Two-way sliding anti-drawing spherical support

An anti-pulling ball type and bearing technology, applied in bridge parts, bridges, buildings and other directions, can solve the problems of inability to meet the requirements of bridge use, small two-way sliding displacement, low upward pulling force, etc., to reduce manpower and Economical investment, reliable strength and stiffness, and low cost of manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following will clearly and completely describe the technical solutions in the embodiments of the present invention in conjunction with the accompanying drawings in the embodiments of the present invention:

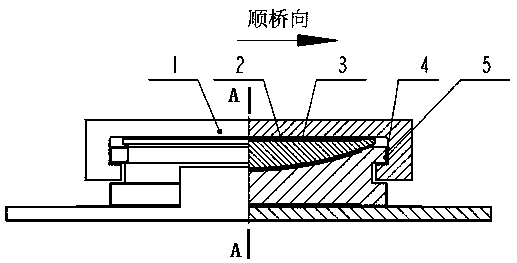

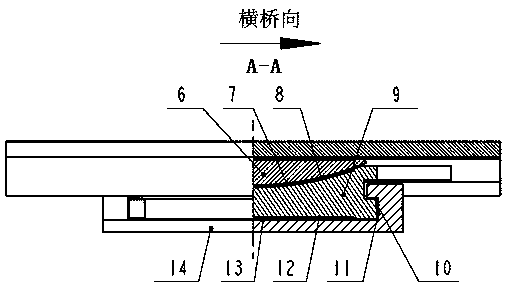

[0021] Such as figure 1 with figure 2 As shown, a two-way slidable anti-pullout spherical bearing includes an upper bearing plate 1, a spherical crown lining plate 6, a middle steel lining plate 9 and a lower bearing plate 14 that are sequentially slidably connected and matched from top to bottom. , the lower surface of the upper support plate 1 is provided with a positive L-shaped cantilever along the direction of the bridge, and the upper surface of the lower support plate 14 is provided with an inverted L-shaped cantilever along the direction of the bridge. The upper and lower ends of the middle steel liner 9 There are flanges suitable for the positive L-shaped cantilever and the inverted L-shaped cantilever, and the flanges at both ends are placed in the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com