Large-tonnage metal bending transmission mechanism

A transmission mechanism, large tonnage technology, applied in the direction of presses, punching machines, manufacturing tools, etc., can solve the problems of large impact, unevenness and low precision of the slider action, and achieve reasonable structural force, simple connection, and reliable rigidity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

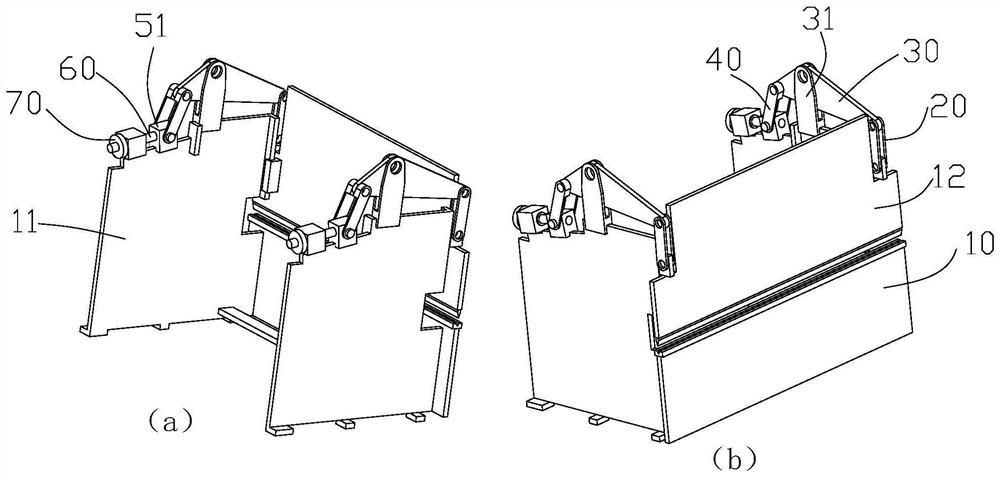

[0073] Such as figure 1 As shown, the sheet metal bending equipment includes a frame 10 and an upper beam 12, wherein the frame includes two symmetrical side plates 11, the upper beam is located directly in front of the two side plates, and can be raised and lowered along the two side plates , the metal bending transmission mechanism in the present invention is used to drive the height of the upper beam.

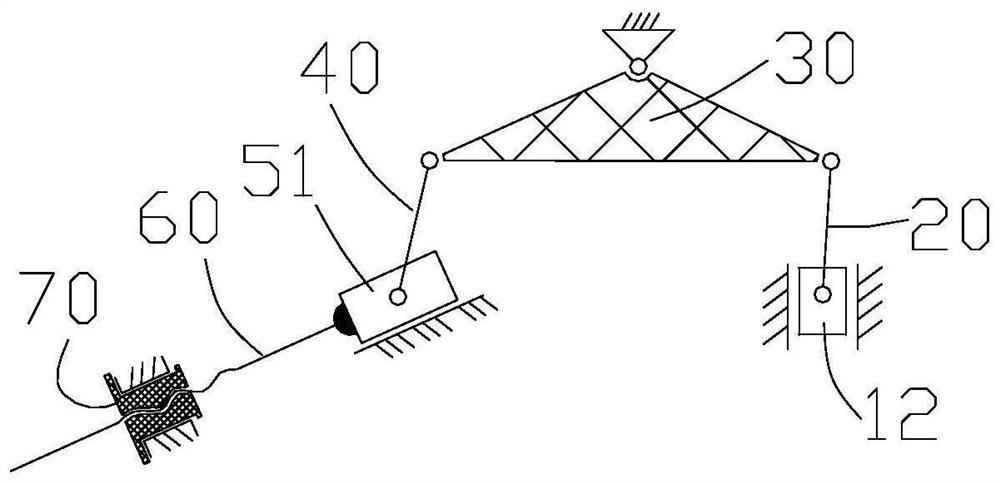

[0074] Such as figure 1 and Figure 5 As shown, a large-tonnage metal bending transmission mechanism includes a connecting rod 20, a pressing arm 30, a hinged support 31, a pressing rod 40, a moving part, a screw rod 60, a nut 70 and a nut rotating drive device.

[0075] There are two pressing arms, which are arranged symmetrically on both sides of the frame of the sheet metal bending equipment, preferably above the tops of the two side plates.

[0076] The above-mentioned pressing arm is equivalent to a lever, with the hinged support as the fulcrum, the combination of th...

Embodiment 2

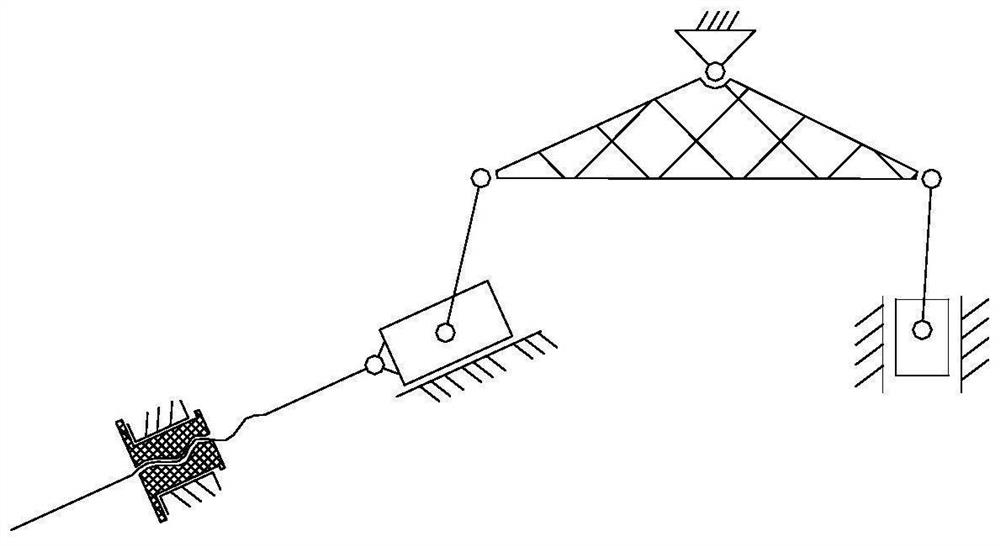

[0097] Such as Figure 5 to Figure 7 As shown, a large-tonnage metal bending transmission mechanism includes a connecting rod 20, a pressing arm 30, a hinged support 31, a pressing rod 40, a moving part, a screw rod 60, a nut 70 and a nut rotating drive device.

[0098] The structures of the pressing arm 20, the connecting rod 30, the hinged support 31, the screw mandrel 60, the nut 70 and the nut rotation driving device are basically the same as those in Embodiment 1, and will not be repeated here.

[0099] The difference is that the structure of the pressing rod and the moving part is different, the moving part is a support rod 52, the bottom end of the pressing rod is hinged with the upper part of the supporting rod, and the lower part of the supporting rod is hinged on the frame; One of the hinges.

[0100] The compression rod and the support rod preferably have the following three embodiments.

[0101] first embodiment

[0102] Such as Figure 6 As shown, the front en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com