A mobile prestressed support system and method of use thereof

A support system and prestressing technology, which is applied to the mine roof support, earth square drilling, mining equipment, etc., can solve the problems that the shield machine cannot provide recoil force, the difficulty of adjusting the support axial force, and the difficult removal of steel wedges, etc., so as to reduce the construction cost. Low cost, easy to support and enter the field, and the effect of uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

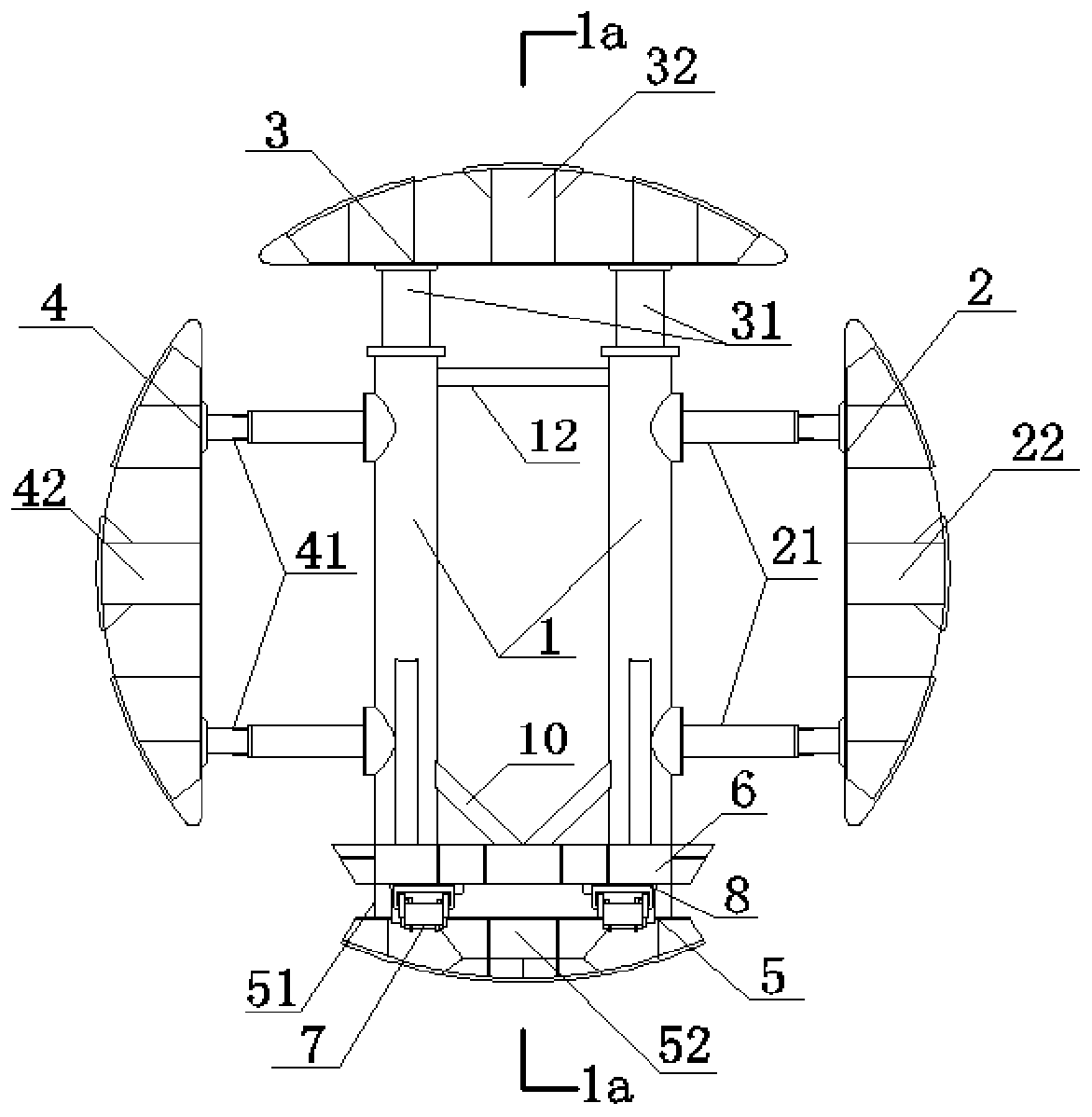

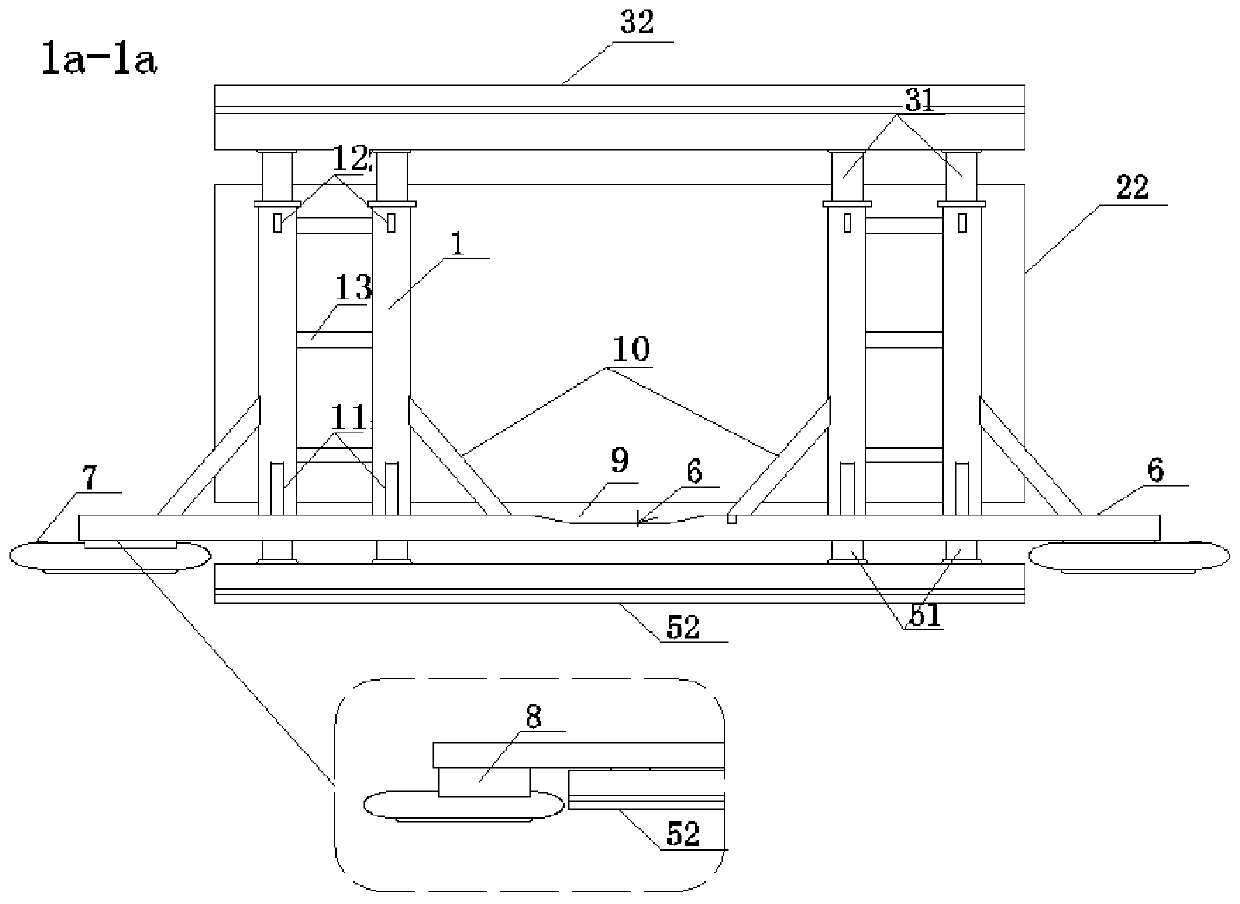

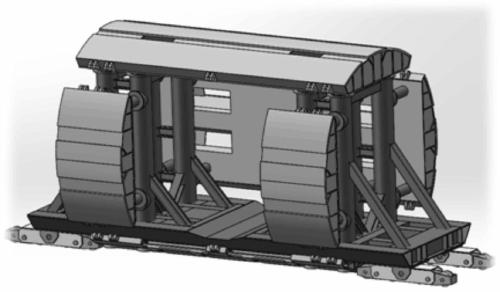

[0051] A movable prestressed support system and method of use thereof, such as figure 1 , figure 2 with image 3As shown, it includes the main frame steel support 1, the rear reaction force seat 2, the inverted arch reaction force seat 3, the construction side reaction force seat 4, the arch bottom reaction force seat 5, the support and protection bracket bottom plate 6, and the moving wheel rail under the plate 7 and wheel rail vertical expansion device 8;

[0052] The main frame-type steel support 1 includes 8 main structural columns forming a rectangle, four main structural columns are arranged parallel to the axial plane of the shield tunnel, and two main structural columns are arranged parallel to the radial plane of the shield tunnel;

[0053] The reclining reaction force seat 2 comprises a transversely telescopic reclining reaction force seat support 21 and a reclining stress buffer block 22, and the inner side of the reclining stress buffer block 22 is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com