Construction method of foundation pit supporting water-stop continuous wall

A water-stop diaphragm wall and construction method technology, which is applied in foundation structure engineering, excavation, sheet pile walls, etc., to achieve the effects of low cost, strong water-retaining and anti-seepage performance, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

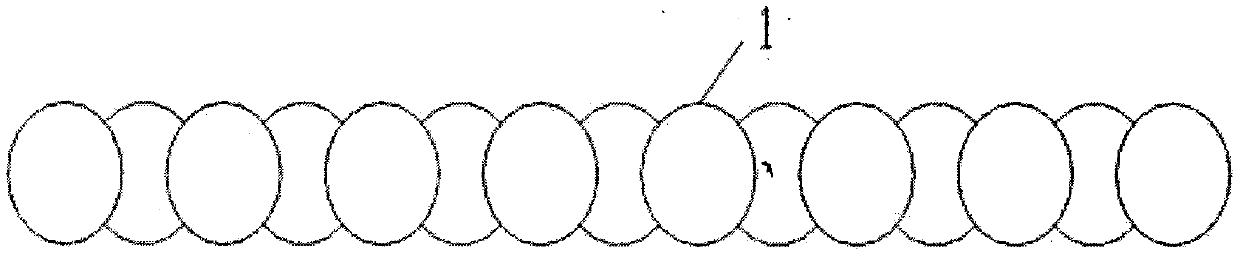

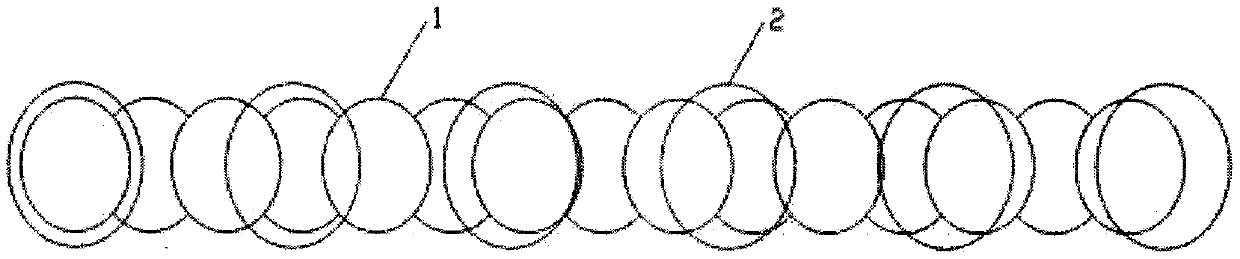

[0015] As shown in the figure, in the foundation pit, there are overlapping three-axis mixing piles 1 and support piles 2 arranged coaxially at fixed intervals, and a steel bar structure is set to form a continuous wall.

[0016] The three-axis mixing piles overlap and overlap to form a three-axis mixing wall, and the three-axis mixing pile machine is used to construct the water-stop curtain of the foundation pit. The pile diameter of the three-axis mixing piles is ¢650mm, and the pile spacing is 0.9m. For compound-stirring connection construction, the length of the pile entering the strong weathered rock shall not be less than 1.0m. The three-axis mixing pile adopts 42.5 grade ordinary Portland cement, the cement content is not less than 20%, and the soil weight is 1.9T / m 3 Considering comprehensively, the water-cement ratio should be 1:1. The 28d unconfined compressive strength of the cement-soil wall is not less than 0.8Mpa. During the construction process, due to overtim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com