Three-plunger hydraulic diaphragm reciprocating pump

A reciprocating pump and hydraulic technology, which is applied in the direction of pumps, liquid variable displacement machines, pumps with flexible working elements, etc., can solve the problems of large transition plate volume, etc., and achieve the effects of compact size, reduced quantity, and simplified processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

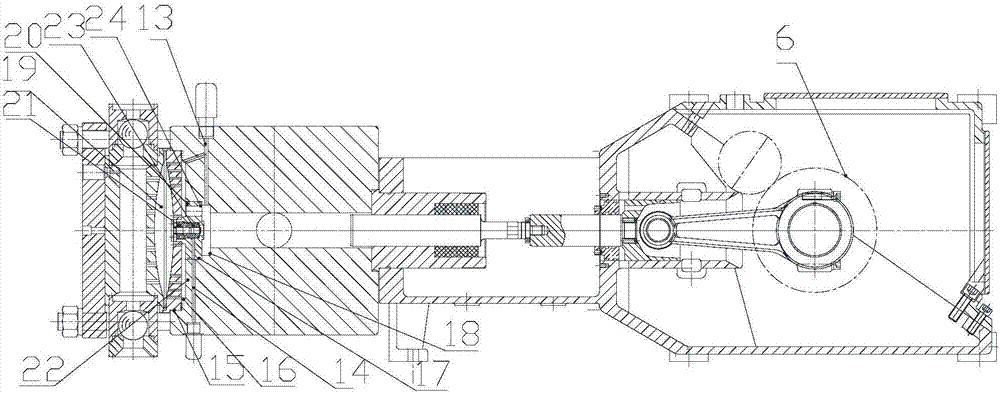

[0023] Below in conjunction with each accompanying drawing, the present invention is described in detail.

[0024] The front and rear in the present invention are defined according to the front and rear of the installation position, wherein the side close to the power end is the front end, and the opposite is the rear end.

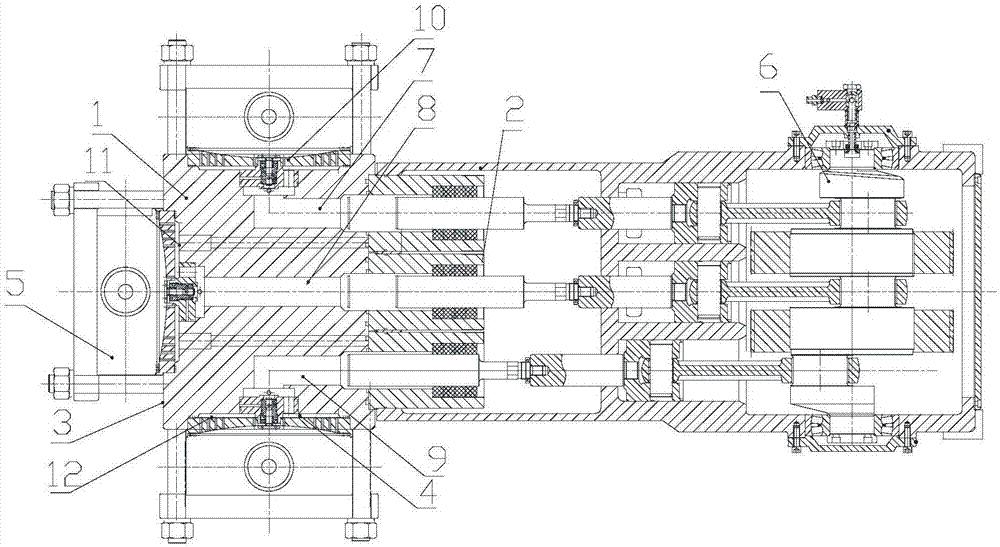

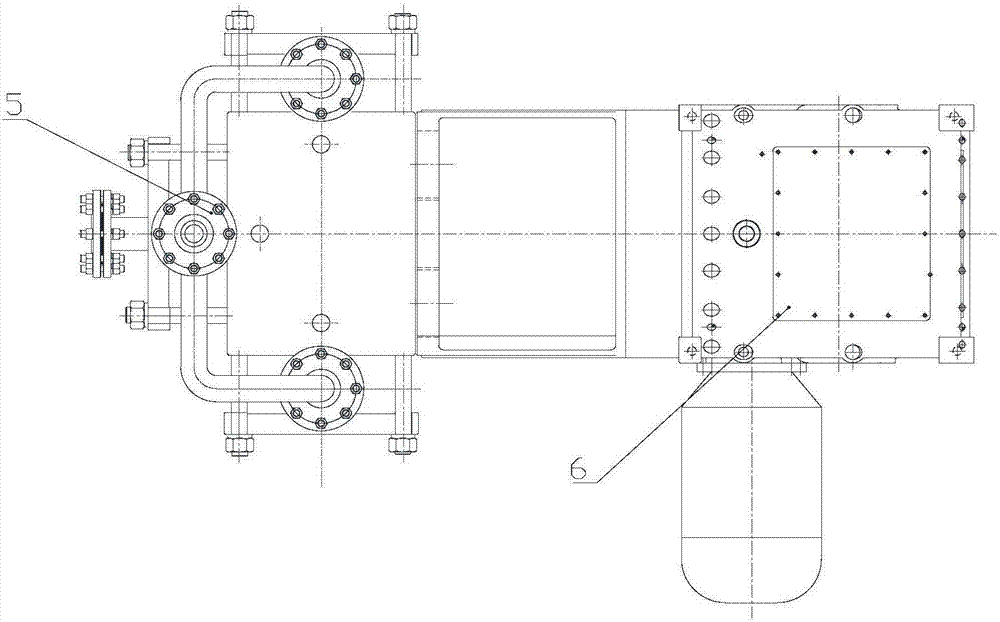

[0025] The invention discloses a three-plunger hydraulic diaphragm reciprocating pump (see attached figure 1 ), including: a transition plate 1 having a front end face 2, a rear end face 3 and several side faces 4, three pump heads 5 and a power end 6; the power end 6 is used to provide power to the pump head 5 through the transition plate 1; The front end of the transition plate 1 is provided with a first hydraulic passage 7, a second hydraulic passage 8 and a third hydraulic passage 9 arranged side by side, and the first hydraulic passage 7, the second hydraulic passage 8 and the third hydraulic passage 9 are all The power end 6 is connected through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com