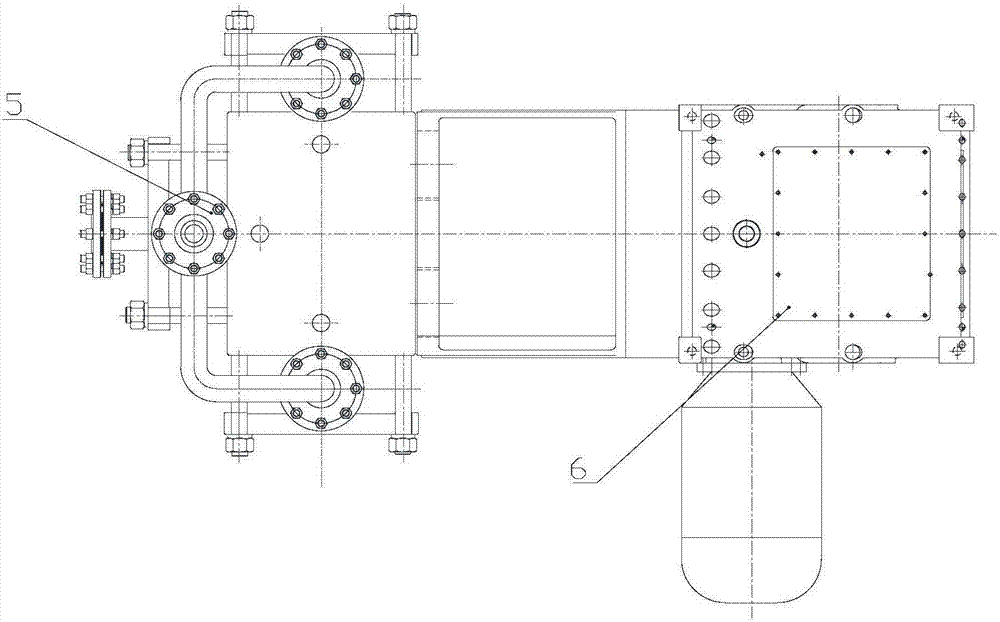

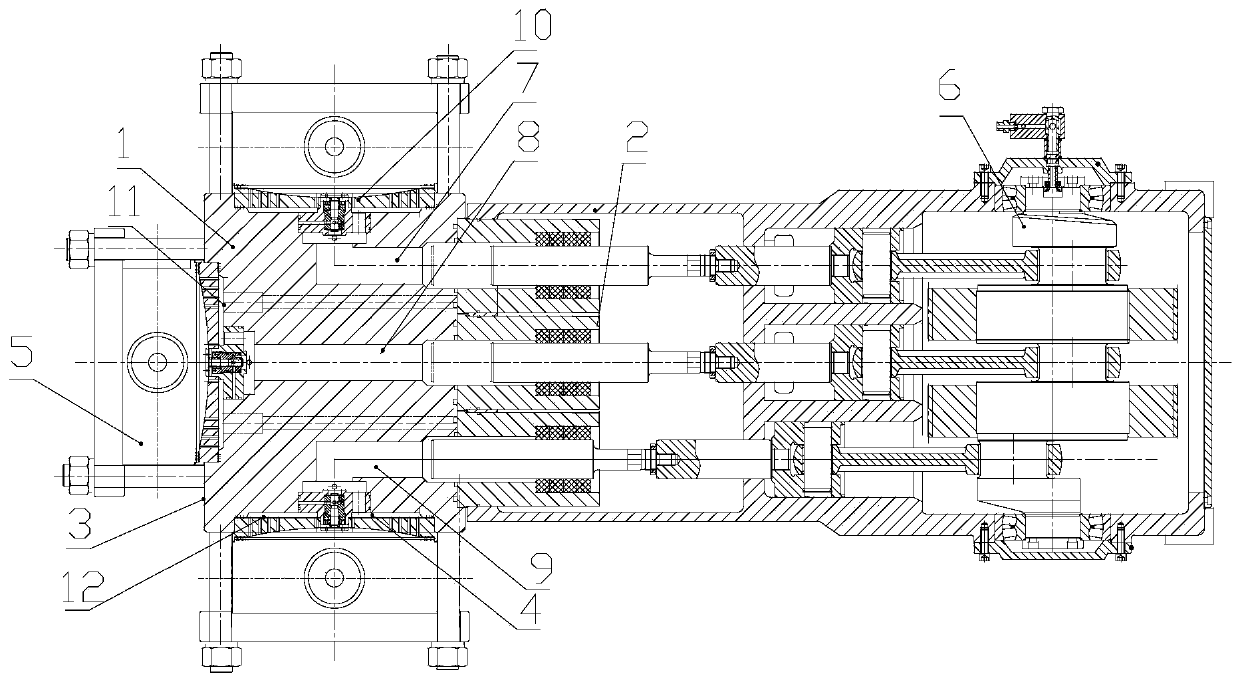

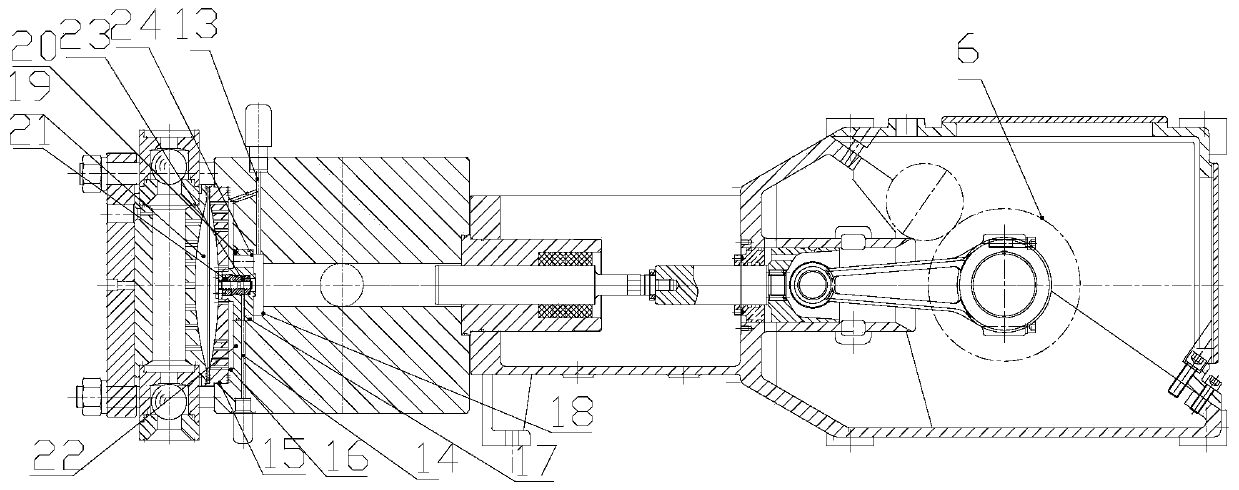

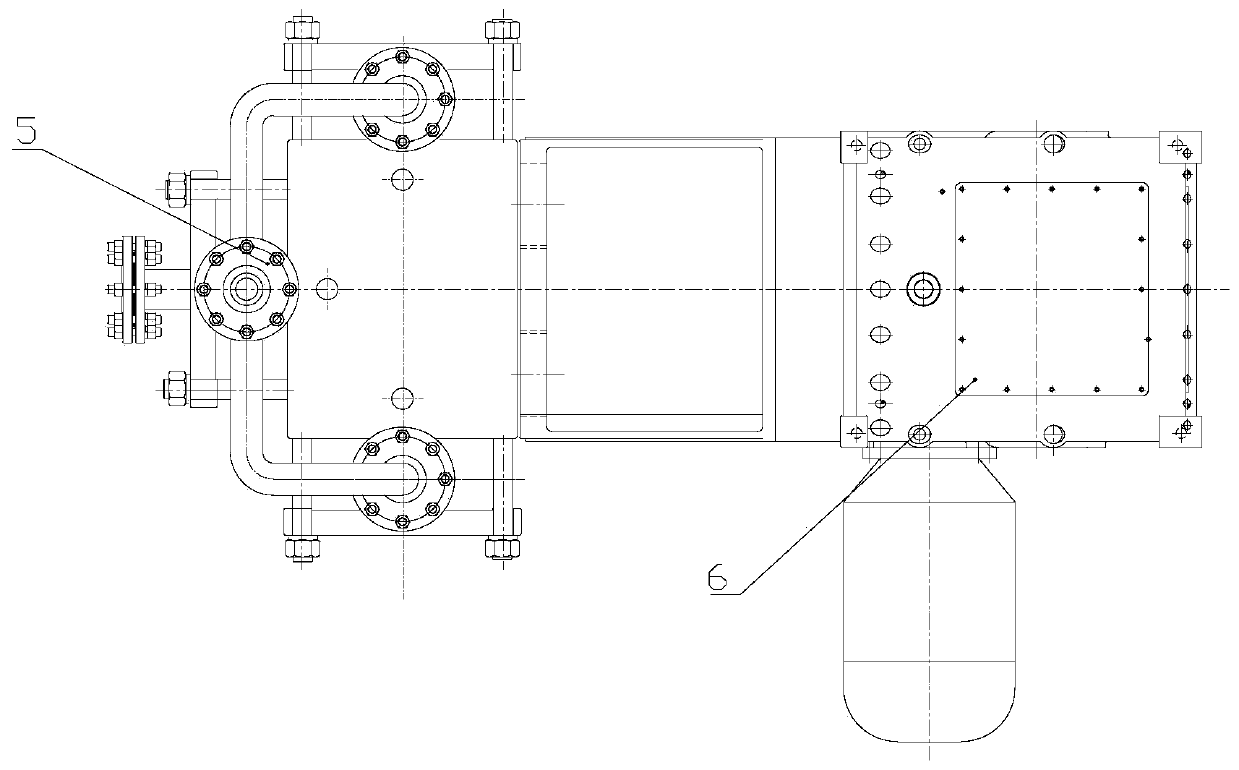

Three-plunger hydraulic diaphragm reciprocating pump

ActiveCN106996366ASmall sizeReasonable dimensionsFlexible member pumpsPositive-displacement liquid enginesDiaphragm pumpEngineering

The invention discloses a three-plunger hydraulic diaphragm reciprocating pump. The pump comprises a transition plate having a front end surface, a back end surface and multiple side surfaces, three pump heads and a power end; a first hydraulic passage, a second hydraulic passage and a third hydraulic passage which are arranged in parallel are arranged at the front end of the transition plate and communicate with the power end through cylinder sleeves; a first pump head connection port, a second pump head connection port and a third pump head connection port which are connected with the three pump heads are formed in the back end of the transition plate; the second pump head connection port is located in the back end surface of the transition plate; and the first pump head connection port and the third pump head connection port are located in the opposite side surfaces of the back end of the transition plate. The novel three-plunger hydraulic diaphragm reciprocating pump is designed, the three hydraulic diaphragm pump heads are arranged in the shape of a left-center-right U-shaped surface, the transverse size is substantially reduced, the U-shaped-surface transition connecting plate can be machined by the aid of a lathe, the distance of communicating runners for the pump heads and the cylinder sleeves is shortened, and the machining technology is simplified.

Owner:DEPAMU HANGZHOU PUMP TECH

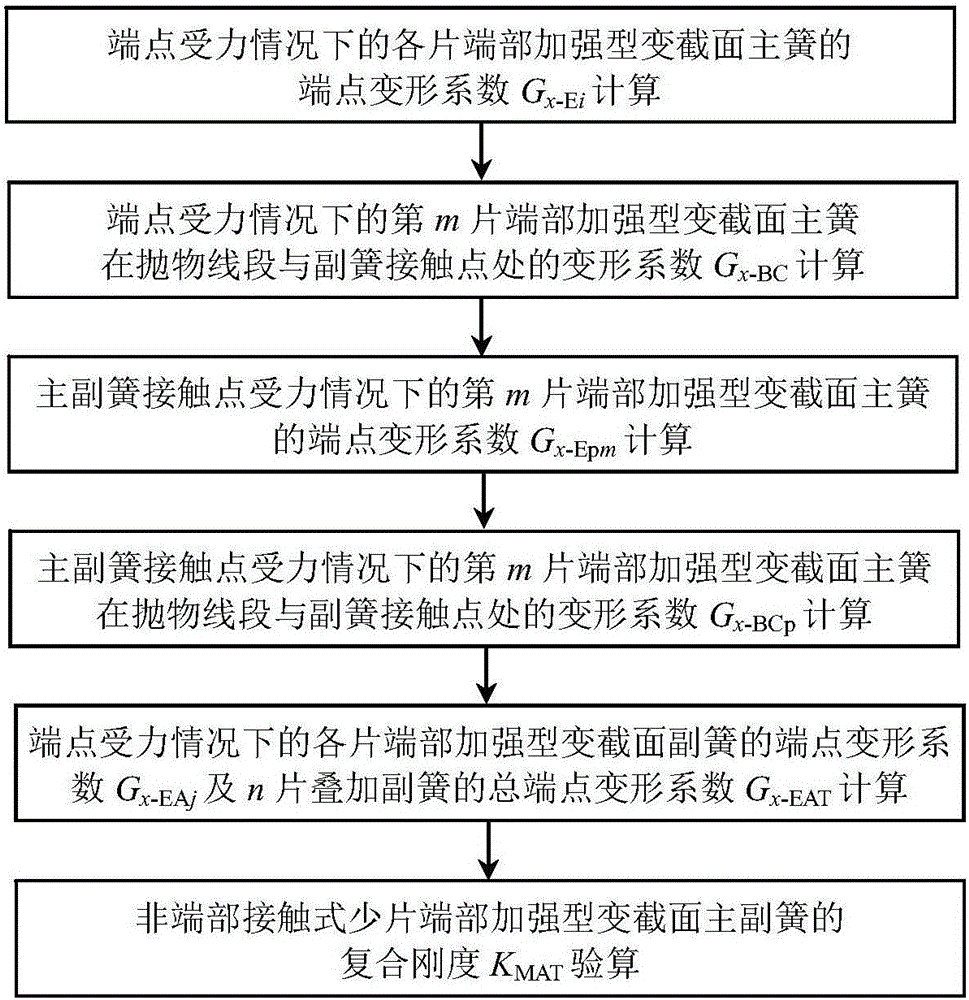

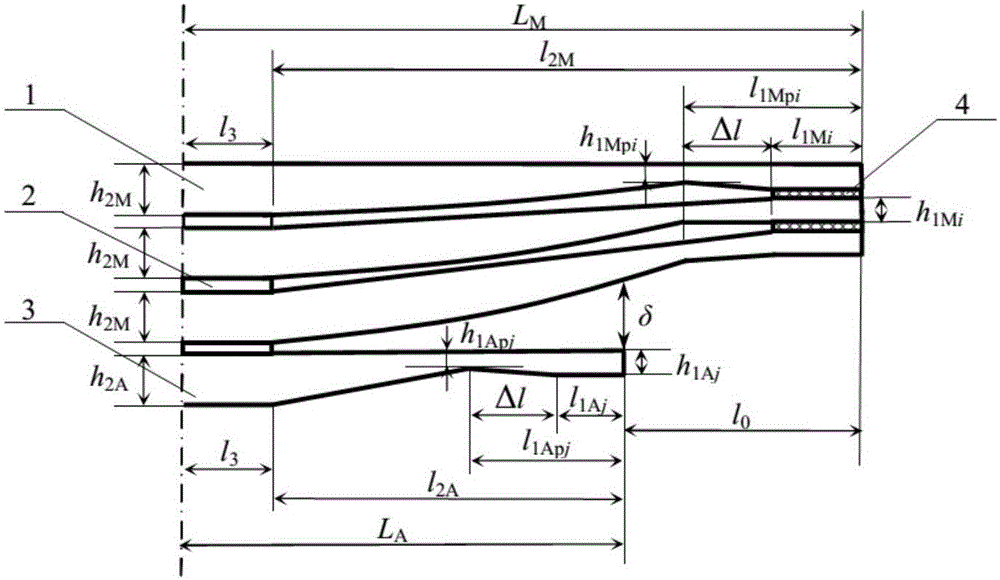

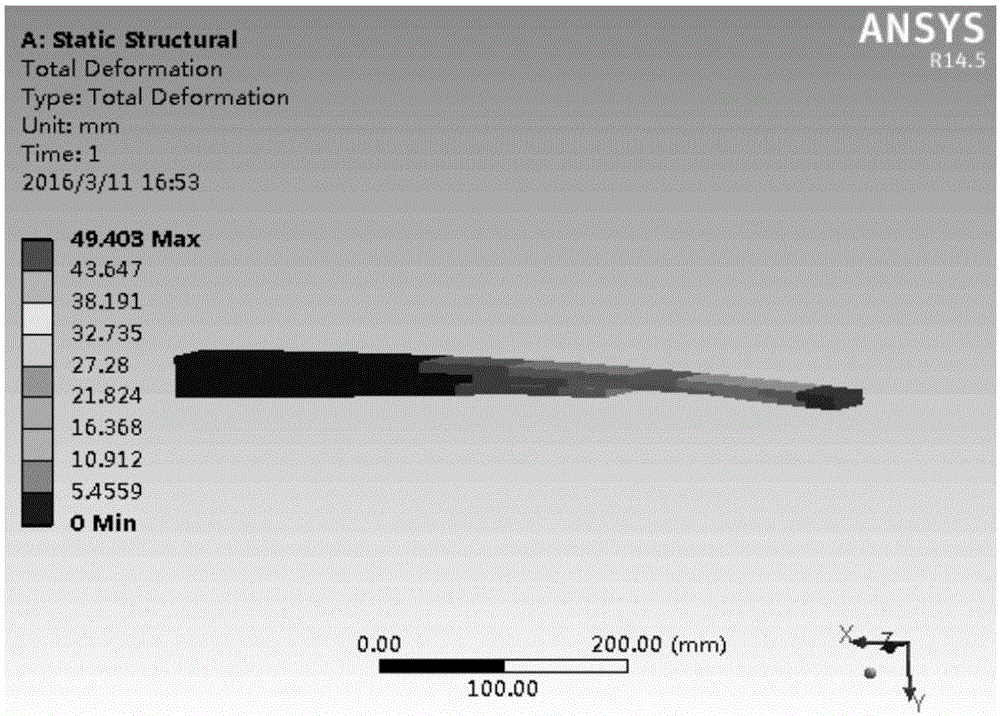

Method for checking composite stiffness of non-end contact type taper leaf root enhanced main and auxiliary leaf springs

InactiveCN105956308AReliable Composite Stiffness Check ValueExact Composite Stiffness Check ValueGeometric CADMachine part testingComputer Aided DesignContact type

The invention provides a method for checking the composite stiffness of non-end contact type taper leaf root enhanced main and auxiliary leaf springs, and belongs to the technical field of suspension leaf springs. The composite stiffness of the main and auxiliary leaf springs can be checked according to the structural parameter and elastic modulus of each main leaf spring and auxiliary leaf spring of the non-end contact type taper leaf root enhanced variable cross-section main and auxiliary leaf springs. An example and ANSYS simulation verification show that, the method can obtain an accurate and reliable composite stiffness checking value of the non-end contact type taper leaf root enhanced main and auxiliary leaf springs, provide a reliable checking method for checking the composite stiffness of the non-end contact type taper leaf root enhanced variable cross-section main and auxiliary leaf springs, and lay a technical foundation for the analytical design and CAD (Computer Aided Design) software development of the main and auxiliary leaf springs of this structure. By using the method for checking the composite stiffness of the non-end contact type taper leaf root enhanced main and auxiliary leaf springs provided by the invention, the design level, the product quality and performance and the vehicle ride comfort of a vehicle suspension variable cross-section main and auxiliary leaf springs can be improved; and meanwhile, the weight and cost of the suspension springs can be reduced, the product design and testing expenses can be reduced, and the product development speed can be accelerated.

Owner:SHANDONG UNIV OF TECH

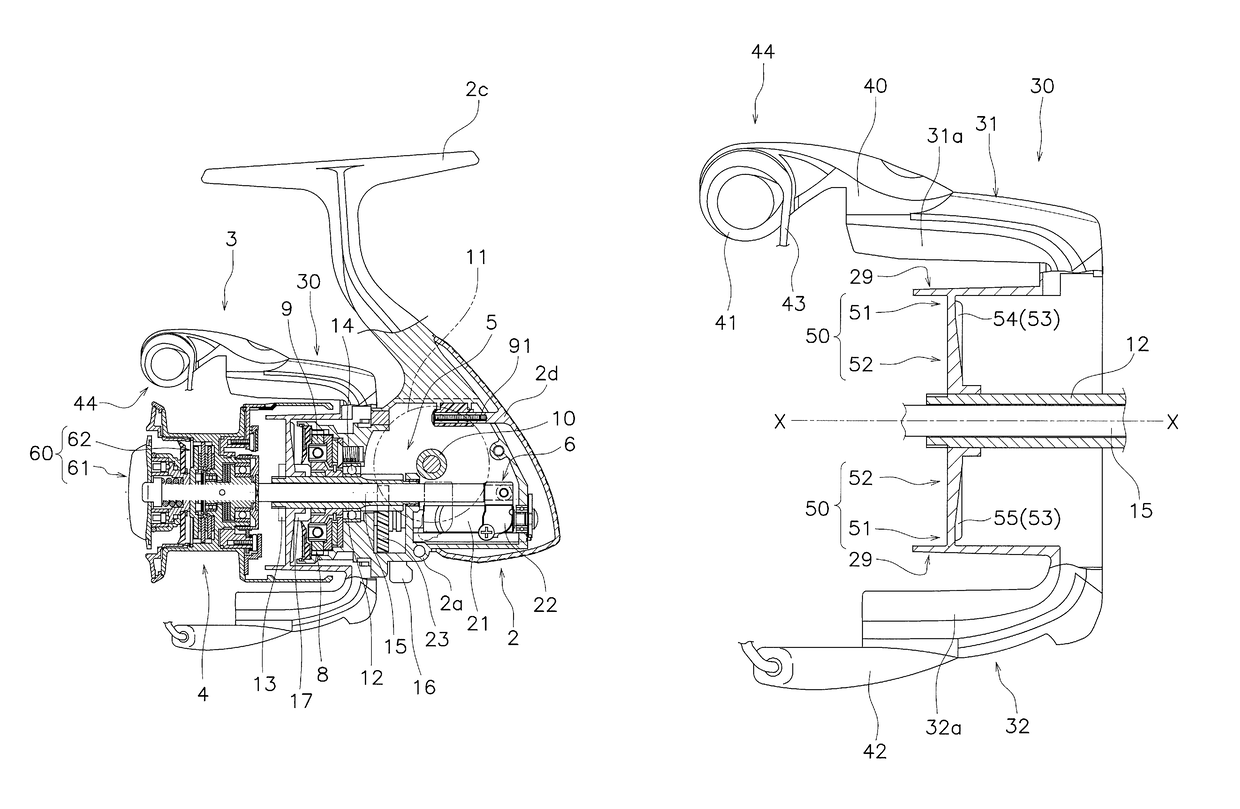

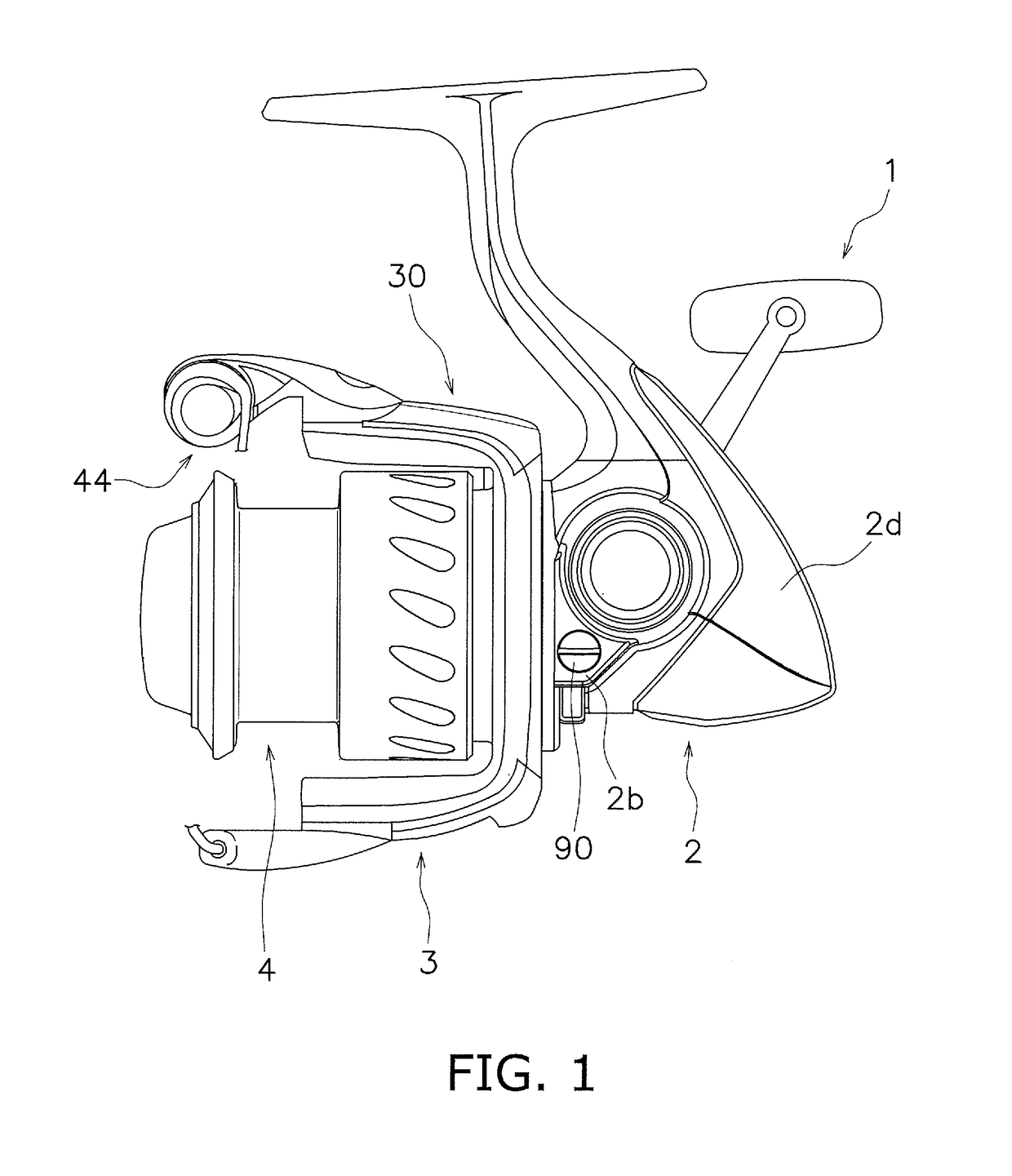

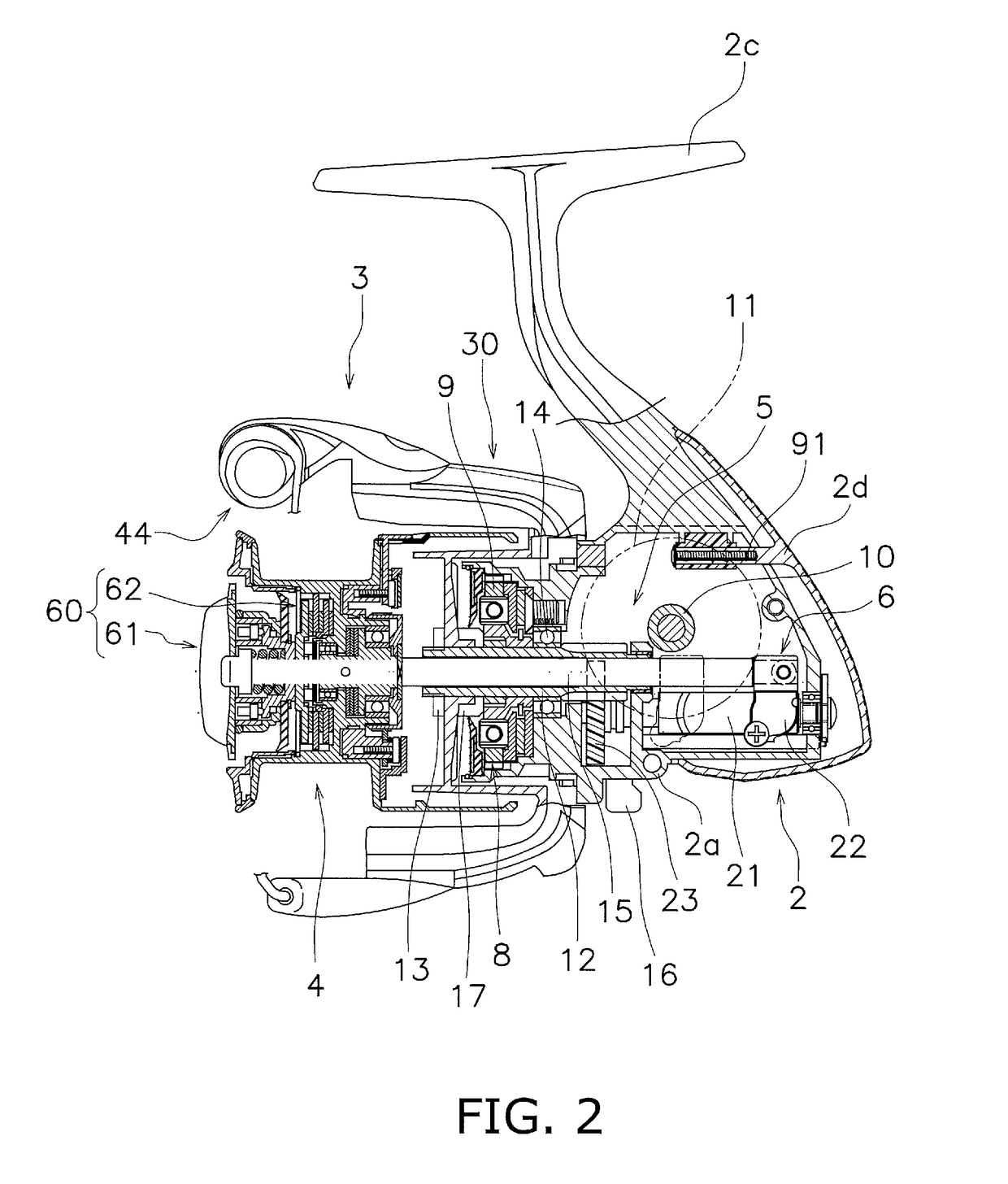

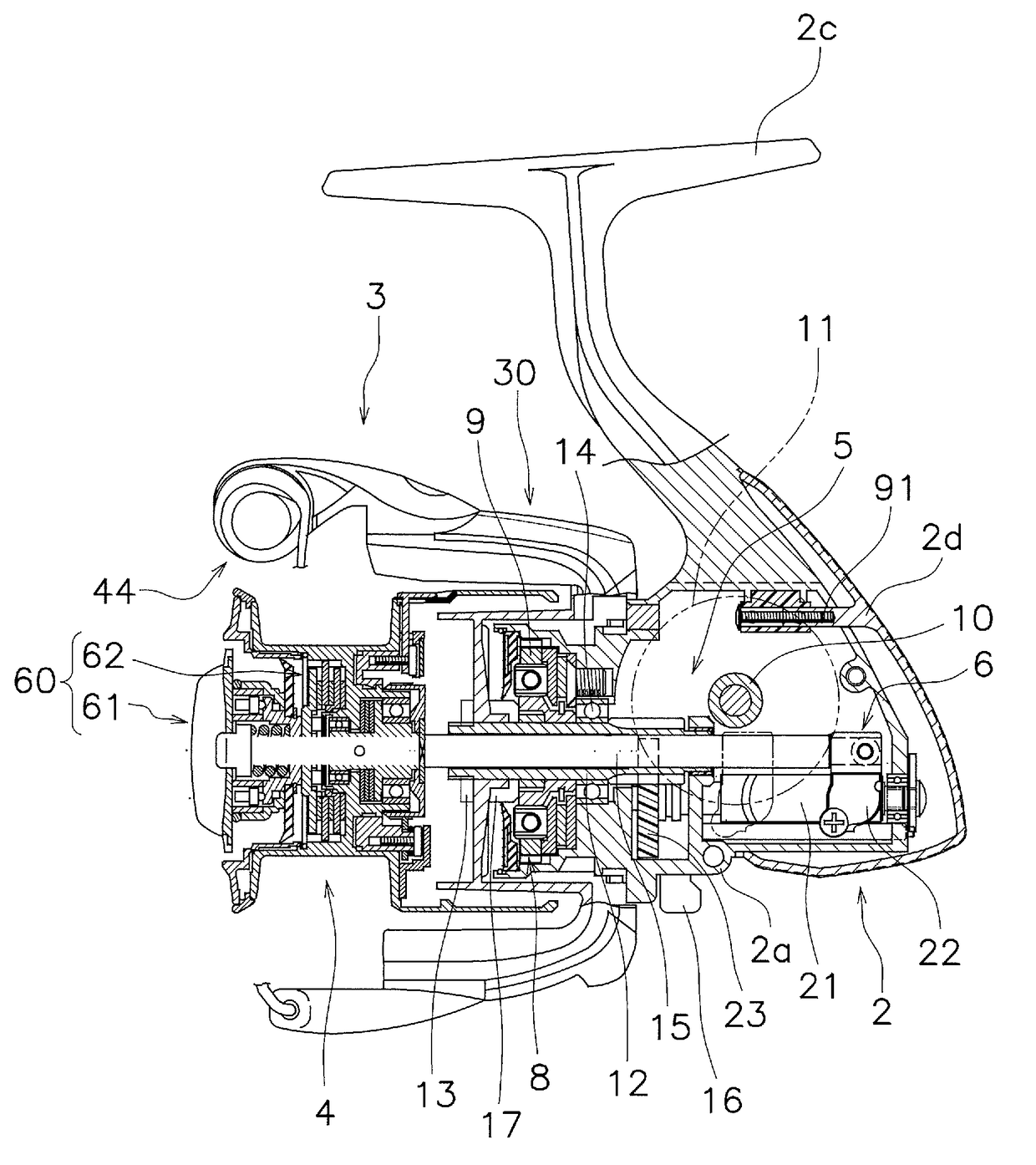

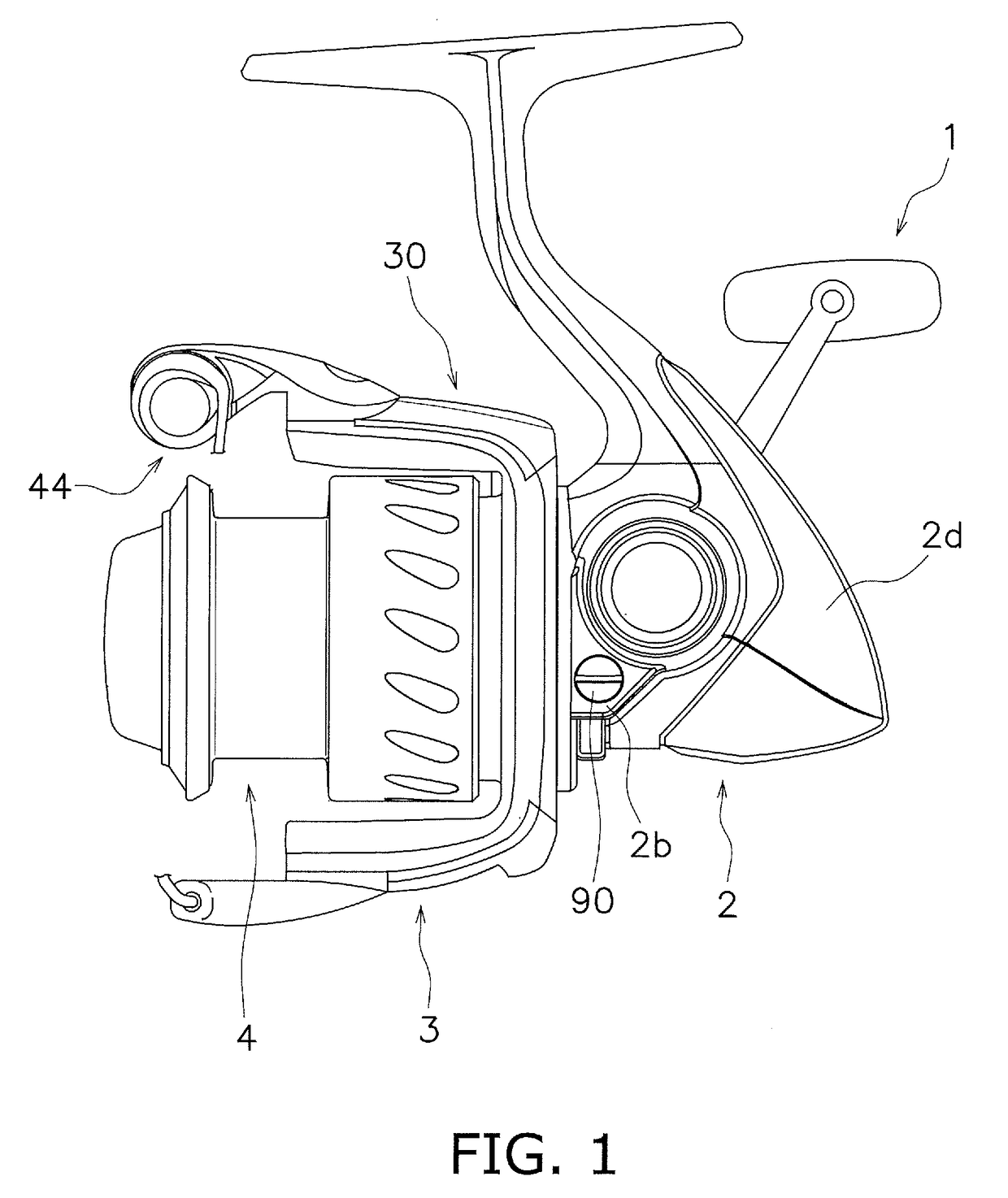

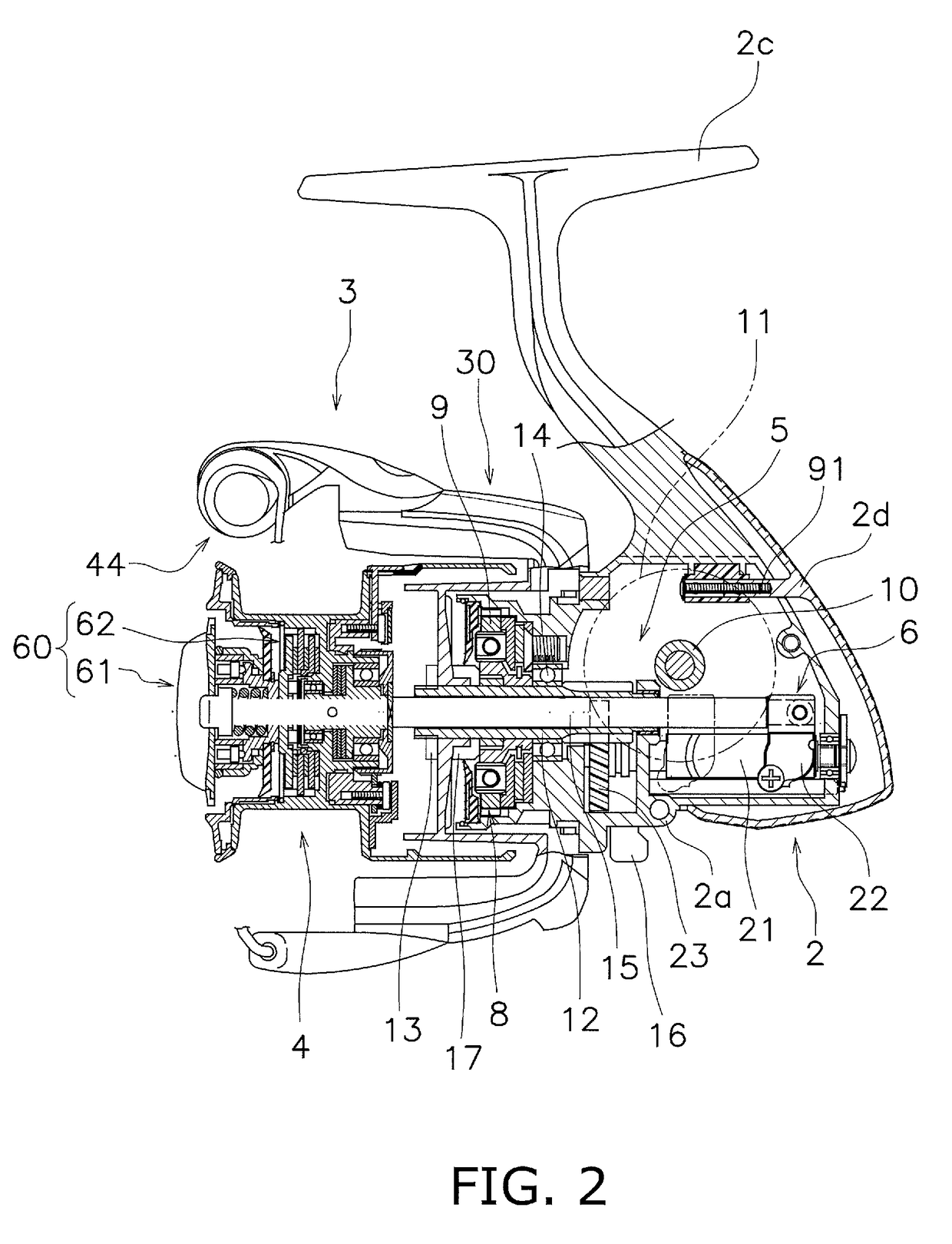

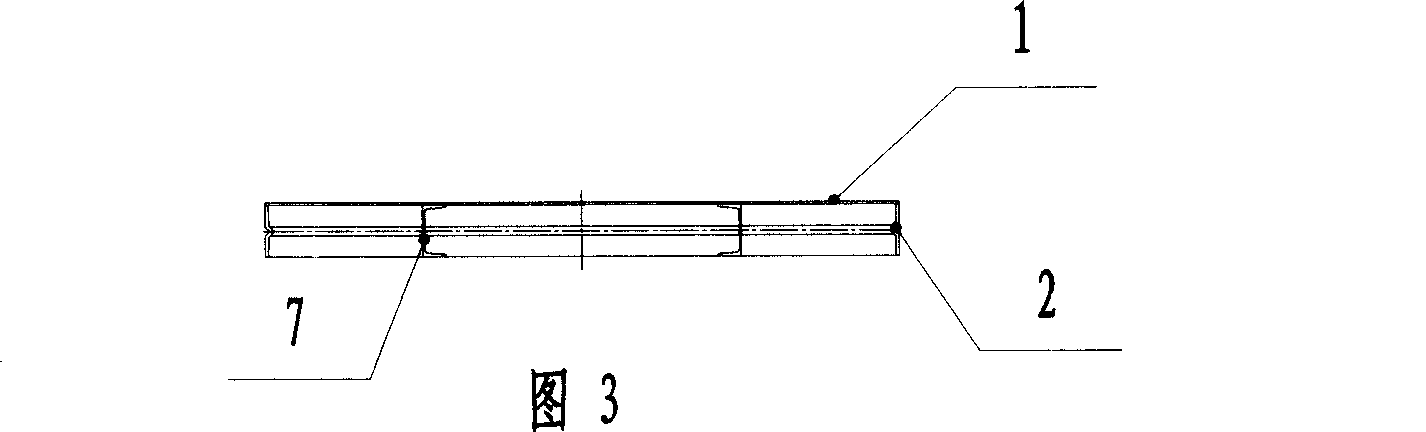

Spinning reel rotor and spinning reel

ActiveUS10028494B2Small thicknessReliable stiffnessReelsOther angling devicesEngineeringMechanical engineering

Owner:SHIMANO INC

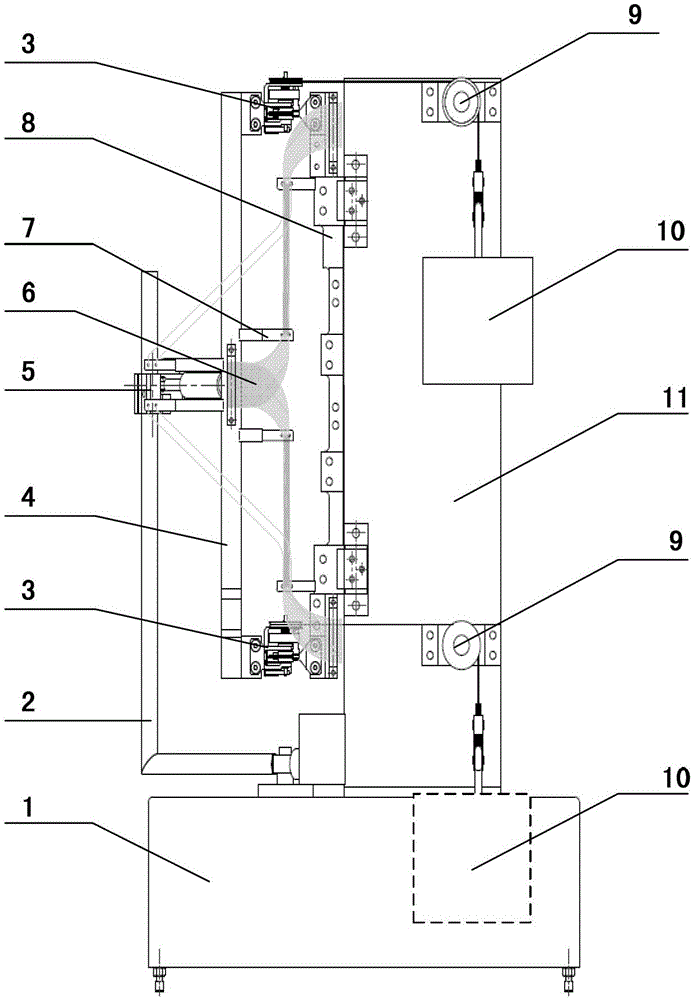

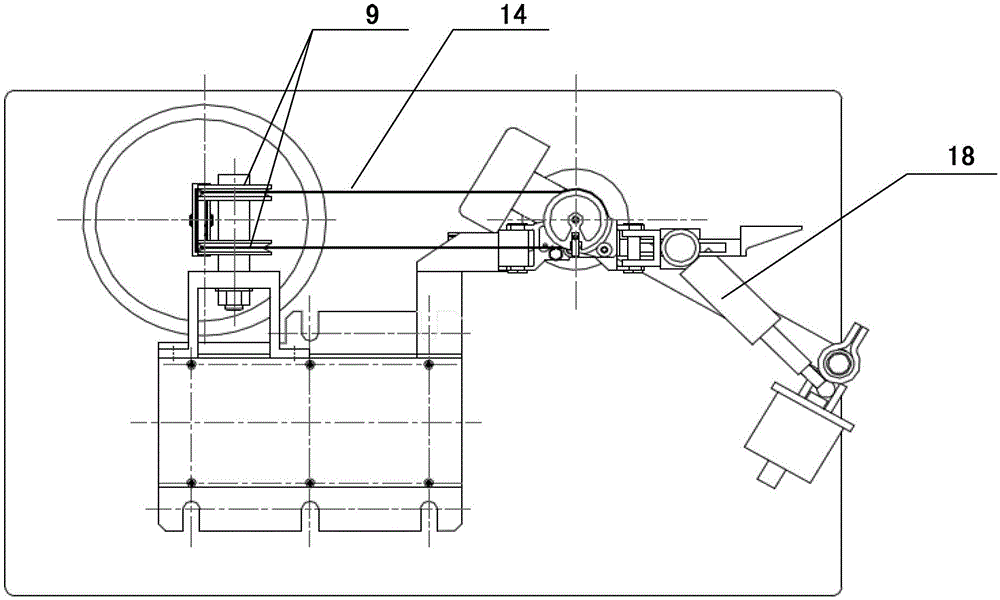

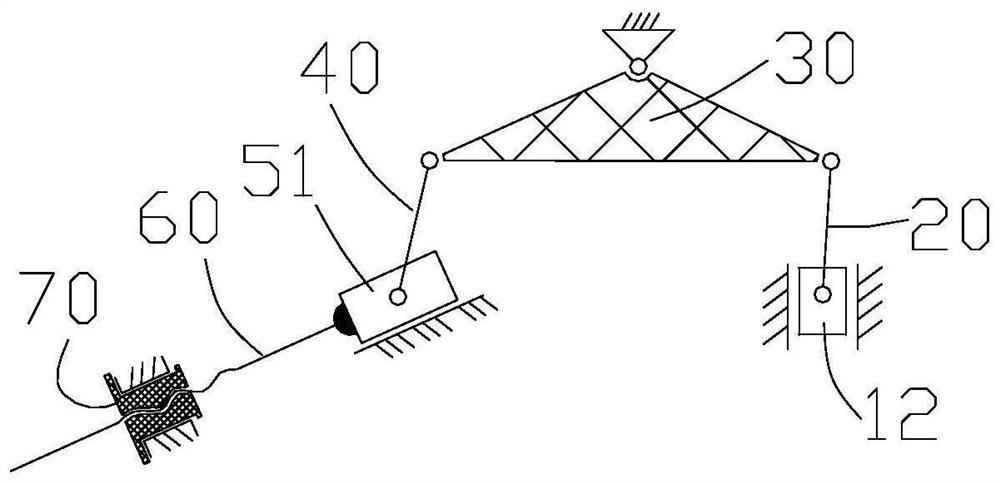

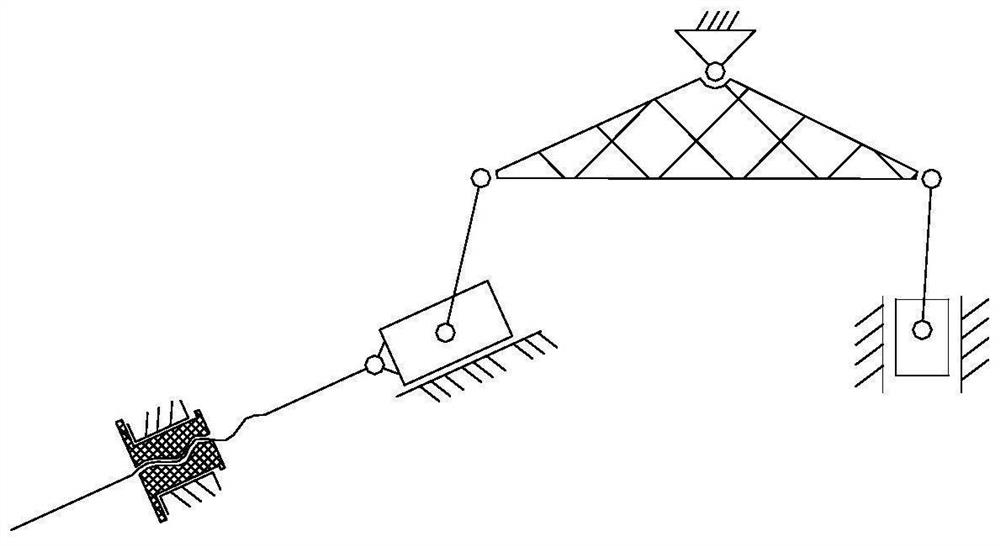

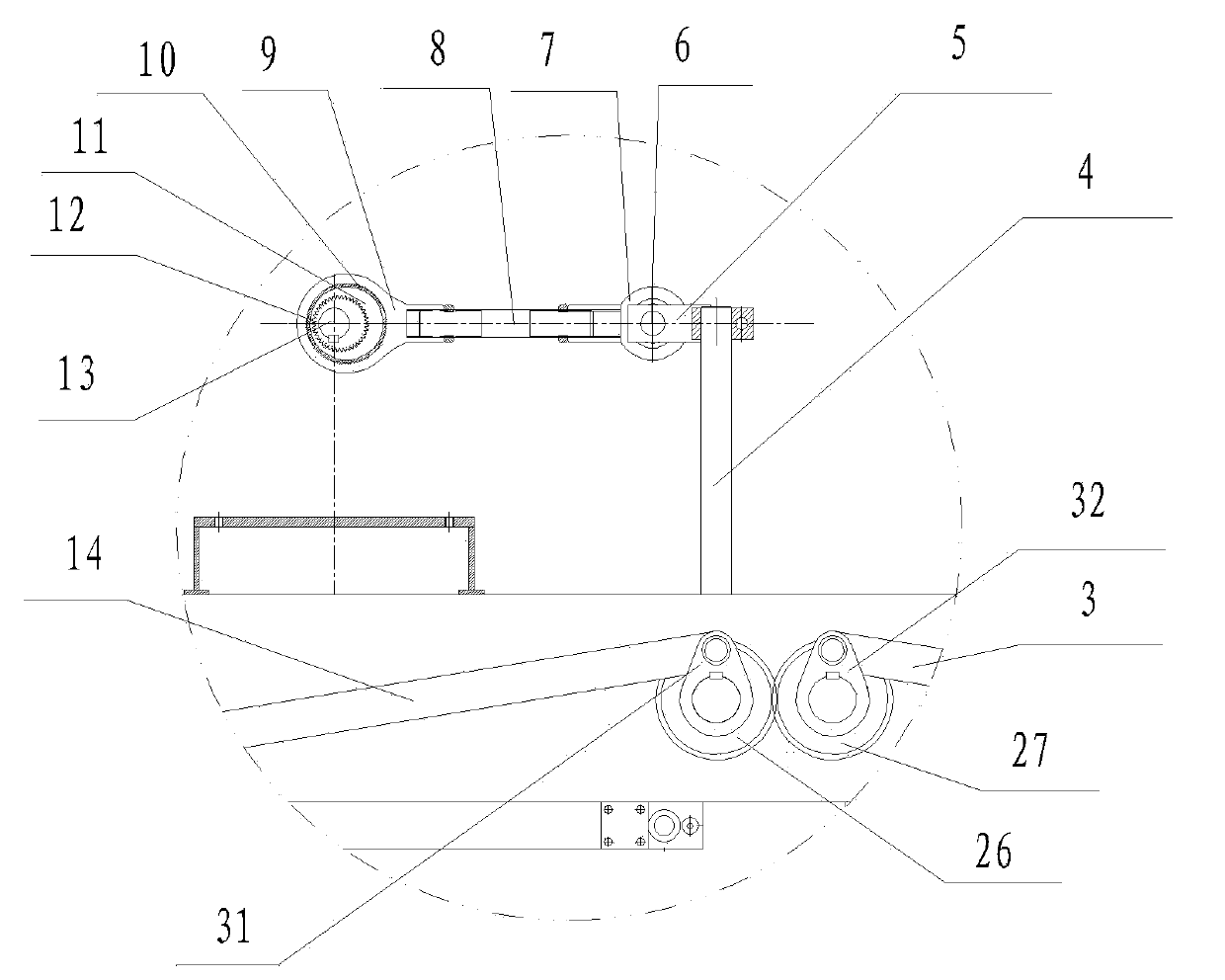

Solar wing hinge line drive characteristic test device

InactiveCN103278318BAchieve installationImprove reliabilityMachine part testingReduction driveBlock and tackle

The invention discloses a driving property test device for a hinge line of a solar wing. The device comprises a base, a shift rod, a rotary bracket a, a sensor seat, a cable fixing seat, a fixed bracket, a double-pulley assembly, a loading heavy block, a vertical column assembly, a fixed seat, a force measuring sensor, a steel wire rope and a movable pulley assembly, wherein the interior of the base is provided with a worm and gear speed reducer, the vertical column assembly is vertically and fixedly arranged at the top of the base, and the double-pulley assembly is fixedly arranged on the vertical column assembly. The test device has the advantages that the unfolding and folding processes of the solar wing can be simulated; the rotation angle and the torque parameter can be tested in real time, and the accurate and reliable test data, such as driving torque, friction drag torque and rigidity, can be obtained; and the reliability and the development level of space application equipment are improved.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

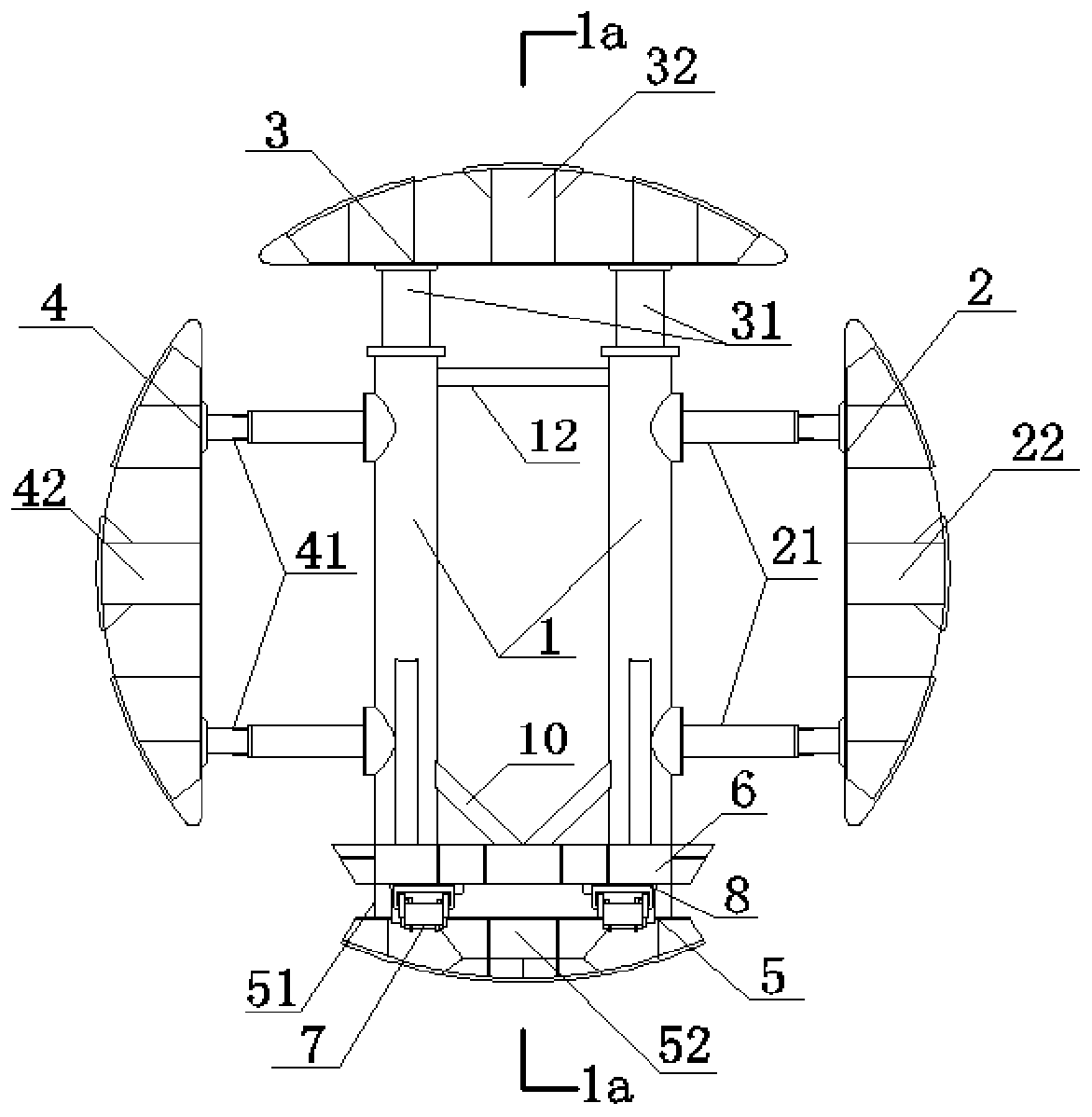

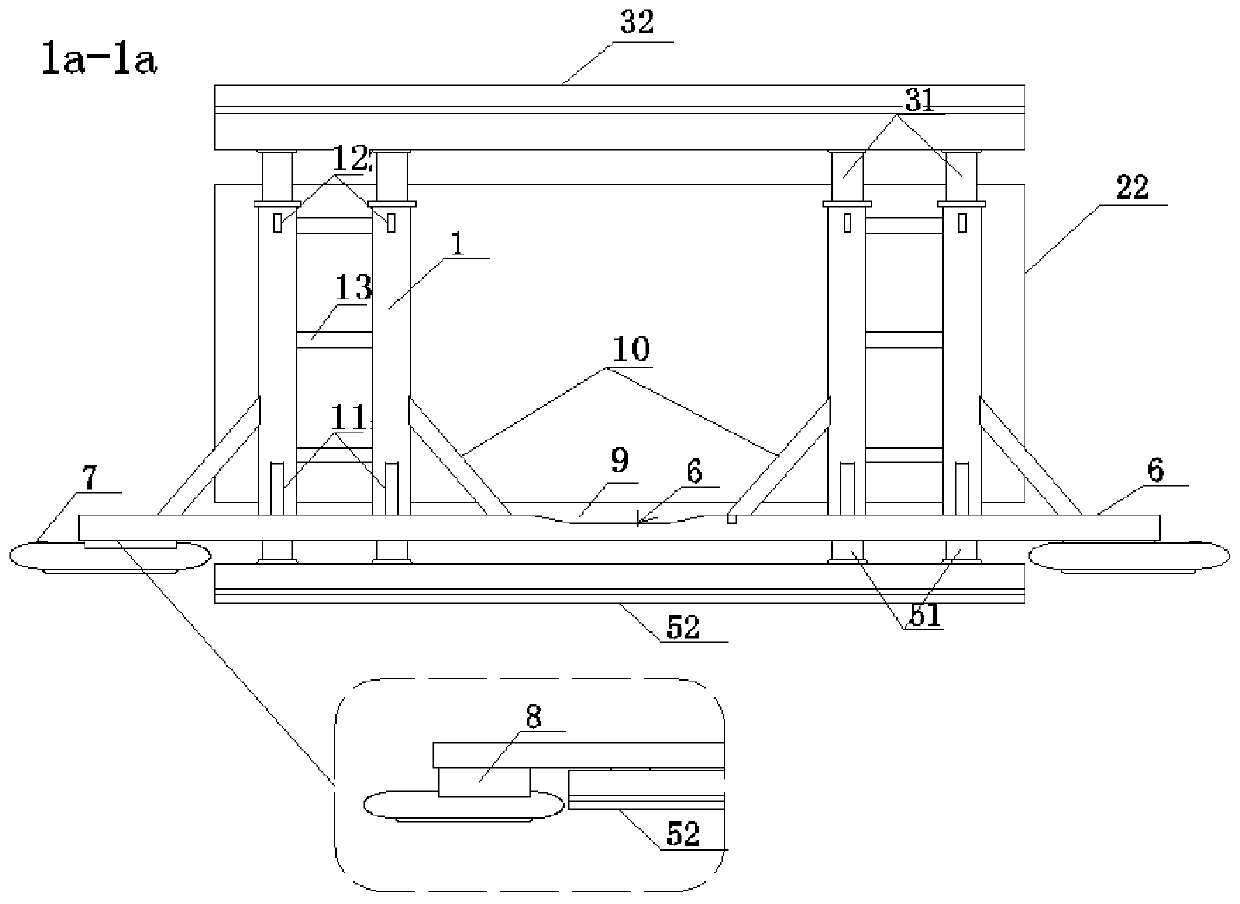

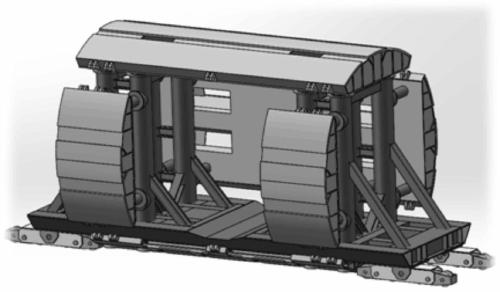

A mobile prestressed support system and method of use thereof

ActiveCN109630175BAvoid additional deformationStable structureMine roof supportsSupporting systemPre stress

The invention discloses a movable prestress supporting system and a using method thereof. The system is characterized by comprising a main frame type steel support, a backrest counter-force seat, an inverted arch counter-force seat, a construction side counter-force seat, an arch bottom counter-force seat, a supporting protection support bottom plate, an under-plate movable wheel rail and a wheelrail vertical telescopic device; the main frame type steel support comprises eight main structure columns which form a rectangle; the backrest counter-force seat comprises a transverse telescopic backrest counter-force seat support and a backrest stress buffer block; the inverted arch counter-force seat comprises a vertical telescopic inverted arch counter-force seat support and an inverted arch stress buffer block; the construction side counter-force seat comprises a transverse telescopic construction side counter-force seat support and two symmetric construction side stress buffer blocks; the arch bottom counter-force seat comprises a vertical telescopic arch bottom counter-force seat support and an arch bottom stress buffer block; the supporting protection support bottom plate is fixedly arranged at the lower end of the main structure column. The system has the advantages of being movable and capable of achieving quick supporting, providing recoil force for a contact channel headingmachine and achieving longitudinal and uniform load distribution.

Owner:NINGBO YONGGONG TECH CO LTD

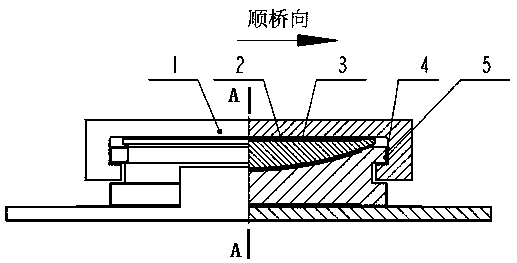

Two-way sliding anti-drawing spherical support

PendingCN109577180AThe solution can only slide in one directionSolve the characteristicsBridge structural detailsEngineeringCantilever

The invention discloses a two-way sliding anti-drawing spherical support which comprises an upper support plate, a spherical crown liner plate, a middle steel liner plate and a lower support plate. Aforward L-shaped cantilever is arranged on the lower surface of the upper support plate in the bridge direction. A reverse L-shaped cantilever is arranged on the upper surface of the lower support plate in the transverse bridge direction. Flanges are arranged at the upper end and the lower end of the middle steel liner plate. The flanges at the two ends are arranged in grooves of the forward L-shaped cantilever and the reverse L-shaped cantilever and are in plane sliding connection with the grooves. An arc-shaped groove is formed in the middle portion of the upper end of the middle steel linerplate. The upper surface of the spherical crown liner plate and the lower surface of the upper support plate are in plane sliding connection. A bottom cambered surface is arranged in the arc-shaped groove of the middle steel liner plate and is in spherical surface sliding connection with the arc-shaped groove. By the adoption of the design, longitudinal sliding and transverse sliding are separated, two sliding faces are arranged, support rotating and two-way sliding functions are achieved, a single-direction sliding function is stable, the displacement can be designed large, an anti-drawing effect is good, the support is not affected by support sliding, and the functions are stable.

Owner:GUIZHOU TRANSPORTATION PLANNING SURVEY & DESIGN ACADEME

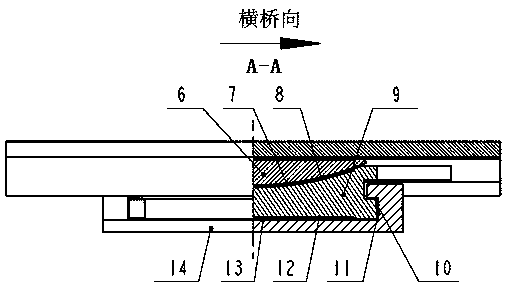

Large-tonnage metal bending transmission mechanism

The invention discloses a large-tonnage metal bending transmission mechanism. The mechanism comprises pressing arms, a connecting rod, a hinge support, a pressing rod, a moving part, a lead screw, a nut and a nut rotation driving device; the two pressing arms are symmetrically arranged on the upper portions of the two sides of a rack of metal plate bending equipment; the front end, facing the upper cross beam, of each pressing arm is hinged to the top end of a connecting rod, and the bottom end of the connecting rod is hinged to the upper cross beam; the middle of each pressing arm is hinged to a hinged support, and the hinged support is fixedly installed on the rack or integrally arranged on the rack; the rear end of each pressing arm is hinged to the top end of a pressing rod, and the bottom end of the pressing rod is hinged to a moving piece; the moving part is mounted at the front end of the screw rod; the nut is arranged on the lead screw in a threaded and sleeving mode and forms lead screw thread pair fit with the lead screw; and the nut is further installed on the machine frame through a bearing seat and can be driven by the nut rotation driving device to rotate. The mechanism can achieve lifting driving of the upper cross beam with the heavy load of 80 tons or above, and the driving noise is low.

Owner:NANJING UNIV OF POSTS & TELECOMM

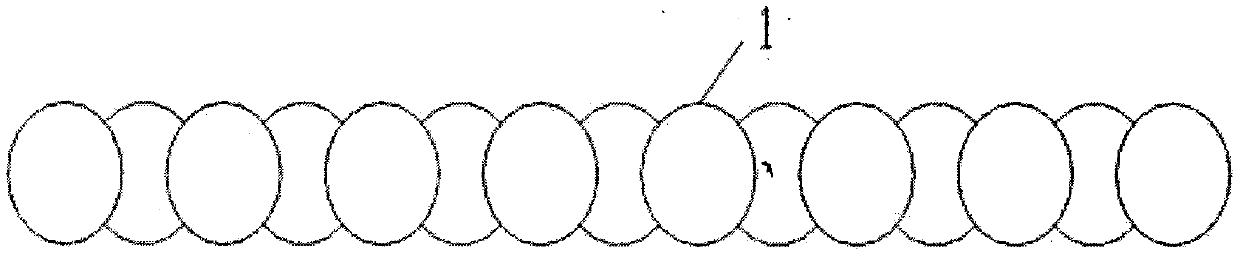

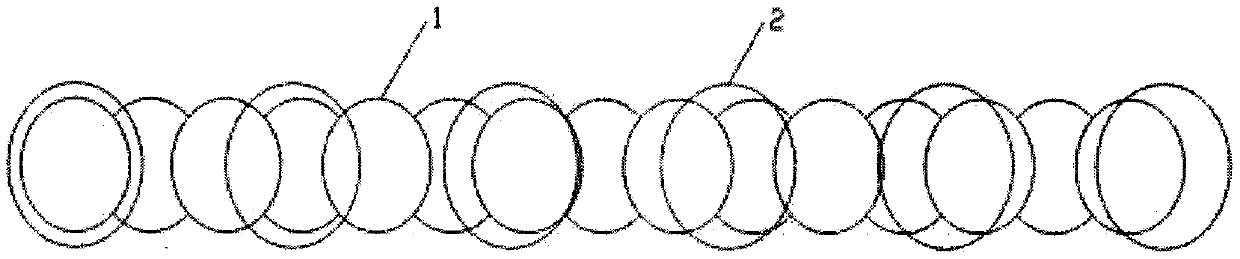

Supporting structure and filter element of filtering structure

PendingCN109772172AReduce thicknessIncrease the effective filter areaSemi-permeable membranesPrincipal stressRadial stress

The invention discloses a supporting structure and filter element of a filtering structure. The supporting structure comprises a supporting cylinder which is formed by winding a strip-shaped coiled material, the coiled material is of a porous structure, and a joint formed by winding the coiled material is not parallel to the central axis of the supporting cylinder. When the supporting cylinder bears internal and external pressure, the maximum principal stress of the supporting cylinder is perpendicular to the central axis and acts on each round section. According to a traditional straight welded pipe (a joint is parallel to the central axis of the welded pipe), the joint directly bears the maximum principal stress, and the requirement of weld joint strength is high. When the joint is not parallel to the central axis of the supporting cylinder, the joint mainly bears component force of the principal stress, namely radial stress and axial stress, the two stress values are obviously smaller than the principal stress of the straight welded pipe, and therefore the thickness of the supporting structure can be obviously reduced at the same work pressure and the same pipe diameter. The porosity can be obviously increased, so that the effect filtering area of the filtering structure is improved.

Owner:CHENGDU INTERMENT TECH

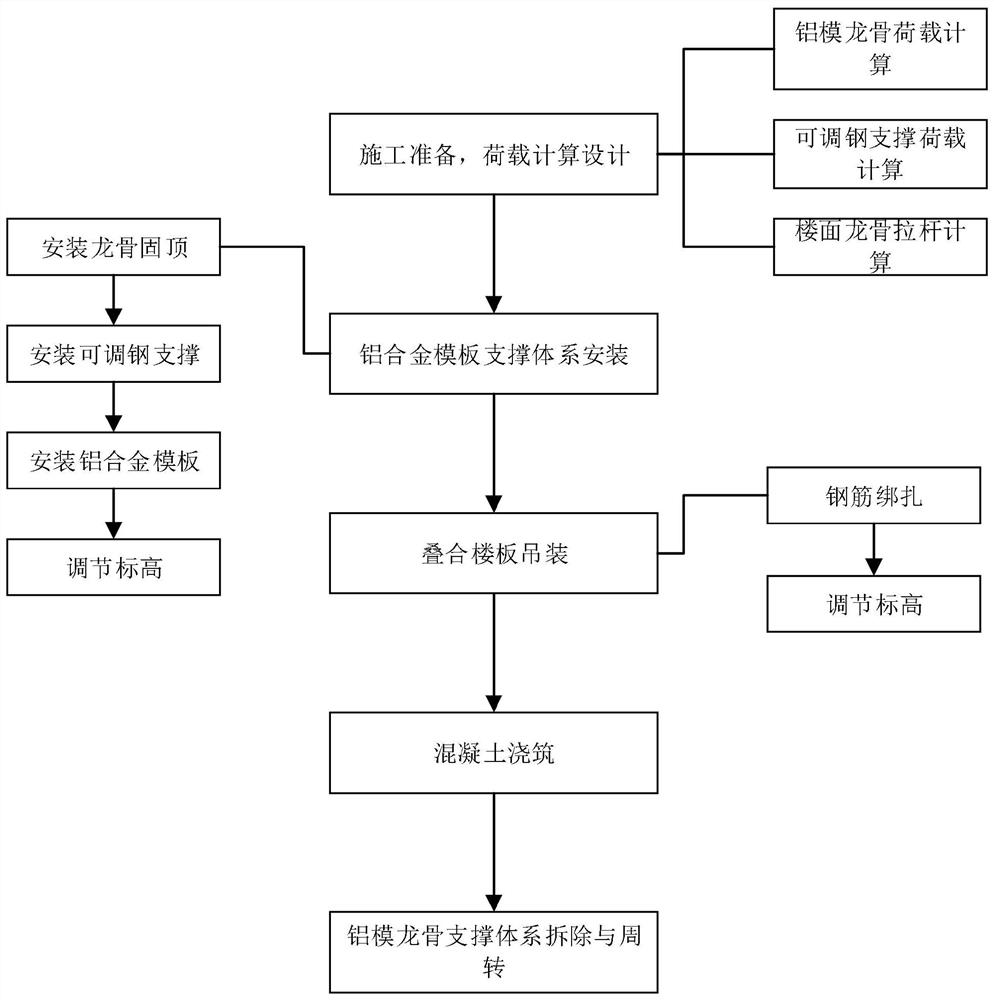

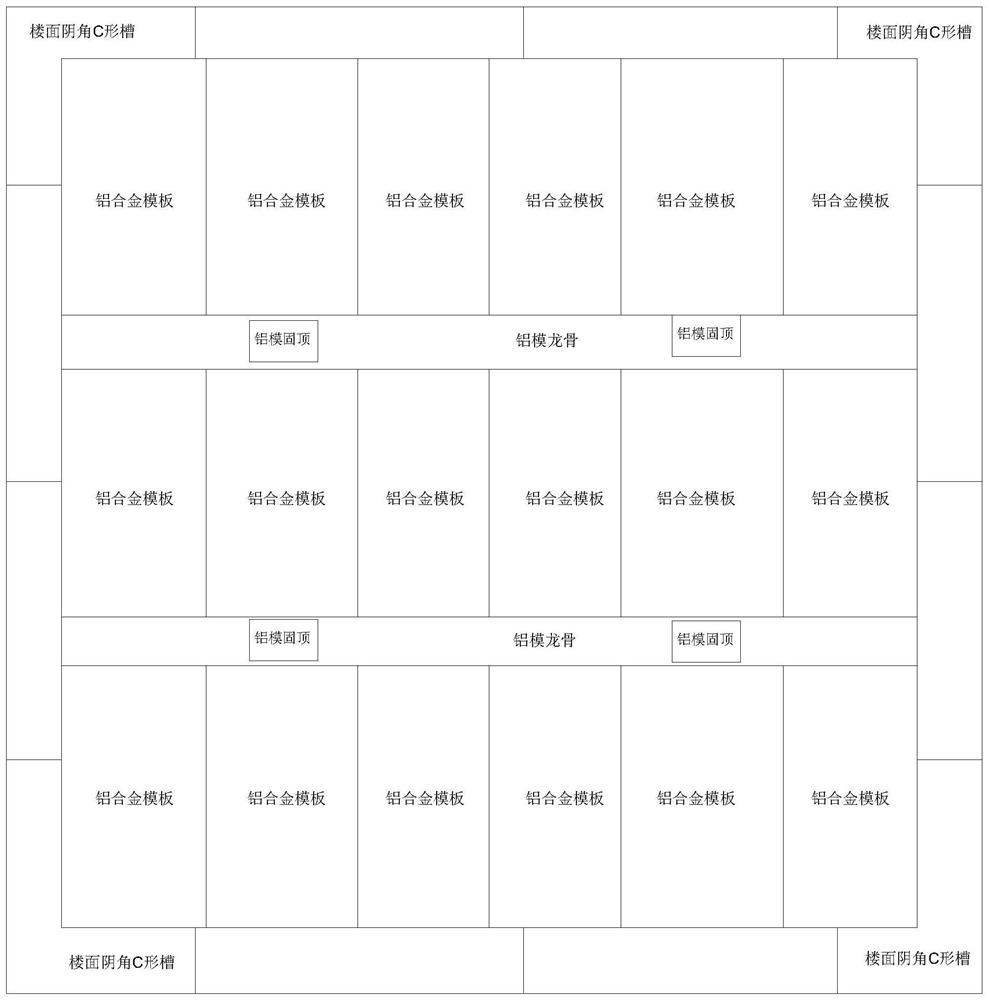

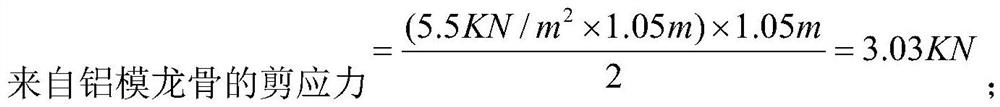

Composite floor slab construction method based on aluminum alloy formwork support

PendingCN113719116AHigh strengthEasy dismantling and turnoverFloorsForms/shuttering/falseworksRebarFloor slab

The invention discloses a composite floor slab construction method based on aluminum alloy formwork support. The composite floor slab construction method comprises the following construction steps that S1, construction preparation is achieved: formwork matching design of an aluminum alloy formwork support system is completed; S2, the aluminum alloy formwork support system is installed; S3, composite floor slabs are hoisted, specifically, the composite floor slabs are arranged at the top of the aluminum alloy formwork support system in a hoisting mode and supported by aluminum alloy formworks and keel fixed tops, and the composite floor slabs are connected through reserved steel bars on the composite floor slabs bonded by steel bars; S4, concrete pouring is conducted, specifically, concrete is poured to the position above a composite floor slab; and S5, an aluminum formwork keel support system is dismantled and turned over, specifically, after concrete curing is achieved, an aluminum alloy formwork support system structure except aluminum formwork fixed tops is dismantled, and turning over is conducted. According to the composite floor slab construction method based on the aluminum alloy formwork support, the composite floor slab is supported through aluminum formwork keels and the aluminum formwork fixed tops, when a plurality of aluminum formwork fixed tops exist, all the aluminum formwork keels are connected through the aluminum alloy formworks, horizontal stability is guaranteed, and overturning is prevented in the hoisting process.

Owner:CHINA HUASHI ENTERPRISES

Special horizontal type shaking table for cooling and sterilizing process for protein preparation

ActiveCN102247609BProcess parameters are easy to controlGood antibacterial effectLavatory sanitoryHeatGear wheelDrive motor

The invention relates to a cooling and sterilizing process for a protein preparation and a special horizontal type shaking table thereof. In the prior art, a sterilizing device for the protein preparation has the defects of poor stability and difficult control of parameters. The special shaking table comprises a cycloidal pin wheel speed reducer, a driving motor and a shaking table, wherein an eccentric outer gear, an eccentric inner gear, a gear shaft sleeve and a left gear base are fixedly arranged on the cycloidal pin wheel speed reducer and an output shaft of the driving motor; the left gear base is connected with one end of a regulating lead screw; the other end of the regulating lead screw is connected with a right bearing base; a shaking amplitude adjustment device is connected with the bearing base and one end of a shaking oscillating bar; the other end of the shaking oscillating bar is connected with one end of a rotating shaft of the shaking oscillating bar; and the other end of the rotating shaft of the shaking oscillating bar is connected with the shaking table by a transmission device in a shaking table cylinder body. The special horizontal type shaking table has a reasonable and compact structure, is reliable in strength, rigidity and toughness of key positions, small in assembly stress of parts and high process performance, process parameters are easy to control, and the optimal bacteriostatic effect can be achieved.

Owner:华原谷道生物科技西安有限公司

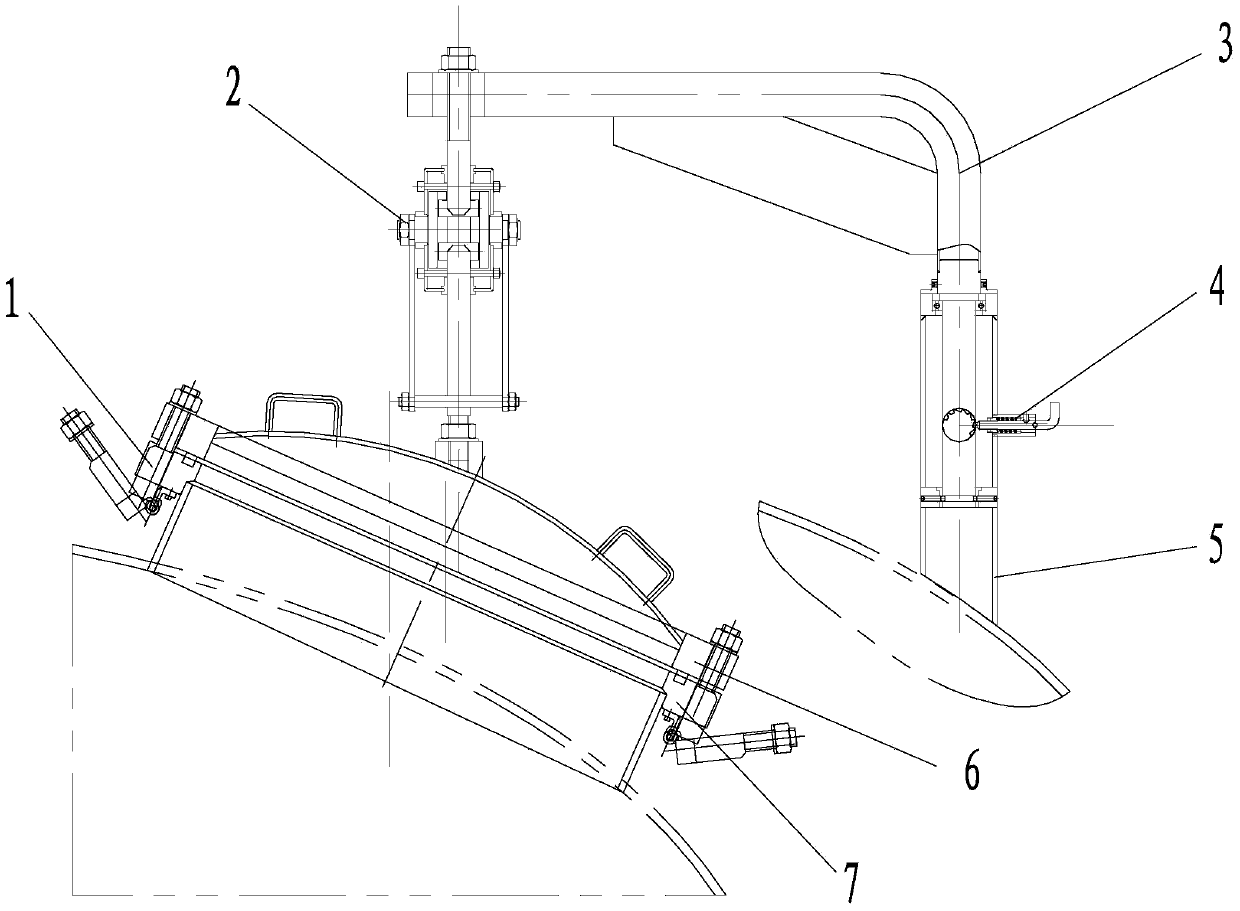

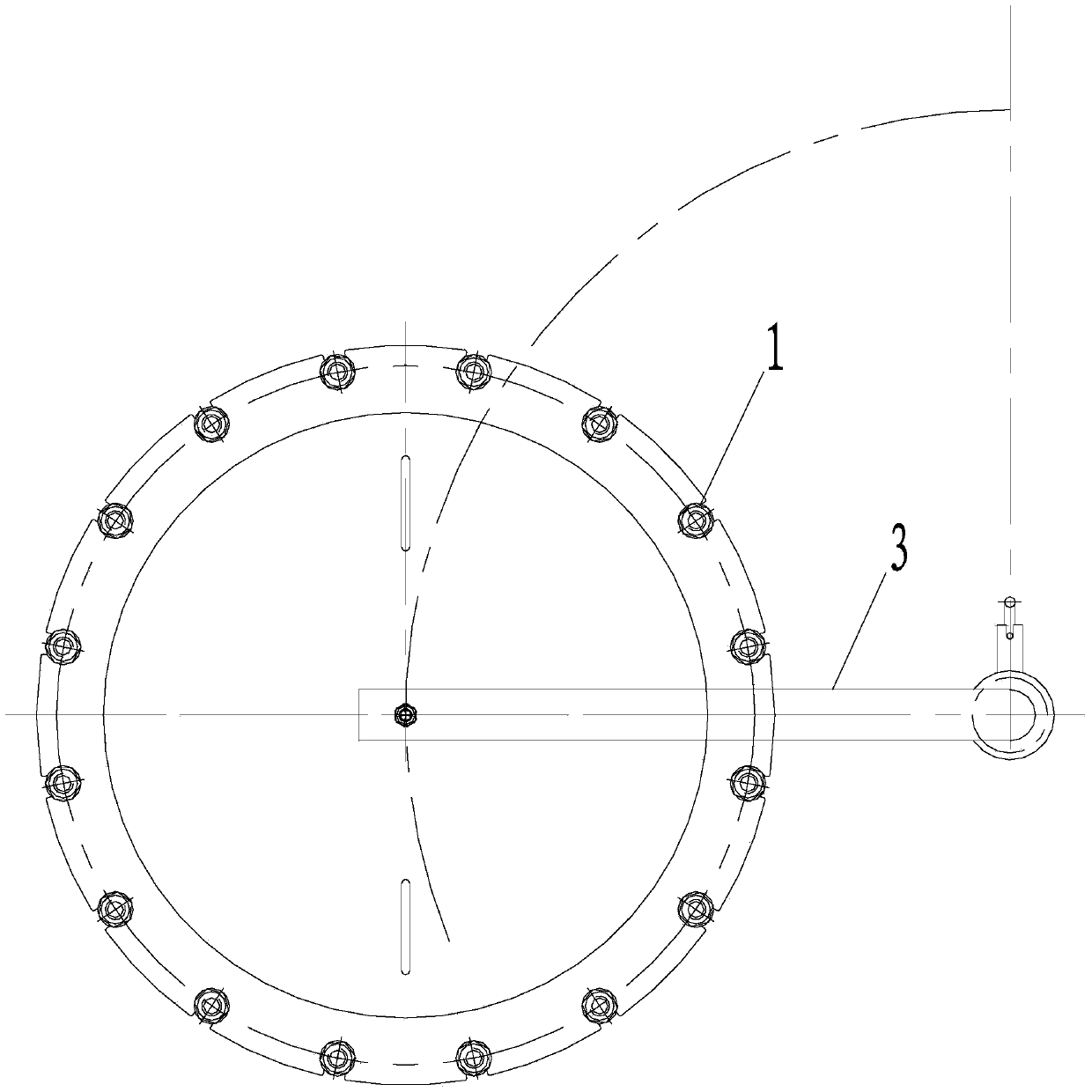

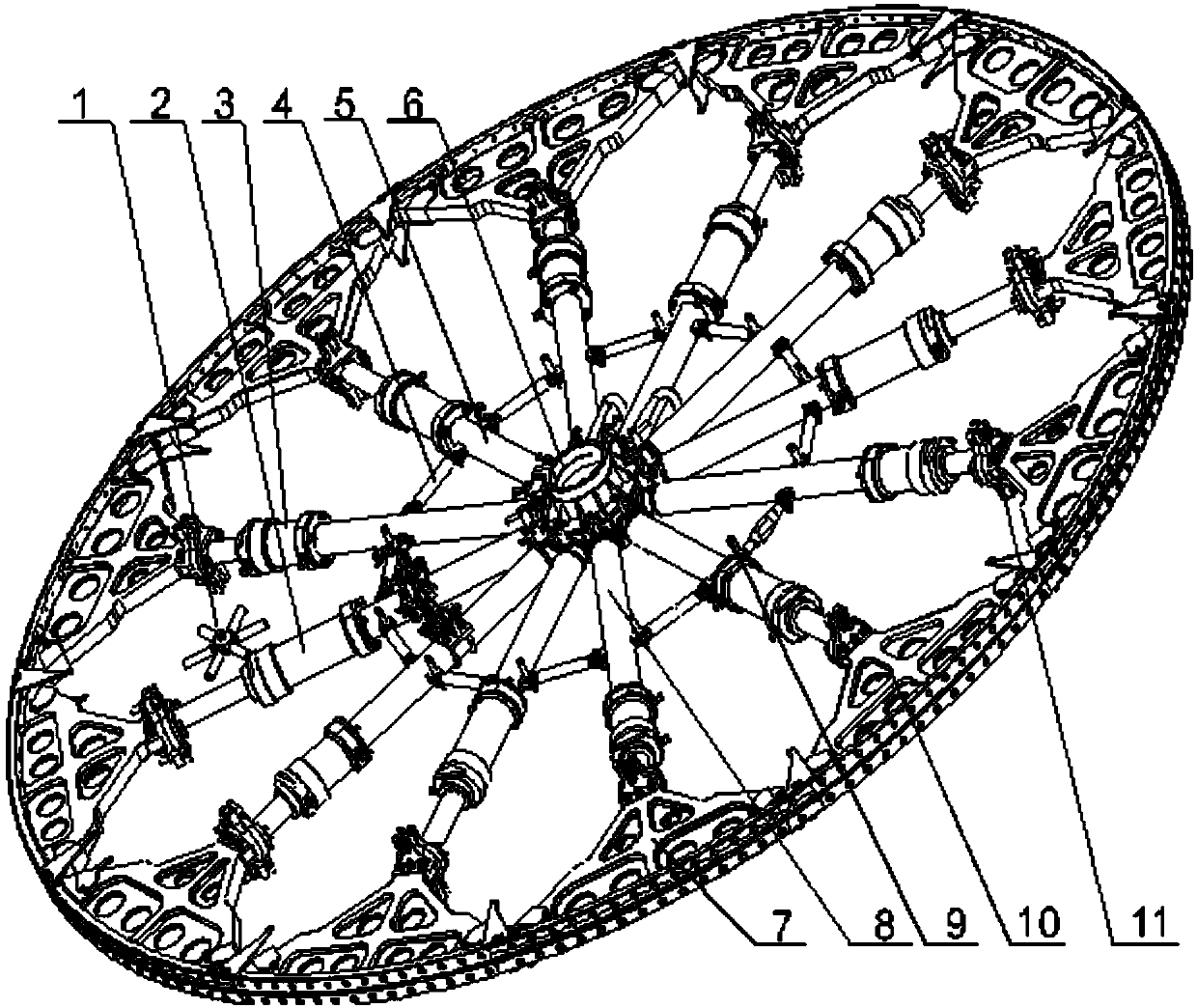

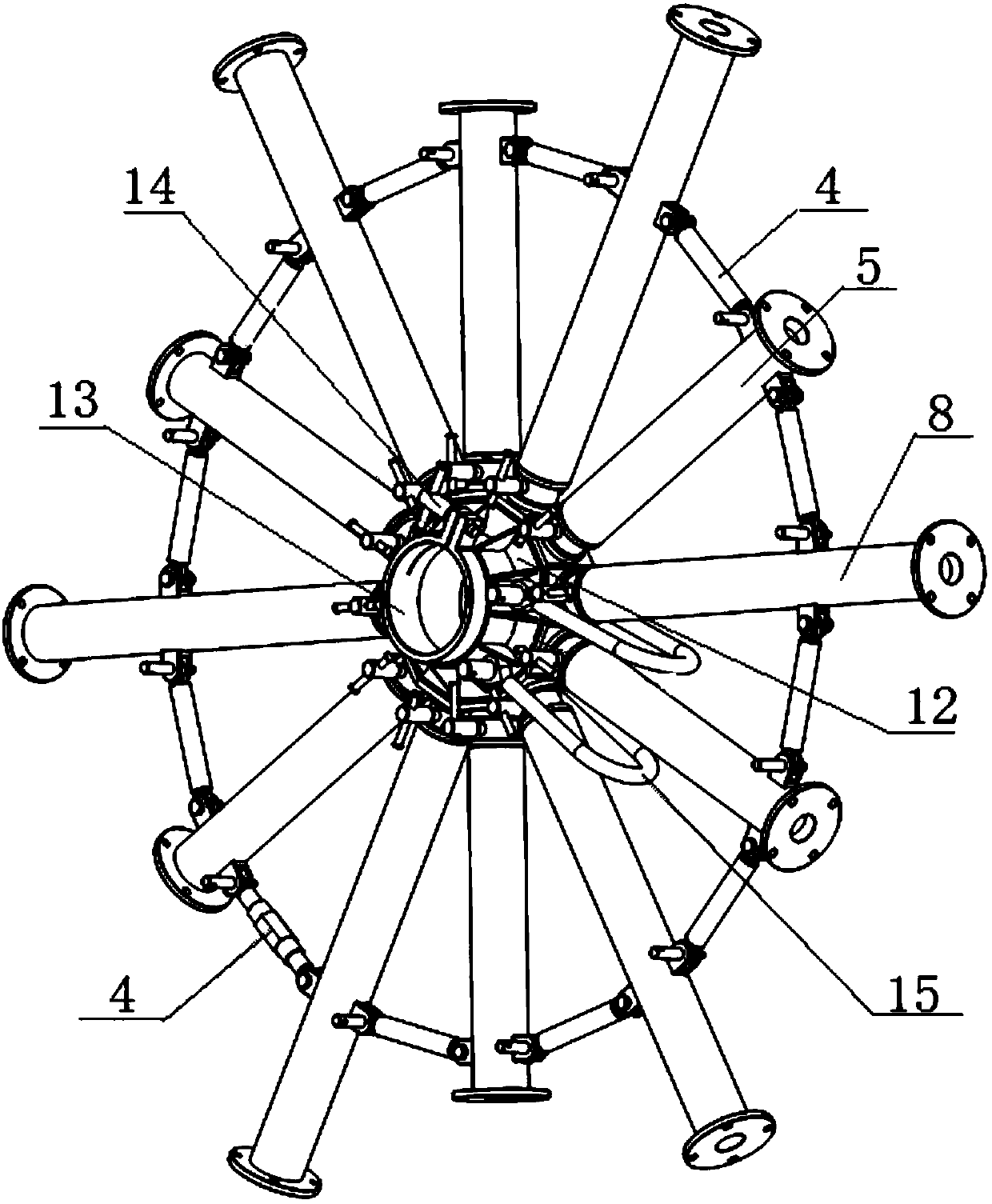

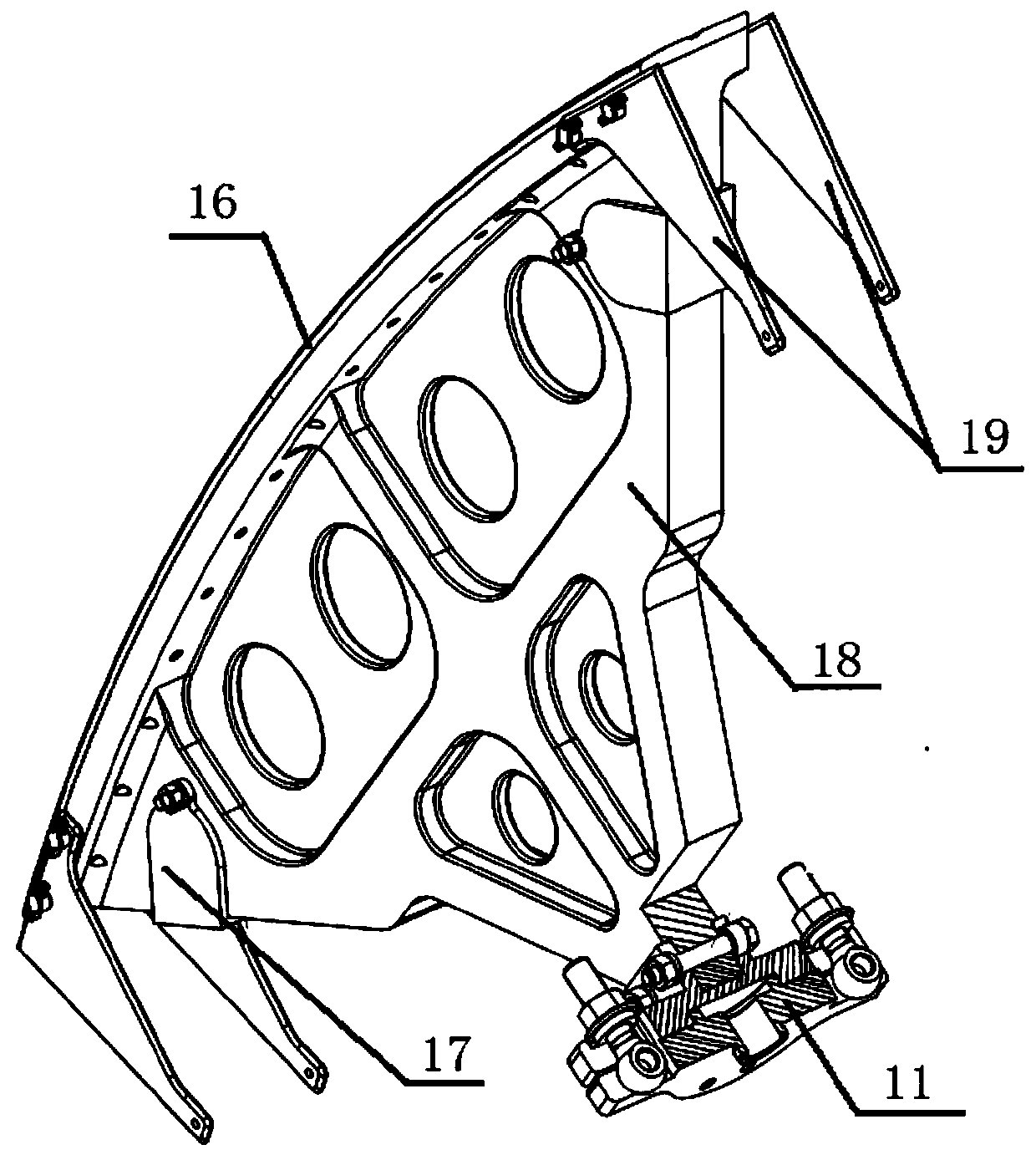

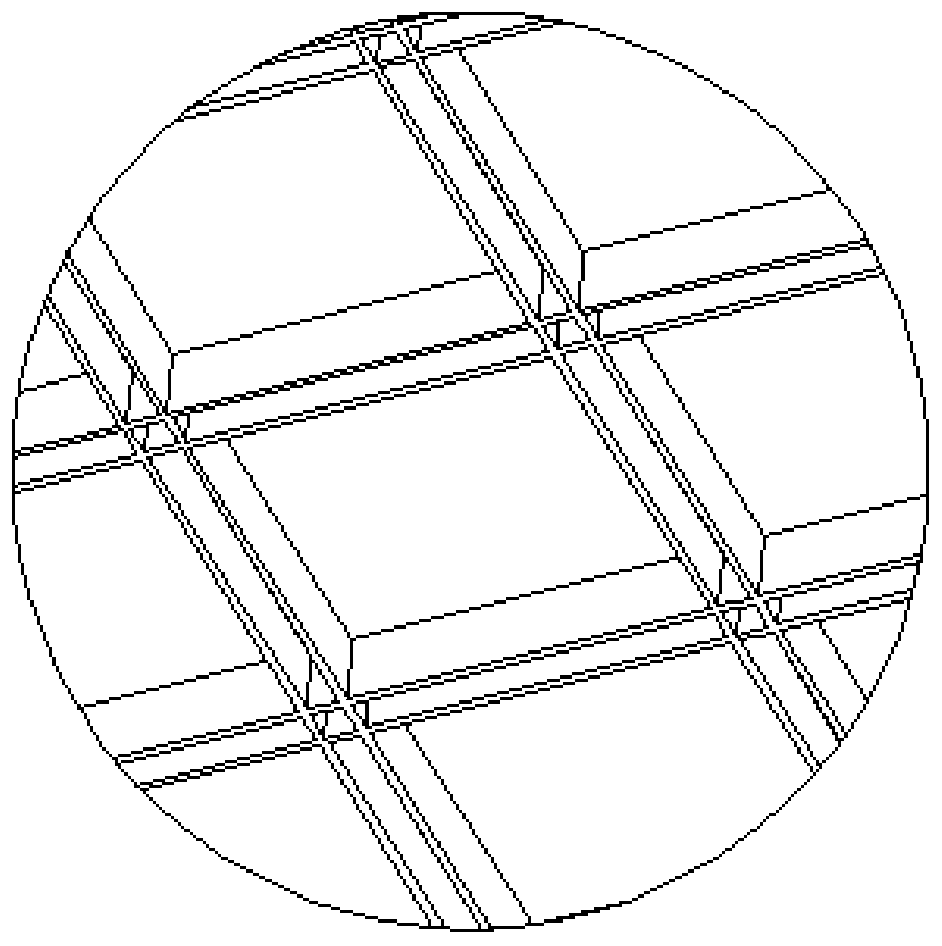

Quick-detachable large storage tank circular seam automatic welding inner support device

ActiveCN107253016BEasy to disassembleEasy to assembleWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSeam welding

The invention discloses a circular-seam automatic-welding inner-supporting device for a quick-disassembly-type large-scale storage tank. The device comprises an adjustable clamping shaft base arranged horizontally, a long support rod and a short support rod, wherein one end of the long support rod passes through a short stroke cylinder and is connected with an outer-arc-shaped support block, and one end of the short support rod passes through a long stroke cylinder and is connected with an inner-arc-shaped support block; after the short stroke cylinder and the long stroke cylinder support the outer-arc-shaped support block and the inner-arc-shaped support block to open, the arc-shaped surfaces of the outer-arc-shaped support block and the inner-arc-shaped support block are positioned at the same circumference, and a gap is arranged between the outer-arc-shaped support block and the adjacent inner-arc-shaped support block. According to the circular-seam automatic-welding inner-supporting device, two groups of gas paths are used to control two groups of cylinders with different lengths respectively to achieve the independent telescopic movements of the outer-arc-shaped support block and the inner-arc-shaped support block. The circular-seam automatic-welding inner-supporting device has the advantages of being light in weight, reliable in rigidity, quick, simple and convenient to disassemble, stable and reliable in process of jacking and loosening, adjustable in jacking pressure of seam welding, and capable of being assembled repeatedly to use, and the device can meet the mass production of large-scale storage tanks and improve the welding efficiency.

Owner:SICHUAN AEROSPACE LONG MARCH EQUIP MFG CO LTD

Spinning reel rotor and spinning reel

ActiveUS20170164592A1Smooth connectionReliable stiffnessReelsOther angling devicesEngineeringMechanical engineering

A rotor for a spinning reel is configured to rotate about a spool shaft, and includes a tubular portion and a plate-shaped portion. The tubular portion is disposed away from the spool shaft at a predetermined interval. The plate-shaped portion includes a radially outer part and a radially inner part. The radially outer part is integrated with an inner peripheral part of the tubular portion. The radially inner part extends from the radially outer part toward the spool shaft. The radially outer part has a smaller thickness than at least a part of the radially inner part.

Owner:SHIMANO INC

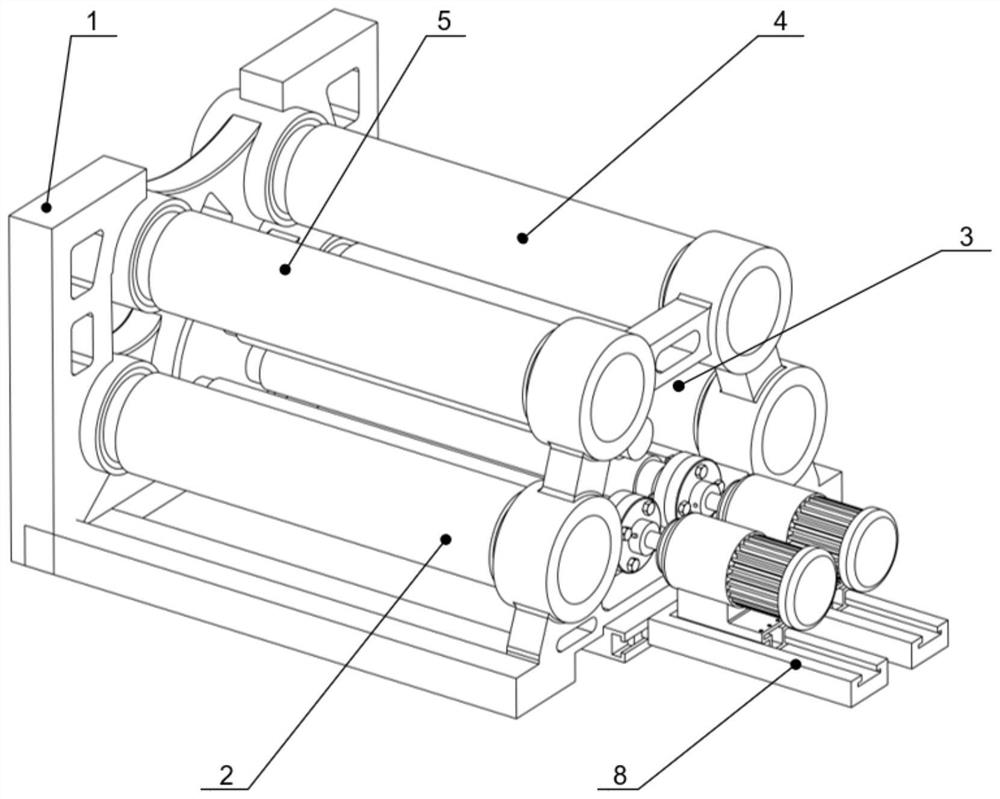

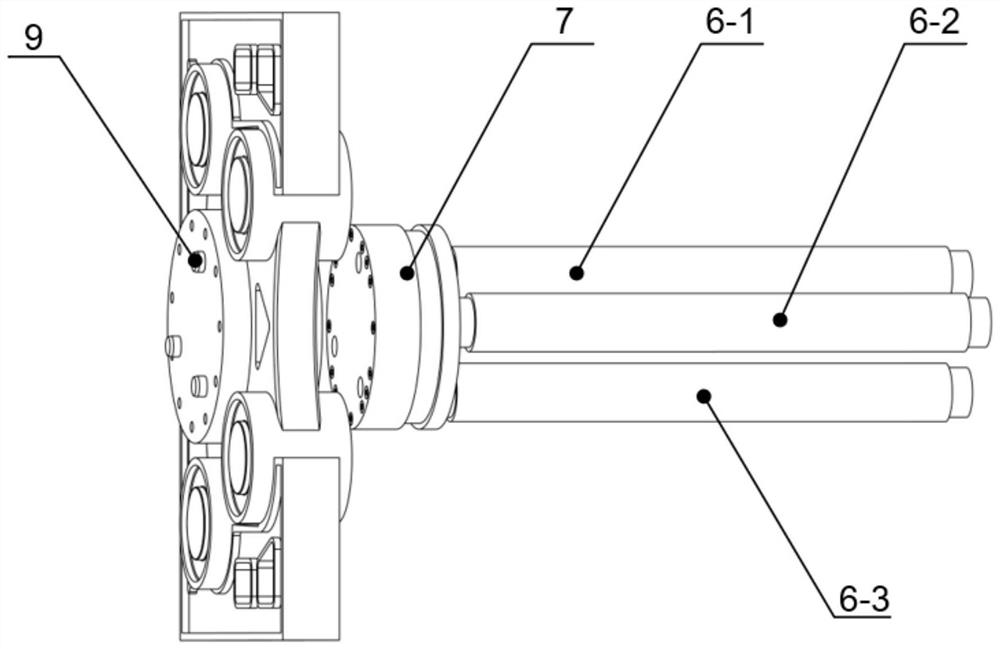

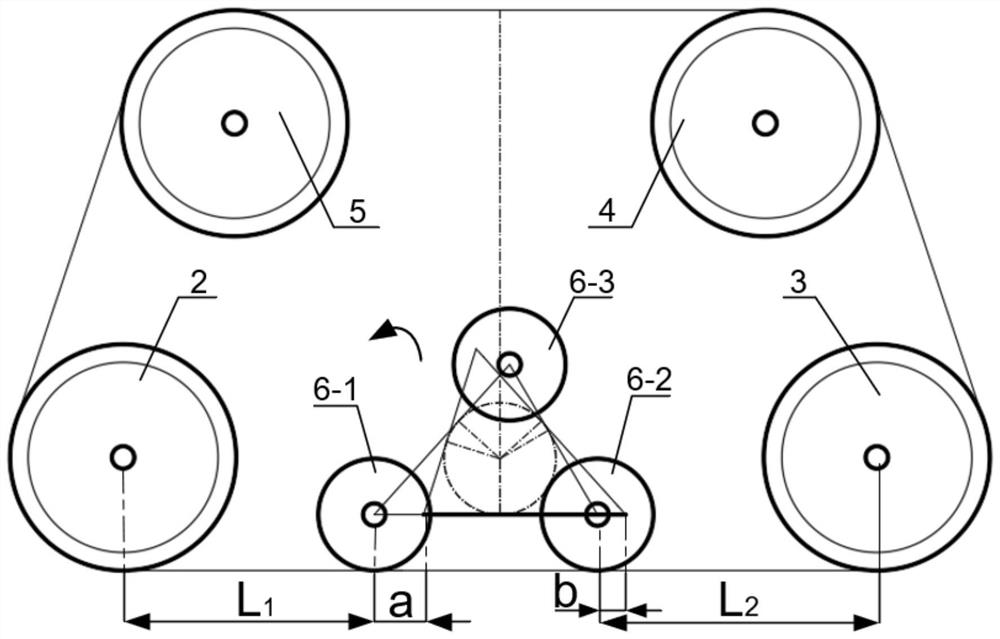

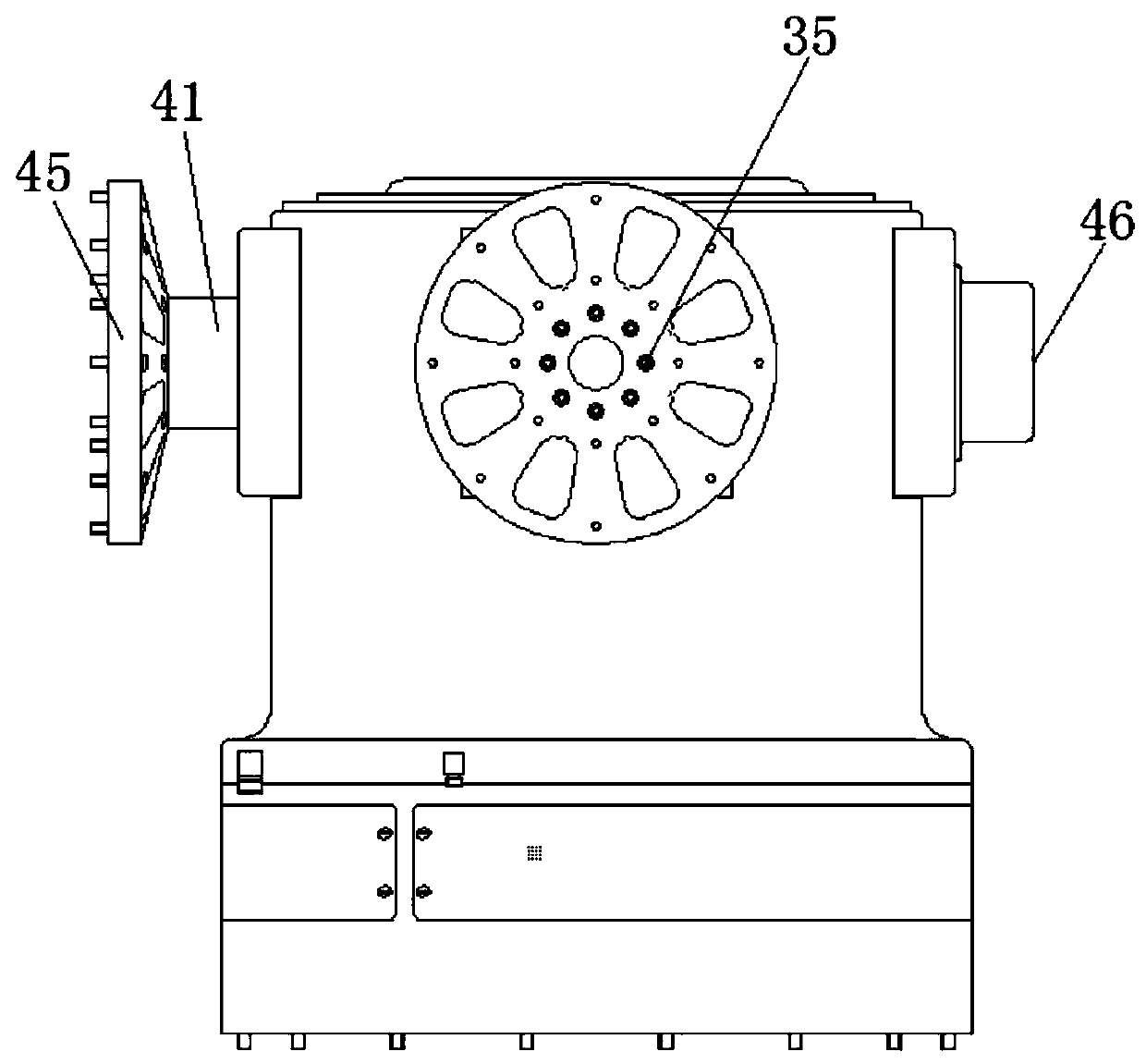

Novel multi-wire cutting mechanism with variable axial spacing

ActiveCN114083704AReliable stiffnessNo mobile viceGrinding carriagesGrinding drivesCable netWire cutting

The invention provides a novel multi-wire cutting mechanism with variable axial spacing, which comprises a rack, a first wire roller, a second wire roller, a third wire roller, a fourth wire roller and a rotor, wherein the first wire roller, the second wire roller, the third wire roller and the fourth wire roller are respectively driven by four servo motors, the rotor is provided with a fifth wire roller, a sixth wire roller and a seventh wire roller, and the connecting lines of the centers of the fifth wire roller, the sixth wire roller and the seventh wire roller form a triangle; a containing space is formed in the first wire roller, the second wire roller, the third wire roller and the fourth wire roller, and the fifth wire roller, the sixth wire roller and the seventh wire roller are all located in the containing space. The cutting wire net is supported and wound by any two of the first wire roller, the second wire roller, the third wire roller, the fourth wire roller, the fifth wire roller, the sixth wire roller and the seventh wire roller. And the rotor is rotated, so that two different wire rollers in the fifth wire roller, the sixth wire roller and the seventh wire roller serve as working wire rollers to support the lower flat cable net to participate in material cutting, the center distance between the wire nets of the left cutting area and the right cutting area is adjusted, and two different workpieces can be cut at the same time.

Owner:DALIAN UNIV OF TECH

Engine generator

Owner:HONDA MOTOR CO LTD

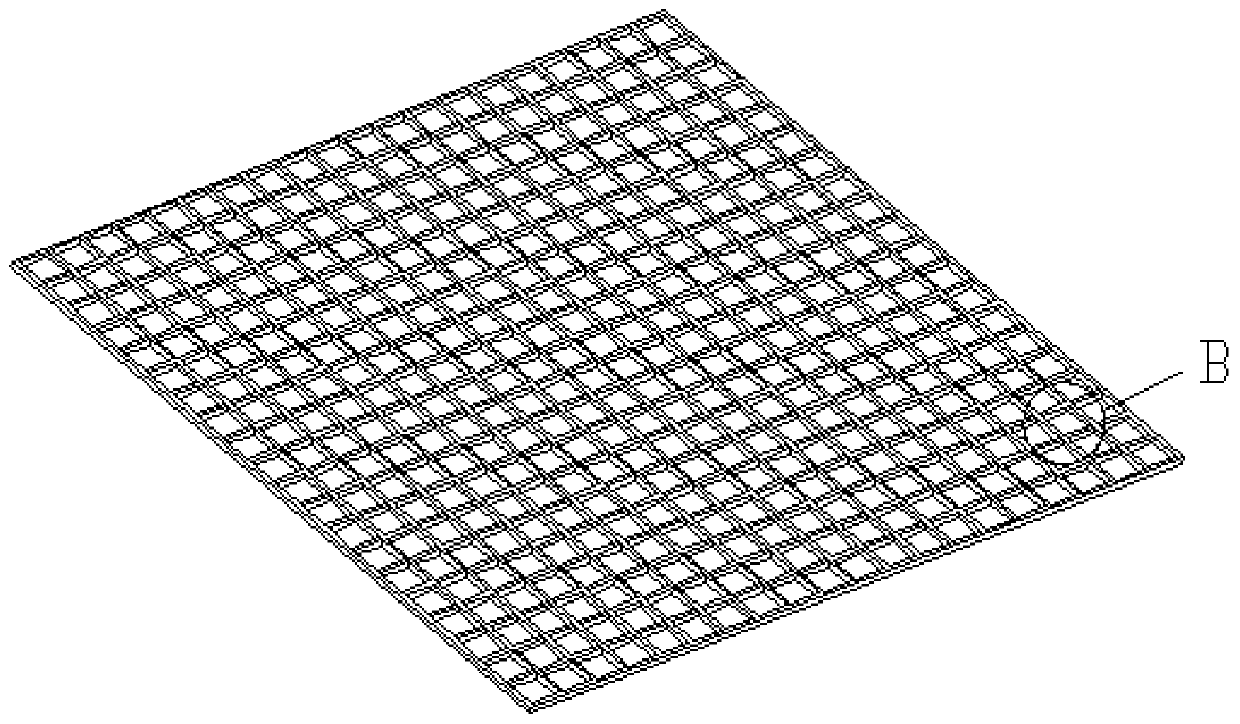

Wear-resistant and impact-resistant logistics carriage bottom plate

PendingCN110937031AIncrease productivityImprove corrosion resistanceLoading-carrying vehicle superstructuresLogistics managementAgricultural engineering

The invention provides a wear-resistant and impact-resistant logistics carriage bottom plate which comprises a double-web grating and a panel, the lower surface of the panel is a smooth welding surface, the double-web grating and the lower surface of the panel are welded and fixed, and the double-web grating is formed by mutually overlapping and fixing crisscrossed U-shaped groove-shaped ribs. According to the invention, starting with material selection and structural design, a feasible design scheme is provided, under the condition that the logistics carriage bottom plate also meets the use working condition of the logistics vehicle; compared with a traditional steel structure, the weight is reduced by 60% or above, compared with a traditional thermosetting resin-based composite material,the composite material has a better weight reduction effect, meanwhile, higher wear resistance and impact resistance are provided, the transportation efficiency of the logistics vehicle is improved to a great extent, the service life of a compartment is prolonged, and economic benefits are greatly improved. The bottleneck problem of light weight of the logistics carriage bottom plate is solved, and then the overall light weight degree of the vehicle is increased.

Owner:天津中科先进技术产业有限公司 +1

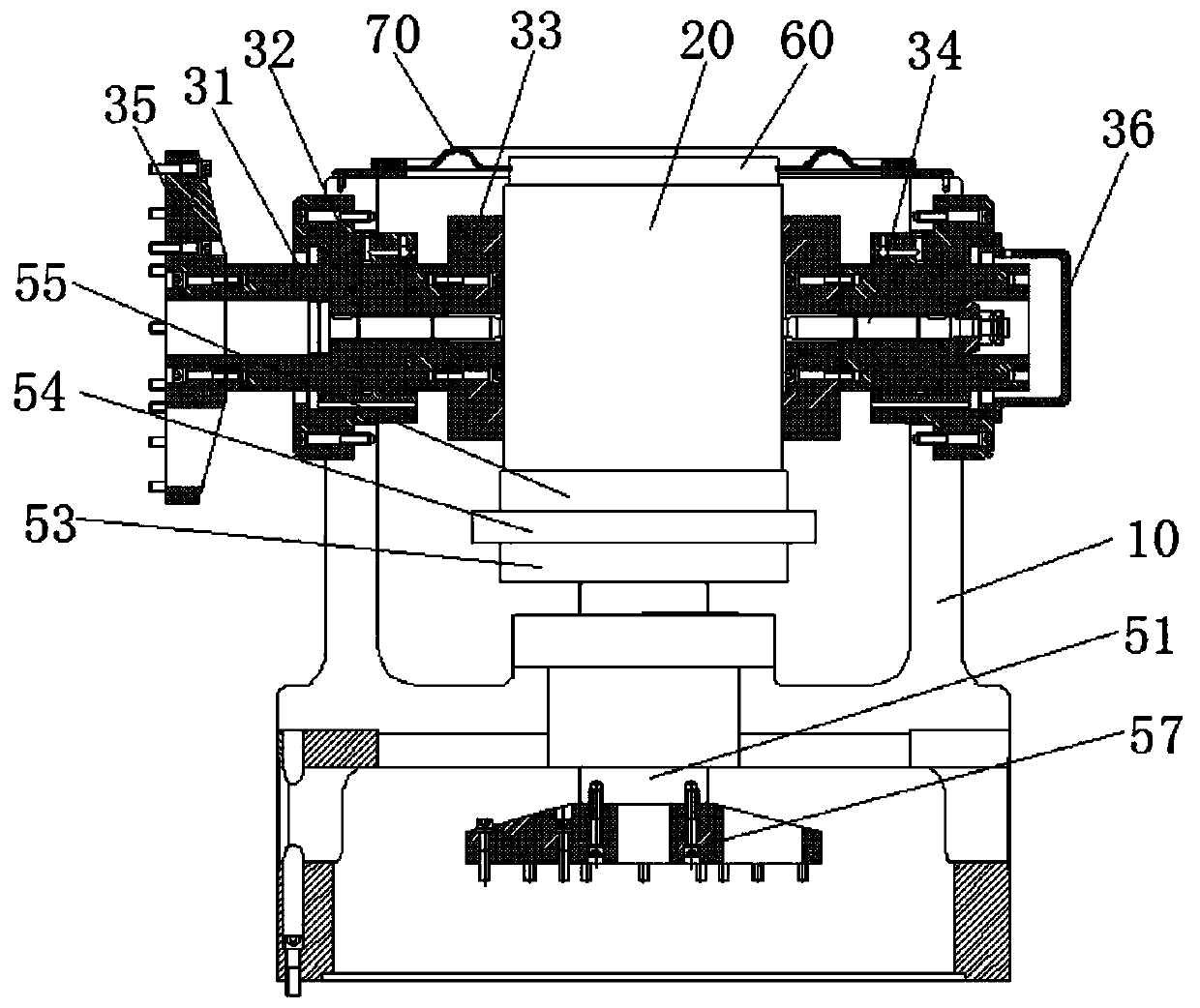

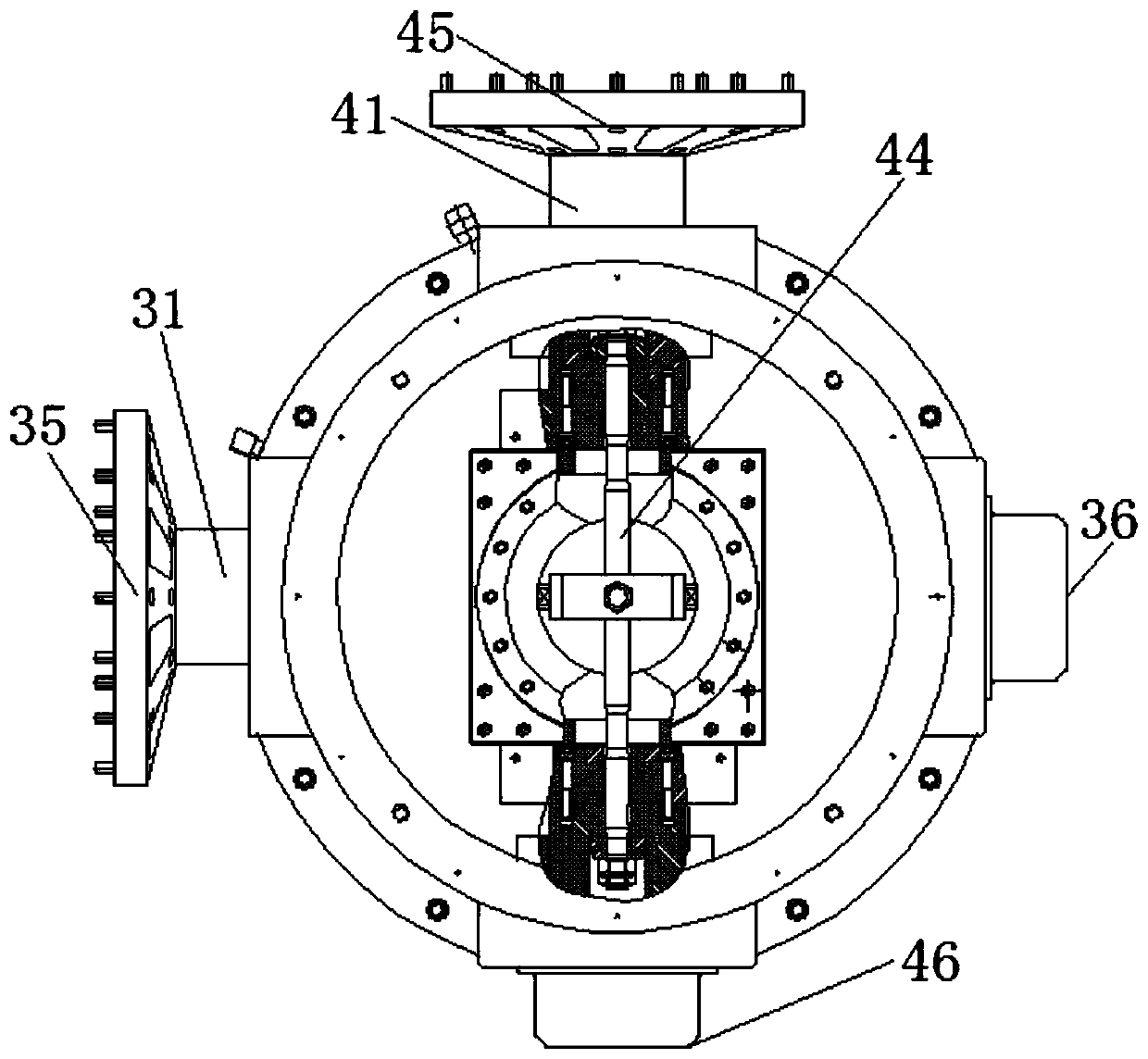

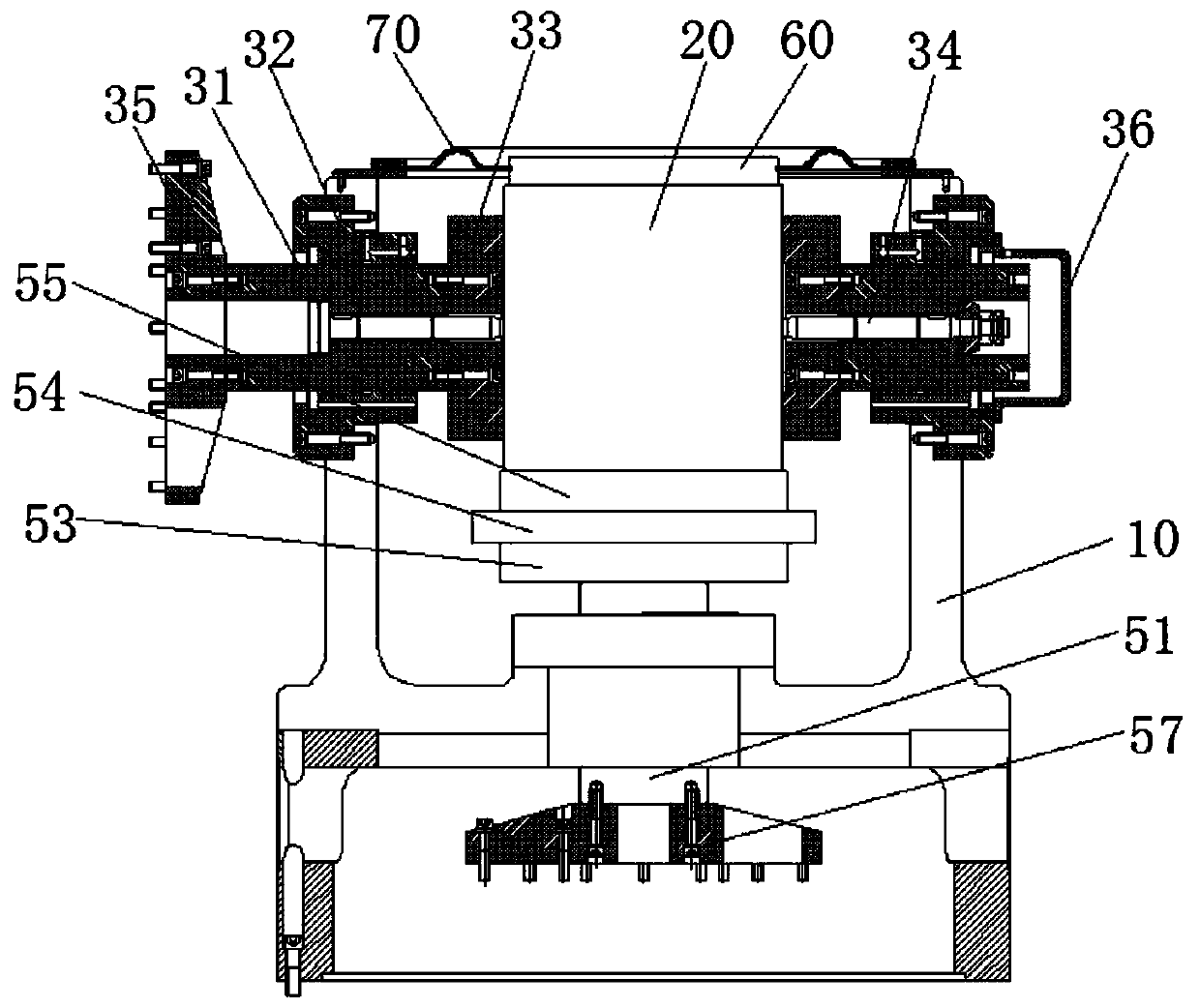

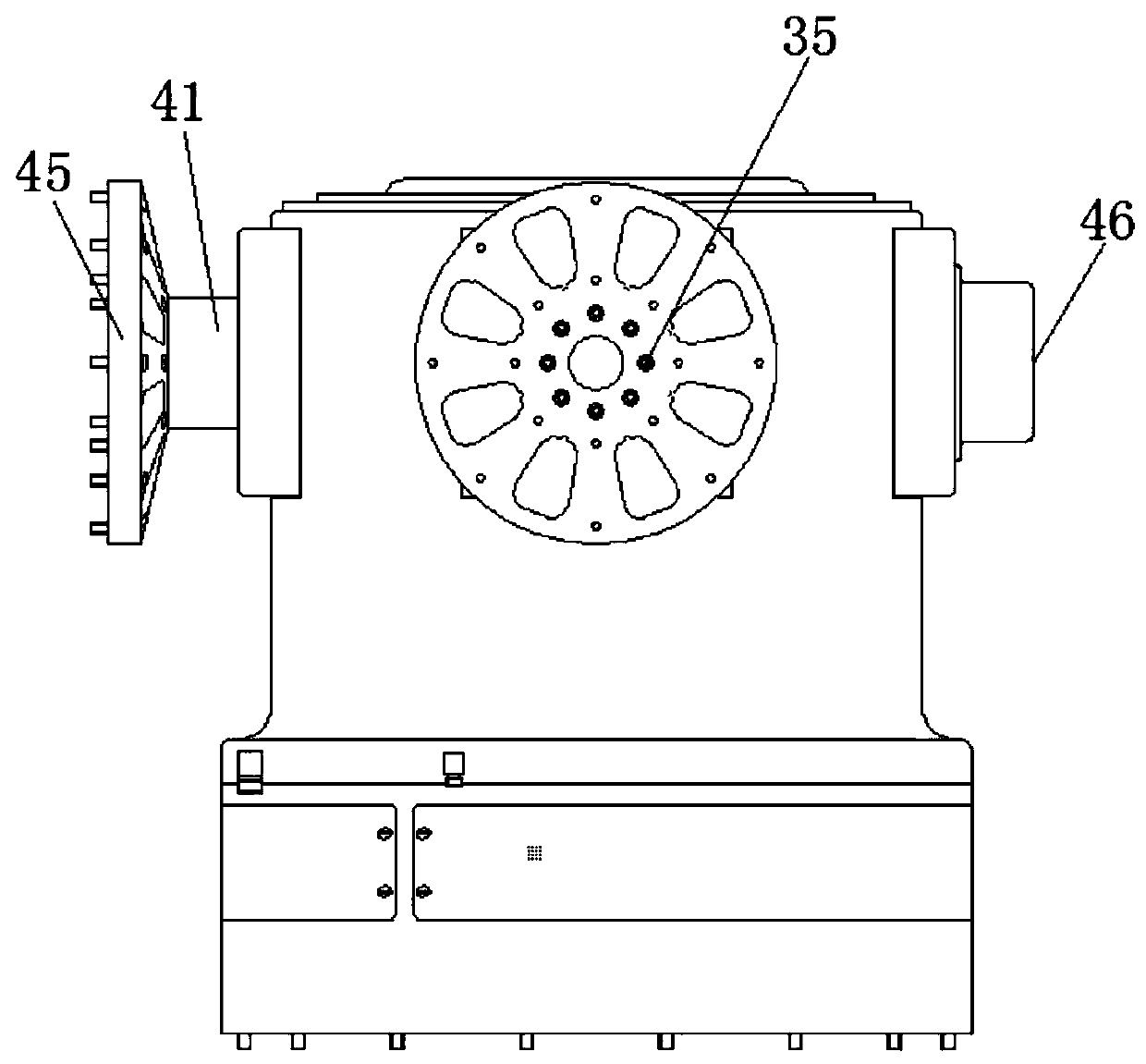

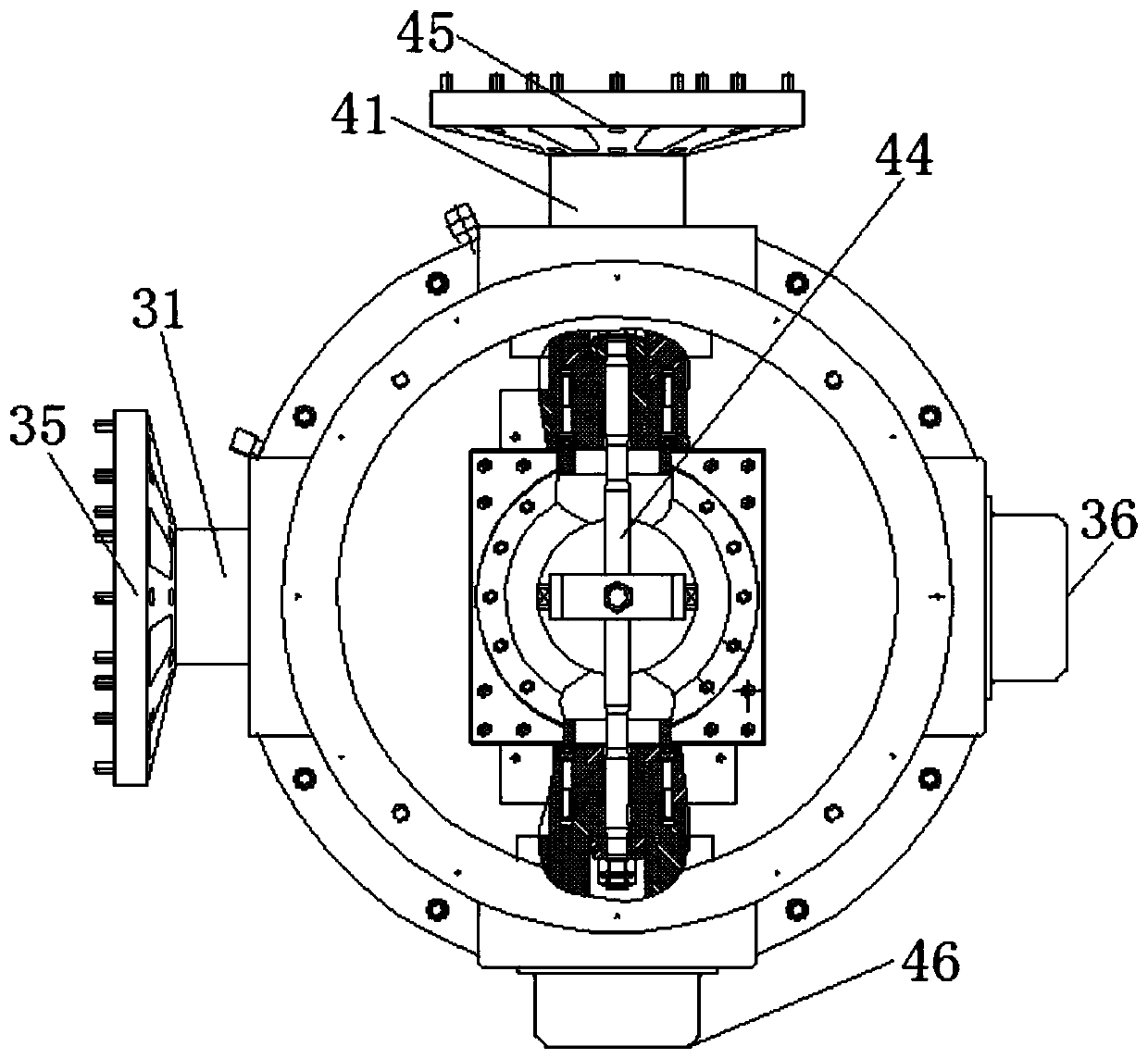

Integrated three-axis decoupling device and vibration table with static pressure guiding function

ActiveCN106556502BImprove self-stiffnessReal test assessmentVibration testingMechanical engineeringOil film

The invention discloses an integrated three-dimensional de-coupling device having the static-pressure guiding function. The integrated three-dimensional de-coupling device comprises a main connection body, a sliding rail, an X-axis guiding assembly, a Y-axis guiding assembly, and a Z-axis guiding assembly. The main connection body includes a housing; the sliding rail is arranged inside the housing; an X-axis channel, a Y-axis channel, and a Z-axis channel are arranged at the side wall of the housing; and an X-axis guiding shaft, a Y-axis guiding shaft, and a Z-axis guiding shaft pass through the X-axis channel, the Y-axis channel, and the Z-axis channel respectively and arranged in a floating manner relative to the X-axis channel, the Y-axis channel, and the Z-axis channel by a hydraulic oil film layer formed by a second static-pressure mechanism. The three-dimensional de-coupling device is designed to have an integrated structure, so that the rigidity of the device as well as stability of the overall system is improved. In addition, the invention also discloses a vibration bench.

Owner:SUZHOU DONGLING VIBRATION TEST INSTR

Three-axis decoupling device and vibration table with pre-tightening structure

ActiveCN106546401BImprove stabilityGuaranteed clearanceVibration testingHigh pressureOperational stability

The present invention discloses a three-axial decoupling device with a pre-tightening structure. The three-axial decoupling device with the pre-tightening structure includes a slide rail, an X guide shaft, a Y guide shaft and a Z guide shaft; each guide shaft is arranged floatingly through a static pressure oil film layer formed by a corresponding first static pressure mechanism; and each first static pressure mechanism is provided with a pre-tightening screw, and one end of the pre-tightening screw is fixed to the first static pressure mechanism oppositely, and the other end of the pre-tightening screw is fixed to a static pressure mechanism at the same side or a static pressure mechanism at the other side oppositely. According to the three-axial decoupling device with the pre-tightening structure of the invention, a connection mode adopts the structural design of the pre-tightening screws. When the three-axial decoupling device is working, high-pressure oil is introduced into the three-axial decoupling device, high-pressure oil films are generated at two oil film layers; the pre-tightening forces of the pre-tightening screws can cancel tensile forces generated by the high-pressure oil films to the outside, and therefore, the gap of the oil film layers and the rigidity of the oil film layers can be ensured, and the operational stability and durability of the three-axial decoupling device can be improved. The invention also discloses a vibration table.

Owner:SUZHOU DONGLING VIBRATION TEST INSTR

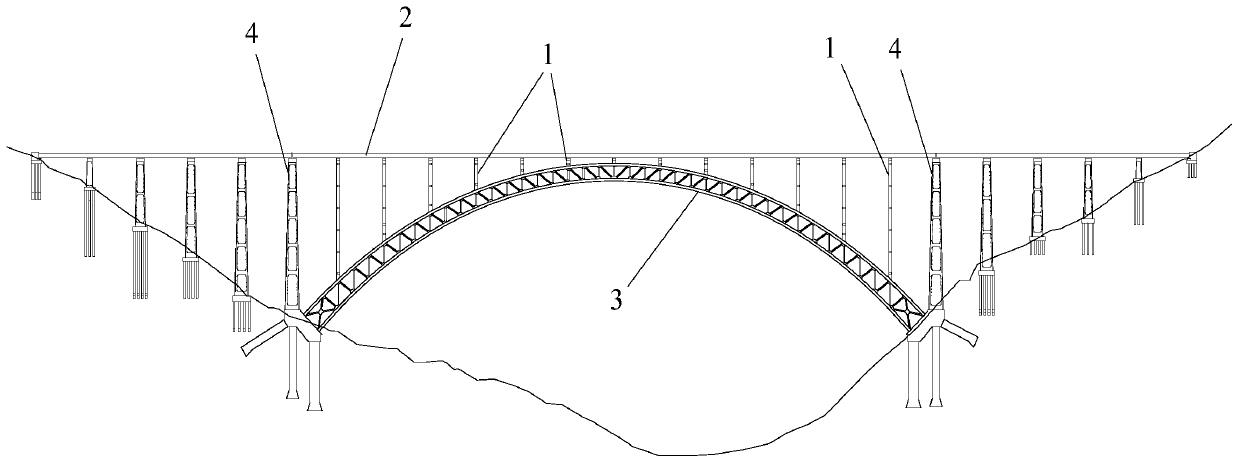

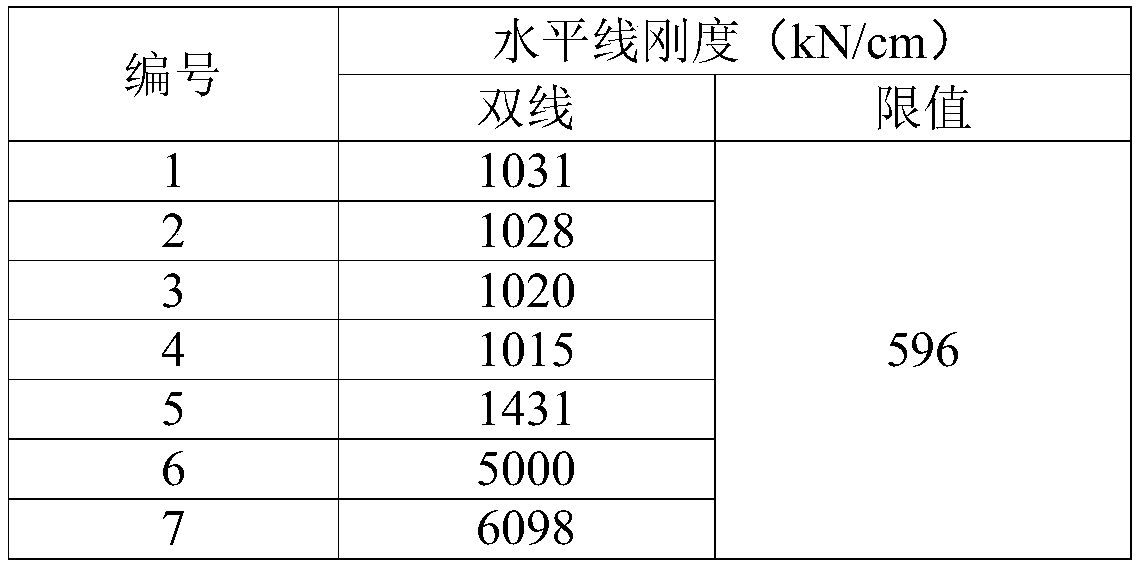

Evaluation method for rigidity of longitudinal horizontal line of arch pier top of steel truss arch bridge for deck-arch railway

ActiveCN111539056ALow costReasonable analysisGeometric CADDesign optimisation/simulationElement modelArchitectural engineering

The invention discloses an evaluation method for rigidity of a longitudinal horizontal line of an arch pier top of a steel truss arch bridge for a deck-arch railway. When the rigidity of the longitudinal horizontal line of the pier top is analyzed, the influence of the arch pier is considered; the influence of the steel truss arch ring and an on-arch beam on an on-arch pier is also considered; establishing a full-bridge finite element model for the steel truss arch bridge, the influence of the longitudinal rigidity and the structural size of the steel truss arch ring, the on-arch pier and theon-arch beam on the rigidity of the longitudinal horizontal line of the pier top of the on-arch pier is comprehensively considered. The conventional method only simulates rigidity of a single pier andmakes judgments based on beam-arch analysis.The method is reasonable in analysis, the calculation process can be simplified, the stress condition of the seamless steel railway under the action of longitudinal force such as braking force does not need to be analyzed, the longitudinal rigidity condition of the whole structure can be comprehensively reflected, the rigidity is real and reliable, thestructural size does not need to be increased blindly, and extra cost increase is avoided.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Three plunger hydraulic diaphragm reciprocating pump

ActiveCN106996366BSmall sizeReasonable dimensionsFlexible member pumpsPositive-displacement liquid enginesDiaphragm pumpEngineering

Owner:DEPAMU HANGZHOU PUMP TECH

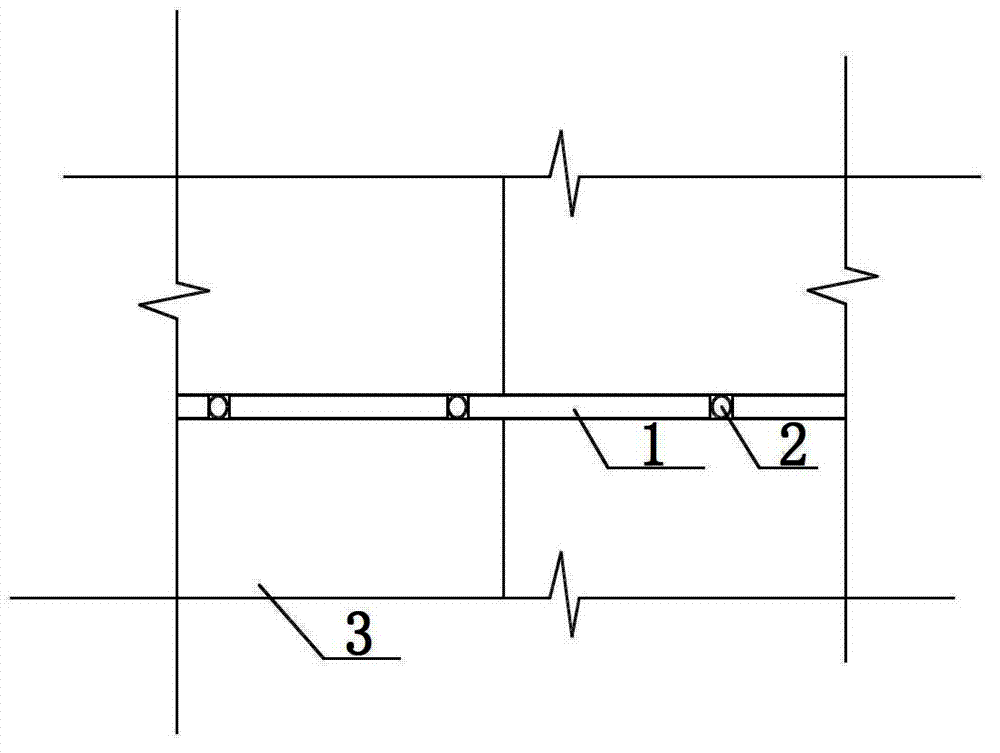

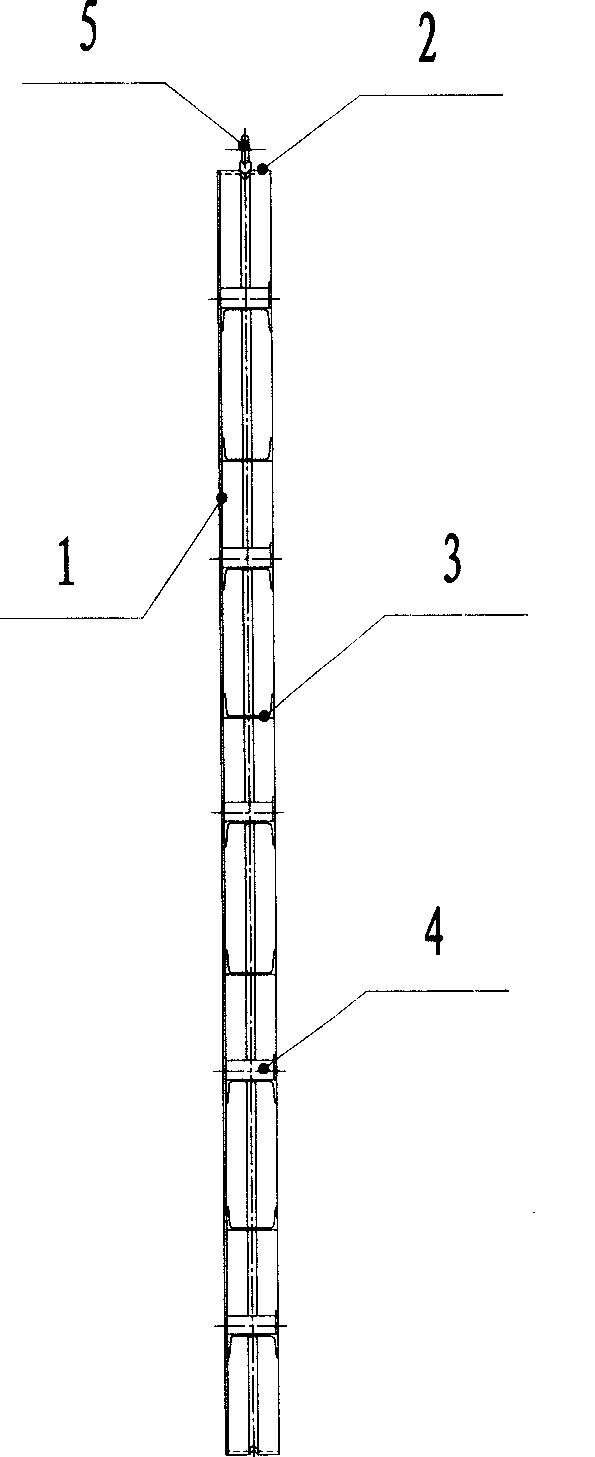

Non-back-ridgebuilt-up type all-steel big shuttering

ActiveCN101457585AReliable strengthReliable stiffnessForms/shuttering/falseworksEngineeringUltimate tensile strength

The invention relates to a non-backridge repetitive all-steel large formwork, which comprises a panel, frames and support ribs, wherein, the frame has a ridge and fold bends in the middle and the cross section of the frame is of a brace shape; four frames form a rectangular framework; the support ribs have a plurality of pieces and are arranged between the two long frames of the rectangular framework equidistantly; both ends of each support rib is fixedly and respectively connected with the two long frames; the panel is arranged on one side of the rectangular framework and the support rib and is fixed with the rectangular framework and the support rib by rational intermittent welding. The formwork has the advantages that the overall strength and stiffness of the formwork are reliable, the structure is simple, the assembly is fast, the joints are free from dislocation, the jointing is compact, leakage is not easy to occur. In addition, the formwork achieves the effect of good rinsing on the surface of the concrete and mobile use times the same as the backridge repetitive all-steel large formwork, facilitates to arrange regular decoration strips on the surface of the concrete and meets the requirement of open joint decoration on the surface of the concrete wall.

Owner:西安奥宇模板有限责任公司

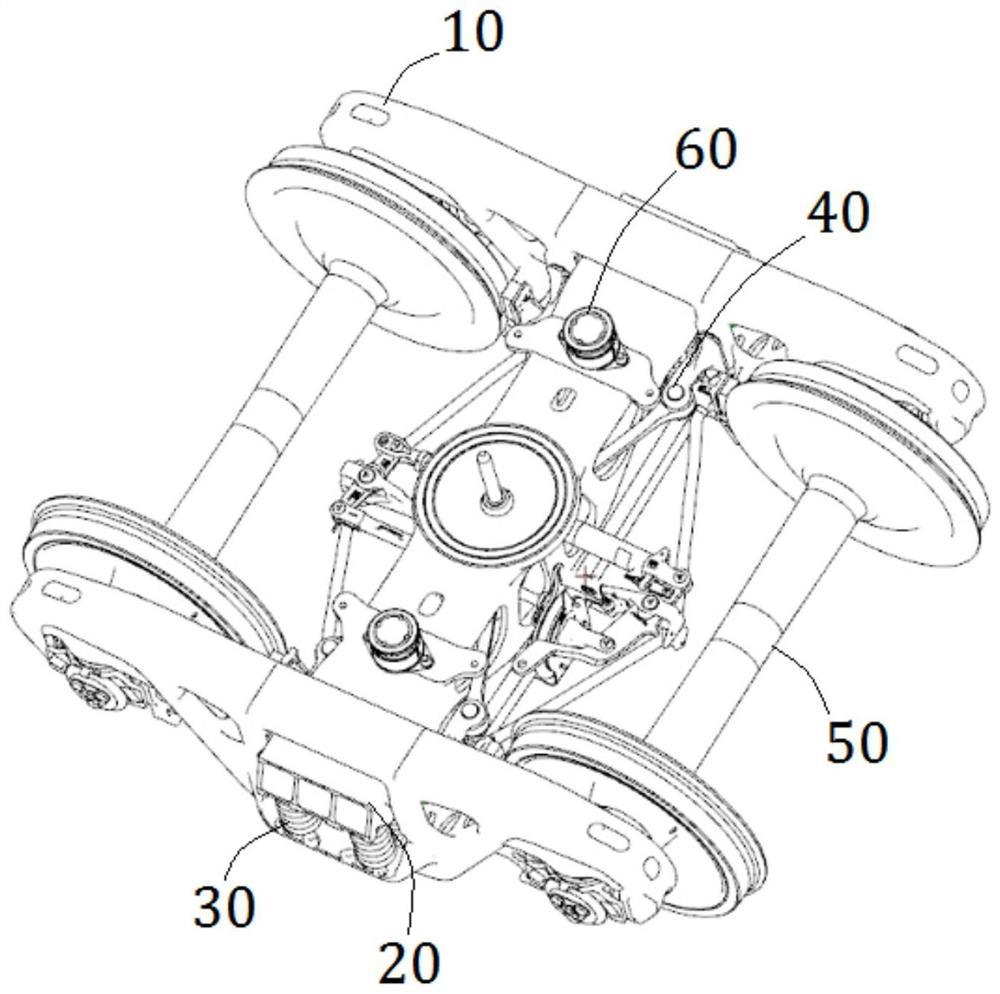

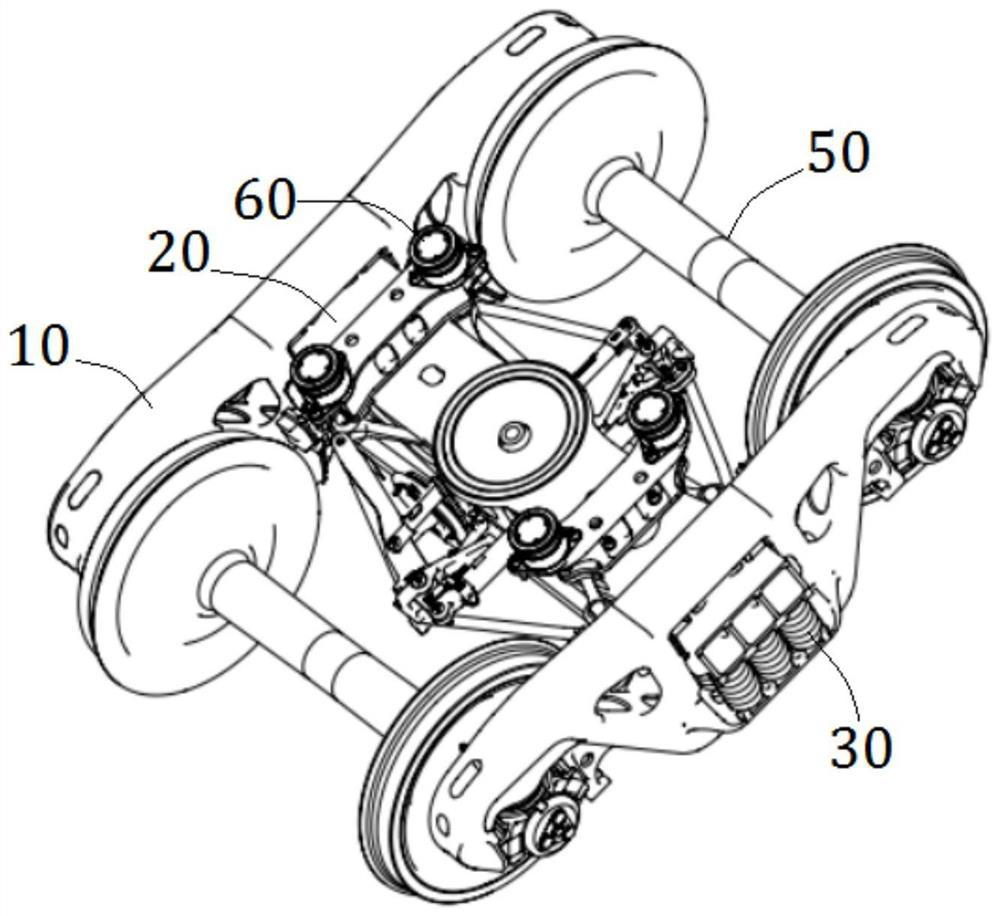

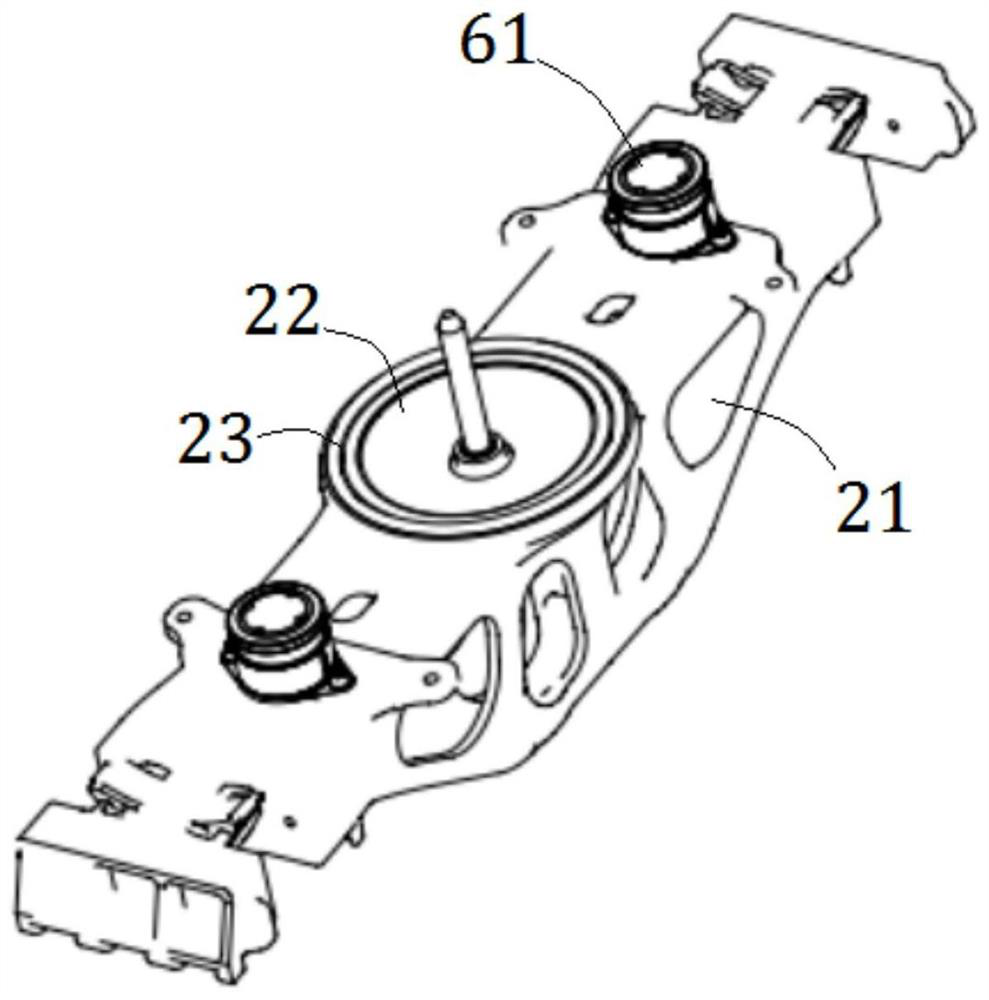

Joint vehicle group

PendingCN114701531AReliable shock absorptionReliable stiffnessBogie-underframe connectionsBogieControl theory

The invention belongs to the technical field of railway vehicles, and discloses a joint train set which comprises a train body and a joint bogie arranged below the train body which are arranged in sequence. Every two adjacent vehicle bodies are supported through a middle joint bogie; in the car bodies arranged in sequence, the ends, deviating from each other, of the two car bodies located at the two ends are supported by the end joint bogies respectively. The low-power joint bogie and the joint car set provided by the invention have good overall performance.

Owner:CRRC YANGTZE CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com